Application status of discrete element method in grinding equipment research and parameter optimization

-

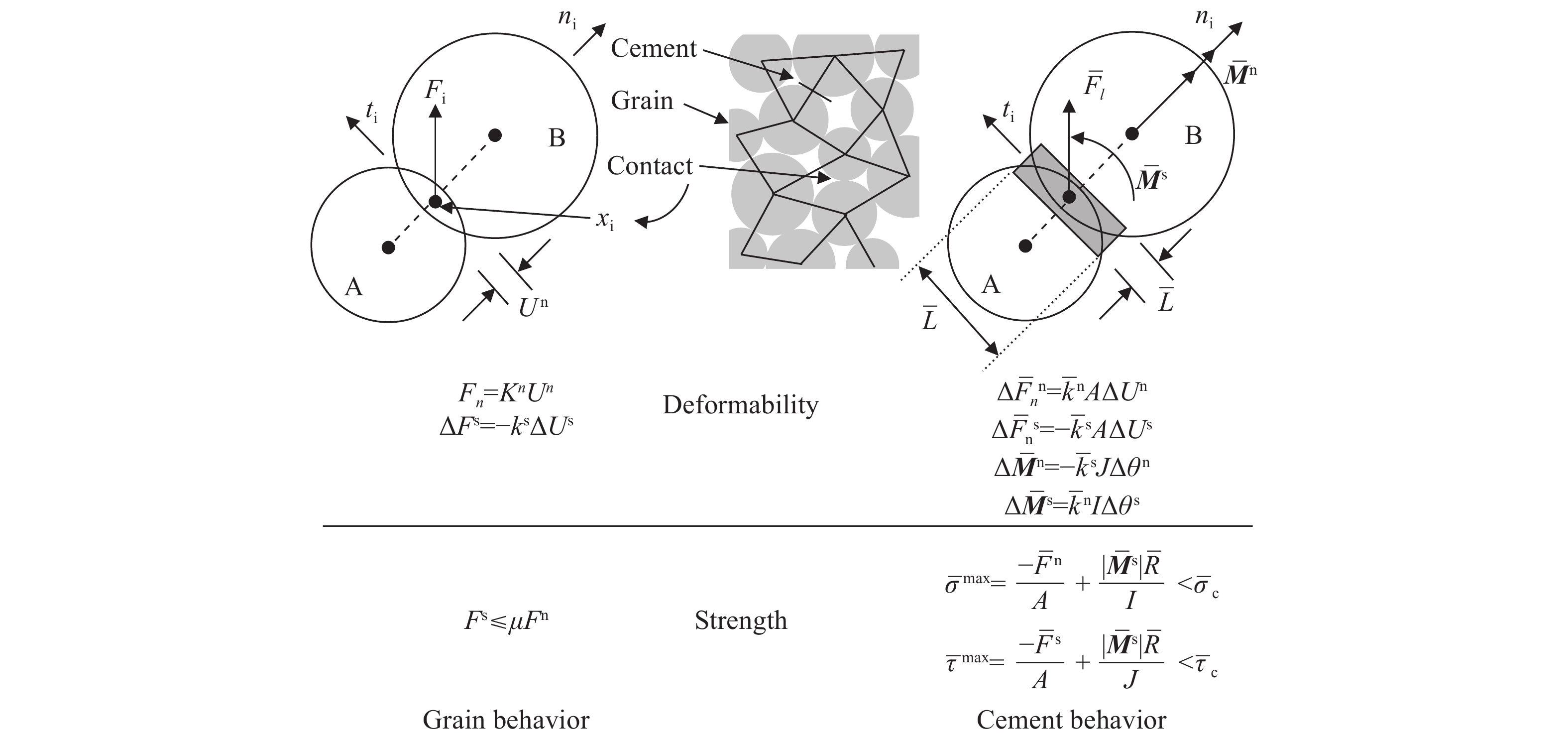

摘要: 介紹了離散元法(DEM)在磨礦領域的應用背景;解釋了DEM中Hertz-Mindlin 接觸模型和顆粒黏結模型的基本原理;分類綜述了DEM在球磨機、攪拌磨機和自磨機/半自磨機等三類磨礦設備及參數優化研究中的應用現狀;指出了DEM在磨礦領域研究中的獨特優勢及其發展方向。Abstract: Grinding is an important link in the process of mineral processing. This is because whether the useful minerals in the ore can fully dissociate the monomers and the particle size meets the sorting requirements have a decisive effect on the beneficiation index. Over the last two decades, the discrete element method (DEM) has become an important tool for understanding comminution fundamentals and providing theoretical guidance for the design, optimization, and operation of comminution devices. DEM is now widely used in industries where comminution is critical. The application of DEM in simulating fracture, breakage, crushing, milling and equipment wear has become increasingly extensive and complex, resulting in tremendous changes in the understanding of the grinding process. In this article, the application background of DEM in the field of grinding was introduced; the basic principles of two commonly used models in DEM, the Hertz-Mindlin contact model, and the bonding particle model, were explained. Subsequently, the application status of DEM in ball mills, stirring mills and self-mill/semi-automatic mills, and other three types of grinding equipment and parameter optimization research were summarized. Finally, it further pointed out the unique advantages of DEM in the field of grinding and its development direction.

-

Key words:

- discrete element method /

- ball mill /

- stirring mill /

- autogenous mill /

- semiautogenous mill

-

表 1 接觸模型中使用的彈簧剛度和阻尼系數

Table 1. Spring stiffness and damping coefficients used in the contact model

Coil type Normal direction Tangential direction Spring stiffness constant, K $ {K_{\text{n}}} = \dfrac{4}{3}{E^*}\sqrt {{R^*}{\delta _{\text{t}}}} $ $ {K_{\text{t}}} = 8{G^*}\sqrt {{R^*}{\delta _{\text{n}}}} $ Damping coefficient, C $ {C_{\text{n}}} = 2\sqrt {\dfrac{5}{6}} \dfrac{{\ln \varepsilon }}{{\sqrt {{{\ln }^2}\varepsilon + {{\text{π}} ^2}} }}\sqrt {{m^*}2{E^*}\sqrt {{R^*}{\delta _{\text{n}}}} } $ $ {C_{\text{t}}} = 2\sqrt {\dfrac{5}{6}} \dfrac{{\ln \varepsilon }}{{\sqrt {{{\ln }^2}\varepsilon + {{\text{π}} ^2}} }}\sqrt {{K_{\text{t}}}{m^*}} $ www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Han Q L, Tian Q J, Tian L. Application status of discrete element method in ball mill. Constr Mach Dig, 2011(1): 36韓清林, 田秋娟, 田磊. 離散元方法在球磨機中的應用現狀. 工程機械文摘, 2011(1):36 [2] Tian Q J. Study on the Working Performances of Large Tumbling Ball Mill Based on the Discrete Element Method [Dissertation]. Changchun: Jilin University, 2011田秋娟. 基于離散元方法的大型球磨機工作性能研究[學位論文]. 長春: 吉林大學, 2011 [3] Sang Y W, Zhang G W, Xiao X, et al. Application status of discrete element method in grinding equipment. Min Metall Eng, 2016, 36(suppl): 242桑艷偉, 張國旺, 肖驍, 等. 離散元法在磨礦設備中的應用現狀. 礦冶工程, 2016, 36(增刊): 242 [4] Gao Q. Analysis Grinding of Horizontal Stirred Mill Based on Distinct Element Method [Dissertation]. Kunming: Kunming University of Science and Technology, 2016高強. 基于離散元法的攪拌球磨機磨礦分析與研究[學位論文]. 昆明: 昆明理工大學, 2016 [5] Tian R X, Jiao H G, Bai J Y. An introduction of distinct element method and its application in mineral processing engineering. Coal Prep Technol, 2012(1): 72 doi: 10.3969/j.issn.1001-3571.2012.01.020田瑞霞, 焦紅光, 白璟宇. 離散元法在礦物加工工程中的應用現狀. 選煤技術, 2012(1):72 doi: 10.3969/j.issn.1001-3571.2012.01.020 [6] Zhu H P, Zhou Z Y, Yang R Y, et al. Discrete particle simulation of particulate systems: Theoretical developments. Chem Eng Sci, 2007, 62(13): 3378 doi: 10.1016/j.ces.2006.12.089 [7] Weerasekara N S, Powell M S, Cleary P W, et al. The contribution of DEM to the science of comminution. Powder Technol, 2013, 248: 3 doi: 10.1016/j.powtec.2013.05.032 [8] Fang Z Q, Wu H L, Zhou X N. Analysis for the mechanical characteristics of contact models in the DEM simulation of a ball mill. Machinery, 2019, 46(2): 17方自強, 吳洪亮, 周享楠. 球磨機DEM仿真中接觸模型的精準性分析. 機械, 2019, 46(2):17 [9] Tsuji Y, Tanaka T, Ishida T. Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol, 1992, 71(3): 239 doi: 10.1016/0032-5910(92)88030-L [10] Mindlin R D. Compliance of elastic bodies in contact. J Appl Mech, 1949, 16(3): 259 doi: 10.1115/1.4009973 [11] Cleary P W. Predicting charge motion, power draw, segregation and wear in ball mills using discrete element methods. Miner Eng, 1998, 11(11): 1061 doi: 10.1016/S0892-6875(98)00093-4 [12] Di Renzo A, di Maio F P. Comparison of contact-force models for the simulation of collisions in DEM-based granular flow codes. Chem Eng Sci, 2004, 59(3): 525 doi: 10.1016/j.ces.2003.09.037 [13] Potyondy D O, Cundall P A. A bonded-particle model for rock. Int J Rock Mech Min Sci, 2004, 41(8): 1329 doi: 10.1016/j.ijrmms.2004.09.011 [14] Mishra B K, Rajamani R K. The discrete element method for the simulation of ball mills. Appl Math Model, 1992, 16(11): 598 doi: 10.1016/0307-904X(92)90035-2 [15] Mishra B K, Rajamani R K. Simulation of charge motion in ball mills. Part 1: Experimental verifications. Int J Miner Process, 1994, 40(3-4): 171 doi: 10.1016/0301-7516(94)90042-6 [16] Cleary P W. Recent advances in DEM modelling of tumbling mills. Miner Eng, 2001, 14(10): 1295 doi: 10.1016/S0892-6875(01)00145-5 [17] Cleary P W, Sinnott M D, Morrison R D. DEM prediction of particle flows in grinding processes. Int J Numer Meth Fluids, 2008, 58(3): 319 doi: 10.1002/fld.1728 [18] Weerasekara N S, Liu L X, Powell M S. Estimating energy in grinding using DEM modelling. Miner Eng, 2016, 85: 23 doi: 10.1016/j.mineng.2015.10.013 [19] Jiang S Q, Ye Y X, Tan Y Q, et al. Discrete element simulation of particle motion in ball mills based on similarity. Powder Technol, 2018, 335: 91 doi: 10.1016/j.powtec.2018.05.012 [20] Radziszewski P, Tarasiewicz S. Simulation of ball charge and liner wear. Wear, 1993, 169(1): 77 doi: 10.1016/0043-1648(93)90393-Z [21] Bian X L, Wang G Q, Wang H D, et al. Effect of lifters and mill speed on particle behaviour, torque, and power consumption of a tumbling ball mill: Experimental study and DEM simulation. Miner Eng, 2017, 105: 22 doi: 10.1016/j.mineng.2016.12.014 [22] Peng Y X, Li T Q, Zhu Z C, et al. Discrete element method simulations of load behavior with mono-sized iron ore particles in a ball mill. Adv Mech Eng, 2017, 9(5): 1 [23] Kalala J T, Breetzke M, Moys M H. Study of the influence of liner wear on the load behaviour of an industrial dry tumbling mill using the discrete element method (DEM). Int J Miner Process, 2008, 86(1-4): 33 doi: 10.1016/j.minpro.2007.10.001 [24] Cleary P W, Owen P, Hoyer D I, et al. Prediction of mill liner shape evolution and changing operational performance during the liner life cycle: Case study of a Hicom mill. Int J Numer Meth Eng, 2010, 81(9): 1157 doi: 10.1002/nme.2721 [25] Kiangi K, Potapov A, Moys M. DEM validation of media shape effects on the load behaviour and power in a dry pilot mill. Miner Eng, 2013, 46-47: 52 doi: 10.1016/j.mineng.2013.03.025 [26] Yao F S. Application of large tower mill in cyanide fine grinding of gold concentrate. Gold Sci Technol, 2014, 22(3): 82 doi: 10.11872/j.issn.1005-2518.2014.03.082姚福善. 大型塔式磨機在金精礦氰化細磨中的應用. 黃金科學技術, 2014, 22(3):82 doi: 10.11872/j.issn.1005-2518.2014.03.082 [27] Morrison R D, Cleary P W, Sinnott M D. Using DEM to compare the energy efficiency of pilot scale ball and tower mills. Miner Eng, 2009, 22(7-8): 665 doi: 10.1016/j.mineng.2009.01.016 [28] Wang X, Xiao Z M, Long W. Simulation and analysis on media movement in tower mill based on DEM. Min Process Equip, 2015, 43(7): 74王鑫, 肖正明, 龍穩. 基于離散元法的塔磨機介質運動仿真分析. 礦山機械, 2015, 43(7):74 [29] Sinnott M D, Cleary P W, Morrison R D. Is media shape important for grinding performance in stirred mills? Miner Eng, 2011, 24(2): 138 [30] Sinnott M, Cleary P W, Morrison R. Analysis of stirred mill performance using DEM simulation: Part 1— Media motion, energy consumption and collisional environment. Miner Eng, 2006, 19(15): 1537 doi: 10.1016/j.mineng.2006.08.012 [31] Cleary P W, Sinnott M, Morrison R. Analysis of stirred mill performance using DEM simulation: Part 2— Coherent flow structures, liner stress and wear, mixing and transport. Miner Eng, 2006, 19(15): 1551 doi: 10.1016/j.mineng.2006.08.013 [32] Ren T Z, Li Z, Liu C Y, et al. Simulation of tower mill analysis based on discrete element method. China Powder Sci Technol, 2016, 22(4): 88任廷志, 李卓, 劉長遠, 等. 基于離散元法的塔磨機數值模擬分析. 中國粉體技術, 2016, 22(4):88 [33] Xiao Z M, Wang X, Wu X, et al. Simulation analyses and experimental investigation on optimum matching of operating parameters of tower mill. China Mech Eng, 2016, 27(4): 483 doi: 10.3969/j.issn.1004-132X.2016.04.011肖正明, 王鑫, 伍星, 等. 塔磨機運行參數優化匹配的仿真分析與試驗研究. 中國機械工程, 2016, 27(4):483 doi: 10.3969/j.issn.1004-132X.2016.04.011 [34] Sinnott M, Cleary P W, Morrison R D. Slurry flow in a tower mill. Miner Eng, 2011, 24(2): 152 doi: 10.1016/j.mineng.2010.11.002 [35] Yang R Y, Jayasundara C T, Yu A B, et al. DEM simulation of the flow of grinding media in IsaMill. Miner Eng, 2006, 19(10): 984 doi: 10.1016/j.mineng.2006.05.002 [36] Jayasundara C T, Yang R Y, Yu A B, et al. Discrete particle simulation of particle flow in the IsaMill process. Ind Eng Chem Res, 2006, 45(18): 6349 doi: 10.1021/ie060474s [37] Jayasundara C T, Yang R Y, Yu A B, et al. Discrete particle simulation of particle flow in IsaMill—Effect of grinding medium properties. Chem Eng J, 2008, 135(1-2): 103 doi: 10.1016/j.cej.2007.04.001 [38] Jayasundara C T, Yang R Y, Yu A B, et al. Effects of disc rotation speed and media loading on particle flow and grinding performance in a horizontal stirred mill. Int J Miner Process, 2010, 96(1-4): 27 doi: 10.1016/j.minpro.2010.07.006 [39] Jayasundara C T, Yang R Y, Yu A B, et al. Prediction of the disc wear in a model IsaMill and its effect on the flow of grinding media. Miner Eng, 2011, 24(14): 1586 doi: 10.1016/j.mineng.2011.08.011 [40] Cleary P W, Sinnott M D, Pereira G G. Computational prediction of performance for a full scale Isamill: Part 1—Media motion and energy utilisation in a dry mill. Miner Eng, 2015, 79: 220 doi: 10.1016/j.mineng.2015.04.005 [41] Cleary P W, Sinnott M D. Computational prediction of performance for a full scale Isamill: Part 2—Wet models of charge and slurry transport. Miner Eng, 2015, 79: 239 doi: 10.1016/j.mineng.2015.04.013 [42] Jayasundara C T, Yang R Y, Guo B Y, et al. Effect of slurry properties on particle motion in IsaMills. Miner Eng, 2009, 22(11): 886 doi: 10.1016/j.mineng.2009.04.009 [43] Cho H, Lee H, Lee Y. Some breakage characteristics of ultra-fine wet grinding with a centrifugal mill. Int J Miner Process, 2006, 78(4): 250 doi: 10.1016/j.minpro.2005.11.005 [44] Bradley A A, Lloyd P J D, Stanton K H. The balancing of a centrifugal mill. J South Afr Inst Min Metall, 1983, 83: 229 [45] Lee H, Cho H, Kwon J. Using the discrete element method to analyze the breakage rate in a centrifugal/vibration mill. Powder Technol, 2010, 198(3): 364 doi: 10.1016/j.powtec.2009.12.001 [46] Chen Y. Motion Analysis of Medium and Numerical Simulation of Horizontal Centrifugal Barrel Finishing [Dissertation]. Kunming: Kunming University of Science and Technology, 2017陳懿. 臥式離心滾磨介質運動分析及數值模擬[學位論文]. 昆明: 昆明理工大學, 2017 [47] Khanal M, Morrison R. Discrete element method study of abrasion. Miner Eng, 2008, 21(11): 751 doi: 10.1016/j.mineng.2008.06.008 [48] Antony S J, Kruyt N P. Role of interparticle friction and particle-scale elasticity in the shear-strength mechanism of three-dimensional granular media. Phys Rev E, 2009, 79: art. No. 031308 doi: 10.1103/PhysRevE.79.031308 [49] Khanal M, Jayasundara C T. Role of particle stiffness and inter-particle sliding friction in milling of particles. Particuology, 2014, 16: 54 doi: 10.1016/j.partic.2014.04.003 [50] Cleary P W. Large scale industrial DEM modelling. Eng Comput, 2004, 21(2/3/4): 169 doi: 10.1108/02644400410519730 [51] Cleary P W. Industrial particle flow modelling using discrete element method. Eng Comput, 2009, 26(6): 698 doi: 10.1108/02644400910975487 [52] Cleary P W. The effect of particle shape on simple shear flows. Powder Technol, 2008, 179(3): 144 doi: 10.1016/j.powtec.2007.06.018 [53] Delaney G W, Cleary P W, Morrison R D, et al. Predicting breakage and the evolution of rock size and shape distributions in Ag and SAG mills using DEM. Miner Eng, 2013, 50-51: 132 doi: 10.1016/j.mineng.2013.01.007 [54] Cleary P W, Morrison R D. Comminution mechanisms, particle shape evolution and collision energy partitioning in tumbling mills. Miner Eng, 2016, 86: 75 doi: 10.1016/j.mineng.2015.12.006 [55] Cleary P W, Delaney G W, Sinnott M D, et al. Inclusion of incremental damage breakage of particles and slurry rheology into a particle scale multiphase model of a SAG mill. Miner Eng, 2018, 128: 92 doi: 10.1016/j.mineng.2018.08.026 [56] Cleary P W, Owen P. Effect of particle shape on structure of the charge and nature of energy utilisation in a SAG mill. Miner Eng, 2019, 132: 48 doi: 10.1016/j.mineng.2018.12.006 [57] Du Q. Wearing analysis of shell liner in large SAG mill based on DEM. Min Process Equip, 2015, 43(1): 62杜強. 基于離散元的大型半自磨機筒體襯板磨損分析. 礦山機械, 2015, 43(1):62 [58] Cai G P, Qi B C, Xiao X H, et al. Numerical simulation and experiment research of grinding efficiency of SAG. J Henan Polytech Univ Nat Sci, 2017, 36(2): 89蔡改貧, 祁步春, 肖賢煌, 等. 半自磨機磨礦效果的數值模擬及實驗研究. 河南理工大學學報(自然科學版), 2017, 36(2):89 -

下載:

下載: