Corrosion effects of longitudinal reinforcement on shear behavior of concrete beams without web reinforcement

-

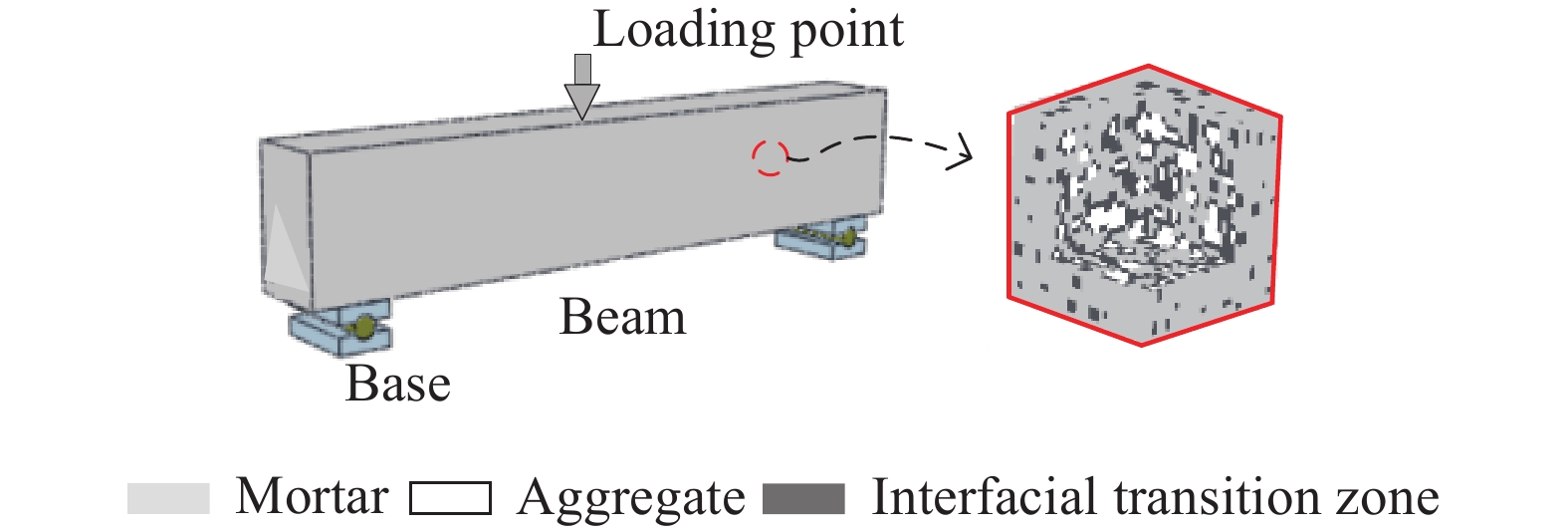

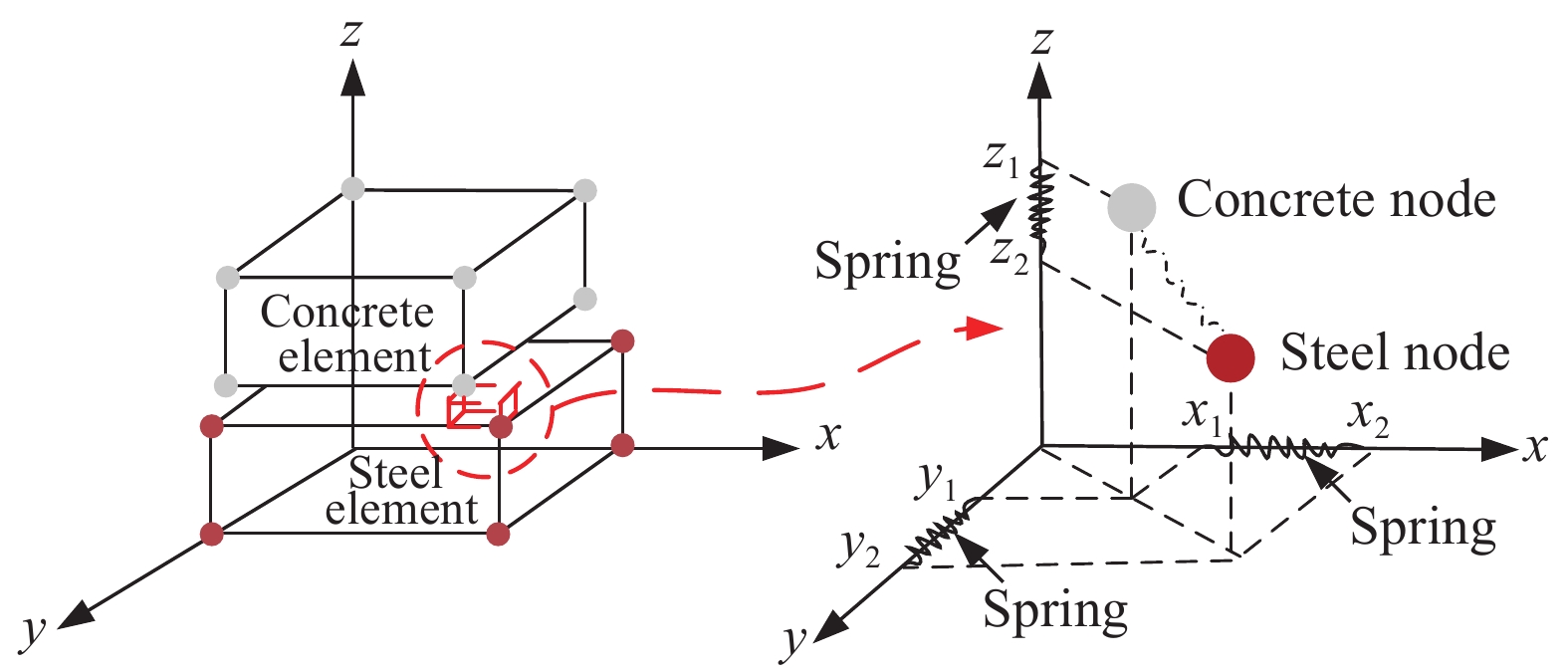

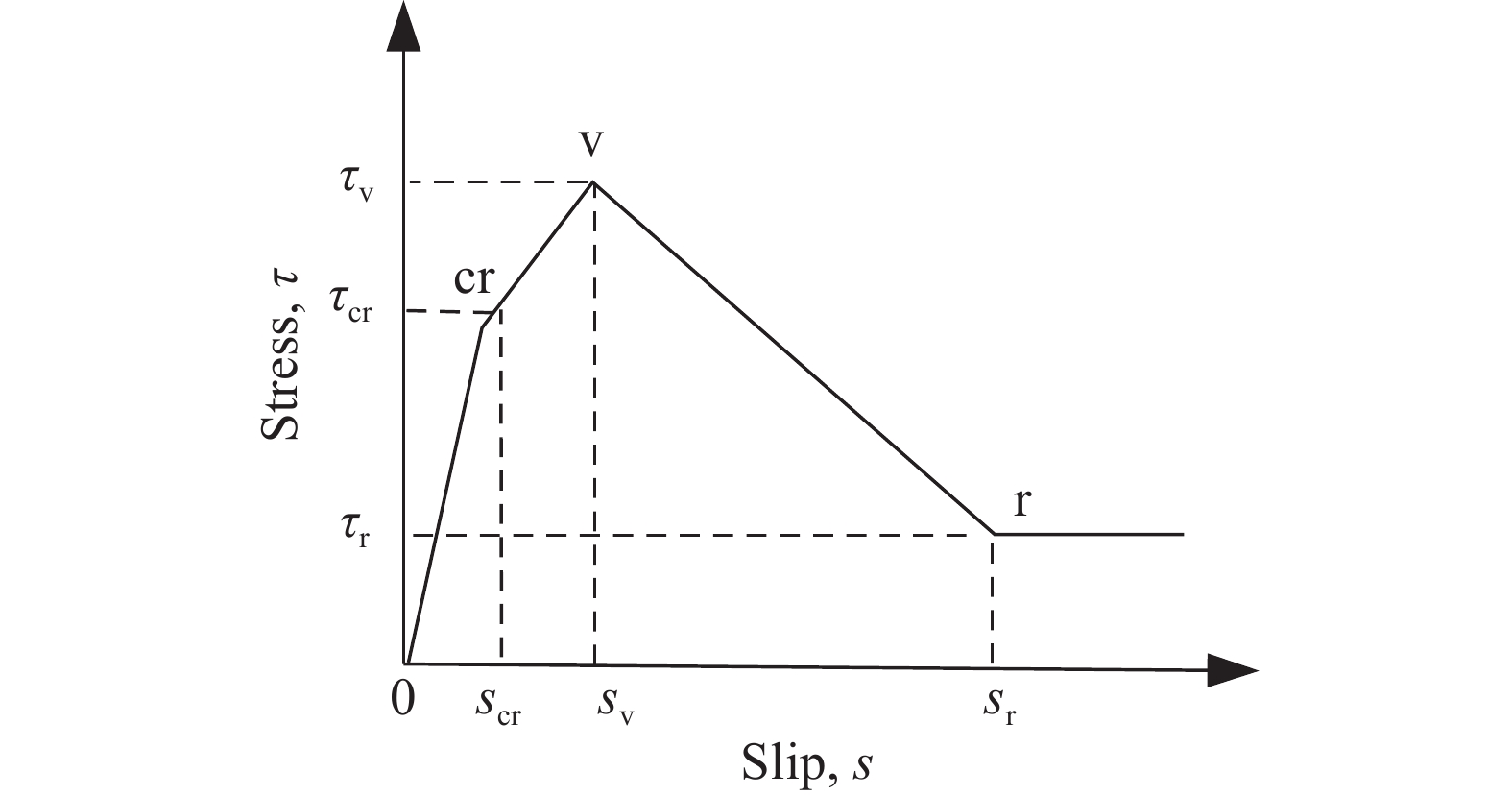

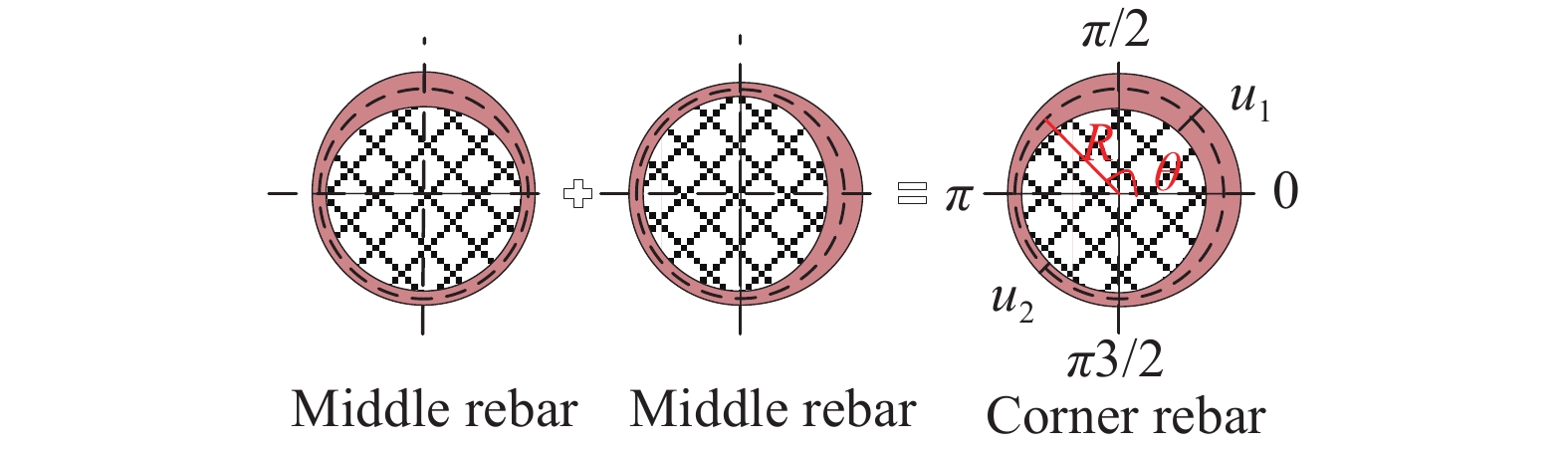

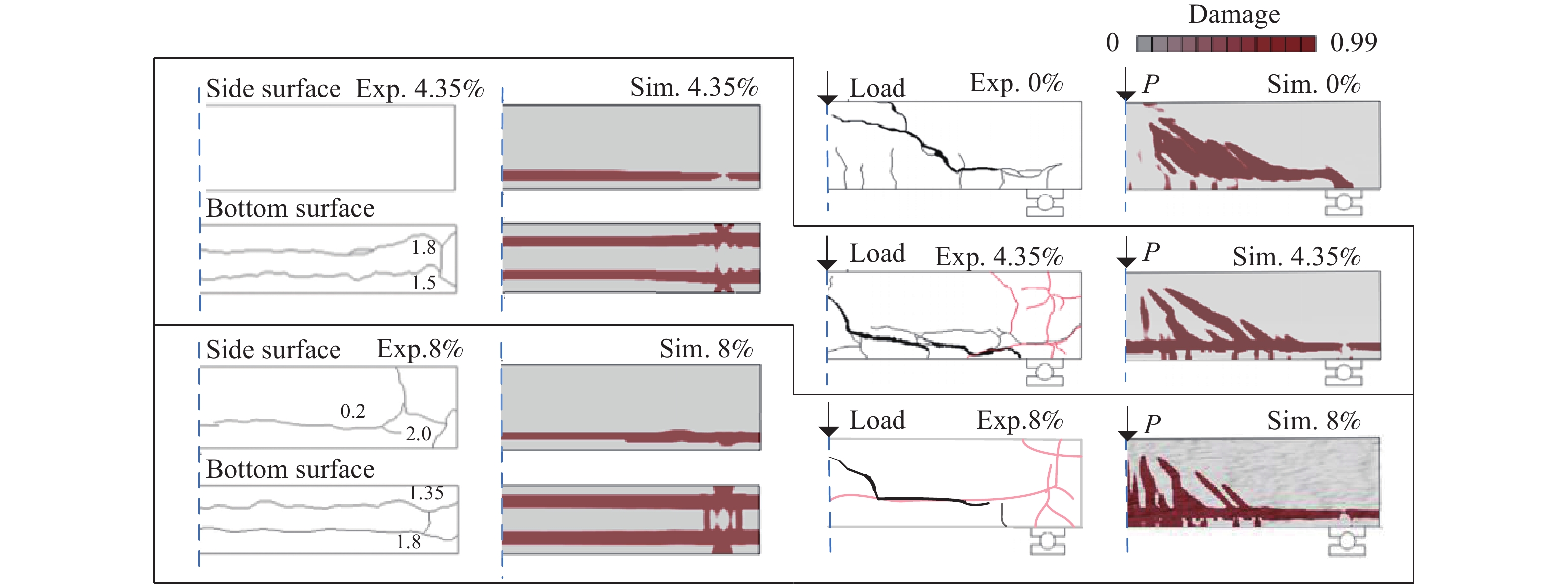

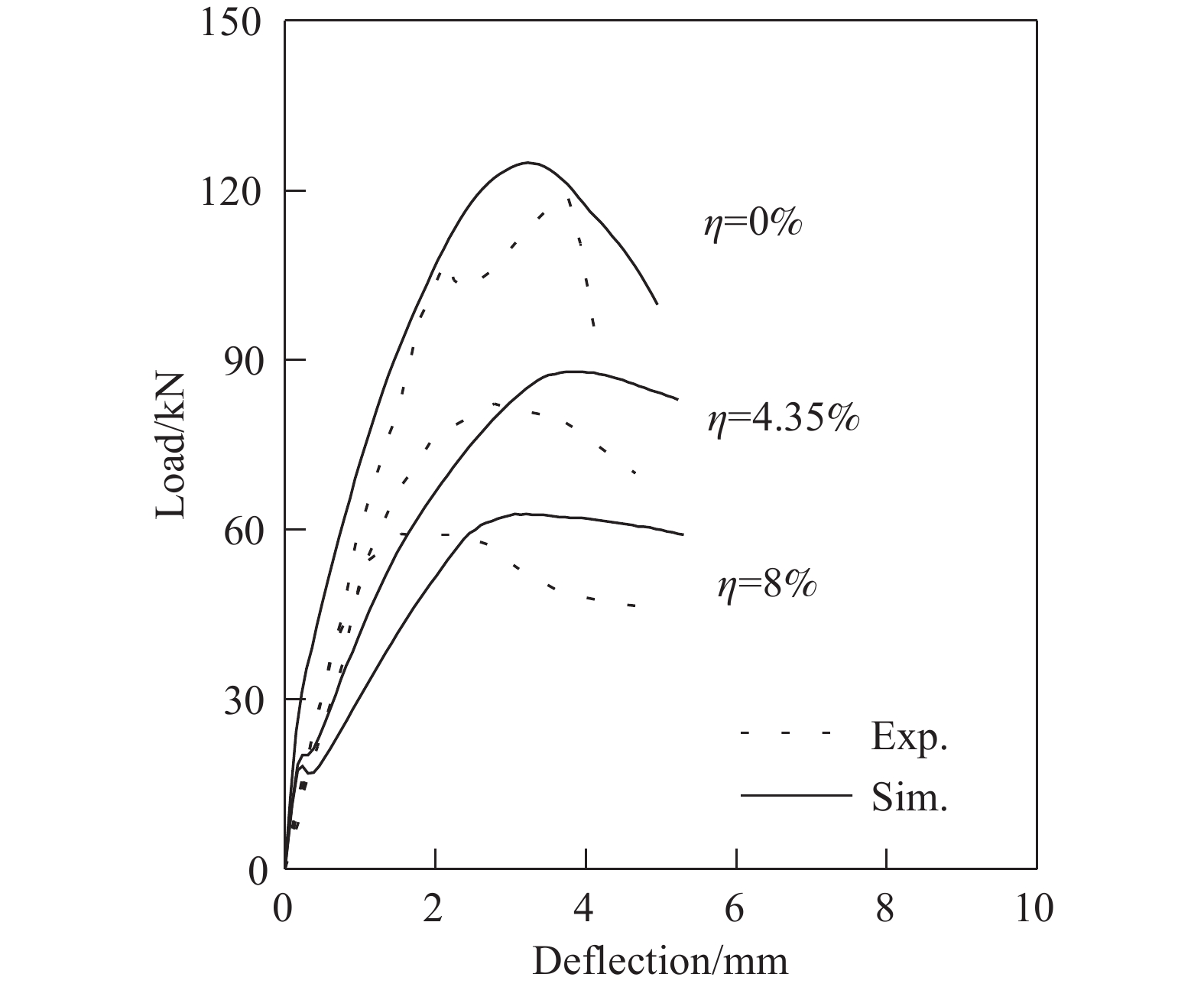

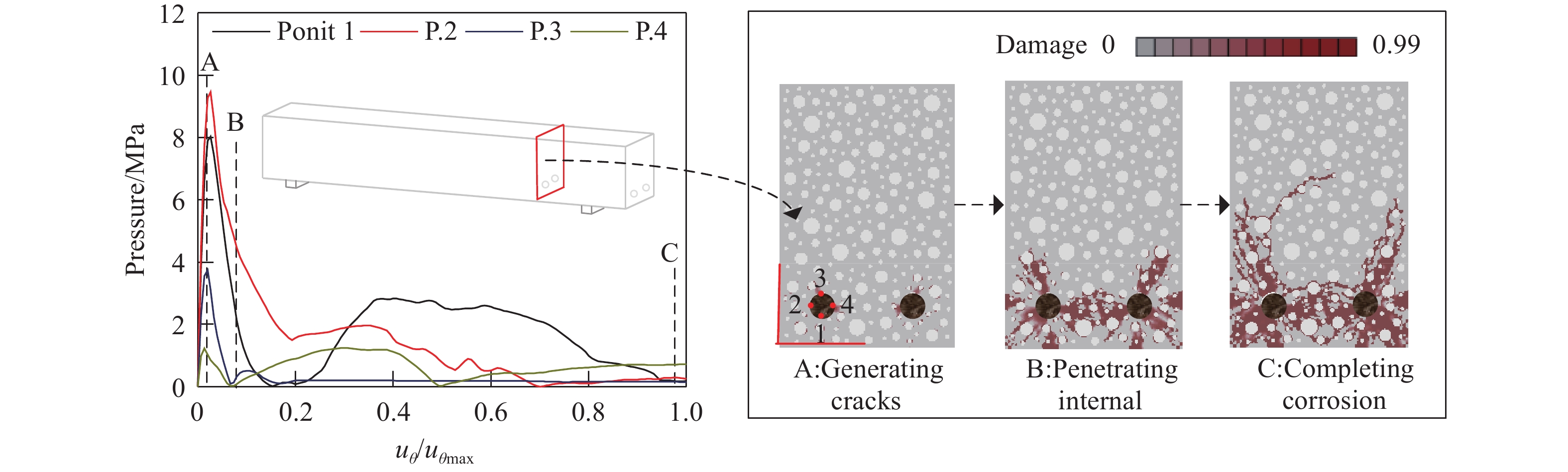

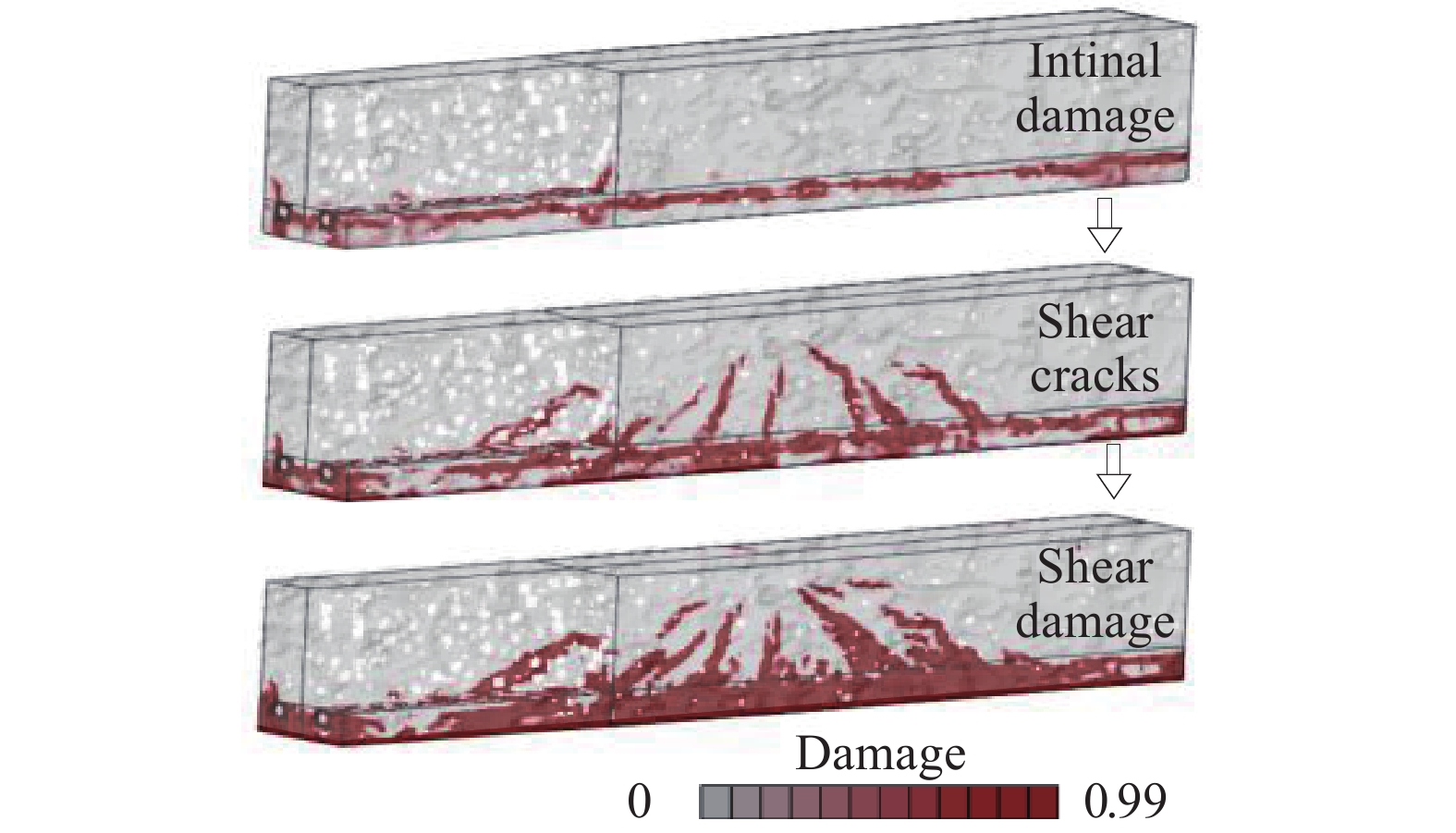

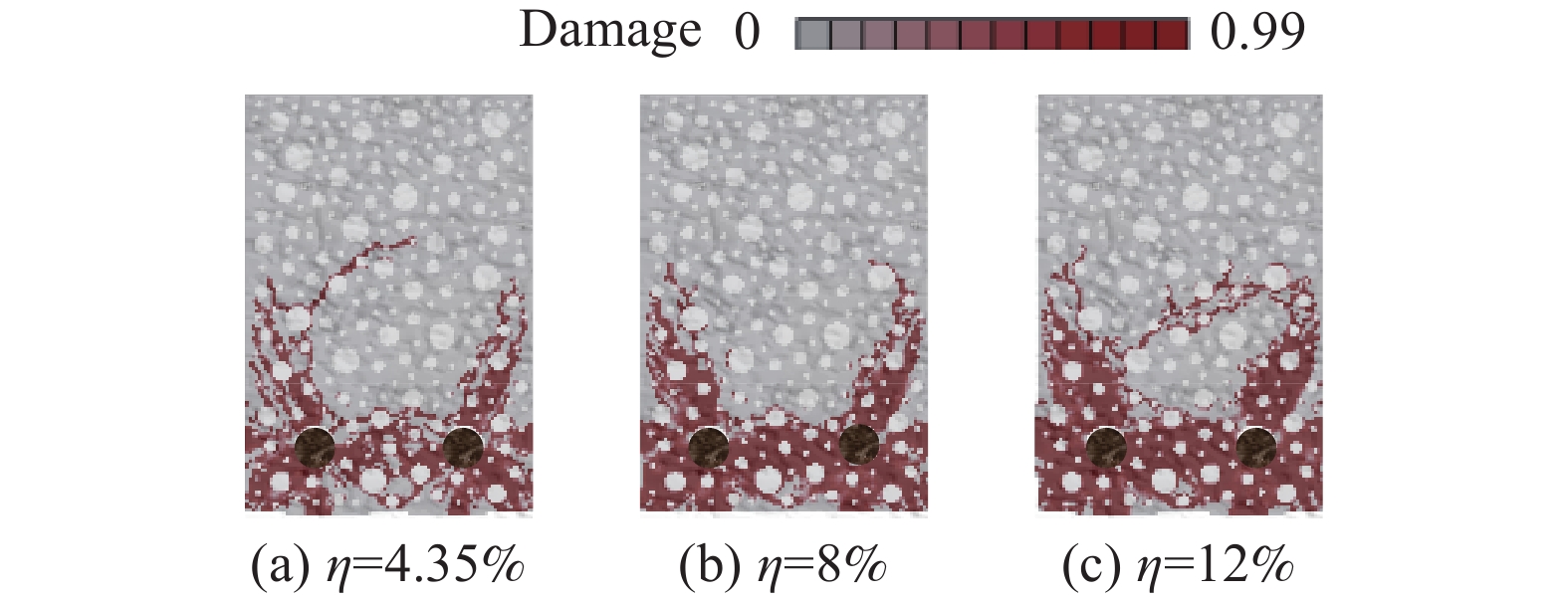

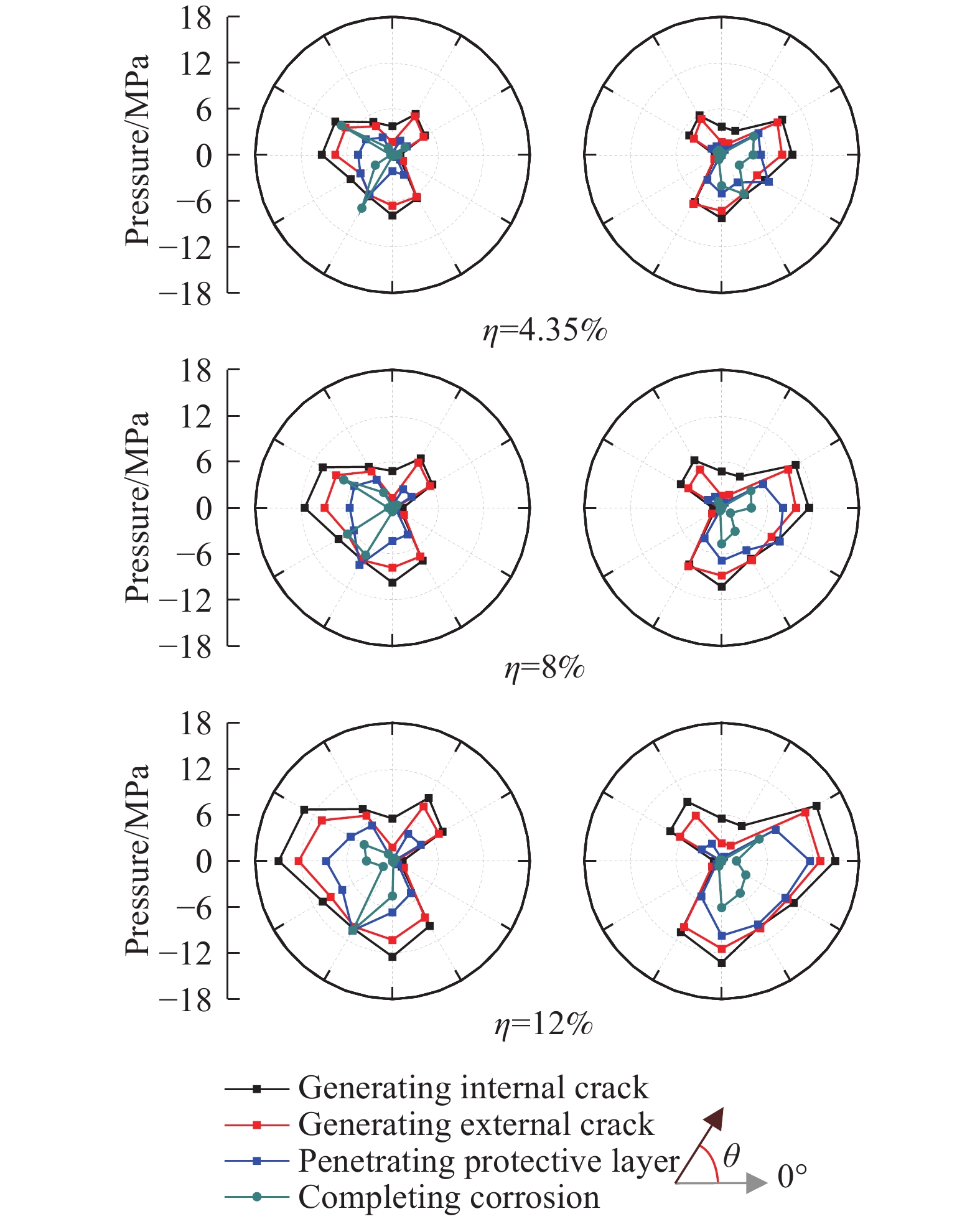

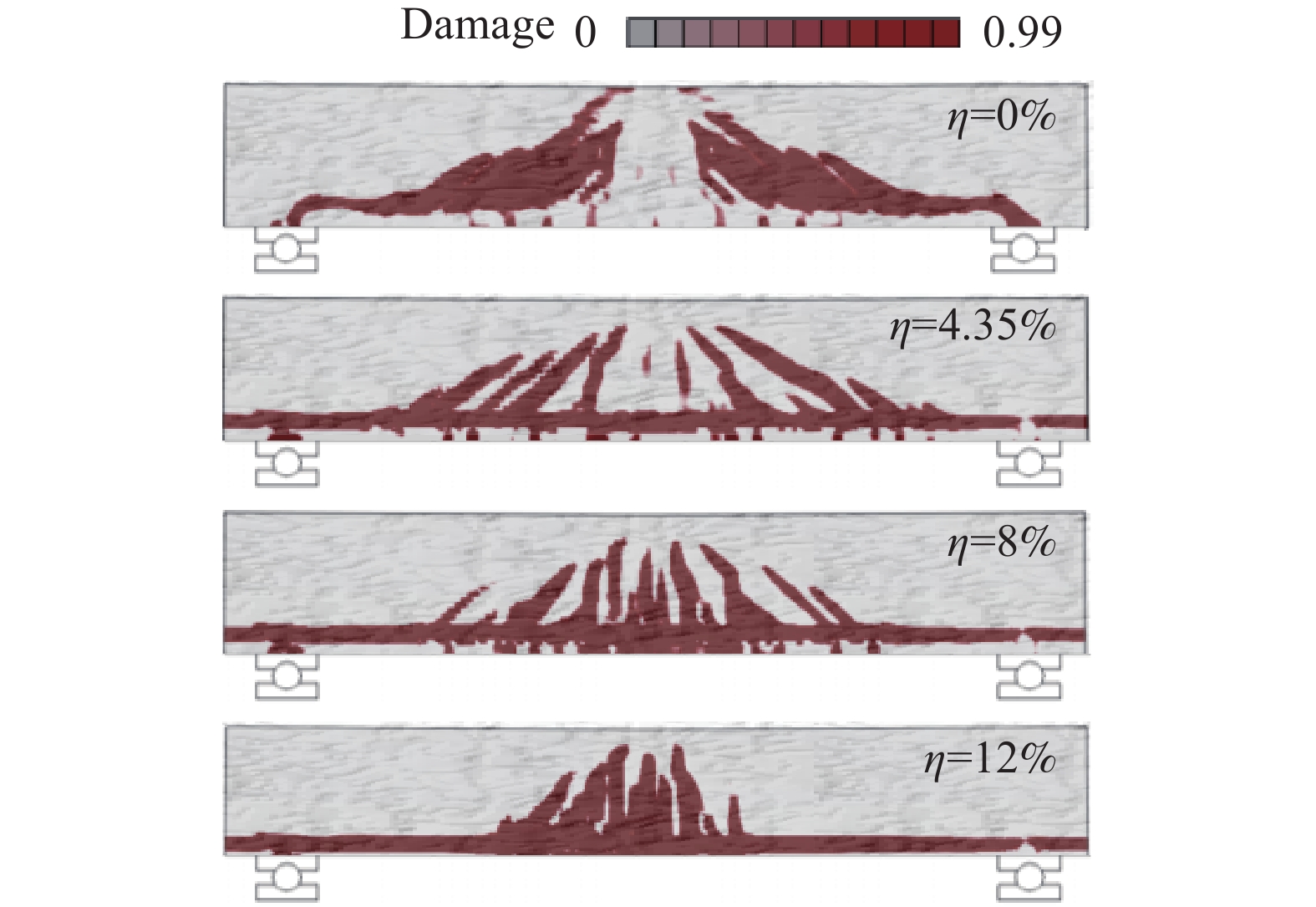

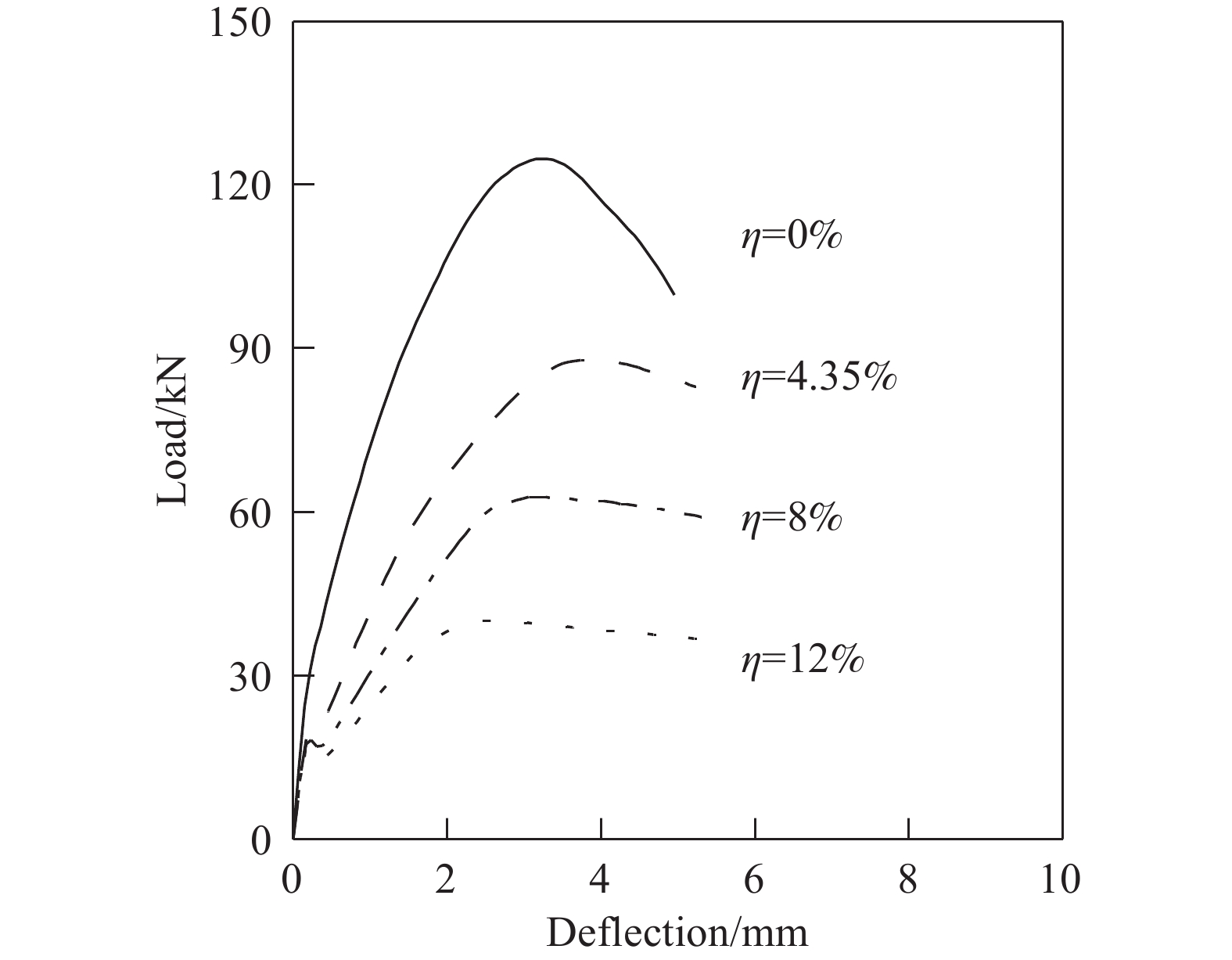

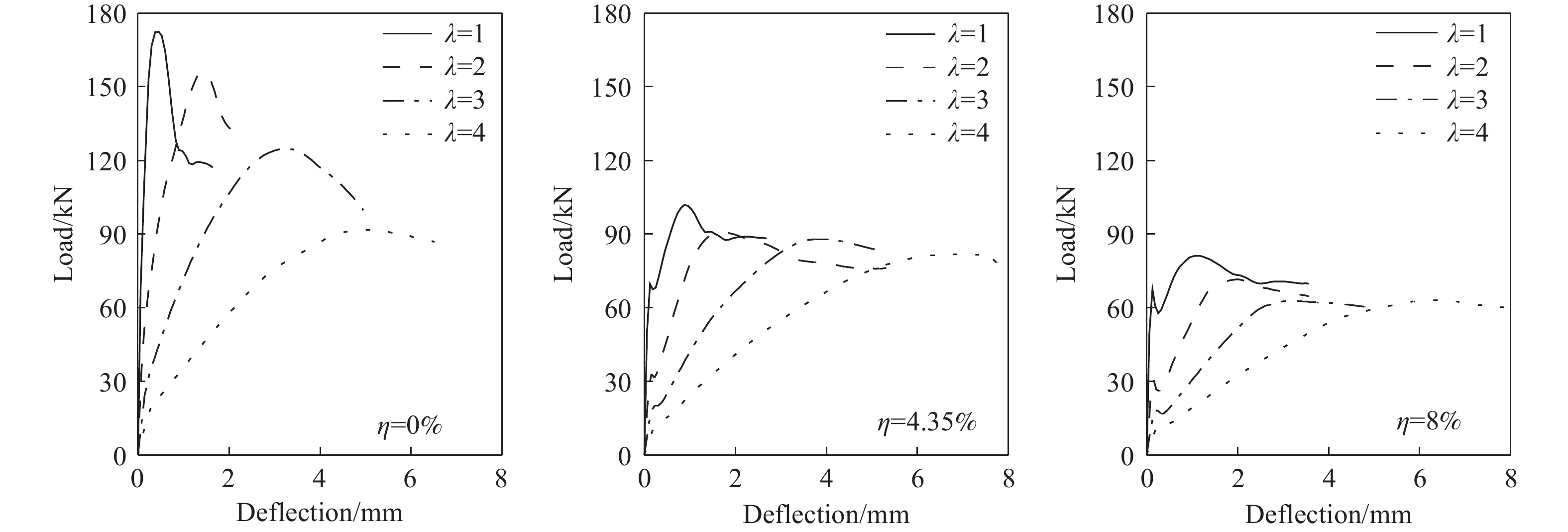

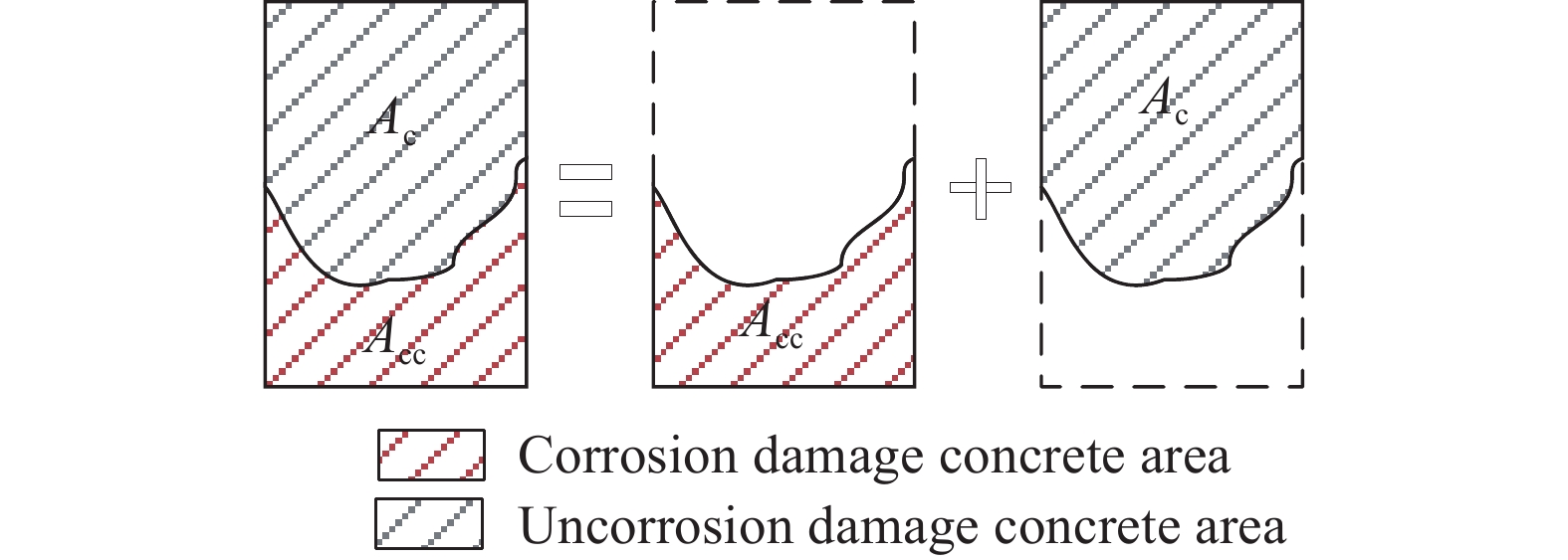

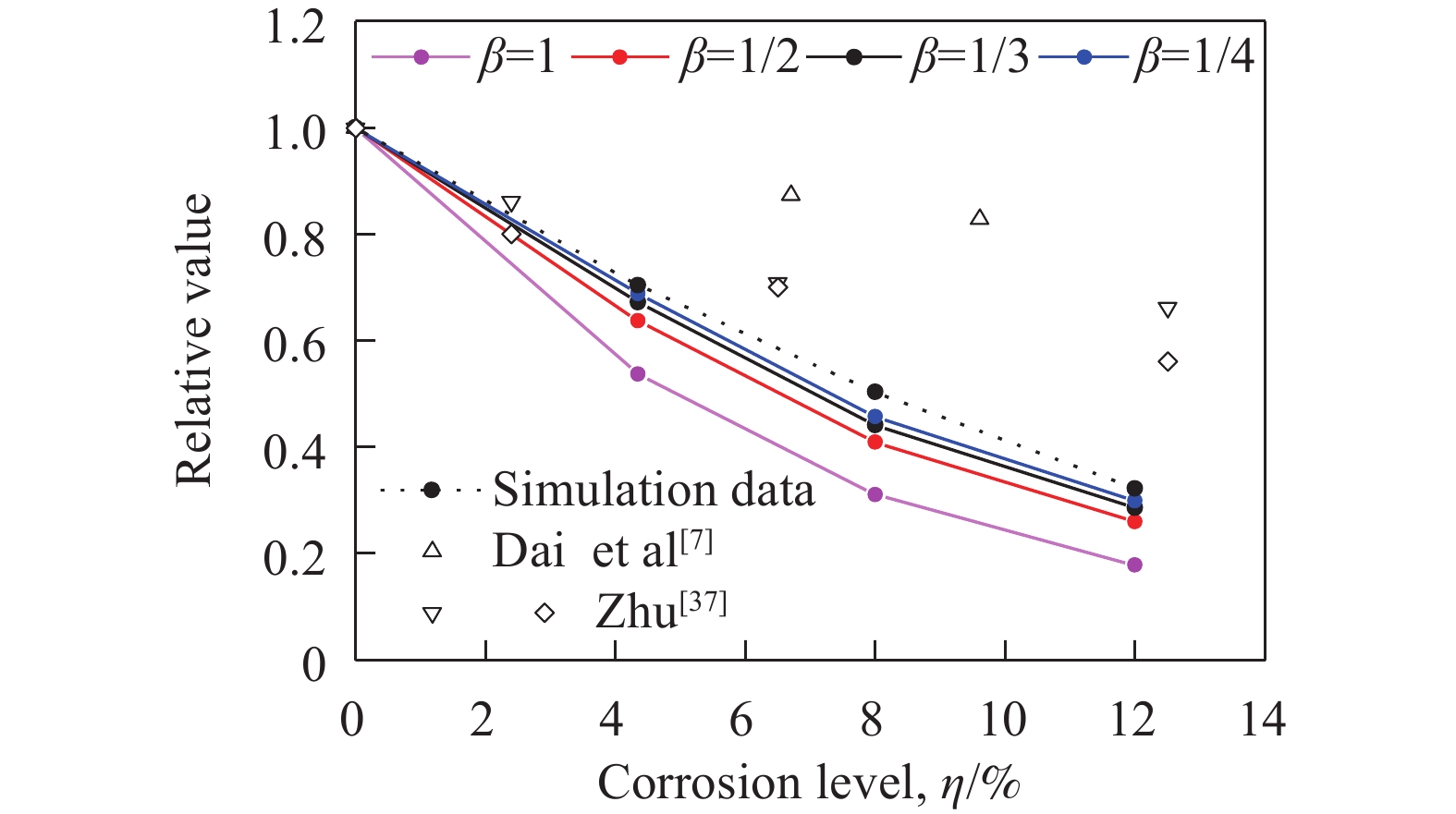

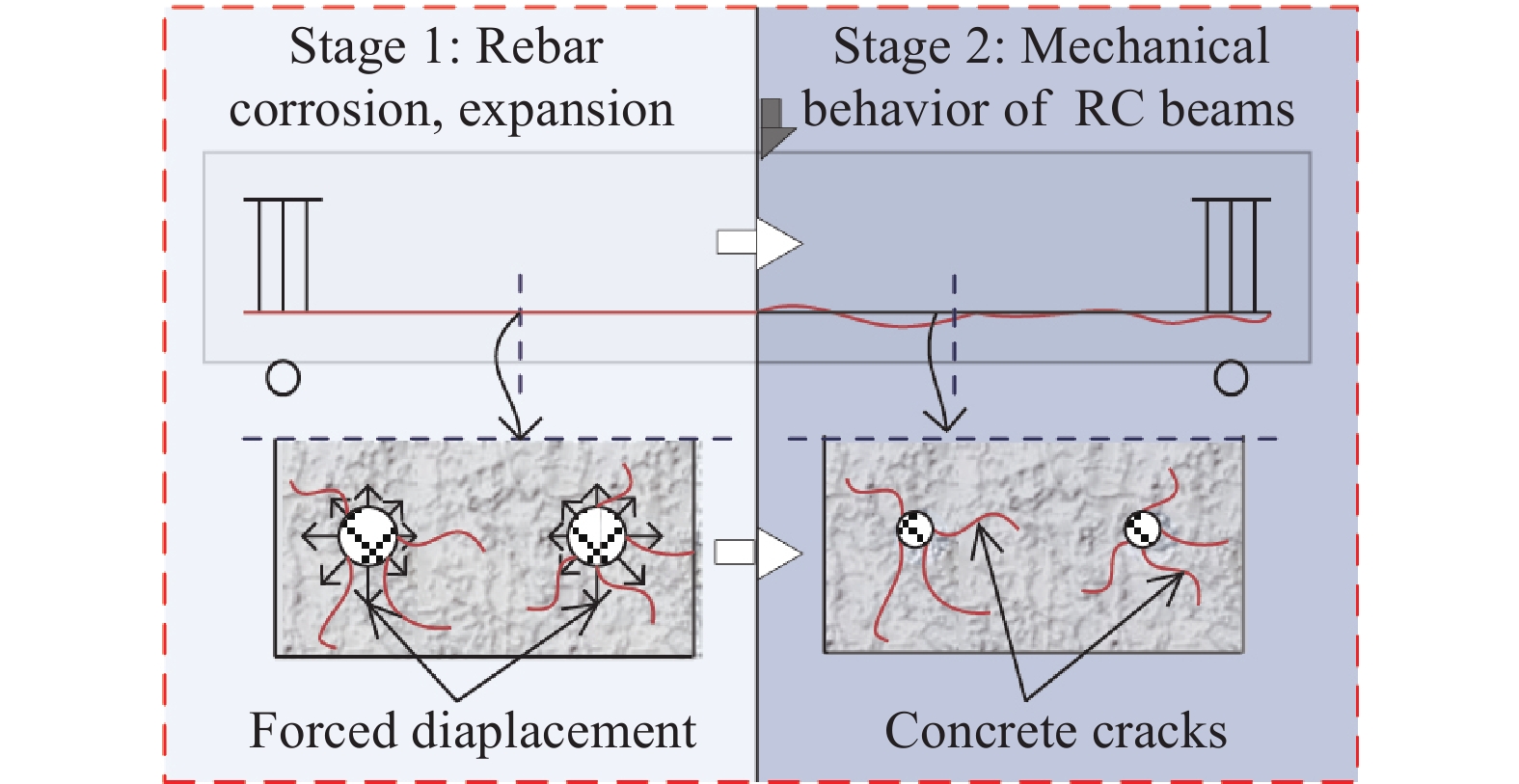

摘要: 以鋼筋混凝土梁為研究對象,考慮鋼筋非均勻銹蝕膨脹效應,建立三維鋼筋混凝土梁剪切破壞分析的數值分析模型。通過多階段分析方法(鋼筋銹蝕階段,構件性能退化階段)探索銹蝕對結構力學行為的影響。鋼筋的非均勻銹蝕膨脹以施加非均勻徑向位移的方式模擬,獲得保護層的破壞狀態,并以此“最終狀態”作為之后混凝土梁靜載試驗的“初始條件”輸入,進而模擬構件的力學行為。在驗證了多階段數值模型合理性的基礎上,分析了縱筋銹蝕、剪跨比對無腹筋混凝土梁抗剪性能的影響規律。結果表明,縱筋銹蝕使混凝土梁產生明顯的縱向裂縫。縱筋銹蝕率增大,保護層開裂區域增加,梁的抗剪承載力下降嚴重。另外,剪跨比對梁的抗剪承載力產生影響,剪跨比對未銹蝕梁的影響明顯大于對銹蝕梁的影響程度。最后,基于模擬結果對相關設計規范中的抗剪承載力計算公式進行了討論,發展建立了考慮銹蝕影響的無腹筋混凝土梁抗剪承載力計算方法。Abstract: Rebar corrosion is the principal factor affecting the service performance of reinforced concrete (RC) structures. Corrosion reduces the effective area of rebars as well as performance, and weakens the pin bolt effect of rebar on concrete. In addition, when the rebar is severely rusted, the concrete cover breaks, and the bond behavior between reinforcement and concrete deteriorates, affecting the mechanical properties of RC structures. In this study, a three-dimensional numerical model for shear analysis incorporating the nonuniform corrosion of reinforcement was established using an RC beam as the research object. The effects of corrosion on the mechanical behavior of the RC beam were explored via a multistage analysis method (namely, corrosion-induced expansion stage and structural deterioration stage). To model and simulate the expansion of the corrosion products, nonuniform radial displacement was applied to the concrete surrounding the rebar. The cracking process and the damage patterns of concrete resulting from corrosion were obtained. Then, taking the corrosion state as the initial condition, the static load was applied to analyze the mechanical behavior of the RC beam. After verifying the rationality of the multistage numerical model, the effect of the corrosion of tensile reinforcement and the shear-span ratio on the shear behavior of concrete beams without web reinforcement was analyzed. The modeling analysis results show that the corrosion of longitudinal reinforcement causes obvious longitudinal corrosion fractures in the concrete beam. Moreover, with the development of corrosion, the cracking area of the protective layer increases, reducing the shear capacity of the beam significantly. Furthermore, the shear-span ratio has a larger effect on the shear capacity of noncorroded beams than that of corroded beams. Finally, based on the simulation results, the calculation formulas of shear capacity in relevant design codes were discussed, and a methodology for predicting the shear capacity of RC beams without web reinforcement was proposed.

-

Key words:

- RC beam /

- longitudinal reinforcement /

- corrosion /

- mesoscale numerical simulation /

- shear behavior

-

表 1 混凝土細觀組分力學參數

Table 1. Mechanical parameters of the mesocomponents of concrete

Components Compressive strength, σc/MPa Tensile strength, σt/MPa Elastic modulus, E/GPa Poisson ratio, ν Aggregate 70 0.2 Mortar *39 *3.5 *32 0.2 Interfacial transition zone ^31 ^2.8 ^26 0.2 Note:data with “*” are measured in the tests[20]; the data with “^” are measured by repeated trial. 表 2 黏結-滑移本構參數

Table 2. Parameters used in the bond-slip model of steel and concrete

Key point Bond stress, τ/MPa Slip, s/mm Crack (cr) τcr = 2.5ft scr =0.025d Peak value (v) τv = 3.0 ft sv = 0.04d Remnant (r) τr = ft sr = 0.55d Note: d means the diameter of steel; ft means the tensile strength of concrete. 表 3 模擬值與理論值對比

Table 3. Comparison of shear capacity between the simulated and theoretical data

Spec. ID Vsiml/kN Vpred/kN β = 1 β = 1/2 β = 1/3 β = 1/4 NS-0 62.4 37.4 37.4 37.4 37.4 NS-4.35 43.9 20.1 23.8 25.1 25.7 NS-8 31.4 11.6 15.3 16.5 17.1 NS-12 20.1 6.8 9.7 10.7 11.2 www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Zhang K J, Xiao J Z, Zhao Y X, et al. Analytical model for critical corrosion level of reinforcements to cause the cracking of concrete cover. Constr Build Mater, 2019, 223: 185 doi: 10.1016/j.conbuildmat.2019.06.210 [2] Biswas R K, Iwanami M, Chijiwa N, et al. Effect of non-uniform rebar corrosion on structural performance of RC structures: A numerical and experimental investigation. Constr Build Mater, 2020, 230: 116908 doi: 10.1016/j.conbuildmat.2019.116908 [3] Li C Q, Melchers R E. Time-dependent risk assessment of structural deterioration caused by reinforcement corrosion. ACI Struct J, 2005, 102(5): 754 [4] Alaskar A, Alqarni A S, Alfalah G, et al. Performance evaluation of reinforced concrete beams with corroded web reinforcement: Experimental and theoretical study. J Build Eng, 2021, 35: 102038 doi: 10.1016/j.jobe.2020.102038 [5] Suffern C, El-Sayed A, Soudki K. Shear strength of disturbed regions with corroded stirrups in reinforced concrete beams. Can J Civ Eng, 2010, 37(8): 1045 doi: 10.1139/L10-031 [6] Huang T L, Zhao Z Y, Song L, et al. Experimental investigation on shear performance of RC beams due to longitudinal reinforcement corrosion. J Central South Univ Sci Technol, 2019, 50(8): 1901黃天立, 趙志彥, 宋力, 等. 縱筋銹蝕對鋼筋混凝土梁抗剪性能影響的試驗研究. 中南大學學報(自然科學版), 2019, 50(8):1901 [7] Dai M J, Yang O, Xiao Y. Influence of longitudinal bar corrosion on shear behavior of RC beams. Ind Constr, 2016, 46(11): 74戴明江, 楊鷗, 肖巖. 縱筋銹蝕對鋼筋混凝土梁抗剪性能影響. 工業建筑, 2016, 46(11):74 [8] Xue X, Seki H. Influence of longitudinal bar corrosion on shear behavior of RC beams. J Adv Concr Technol, 2010, 8(2): 145 doi: 10.3151/jact.8.145 [9] Xu S H, Niu D T. The shear behavior of corroded simply supported reinforced concrete beam. J Build Struct, 2004, 25(5): 98 doi: 10.3321/j.issn:1000-6869.2004.05.016徐善華, 牛荻濤. 銹蝕鋼筋混凝土簡支梁斜截面抗剪性能研究. 建筑結構學報, 2004, 25(5):98 doi: 10.3321/j.issn:1000-6869.2004.05.016 [10] Khan I, Fran?ois R, Castel A. Experimental and analytical study of corroded shear-critical reinforced concrete beams. Mater Struct, 2014, 47(9): 1467 doi: 10.1617/s11527-013-0129-y [11] El-Sayed A K. Shear capacity assessment of reinforced concrete beams with corroded stirrups. Constr Build Mater, 2017, 134: 176 doi: 10.1016/j.conbuildmat.2016.12.118 [12] Azam R, Soudki K. Structural behavior of shear-critical RC slender beams with corroded properly anchored longitudinal steel reinforcement. J Struct Eng, 2013, 139(12): 04013011 doi: 10.1061/(ASCE)ST.1943-541X.0000799 [13] Azam R, Soudki K. Structural performance of shear-critical RC deep beams with corroded longitudinal steel reinforcement. Cem Concr Compos, 2012, 34(8): 946 doi: 10.1016/j.cemconcomp.2012.05.003 [14] Yu F J. Experimental Study and Analysis on the Diagonal Shear Property of Corroded Reinforced Concrete Beam [Dissertation]. Nanjing: Hohai University, 2005余璠璟. 銹蝕鋼筋混凝土梁斜截面性能試驗研究和分析[學位論文]. 南京: 河海大學, 2005 [15] Cui Z, Alipour A. Concrete cover cracking and service life prediction of reinforced concrete structures in corrosive environments. Constr Build Mater, 2018, 159: 652 doi: 10.1016/j.conbuildmat.2017.03.224 [16] Jin L, Liu M J, Zhang R B, et al. Cracking of cover concrete due to non-uniform corrosion of corner rebar: A 3D meso-scale study. Constr Build Mater, 2020, 245: 118449 doi: 10.1016/j.conbuildmat.2020.118449 [17] Lim S, Akiyama M, Frangopol D M. Assessment of the structural performance of corrosion-affected RC members based on experimental study and probabilistic modeling. Eng Struct, 2016, 127: 189 doi: 10.1016/j.engstruct.2016.08.040 [18] Coronelli D, Gambarova P. Structural assessment of corroded reinforced concrete beams: Modeling guidelines. J Struct Eng, 2004, 130(8): 1214 doi: 10.1061/(ASCE)0733-9445(2004)130:8(1214) [19] Chen E, Leung C K Y. Finite element modeling of concrete cover cracking due to non-uniform steel corrosion. Eng Fract Mech, 2015, 134: 61 doi: 10.1016/j.engfracmech.2014.12.011 [20] Han S J, Lee D, Yi S T, et al. Experimental shear tests of reinforced concrete beams with corroded longitudinal reinforcement. Struct Concr, 2020, 21(5): 1763 doi: 10.1002/suco.201900248 [21] Jin L, Lan Y C, Zhang R B, et al. Impact performances of RC beams at/after elevated temperature: A meso-scale study. Eng Fail Anal, 2019, 105: 196 doi: 10.1016/j.engfailanal.2019.07.002 [22] Wu X N, Xu W, Sun Y, et al. Experimental study on property of RC concrete beams corroded by Nacl. Ind Constr, 2012, 42(Suppl 1): 126伍雪南, 徐為, 孫勇, 等. 考慮粘結滑移的銹蝕鋼筋混凝土梁數值模擬研究. 工業建筑, 2012, 42(增刊1): 126 [23] Jin L, Fan L L, Li P, et al. Size effect of axial-loaded concrete-filled steel tubular columns with different confinement coefficients. Eng Struct, 2019, 198: 109503 doi: 10.1016/j.engstruct.2019.109503 [24] Ministry of Housing and Urban-Rural Development of the People’s Republic of China. GB 50010—2010 Code for Design of Concrete Structures. Beijing: China Architecture & Building Press, 2010中華人民共和國住房和城鄉建設部. GB 50010―2010混凝土結構設計規范. 北京: 中國建筑工業出版社, 2010 [25] Yuan Y S, Ji Y S. Modeling corroded section configuration of steel bar in concrete structure. Constr Build Mater, 2009, 23(6): 2461 doi: 10.1016/j.conbuildmat.2008.09.026 [26] Zhao Y X, Jin W L. Modeling the amount of steel corrosion at the cracking of concrete cover. Adv Struct Eng, 2006, 9(5): 687 doi: 10.1260/136943306778827556 [27] Xue S G. FEM Analysis on the Crack Process of Concrete Cover Induced by Rebar Non-Uniform Corrosion [Dissertation]. Xi'an: Xi'an University of Architecture and Technology, 2008薛圣廣. 鋼筋非均勻銹蝕引起的混凝土保護層開裂有限元分析[學位論文]. 西安: 西安建筑科技大學, 2008 [28] Lu C H, Jin W L, Liu R G. Reinforcement corrosion-induced cover cracking and its time prediction for reinforced concrete structures. Corros Sci, 2011, 53(4): 1337 doi: 10.1016/j.corsci.2010.12.026 [29] Liu Y P, Weyers R E. Modeling the time-to-corrosion cracking in chloride contaminated reinforced concrete structures. ACI Mater J, 1998, 95(6): 675 [30] Sun X Y, Kong H T, Wang H L, et al. Evaluation of corrosion characteristics and corrosion effects on the mechanical properties of reinforcing steel bars based on three-dimensional scanning. Corros Sci, 2018, 142: 284 doi: 10.1016/j.corsci.2018.07.030 [31] Xing G H, Niu D T. Analytical model of flexural behavior of corroded reinforced concrete beams. J Central South Univ Sci Technol, 2014, 45(1): 193邢國華, 牛荻濤. 銹蝕鋼筋混凝土梁的受彎分析模型. 中南大學學報(自然科學版), 2014, 45(1):193 [32] Lin H W, Zhao Y X, Feng P, et al. State-of-the-art review on the bond properties of corroded reinforcing steel bar. Constr Build Mater, 2019, 213: 216 doi: 10.1016/j.conbuildmat.2019.04.077 [33] Bhargava K, Ghosh A K, Mori Y, et al. Suggested empirical models for corrosion-induced bond degradation in reinforced concrete. J Struct Eng, 2008, 134(2): 221 doi: 10.1061/(ASCE)0733-9445(2008)134:2(221) [34] Canadian Standards Association. CSA A23.3-19 Design of Concrete Structures. Toronto: Canadian Standards Association, 2019 [35] British Standards Institution. BS EN 1992-1-1: 2004 Eurocode 2: Design of Concrete Structures. London: British Standards Institution, 2004 [36] American Concrete Institute. ACI 318-19 Building Code Requirements for Structural Concrete. Farmington Hills: American Concrete Institute, 2019 [37] Zhu J J. Effect of Corroded Longitutal Reinforcements on Shear Capacity of Simple Supported Concrete Beam without Stirrups [Dissertation]. Nanchang: Nanchang University, 2007祝建軍. 縱筋銹蝕對無腹筋梁斜截面受剪承載力的影響[學位論文]. 南昌: 南昌大學, 2007 -

下載:

下載: