Numerical simulation of fractured imbibition in a shale oil reservoir based on the discrete fracture model

-

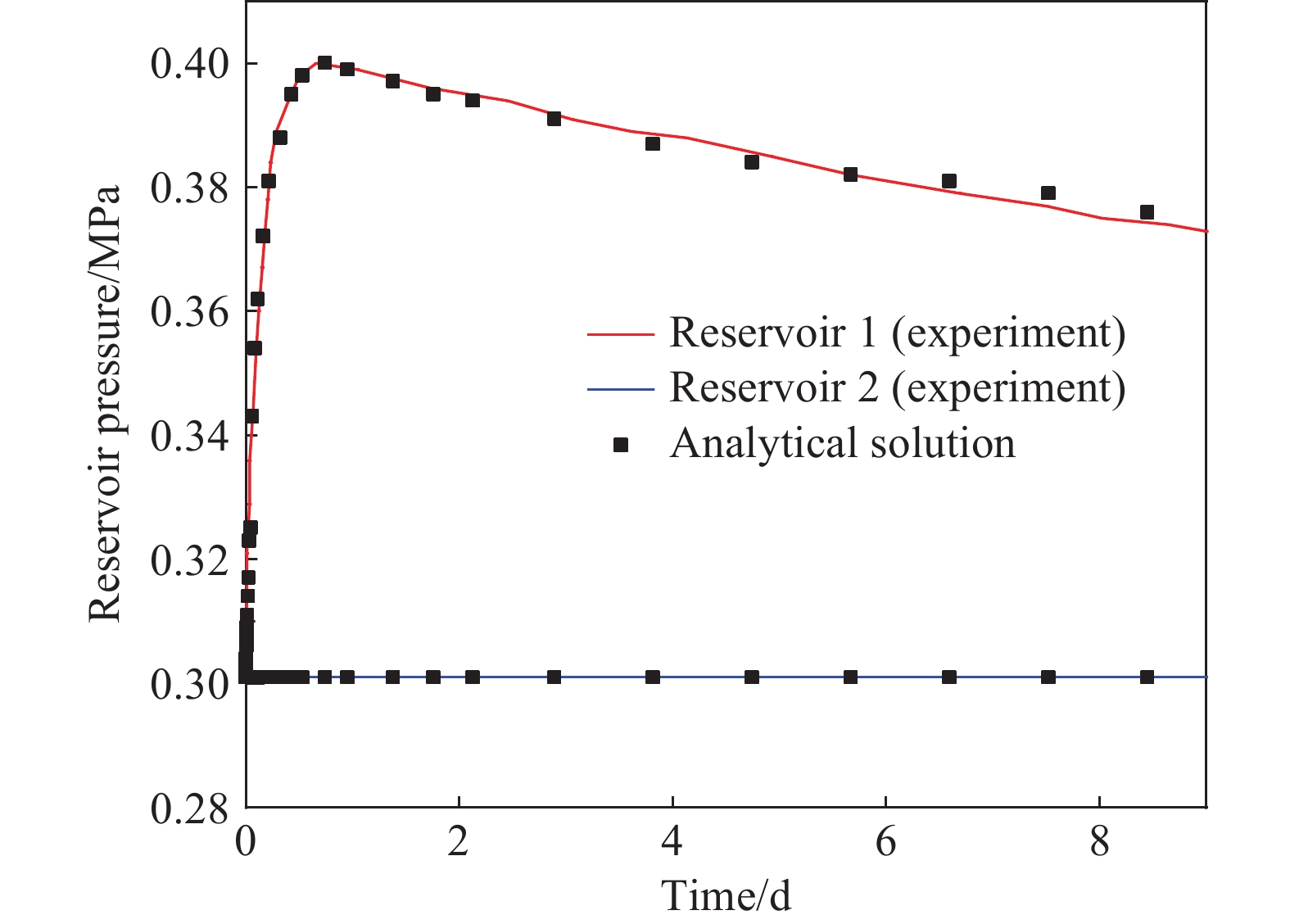

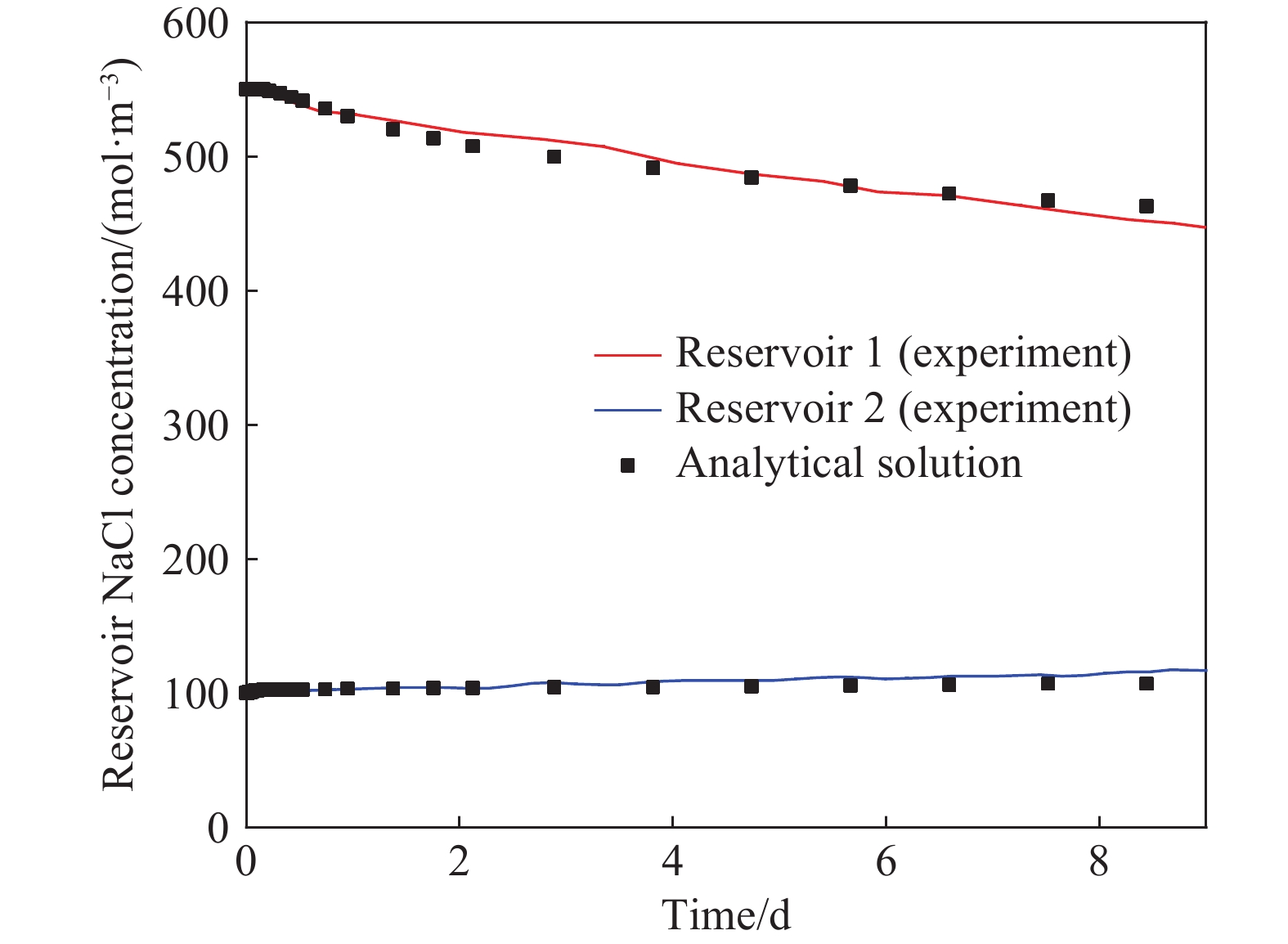

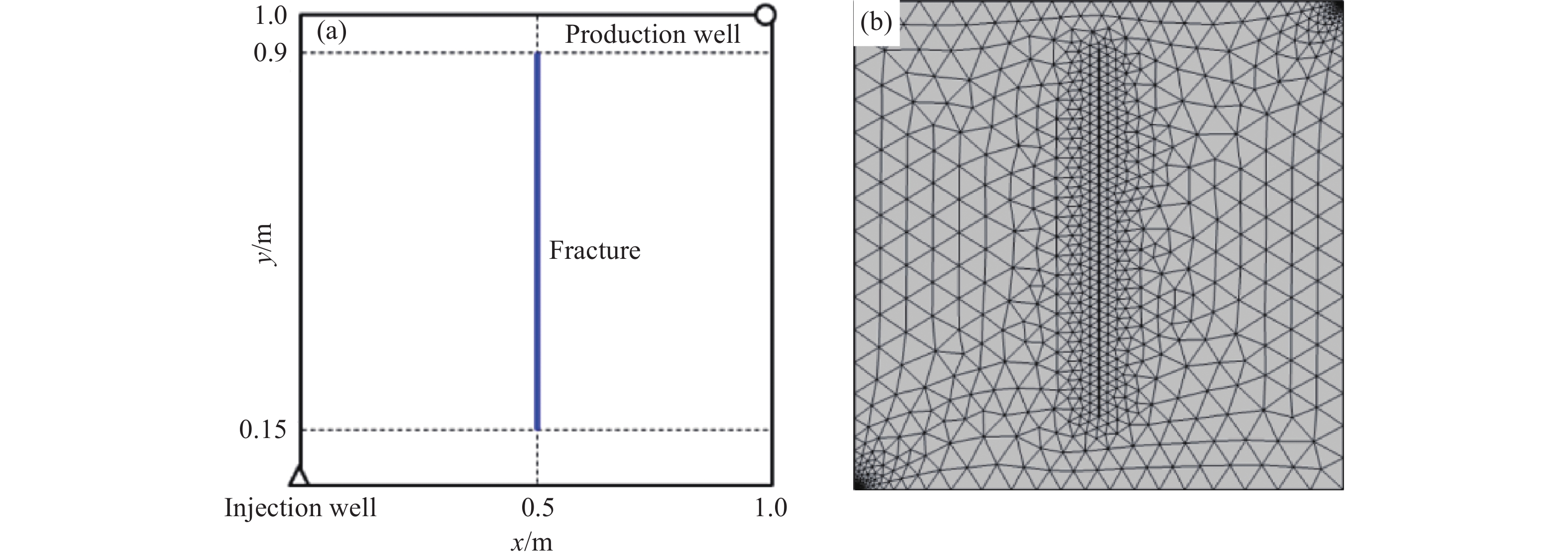

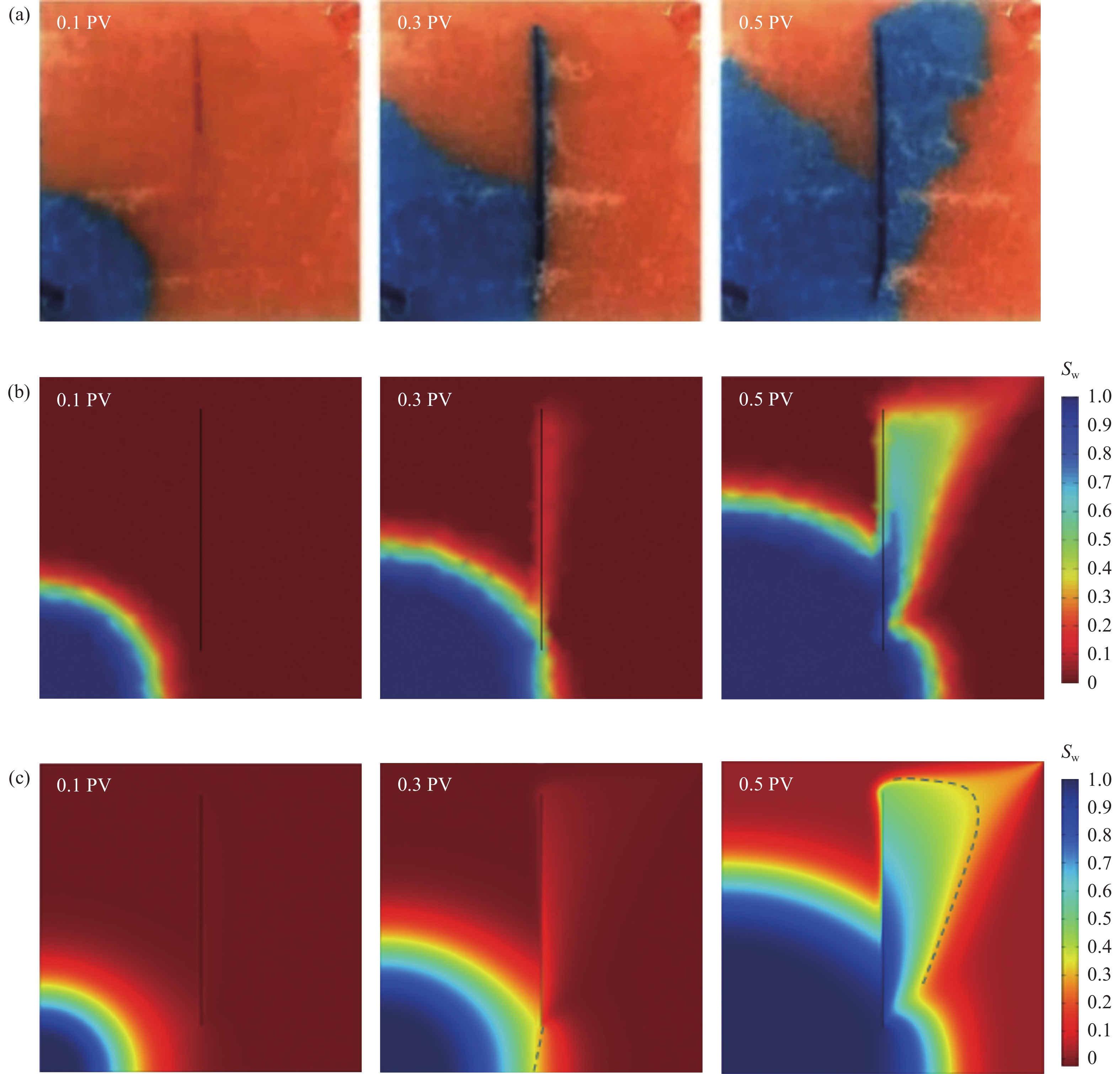

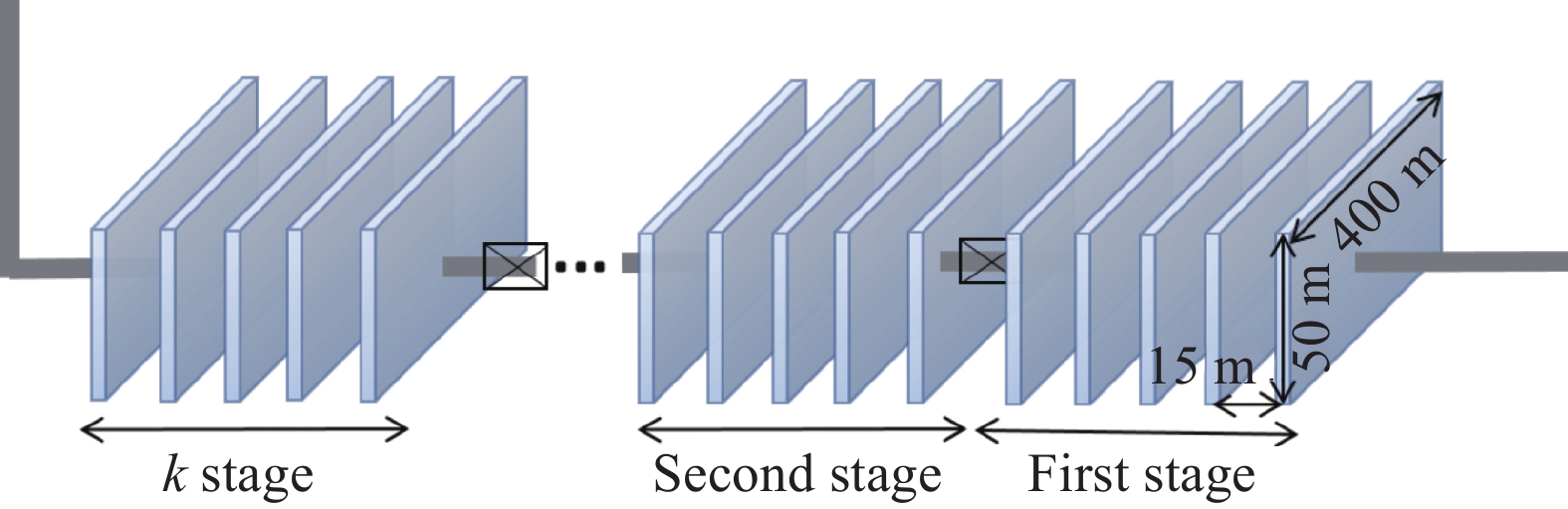

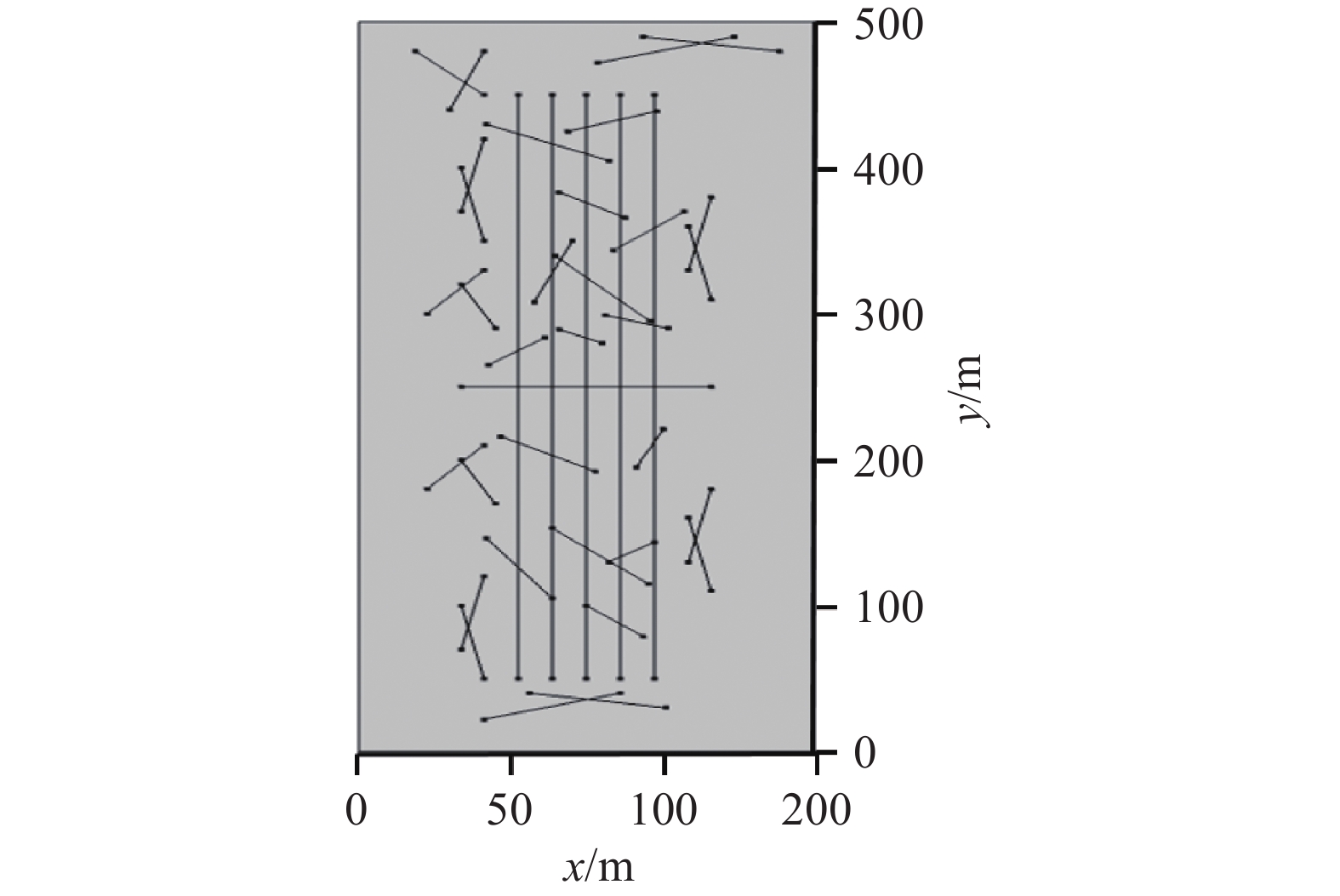

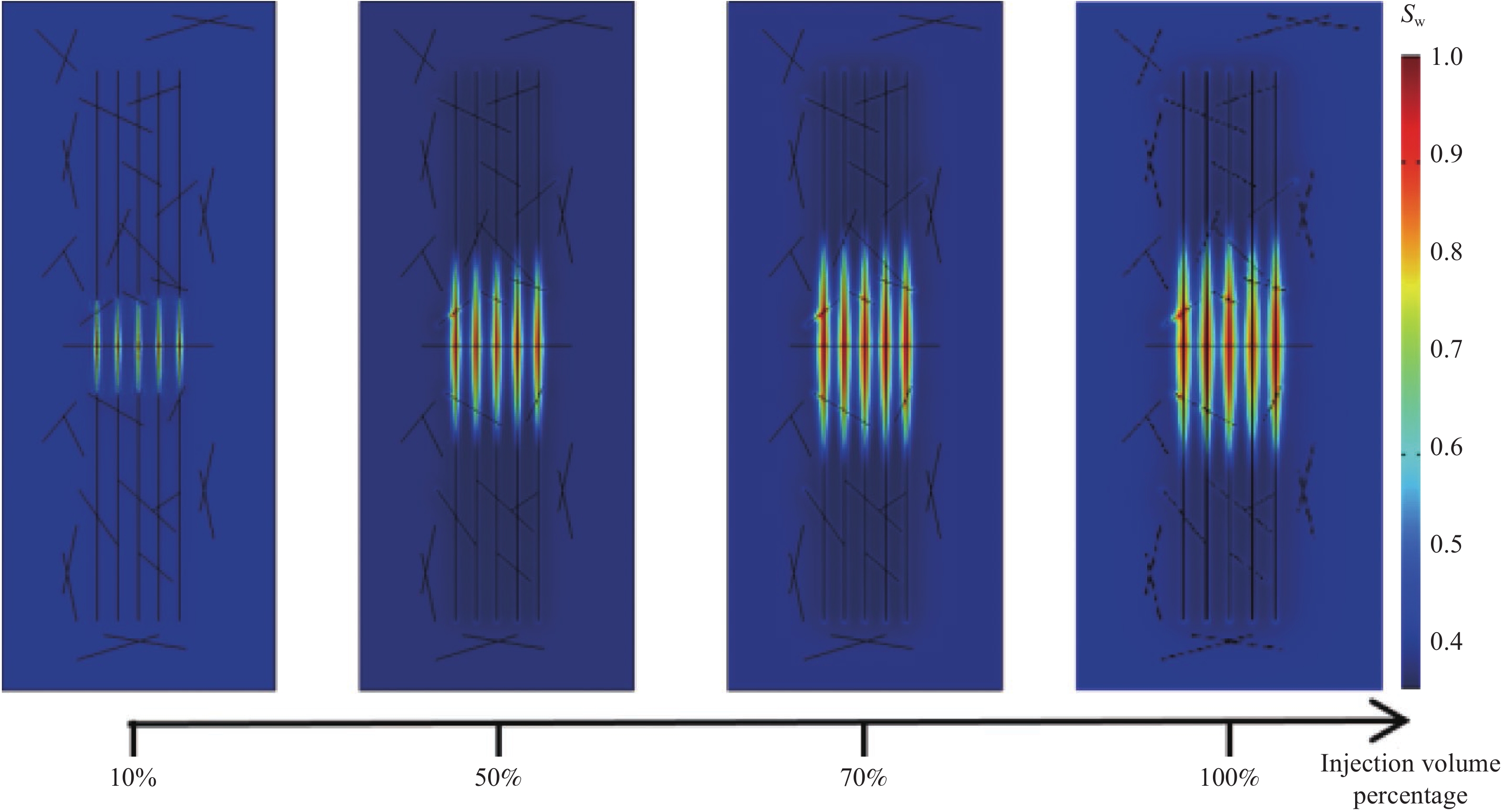

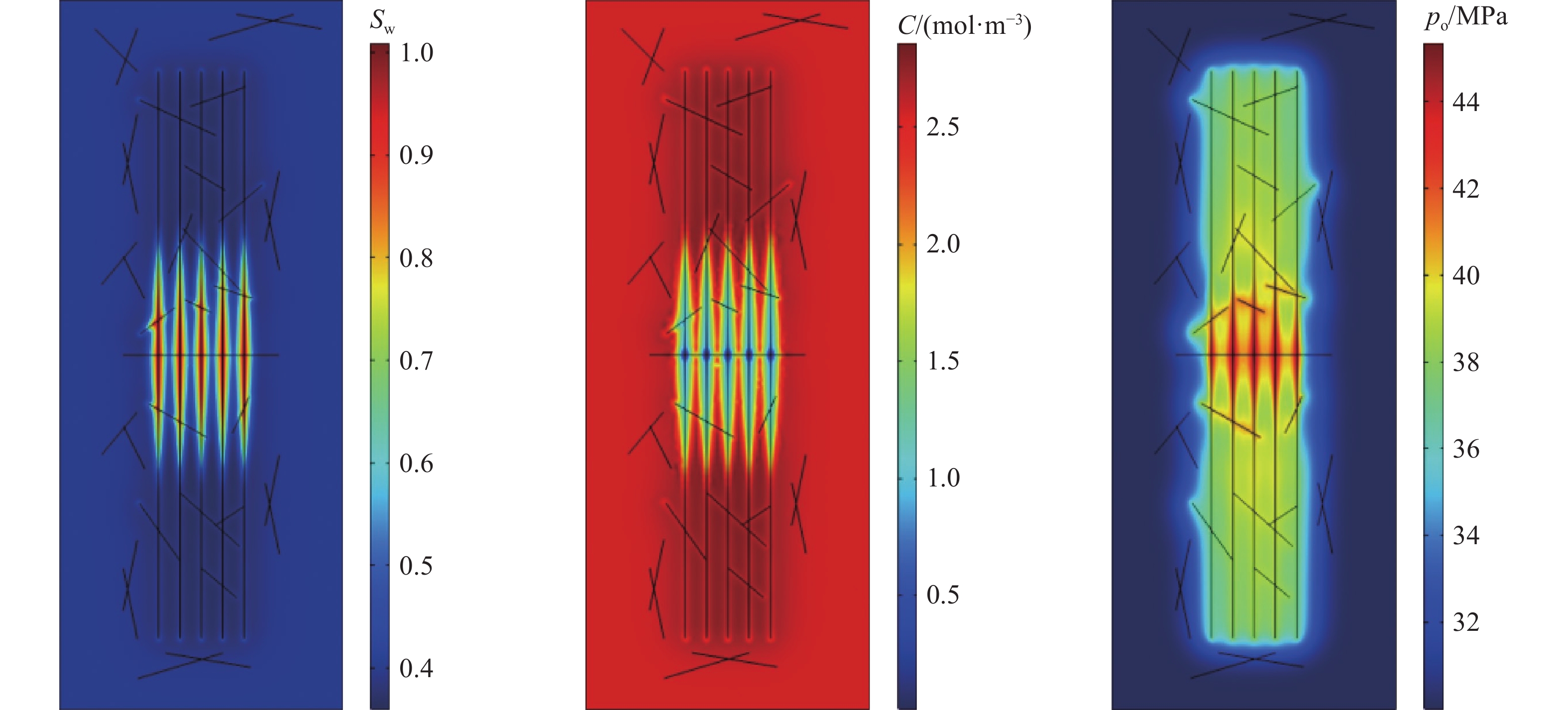

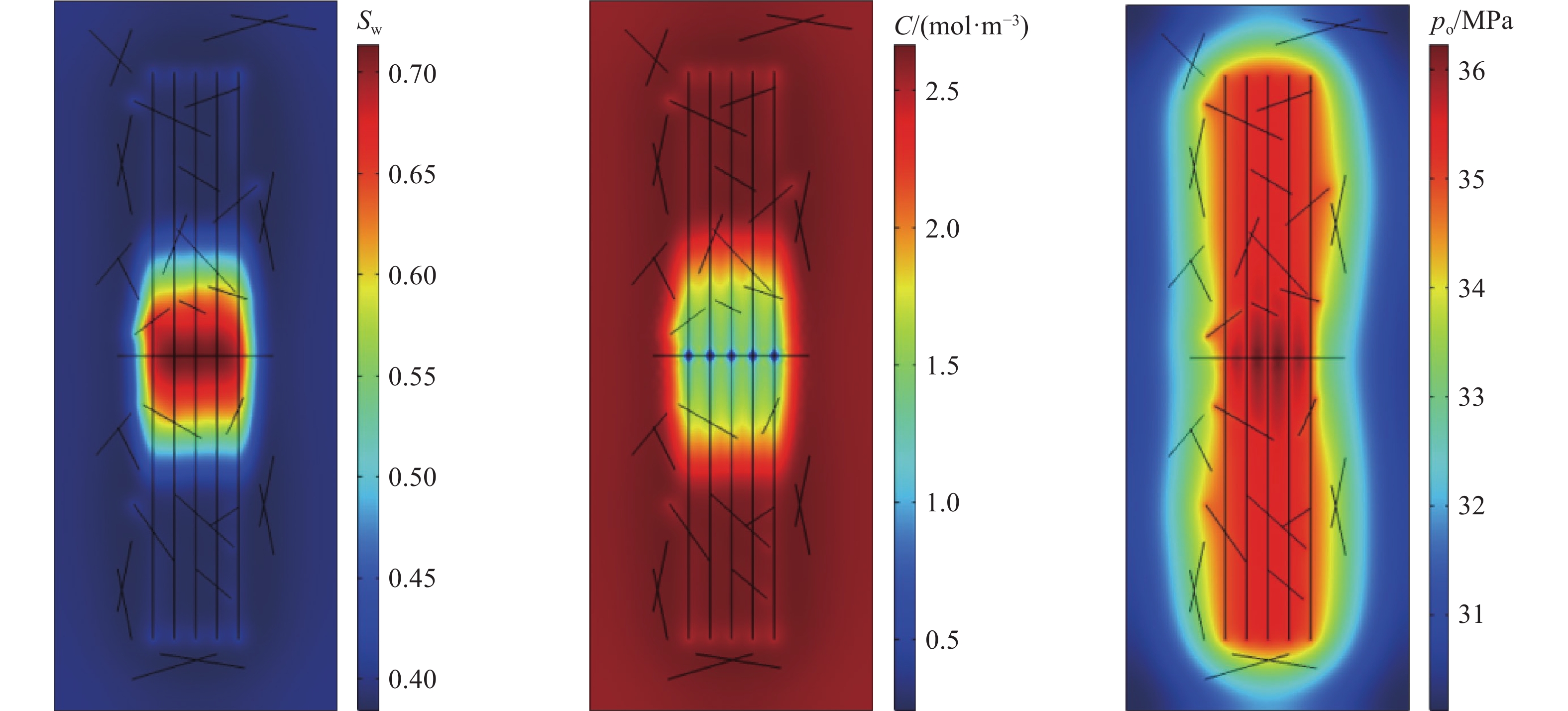

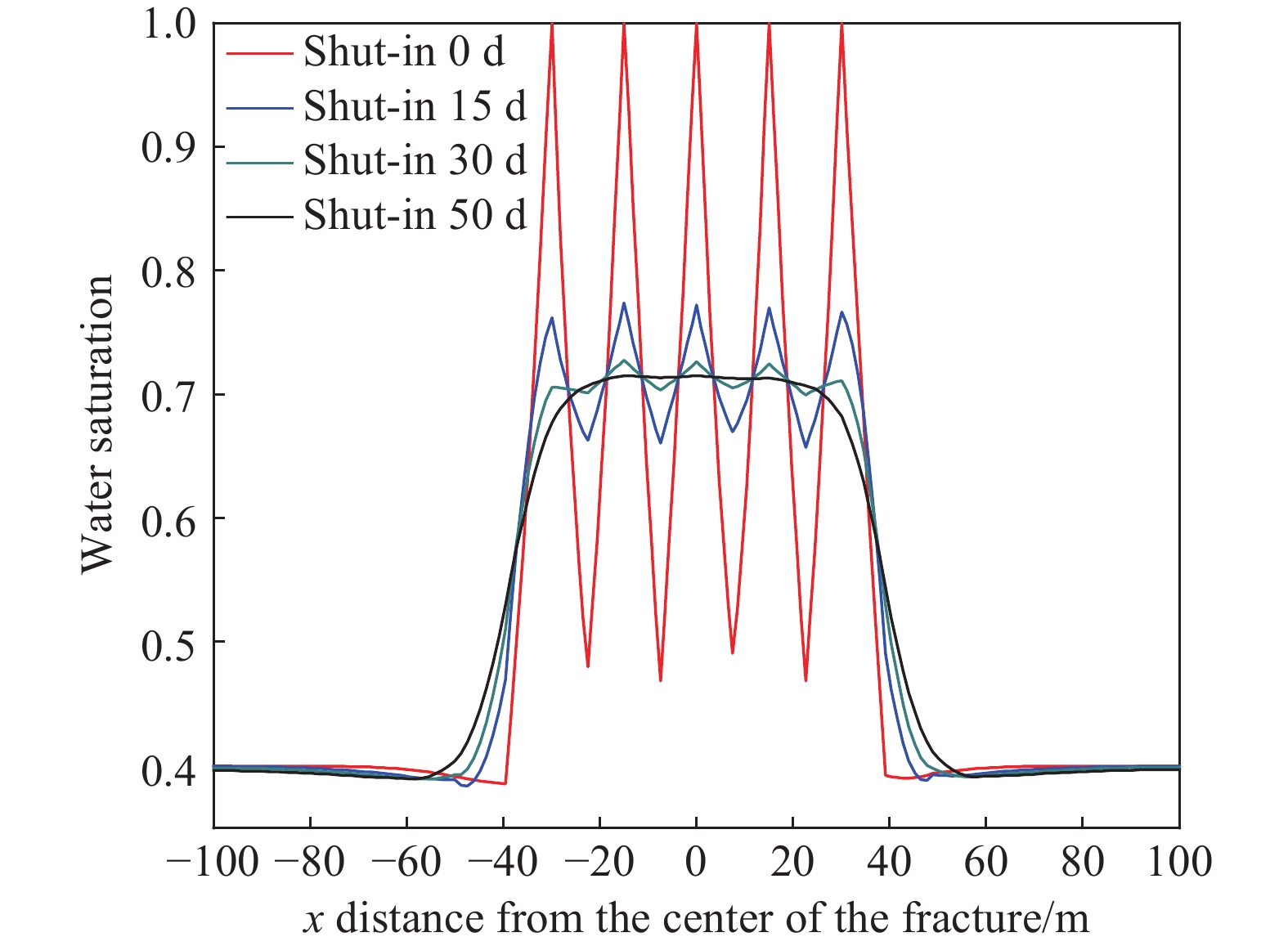

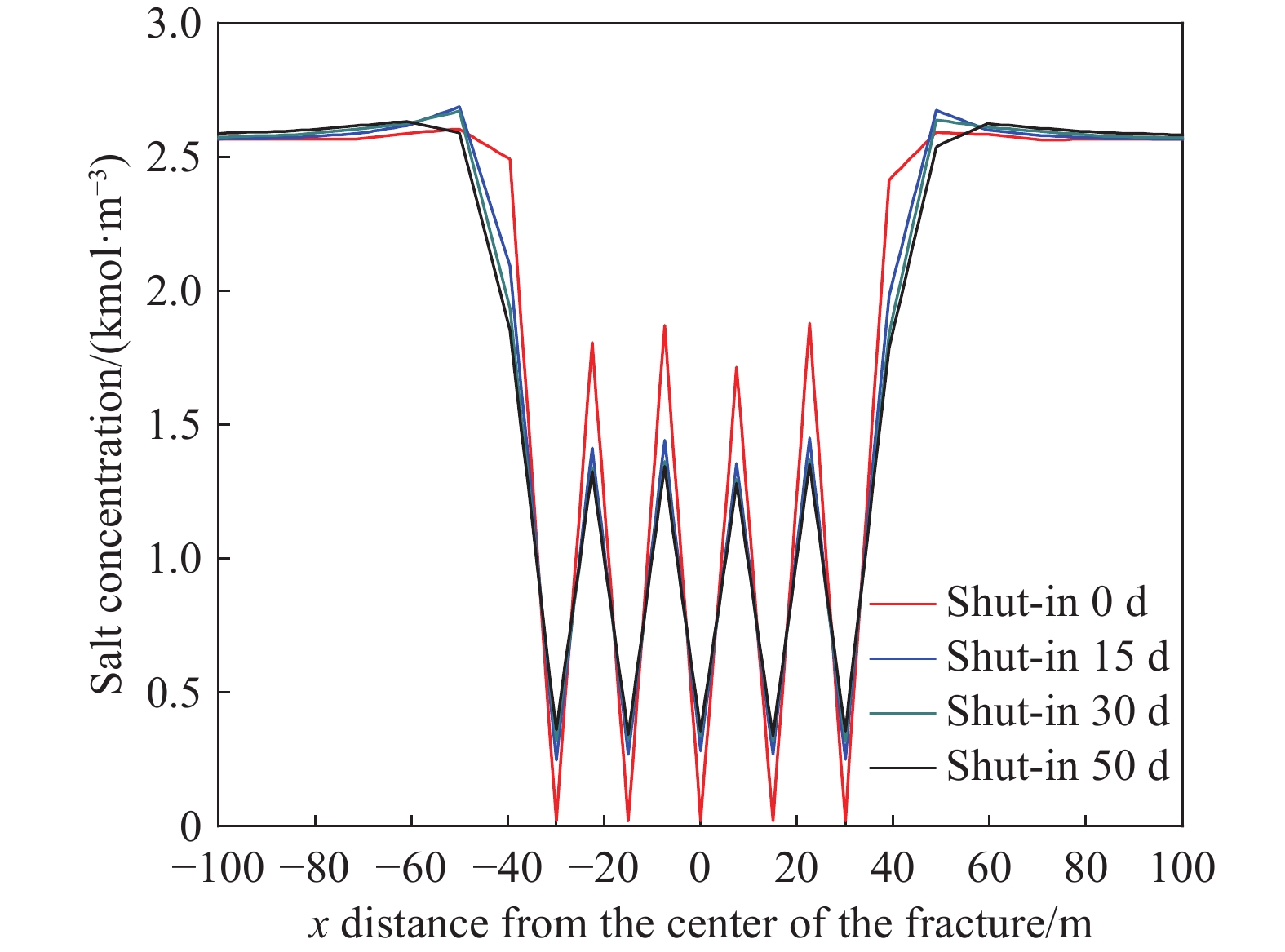

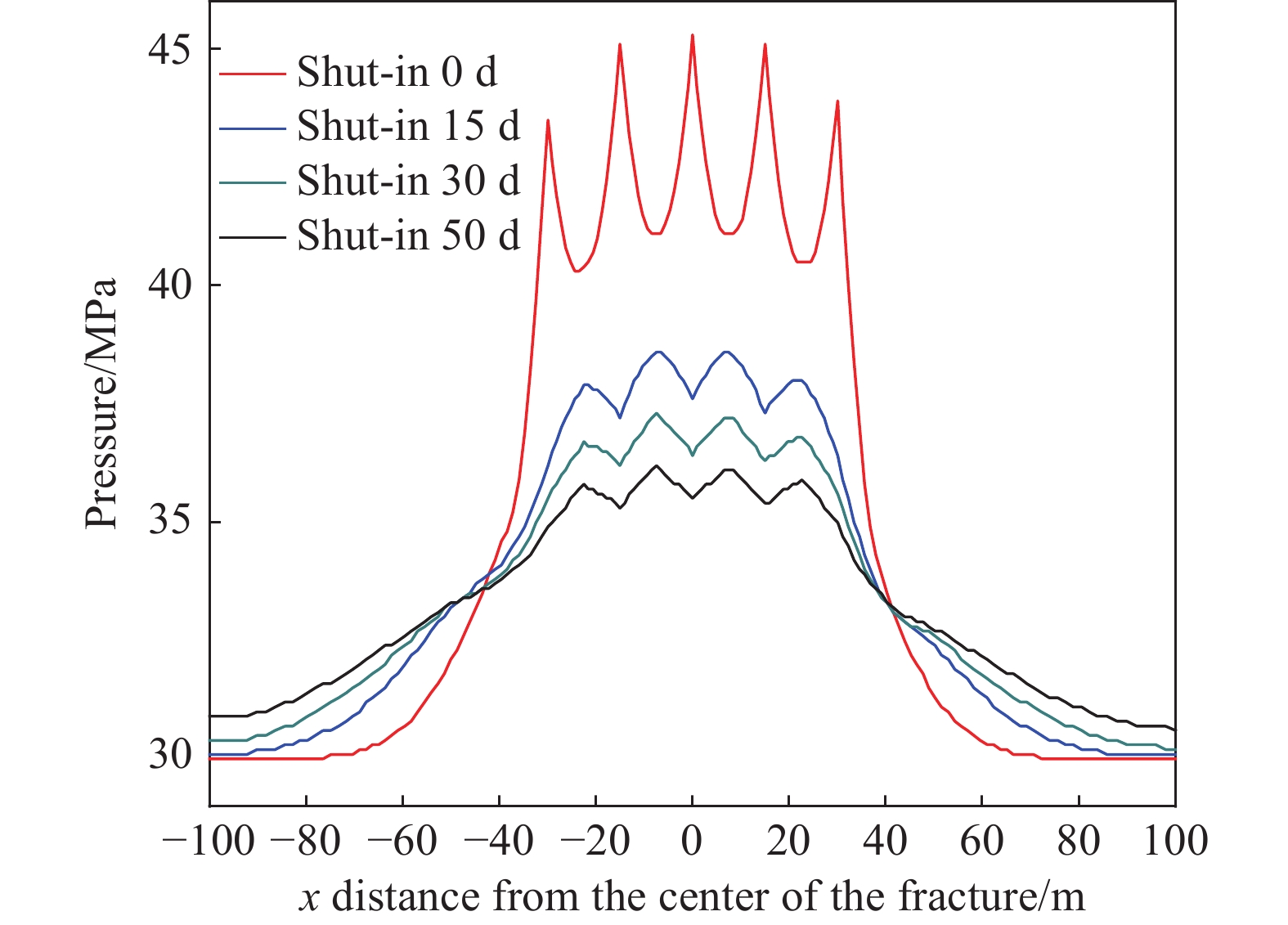

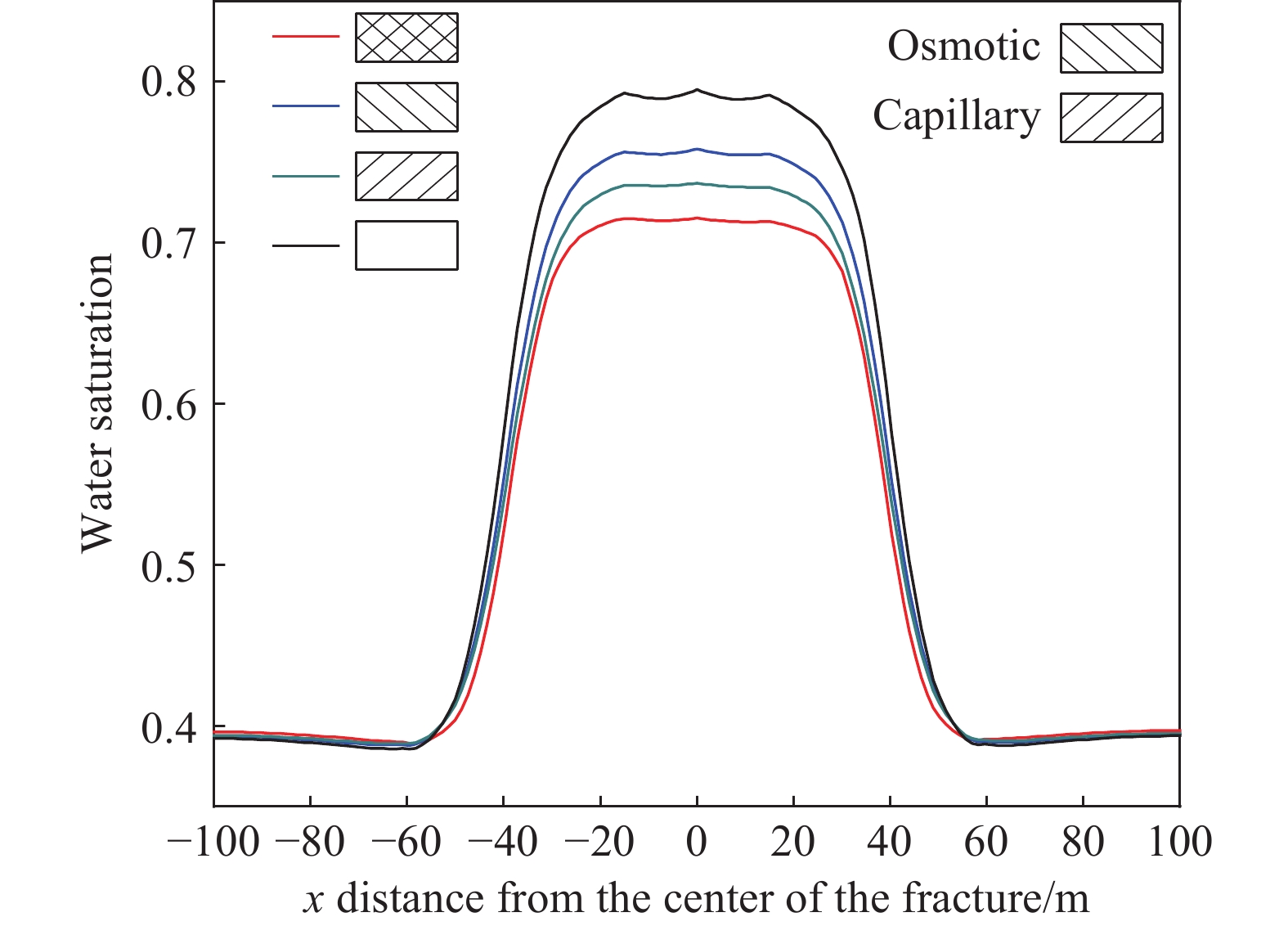

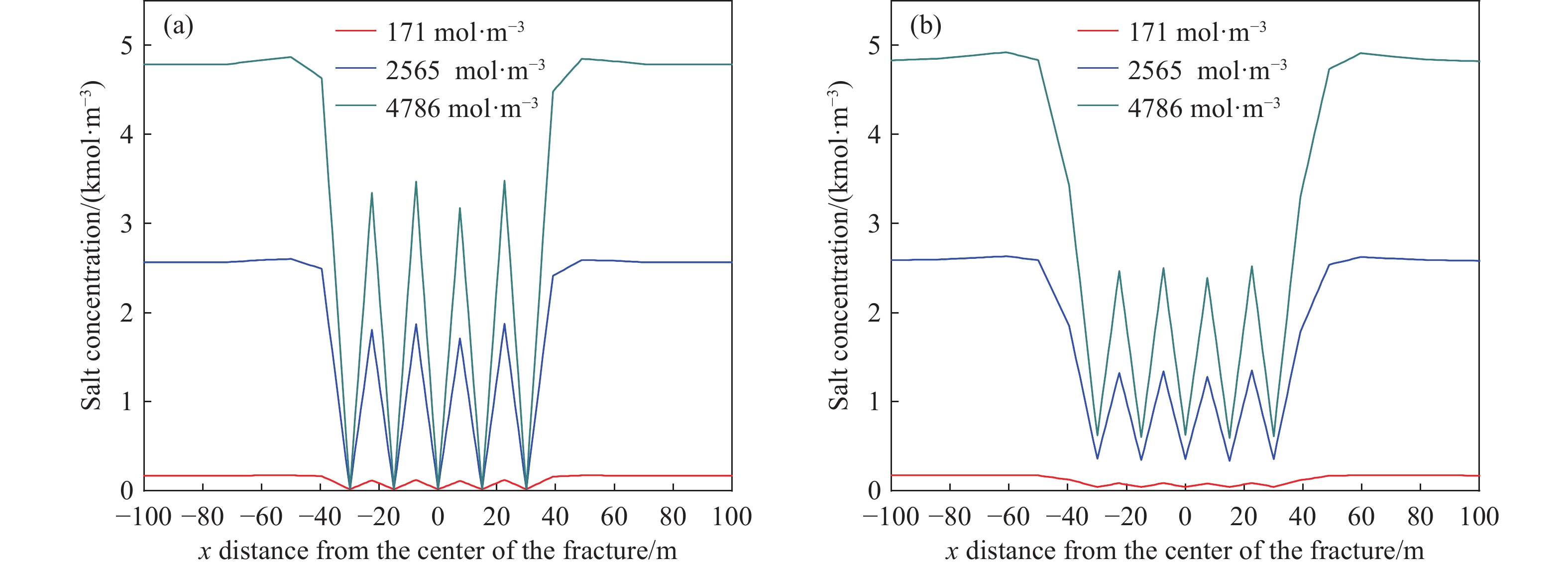

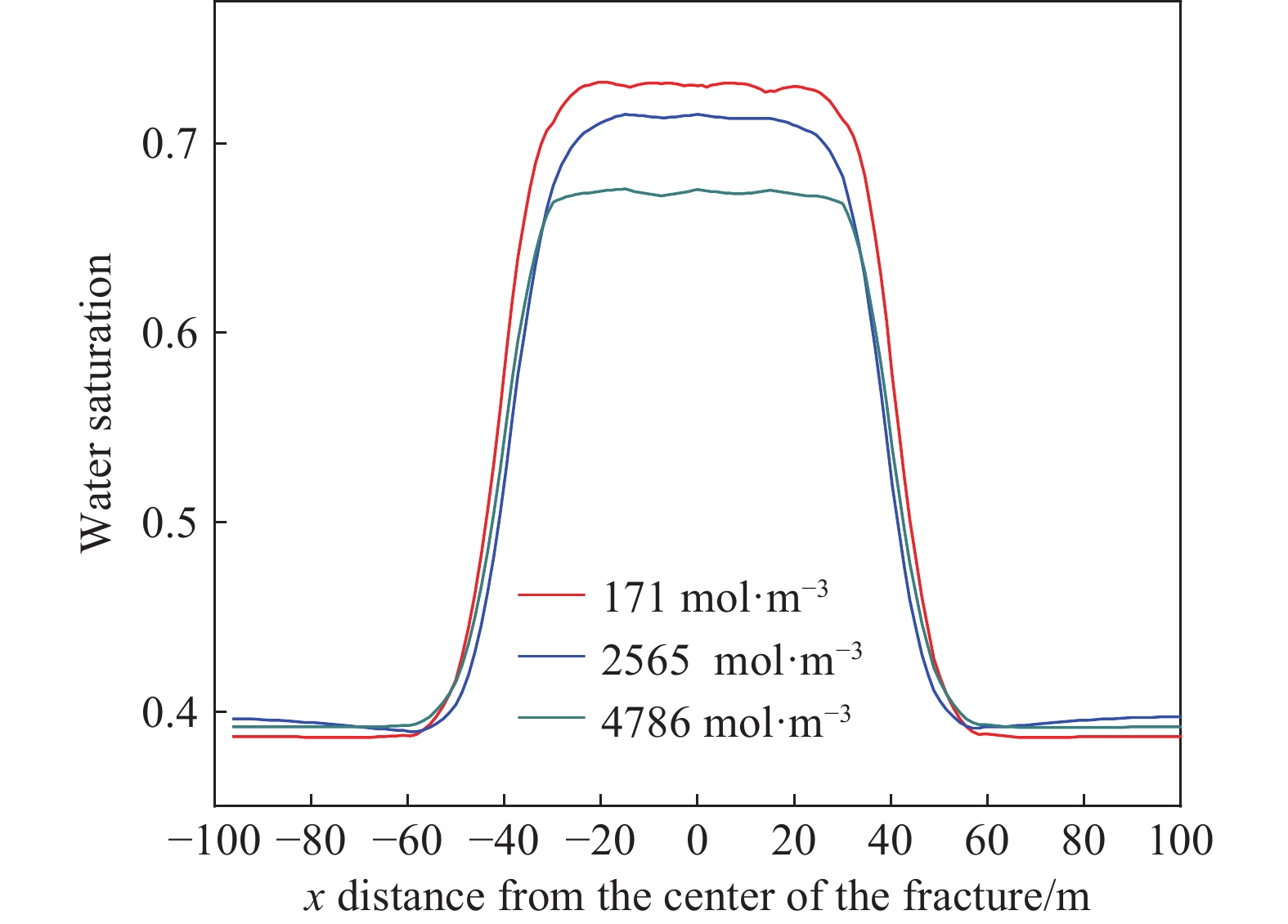

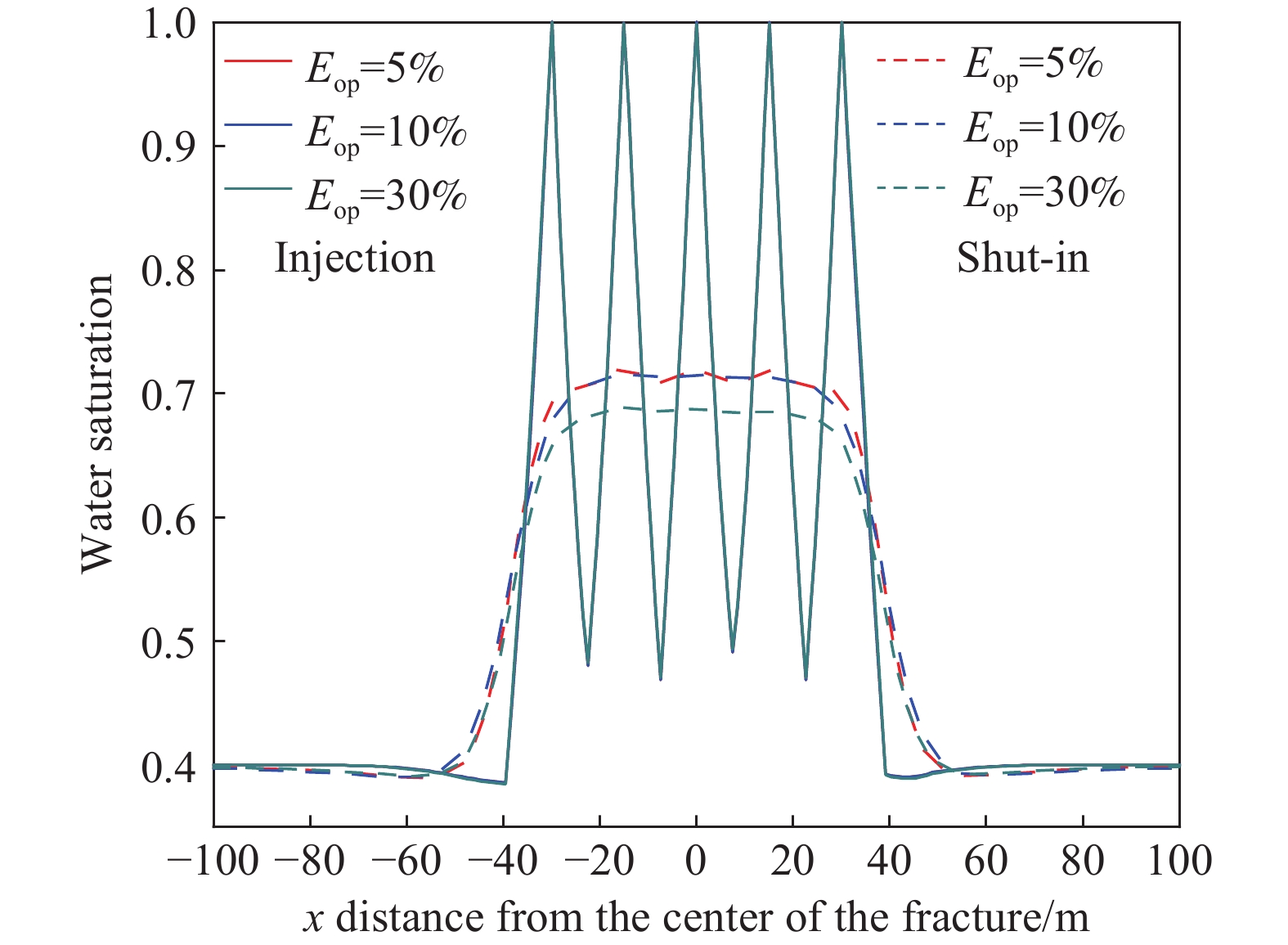

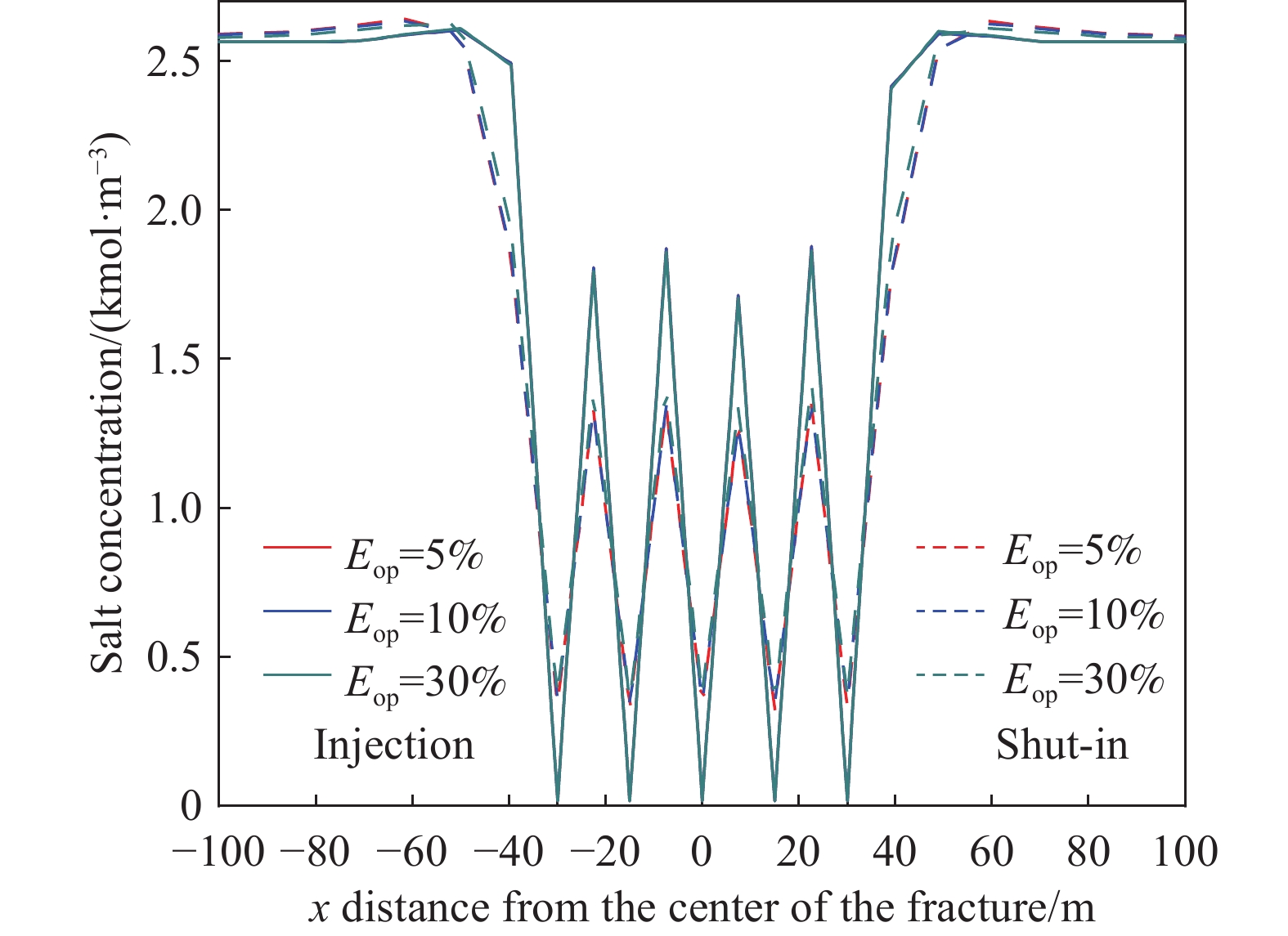

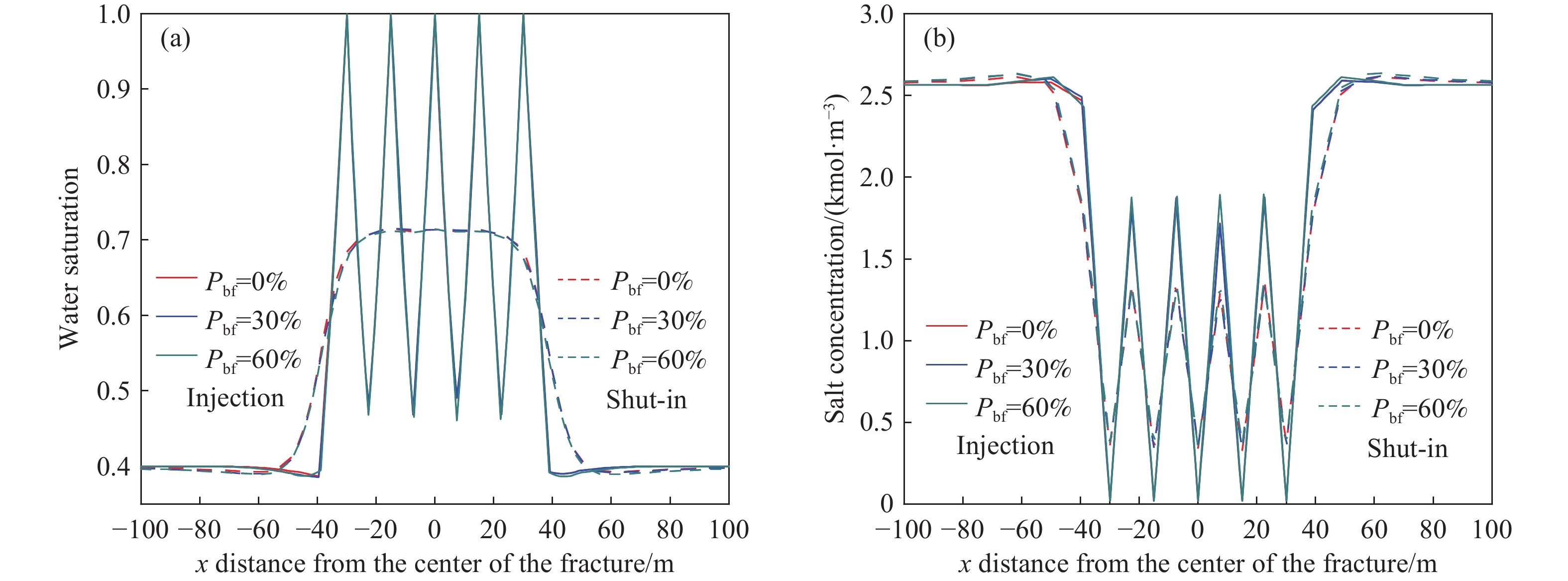

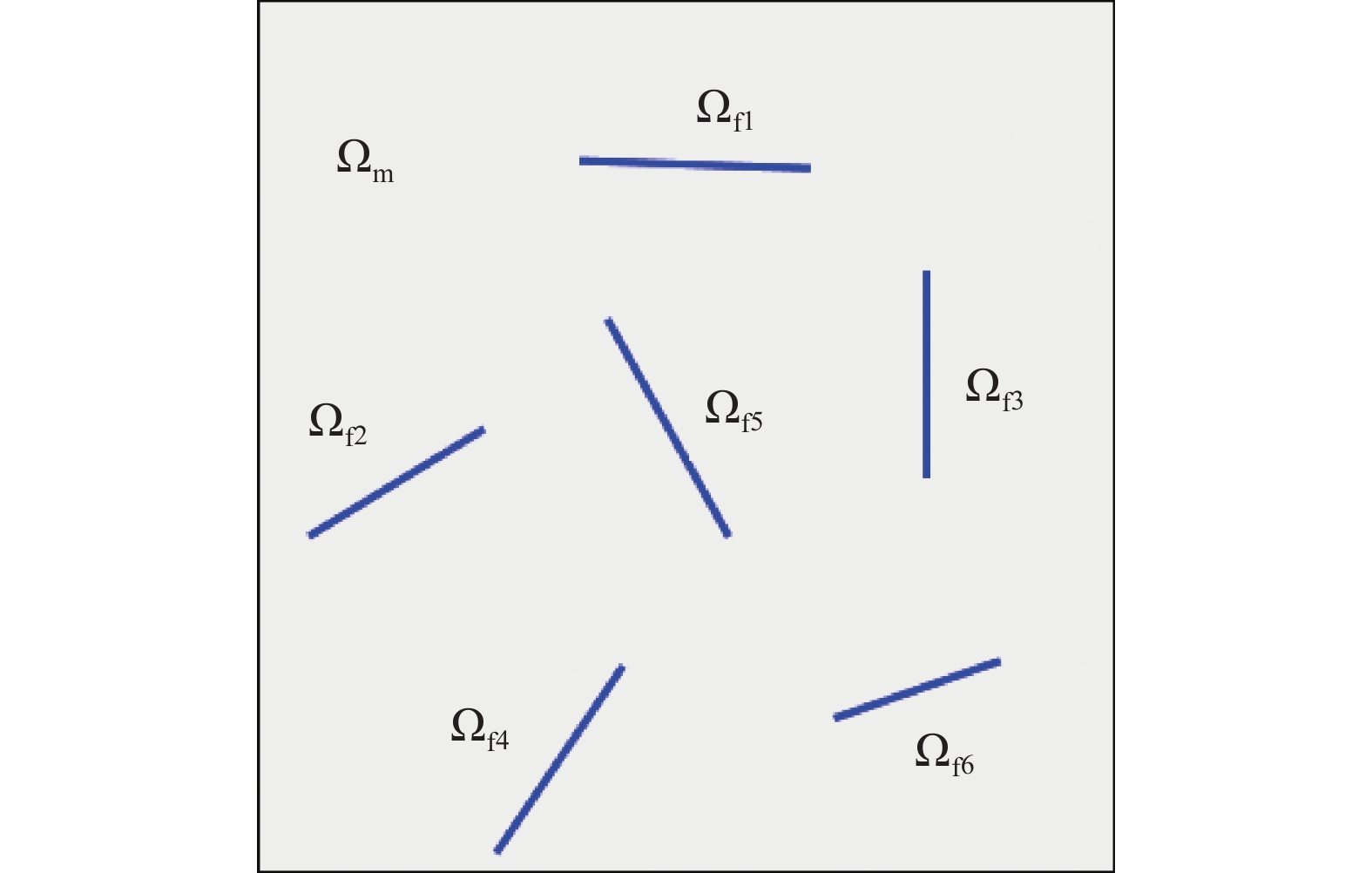

摘要: 對于含黏土礦物較高的頁巖油儲層,地層水的礦化度可高達4.786×103 mol·m?3,壓裂過程中與注入的低礦化度壓裂液形成的滲透壓作用顯著。為探究滲透壓對滲吸的影響作用,建立了綜合考慮滲透壓和毛管力滲吸作用的油水兩相二維離散裂縫網絡模型,開展了頁巖油儲層壓裂液泵注和關井階段滲透壓、毛管力、關井時間、鹽濃度、膜效率、分支縫面積占比等對滲吸的影響規律研究。結果表明:①濾失主要由壓力差、毛管力和滲透壓3種機制驅動,其中壓力差是濾失的關鍵控制機制;②關井時間對壓裂液的滲吸作用影響較大,關井50 d時,前15 d滲吸量可達到總滲吸量的80%,且關井壓力擴散會波及到兩側壓裂段;③與壓力擴散相比,滲透壓達到平衡的時間較長,對于地層水礦化度為4.786×103 mol·m?3的情況,裂縫附近的礦化度達到600 mol·m?3左右所需關井時間為50 d;④由于壓力差是滲吸主要驅動力,頁巖膜效率對滲透壓力擴散影響微弱,頁巖膜效率30%與5%相比滲吸量僅增加4%;⑤對于密切割壓裂,關井后,含水飽和度受小間距水力裂縫控制,分支縫對滲吸含水飽和度的影響有限。Abstract: When a shale oil reservoir contains a mass of clay minerals, the salinity of formation water can reach up to 4.786×103 mol·m?3 and the formation water and low salinity fracturing fluid create significant osmotic pressure during the fracturing process. To investigate the effect of osmotic pressure on the imbibition effect, a two-dimensional, oil-water, two-phase, discrete fracture network model was established. This model comprehensively considers osmotic pressure and capillary force. Additionally, a series of studies were carried out to explore the influence of osmotic pressure, capillary force, shut-in time, salt concentration, membrane efficiency, and the proportion of branch fracture area on the imbibition effect in shale oil reservoirs during fracturing fluid pumping and shut-in. The results show that: (1) Filtration is mainly influenced by pressure difference, capillary force, and osmotic pressure, and pressure difference is the key control mechanism of filtration. (2) The shut-in time has a great influence on the imbibition effect of fracturing fluid. The imbibition amount in the first 15 d can reach 80% of the total imbibition amount when the well is shut in for 50 d, leading to the shut-in pressure spreading to the fracturing interval on either side. (3) Osmotic pressure takes longer to reach equilibrium than diffusion pressure. Osmotic pressure takes 50 d to shut in the well and make the salinity near the fracture reach 600 mol·m?3 when the salinity of local layer water is 4.786×103 mol·m?3. (4) As pressure difference is the main factor that affects the imbibition effect and the effect of shale film efficiency on seepage pressure diffusion is weak, the extent of imbibition increases by only 4% when the shale film efficiency increases from 5% to 30%. (5) Water saturation is controlled using hydraulic fractures through small spacing during shut-in, and the influence of branch fractures on water saturation is limited in intensive volume fracturing to horizontal wells.

-

Key words:

- shale oil reservoir /

- imbibition /

- osmotic pressure /

- discrete fracture model /

- numerical simulation /

- shut-in time

-

表 1 模型參數

Table 1. Simulation parameters

Parameter Value Parameter Value Reservoir area/(m×m) 200 × 500 Hydraulic fracture spacing/m 15 Initial reservoir pressure/MPa 30 Reservoir temperature/℃ 90 Rock compressibility/Pa?1 2 × 10?9 Initial water saturation/dimensionless 0.2 Water compressibility/Pa?1 5 × 10?9 Oil compressibility/Pa?1 2×10?9 Permeability of matrix/mD 0.01 Permeability of hydraulic fracture/D 10 Porosity of matrix 0.1 Porosity of hydraulic fracture 0.25 Water density/(kg·m?3) 1000 Oil density/(kg·m?3) 800 Water viscosity/(mPa·s) 1 Oil viscosity/(mPa·s) 5 Hydraulic fracture width/mm 5 Pumping rate/(m3·min?1) 15 Residual oil saturation 0.05 residual water saturation 0.2 Initial reservoir salt concentration /(mol·m?3) 2.565 × 103 [15] Fracturing fluid salt concentration/(mol·m?3) 17.1 [15] Diffusion coefficient/(m2·s?1) 1 × 10?9 [14] Osmotic efficiency 10% [15] Secondary fracture permeability/D 1 Secondary fracture porosity 0.15 Unconnected natural fracture permeability/mD 10 Unconnected natural fracture porosity 5 × 10?4 Hydraulic fracture half-length/m 200 Secondary fracture length/m 20–70 Secondary fracture aperture /mm 2 Unconnected natural fracture aperture/mm 0.5 www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Xu Y, Lei Q, Chen M, et al. Progress and development of volume stimulation techniques. Petroleum Explor Dev, 2018, 45(5): 874胥云, 雷群, 陳銘, 等. 體積改造技術理論研究進展與發展方向. 石油勘探與開發, 2018, 45(5):874 [2] Denney D. Thirty years of gas-shale fracturing: What have we learned? J Petroleum Technol, 2010, 62(11): 88 [3] Makhanov K, Dehghanpour H, Kuru E. An experimental study of spontaneous imbibition in Horn River shales // SPE Canadian Unconventional Resources Conference. Alberta, 2012 [4] Dehghanpour H, Zubair H A, Chhabra A, et al. Liquid intake of organic shales. Energy Fuels, 2012, 26(9): 5750 doi: 10.1021/ef3009794 [5] Pagels M, Hinkel J J, Willberg D M. Measuring capillary pressure tells more than pretty pictures // SPE International Symposium and Exhibition on Formation Damage Control. Louisiana, 2012: SPE-151729-MS [6] Cheng Y. Impact of water dynamics in fractures on the performance of hydraulically fractured wells in gas-shale reservoirs. J Can Pet Technol, 2012, 51(2): 143 [7] Wang M Y, Leung J Y. Numerical investigation of coupling multiphase flow and geomechanical effects on water loss during hydraulic-fracturing flowback operation. SPE Reserv Eval Eng, 2016, 19(3): 520 doi: 10.2118/178618-PA [8] Meng M M, Ge H K, Ji W M, et al. Investigation on the variation of shale permeability with spontaneous imbibition time: Sandstones and volcanic rocks as comparative study. J Nat Gas Sci Eng, 2015, 27: 1546 doi: 10.1016/j.jngse.2015.10.019 [9] Wang S, Javadpour F, Feng Q H. Confinement correction to mercury intrusion capillary pressure of shale nanopores. Sci Rep, 2016, 6: 20160 doi: 10.1038/srep20160 [10] Zhang T, Li X F, Yang L F, et al. Effects of shut-in timing on flowback rate and productivity of shale gas wells. Nat Gas Ind, 2017, 37(8): 48 doi: 10.3787/j.issn.1000-0976.2017.08.006張濤, 李相方, 楊立峰, 等. 關井時機對頁巖氣井返排率和產能的影響. 天然氣工業, 2017, 37(8):48 doi: 10.3787/j.issn.1000-0976.2017.08.006 [11] Dehghanpour H, Lan Q, Saeed Y, et al. Spontaneous imbibition of brine and oil in gas shales: Effect of water adsorption and resulting microfractures. Energy Fuels, 2013, 27(6): 3039 doi: 10.1021/ef4002814 [12] Yang L. Fracturing Fluid Imbibition into Gas Shale and Its Impact on Engineering [Dissertation]. Beijing: China University of Petroleum (Beijing), 2016楊柳. 壓裂液在頁巖儲層中的吸收及其對工程的影響[學位論文]. 北京: 中國石油大學(北京), 2016 [13] Zhou Z. The Impact of Capillary Imbibition and Osmosis During Hydraulic Fracturing of Shale Formations. Colorado: ProQuest Dissertations Publishing, 2015 [14] Fakcharoenphol P, Torcuk M, Bertoncello A, et al. Managing shut-in time to enhance gas flow rate in hydraulic fractured shale reservoirs: a simulation study // SPE Annual Technical Conference and Exhibition. New Orleans, 2013: SPE-166098-MS [15] Fakcharoenphol P, Kurtoglu B, Kazemi H, et al. The effect of osmotic pressure on improve oil recovery from fractured shale formations // SPE Unconventional Resources Conference. The Woodlands, 2014: SPE-168998-MS [16] Wang F, Pan Z Q. Numerical simulation of chemical potential dominated fracturing fluid flowback in hydraulically fractured shale gas reservoirs. Petroleum Explor Dev, 2016, 43(6): 971王飛, 潘子晴. 化學勢差驅動下的頁巖儲集層壓裂液返排數值模擬. 石油勘探與開發, 2016, 43(6):971 [17] Almulhim A, Alharthy N, Tutuncu A N, et al. Impact of imbibition mechanism on flowback behavior: a numerical study // Abu Dhabi International Petroleum Exhibition and Conference. Abu Dhabi, 2014: SPE-171799-MS [18] Wang J L, Liu Y Z, Chen M Q, et al. Experimental study on dynamic imbibition mechanism of low permeability reservoirs. Petroleum Explor Dev, 2009, 36(1): 86 doi: 10.3321/j.issn:1000-0747.2009.01.011王家祿, 劉玉章, 陳茂謙, 等. 低滲透油藏裂縫動態滲吸機理實驗研究. 石油勘探與開發, 2009, 36(1):86 doi: 10.3321/j.issn:1000-0747.2009.01.011 [19] Zhu W Y, Yue M, Liu Y F, et al. Research progress on tight oil exploration in China. Chin J Eng, 2019, 41(9): 1103朱維耀, 岳明, 劉昀楓, 等. 中國致密油藏開發理論研究進展. 工程科學學報, 2019, 41(9):1103 [20] Zhang T, Li X F, Li J, et al. Numerical investigation of the well shut-in and fracture uncertainty on fluid-loss and production performance in gas-shale reservoirs. J Nat Gas Sci Eng, 2017, 46: 421 doi: 10.1016/j.jngse.2017.08.024 [21] Wang F, Pan Z Q, Zhang Y C, et al. Simulation of coupled hydro-mechanical-chemical phenomena in hydraulically fractured gas shale during fracturing-fluid flowback. J Petroleum Sci Eng, 2018, 163: 16 doi: 10.1016/j.petrol.2017.12.029 [22] Wang X H, Li L, Wang M, et al. A discrete fracture model for two-phase flow involving the capillary pressure discontinuities in fractured porous media. Adv Water Resour, 2020, 142: 103607 doi: 10.1016/j.advwatres.2020.103607 [23] Li Z K, Cao W D, Liu Z F, et al. The advanced embedded discrete fracture model considering the capillary pressure difference. J Por Media, 2020, 23(10): 969 doi: 10.1615/JPorMedia.2020034976 [24] Zhang K N, Woodbury A D. A Krylov finite element approach for multi-species contaminant transport in discretely fractured porous media. Adv Water Resour, 2002, 25(7): 705 doi: 10.1016/S0309-1708(02)00084-2 [25] Takeda M, Hiratsuka T, Ito K, et al. Development and application of chemical osmosis simulator based on TOUGH2 // 2012 TOUGH2 Symposium of Lawrence Berkeley National Laboratory Berkeley. California, 2012: 1 [26] Fritz S J. Ideality of clay membranes in osmotic processes: A review. Clays Clay Miner, 1986, 34(2): 214 doi: 10.1346/CCMN.1986.0340212 [27] Guo T K, Wang X Z, Li Z, et al. Numerical simulation study on fracture propagation of zipper and synchronous fracturing in hydrogen energy development. Int J Hydrog Energy, 2019, 44(11): 5270 doi: 10.1016/j.ijhydene.2018.08.072 [28] Zhu W Y, Ma D X, Zhu H Y, et al. Stress sensitivity of shale gas reservoir and its influence on productivity. Nat Gas Geosci, 2016, 27(5): 892 doi: 10.11764/j.issn.1672-1926.2016.05.0892朱維耀, 馬東旭, 朱華銀, 等. 頁巖儲層應力敏感性及其對產能影響. 天然氣地球科學, 2016, 27(5):892 doi: 10.11764/j.issn.1672-1926.2016.05.0892 [29] Ghorayeb K, Firoozabadi A. Numerical study of natural convection and diffusion in fractured porous media. SPE J, 2000, 5(1): 12 doi: 10.2118/51347-PA [30] Ma T R, Xu H, Guo C B, et al. A discrete fracture modeling approach for analysis of coalbed methane and water flow in a fractured coal reservoir. Geofluids, 2020, 2020: 1 [31] Zhang Q F, Huang Z Q, Yao J, et al. Two-phase numerical simulation of discrete fracture model based on multiscale mixed finite element method. Chin Sci Bull, 2017, 62(13): 1392 doi: 10.1360/N972016-00584張慶福, 黃朝琴, 姚軍, 等. 基于多尺度混合有限元的離散裂縫兩相滲流數值模擬. 科學通報, 2017, 62(13):1392 doi: 10.1360/N972016-00584 [32] Huang Z Q, Gao B, Wang Y Y, et al. Two-phase flow simulation of discrete fracture model using a novel mimetic finite difference method. J China Univ Pet, 2014, 38(6): 97黃朝琴, 高博, 王月英, 等. 基于模擬有限差分法的離散裂縫模型兩相流動模擬. 中國石油大學學報(自然科學版), 2014, 38(6):97 [33] Zheng M, Li J Z, Wu X Z, et al. Physical modeling of oil charging in tight reservoirs: A case study of Permian Lucaogou Formation in Jimsar Sag, Junggar Basin, NW China. Pet Explor Dev, 2016, 43(2): 219鄭民, 李建忠, 吳曉智, 等. 致密儲集層原油充注物理模擬——以準噶爾盆地吉木薩爾凹陷二疊系蘆草溝組為例. 石油勘探與開發, 2016, 43(2):219 [34] Sun B, Liu L F, Ding J H. Main geologic factors controlling the productivity of horizontal wells in tight oil reservoirs. Special Oil Gas Reserv, 2017, 24(2): 115 doi: 10.3969/j.issn.1006-6535.2017.02.023孫兵, 劉立峰, 丁江輝. 致密油水平井產能主控地質因素研究. 特種油氣藏, 2017, 24(2):115 doi: 10.3969/j.issn.1006-6535.2017.02.023 [35] Schlemmer R, Friedheim J E, Growcock F B, et al. Chemical osmosis, shale, and drilling fluids. SPE Drill Complet, 2003, 18(4): 318 doi: 10.2118/86912-PA -

下載:

下載: