Research progress on austenite grain growth and second-phase particle control technology in automotive gear steel

-

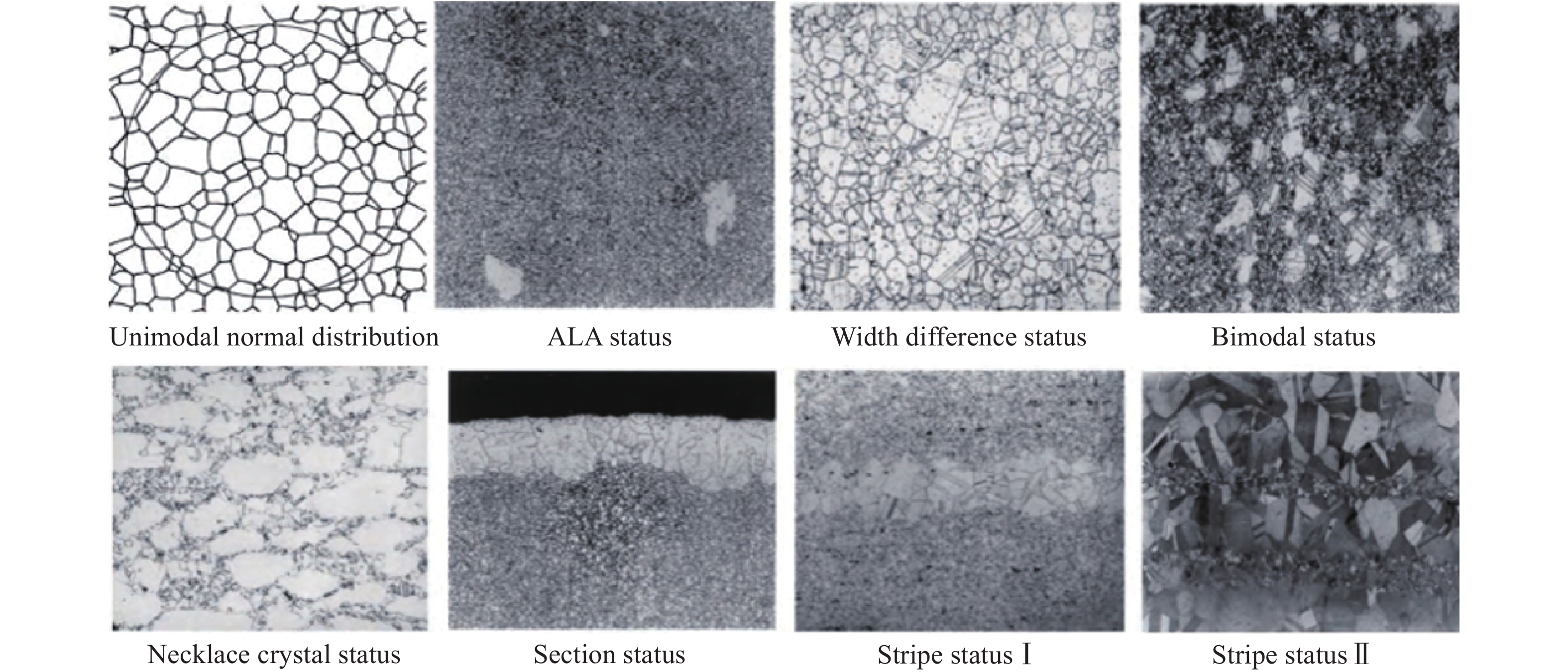

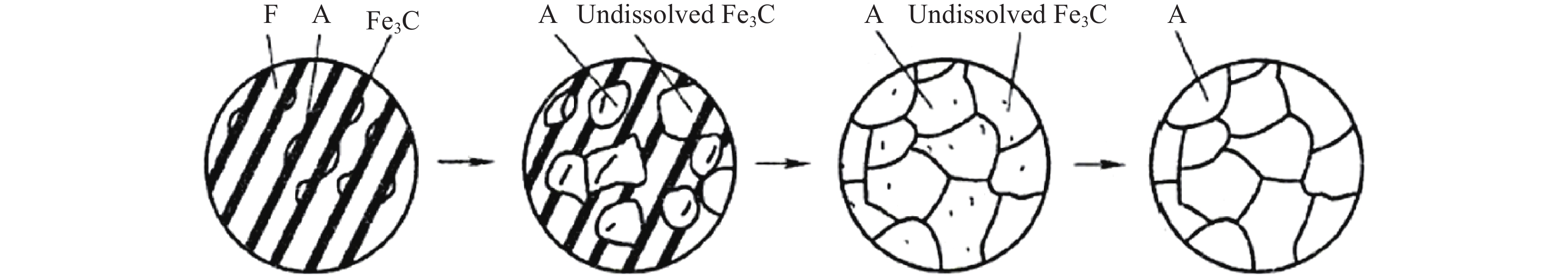

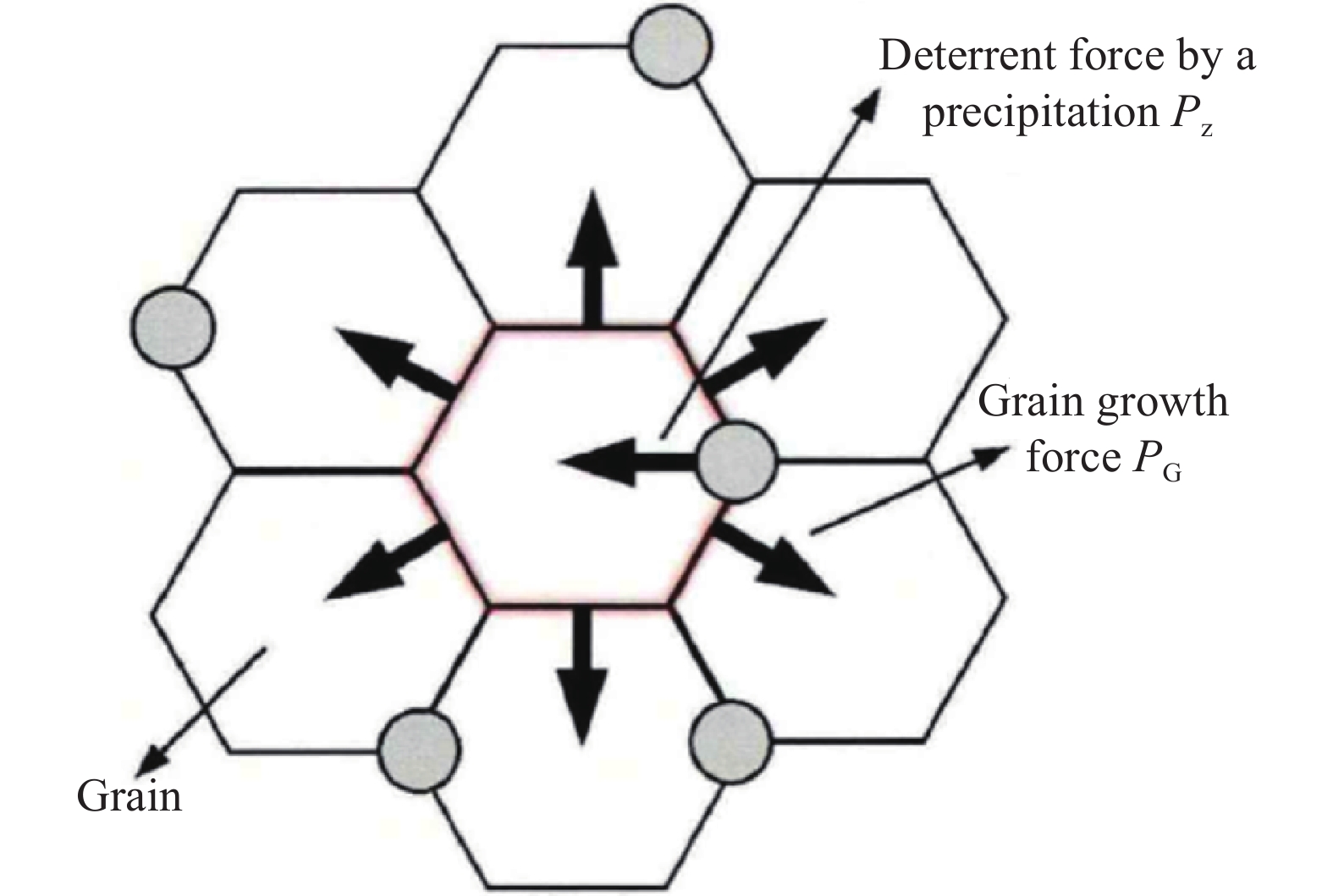

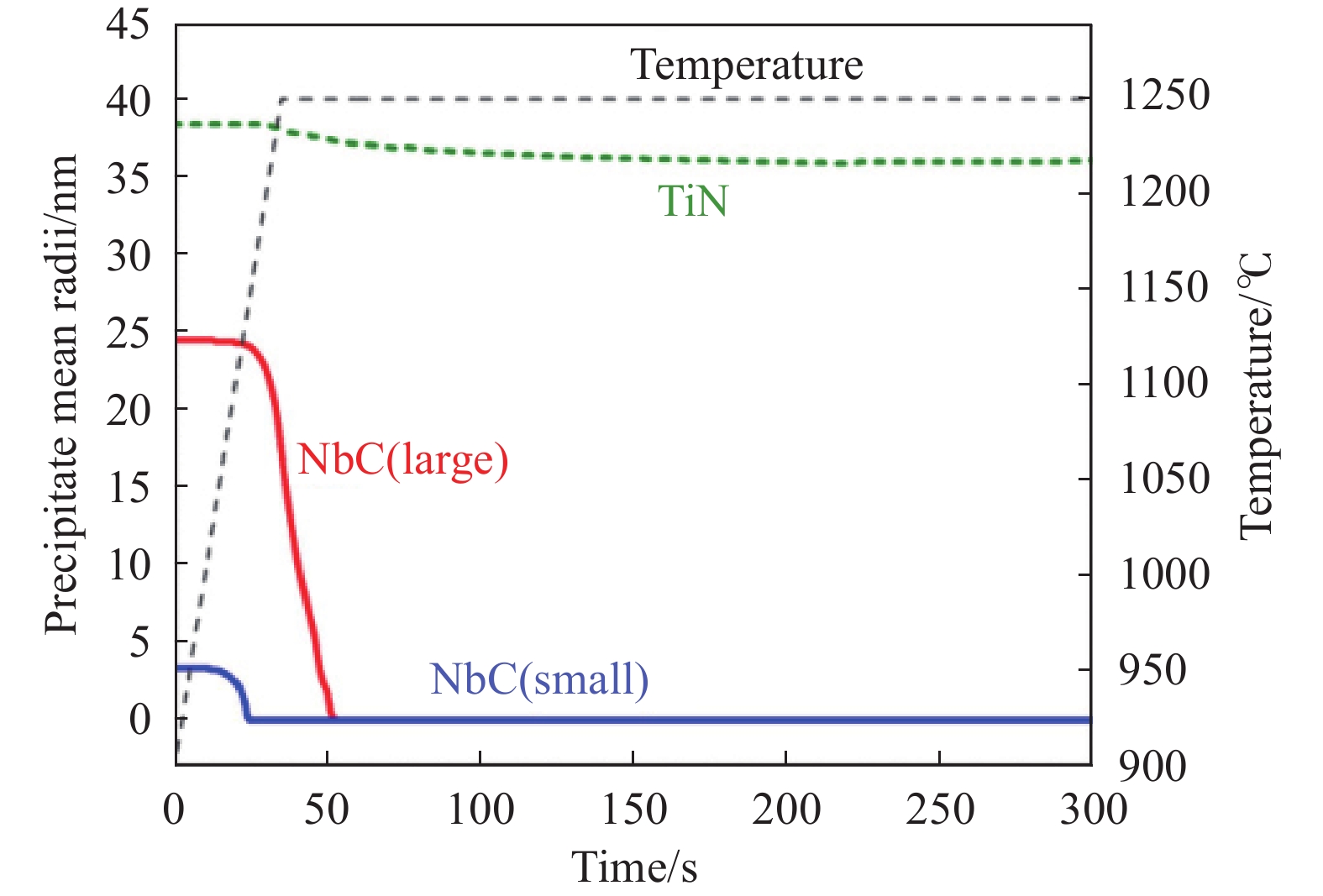

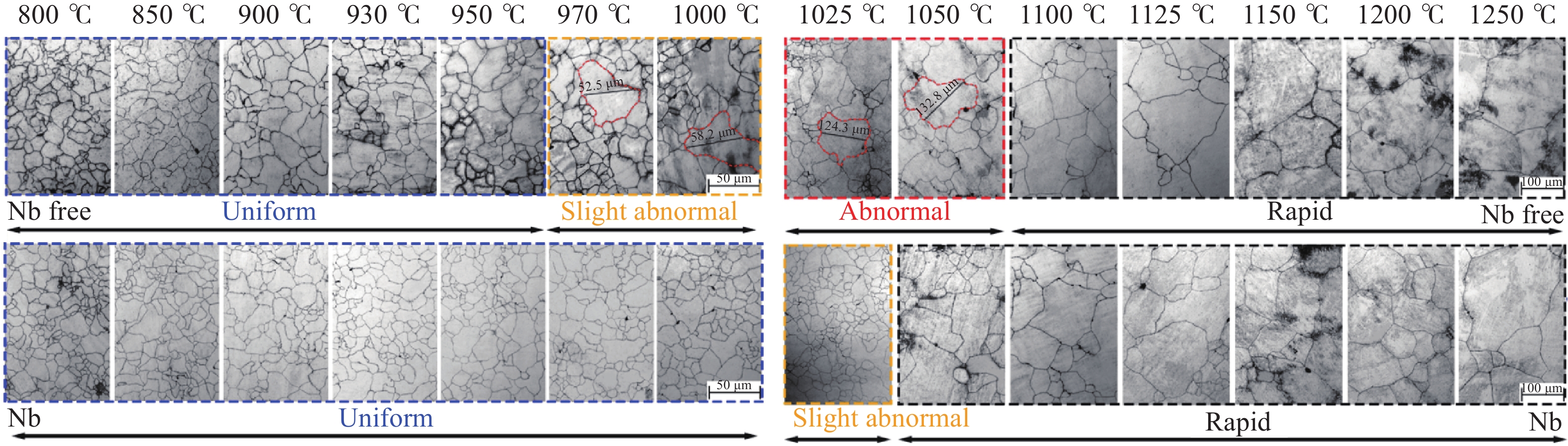

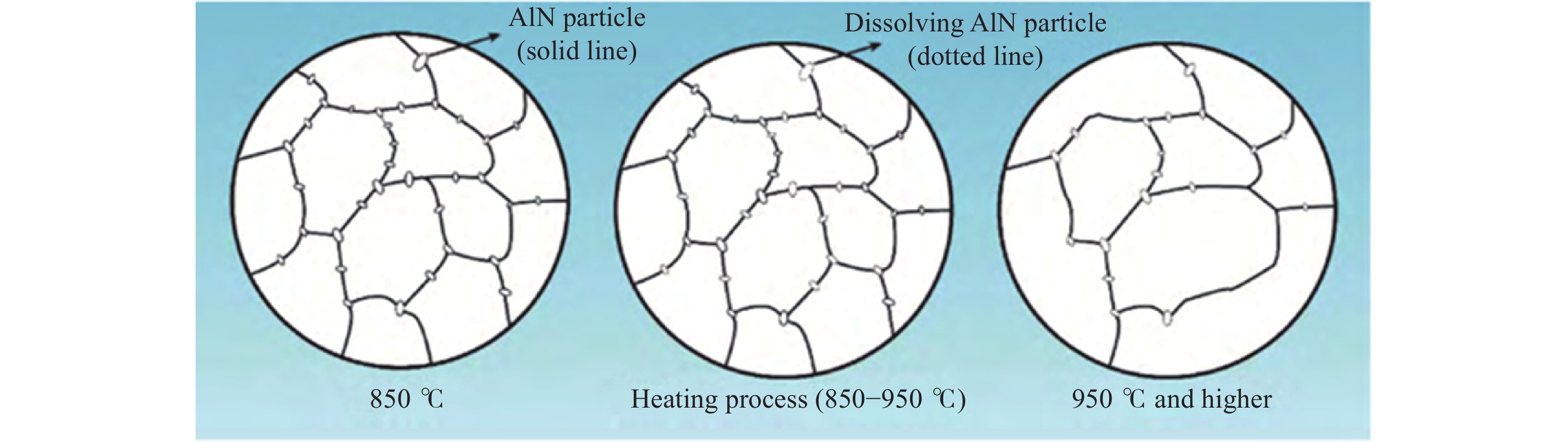

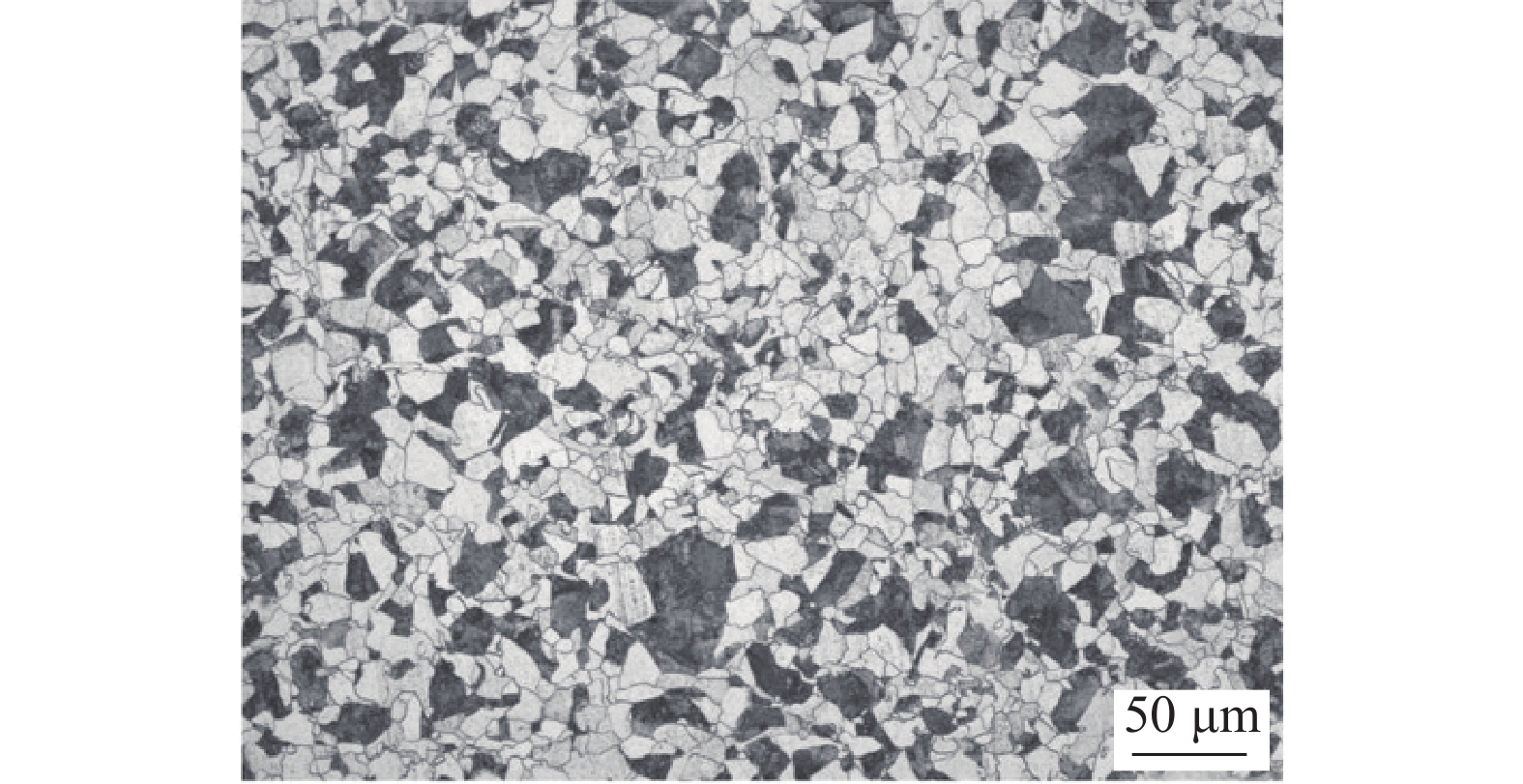

摘要: 伴隨著全球雙碳政策的實施,節能減排成為汽車制造業發展的首要目標之一. 汽車用齒輪鋼采用的更高溫度結合更短時間的滲碳工藝是目前各齒輪生產企業最為直接的降碳措施,但齒輪鋼在高溫滲碳生產過程中卻時常發生奧氏體晶粒異常粗大的問題,且滲碳溫度越高混晶現象越嚴重. 因此,各企業對齒輪鋼進行微合金化,通過添加微合金元素在加熱過程中析出第二相粒子產生釘扎作用來阻礙奧氏體晶粒異常長大,從而需要對復雜的齒輪鋼奧氏體晶粒長大與第二相粒子析出機制進行研究. 通過對奧氏體晶粒度、奧氏體晶粒長大機制及模型、第二相粒子(Nb(C,N)/AlN)對奧氏體晶界移動的釘扎作用及模型、以及加熱溫度與保溫時間對奧氏體晶粒長大和第二相粒子釘扎作用的影響等進行了文獻綜述,闡明了奧氏體晶粒長大規律、第二相粒子的控制方法與抑制奧氏體晶粒長大的釘扎機制,為高質量齒輪鋼的生產提供參考.Abstract: With the implementation of the global two-carbon policy, energy saving and CO2 emission reduction have become important developmental goals of the automobile manufacturing industry. At present, the combination of high temperature for the automobile gear steel and short carburizing time is the most direct carbon reduction countermeasure for gear production enterprises. However, the problem of abnormally coarsened austenite grains often occurs in the high-temperature carburization of gear steel. With the increase in carburizing temperature, the degree of mixing crystals becomes serious. As a requirement of gear manufacturing enterprises, microalloying is carried out on the carburized gear steel. Upon the addition of microalloying elements, the second-phase particles are precipitated during heating, and the pinning effect is generated to prevent the movement of austenite grain boundaries, thus preventing the abnormal growth of austenite grains. Although the second-phase particles precipitate at the usual carburizing temperature, the partial solid solution of particles appears. In this work, the effects of the heating temperature and holding time on the austenite grain size of gear steel are studied to clarify the mechanisms of complex austenite grain growth and second-phase particle precipitation for the realization of fine austenite grain size after high-temperature carburization. The influence of the contents of microalloying elements (Nb, Al) on the pinning effect, precipitation position, and solution temperature of the second-phase particles (Nb (C, N)/AlN) are also discussed. Austenite grain growth models, critical sizes of austenite grain abnormal growth, and pinning force models of second-phase particles are summarized. The austenite grain growth model is based on the Beck equation, and the most common models are the modified Sellars and Arrhenius models. For the study of the inhibition effect on austenite grains, the pinning force model is used to study the critical size of austenite by modifying the dimensionless constant (A) of the Zener equation mainly through the pinning effect (Pz) produced by all particles on the grain boundary. After the experimental data are obtained, the trend of austenite growth can be predicted accurately by fitting the curve using the mathematical method. The precipitated second-phase particles are generally distributed along the grain boundary. Nb (C, N) particles have a higher solution temperature than AlN particles, so they are more stable at high temperatures. When the temperature exceeds the grain coarsening temperature, the precipitated particles become dissolved or coarsened. The mixed crystal structure generally starts to appear at about 1000 ℃, and adding the appropriate amount of microalloying elements can increase the coarsening temperature.

-

Key words:

- gear steel /

- austenite grain size /

- abnormal growth /

- second-phase particle /

- mixed crystal /

- pining force

-

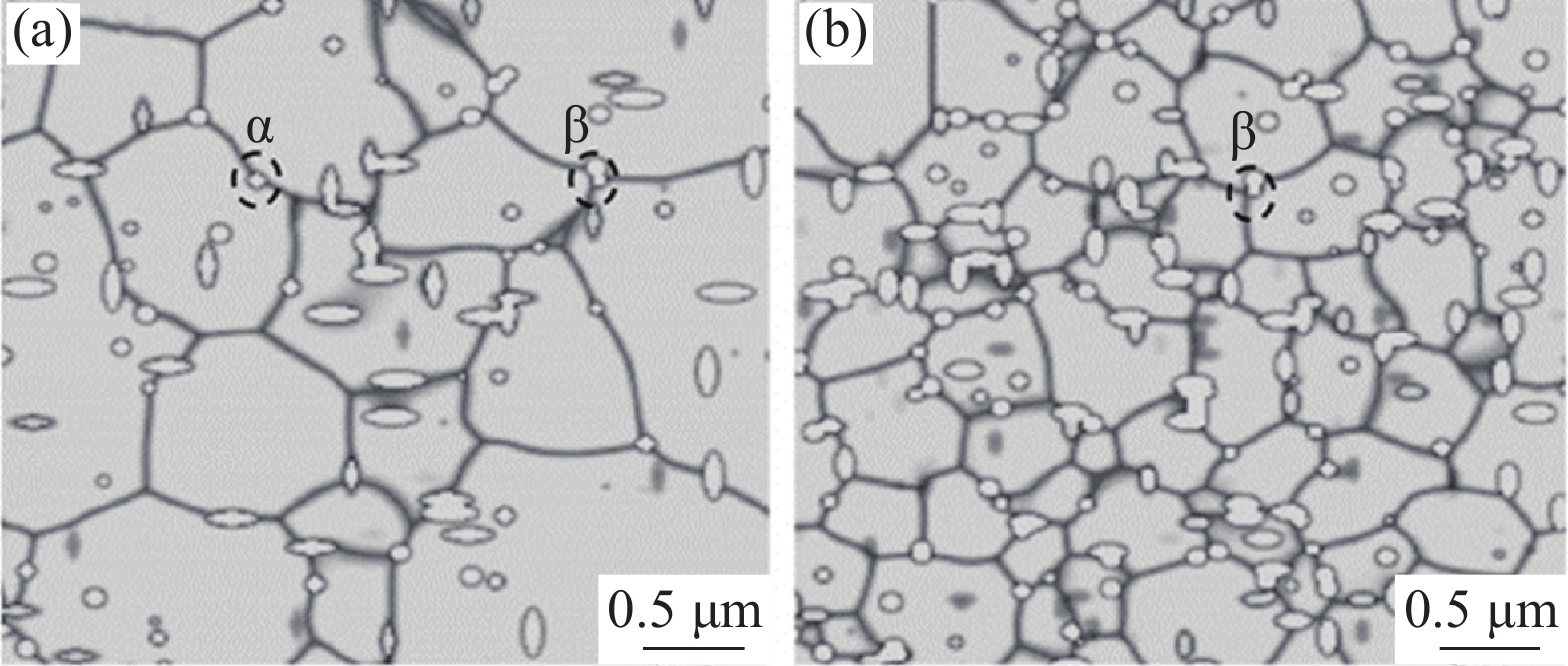

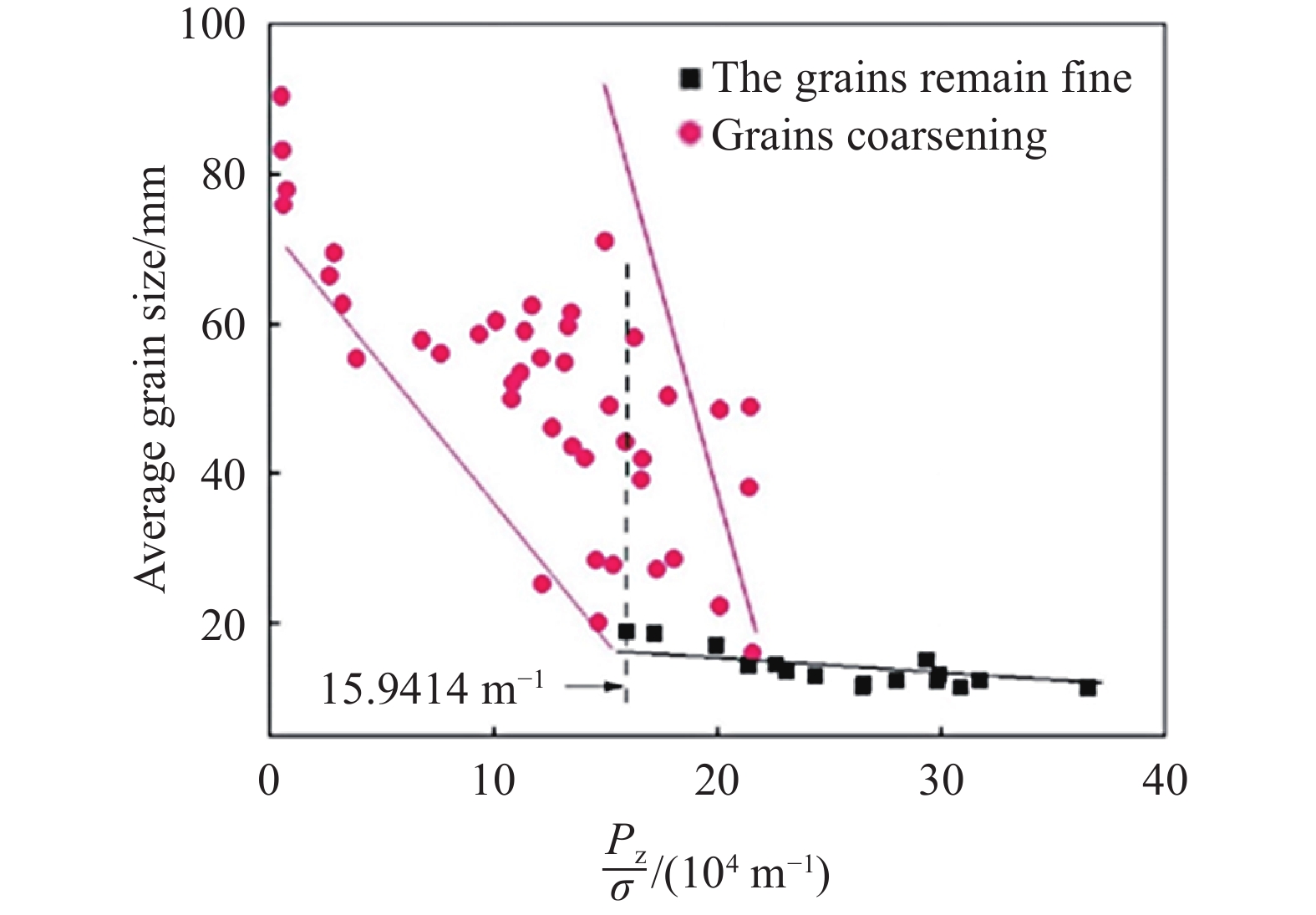

圖 19 偽滲碳后奧氏體晶粒粗化情況與鋼中析出粒子釘扎強度間的關系[48]

Figure 19. Relationship between average austenite grain size and pinning strength after pseudocarburization

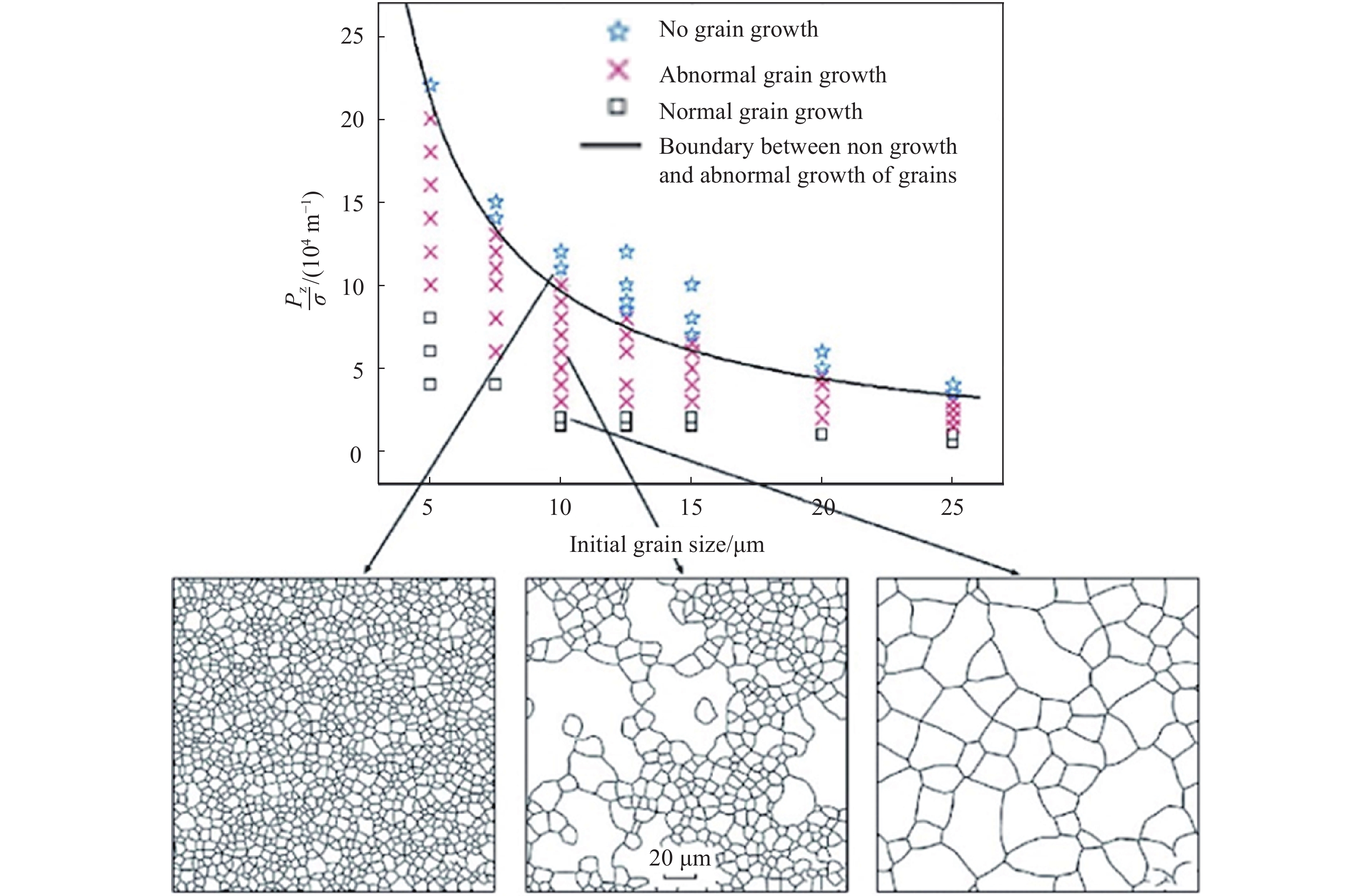

圖 20 初始晶粒尺寸及釘扎力與晶粒長大模式間的關系[48]

Figure 20. Grain growth regimes as functions of prior grain size and pinning force

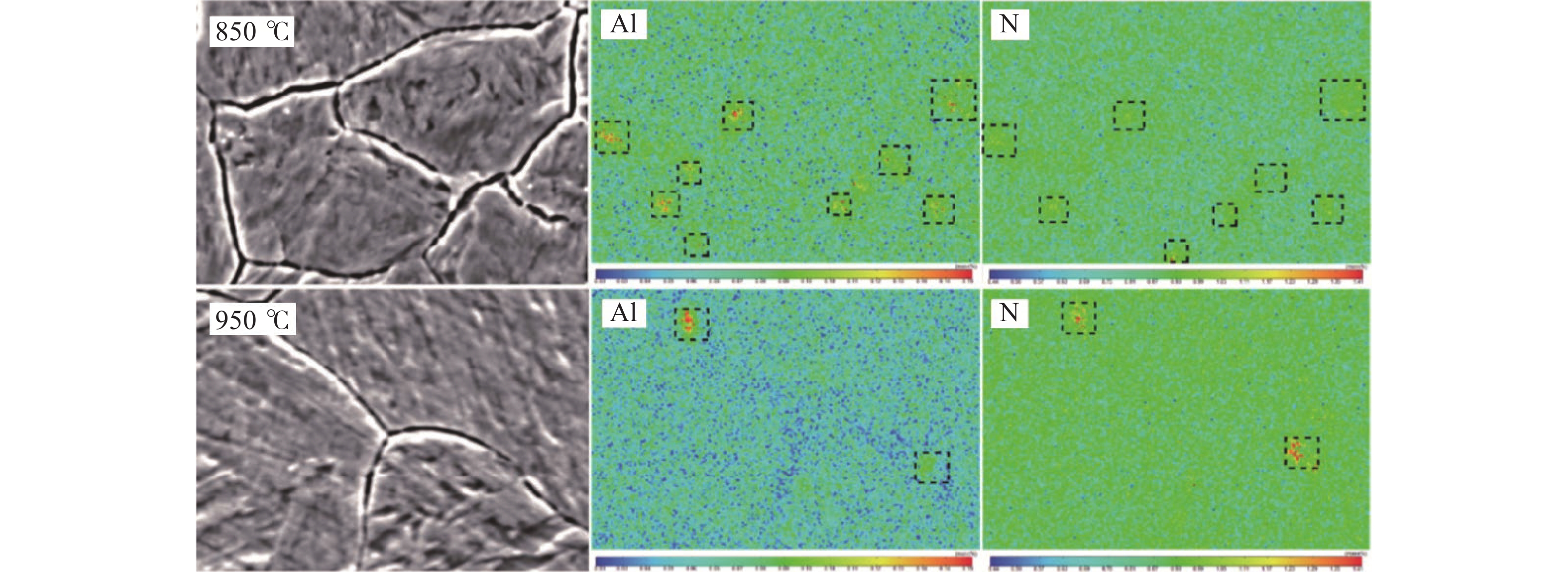

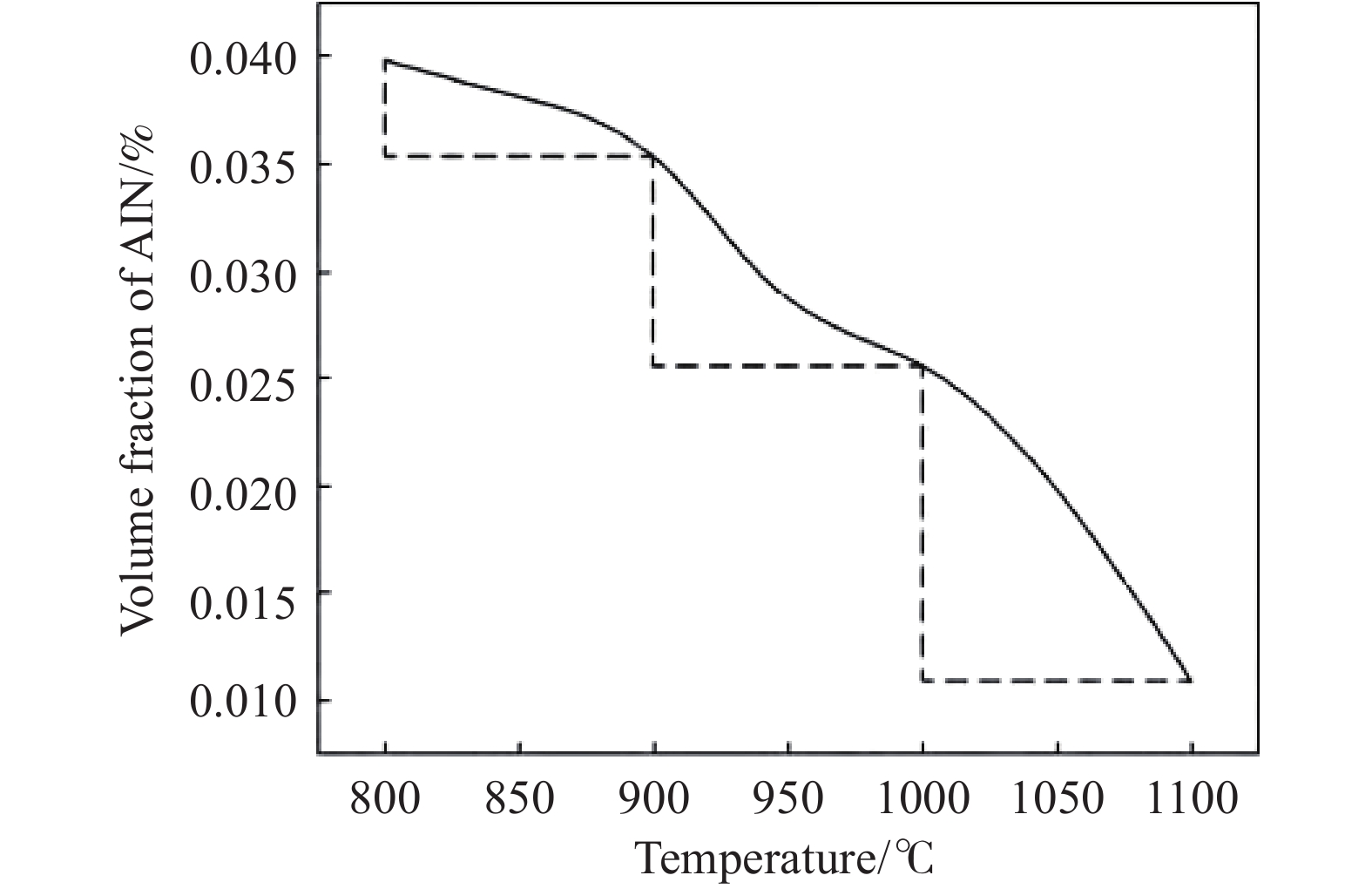

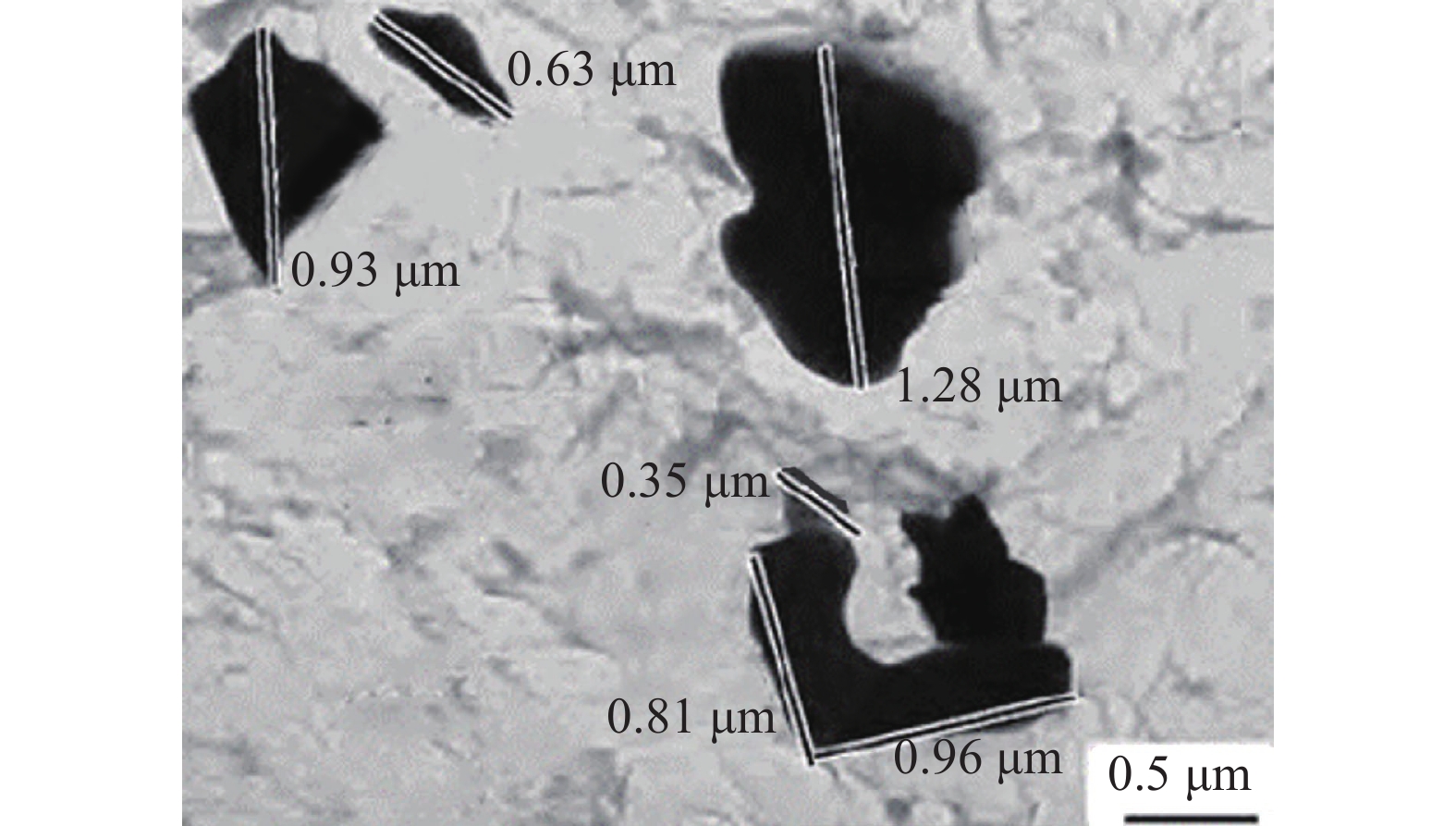

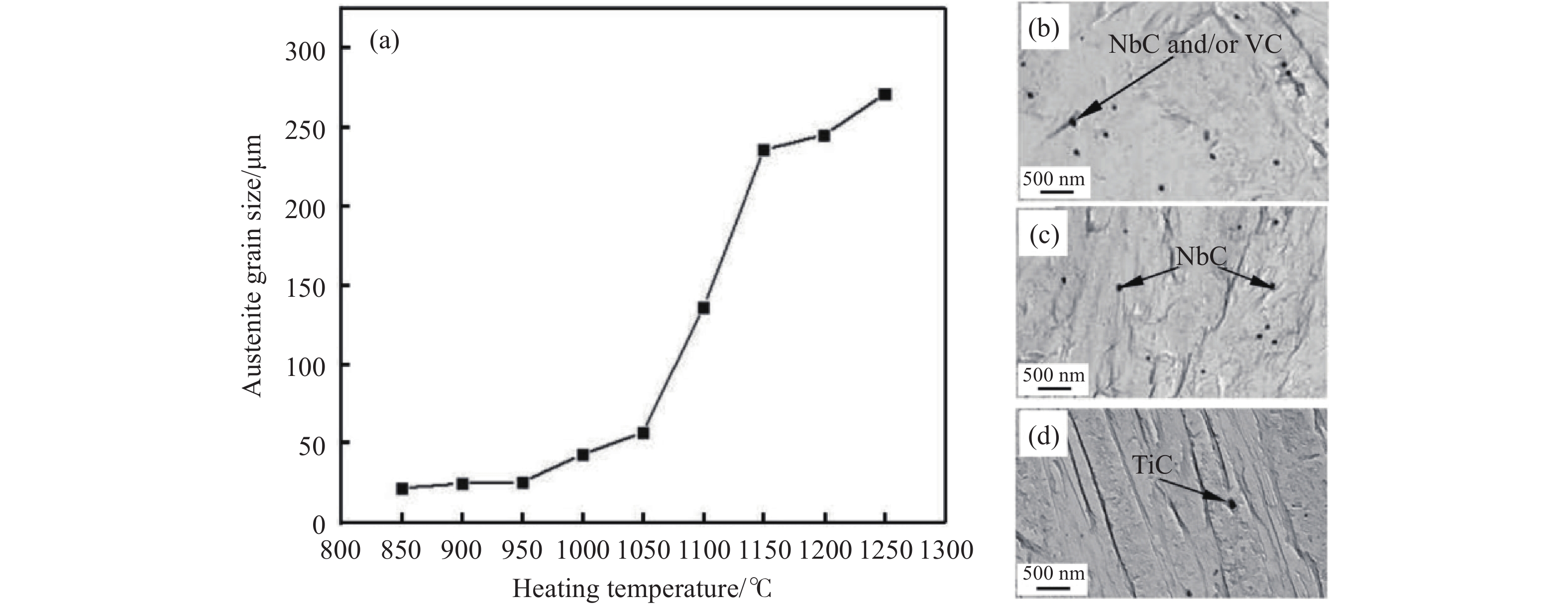

圖 21 溫度對奧氏體晶粒與析出相的影響[81]. (a) 奧氏體晶粒尺寸隨加熱溫度的變化; (b) 850 ℃溫度下析出相; (c) 1150 ℃溫度下析出相; (d) 1250 ℃溫度下析出相

Figure 21. The effect of temperature on austenite grain and precipitated phase[81]: (a) change of austenite grain size with heating temperature; (b) precipitated phase at 850 ℃; (c) precipitated phase at 1150 ℃; (d) precipitated phase at 1250 ℃

表 1 20MnCr5鋼的化學成分標準(質量分數)

Table 1. Standard chemical composition of 20MnCr5 steel (mass fraction)

% C Mn Cr Ni Mo Nb Si Al 0.17–0.22 1.10–1.40 1.00–1.30 ≤0.25 ≤0.03 trace ≤0.18 0.02–0.05 表 2 奧氏體晶粒長大模型

Table 2. Austenite grain growth models

Author and publication Unit Material Equation Brief description Beck et al.[12] Notre Dame University High purity aluminum $ D = {D_{\text{0}}} \cdot {t^n} $ Relationship between austenite grain size and holding time at a certain heating temperature. Hillert[13] Royal Polytechnic $ {D^2} = D_0^2 + C \cdot t $ Relationship among austenite grain growth and temperature and time Hu and Rath[16] American Steel Company $ {D^{\left(1/n\right)}} = D_0^{\left(1/n\right)} + K \cdot t $ Isothermal grain growth kinetics, n and K, are the growth index and rate constant, respectively. Sellars and Whiteman[14] Sheffield University Low-carbon manganese steel $ {D^n} = D_0^n + {K_0} \cdot \exp \left( - \dfrac{Q}{{RT}}\right) \cdot t $ Most existing empirical models for austenite grain growth are based on this study. Nishizawa[17] Tohoku University, Japan High purity iron $ {D^2} = D_0^2 + C \cdot t $ $ C = \dfrac{{\sigma V{D_{{\text{gb}}}}}}{{\lambda RT}} $ Jiao et al.[18] Ghent University Si?Mn steel $ {D^n} = D_0^n + {K_1} \cdot \exp \left(\dfrac{{{K_2}}}{T}\right) \cdot t $ K1, K2, and n are related to temperature. Moon et al.[19] POSCO C?Mn steel $ \dfrac{{{\text{d}}D}}{{{\text{d}}t}} = n \cdot K \cdot {\left(\dfrac{1}{D}\right)^{\left(\frac{1}{n}\right)}}^{ - 1} $ According to Hu’s model[16], the equation of grain growth rate is obtained by the differential method. Yue et al.[20] Northeast Special Steel GCr15 $ {D^n} = D_0^n + {K_0} \cdot \exp \left( - \dfrac{Q}{{RT}}\right) \cdot t $ Coefficients K0 and n and activation energy Q in the model have different values for various steel grades and transformation stages. Lee and Lee[15] Yonsei University Cr?Mo steel $ D = K \cdot {t^n} $ K is expressed by Arrhenius equation:

$ K = {K_0} \cdot \exp \left( - \dfrac{Q}{{RT}}\right) $.Zhu et al.[21] Beijing University of Science and Technology Carburized bearing steel SAE8620H $ {D^n} = {K_0} \cdot \exp \left( - \dfrac{Q}{{RT}}\right) \cdot t $ When D0 is ignored, the simplified Sellars model is the most accurate, and the correlation between the predicted value and the experimental value is the highest. Yang et al.[22] Angang Steel Group Limited 18CrNiMo7-6 $ D = {K_0} \cdot \exp \left( - \dfrac{Q}{{RT}}\right) \cdot {t^n} $ When D>3D0, D0 can be ignored. Yang et al.[23] Central Iron & Steel Research Institute 20CrMnTiNb $ {D^2} = D_0^2 + C \cdot \exp \left( - \dfrac{Q}{{RT}}\right) \cdot t $ Comparison of grain growth between Nb-containing and Nb-free 20CrMnTi steel samples by Hillert model Bao et al.[24] Wuhan University of Science and Technology Medium manganese martensitic wear-resistant steel NM500 $ D = {K_0} \cdot \exp \left( - \dfrac{Q}{{RT}}\right) \cdot {t^n} $ When the temperature is less than 950 ℃, n is relatively small, and the experimental data are close to the predicted value. He et al.[25] Xining Special Steel Plant 20MnCr5 $ {D^2} = D_0^2 + C \cdot \exp \left( - \dfrac{Q}{{RT}}\right) \cdot t $ This model is applicable to normal grain growth. 表 3 奧氏體晶粒臨界尺寸的研究

Table 3. Studies on the critical grain size of austenite

Author and publication Unit Material Equation (R0) Brief description Smith[27] University of Chicago High purity aluminum $ A \cdot \dfrac{r}{f} $ $ A = \dfrac{4}{3} $, general form: $ A \cdot \dfrac{r}{{{f^m}}} $. Hillert[13] Royal Polytechnic $ \dfrac{{4r}}{{9f}}\left(\min \right)/\dfrac{{2r}}{{3f}}\left(\max \right) $ When R reaches the lower limit, the grains will stop growing normally and begin to grow abnormally until the upper limit value is reached. Gladman[26] United Steel $ \left[\pi \cdot \left(\dfrac{1}{4} - \dfrac{1}{{3Z}}\right)\right] \cdot \dfrac{r}{f} $ Z is the nonuniformity factor representing the particle size distribution. When Z ≤ 4/3, grain growth is inhibited. Haroun and Budworth[28]

Sheffield University $ 1.03 \cdot \dfrac{r}{{{f^{0.5}}}} $ Modified Zener equation under the condition that at least one particle exists at each grain boundary. Nes et al.[29] Norwegian Institute of Technology $ 1.54 \cdot \dfrac{r}{{{f^{0.92}}}} $ Considering the influence of particle shape and distribution. Elst et al.[30] Philips Copper alloy $ \dfrac{{2\beta }}{3} \cdot \left(\dfrac{3}{2} - \dfrac{2}{Z}\right) \cdot \dfrac{r}{f} $ The bimodal grains and the particles precipitated at the grain boundary are calculated; β is a function of R0/r. Rios[31] Volta Redonda Steel $ 0.33 \cdot \dfrac{r}{f} $ Derived based on three different methods. Kad and Hazzledine[32] University of California $ 1.41 \cdot \dfrac{r}{{{f^{0.5}}}} $ Simulation results of square and hexagonal lattices reveal the diffusion of particles with special shapes \left(sphere, needle, and plate\right). Moon et al.[33] Hanyang University TiN Steel $ 1.5 \cdot \dfrac{r}{f} $ The Zener coefficient of TiN particles is 1.5. Zhou et al.[34] Wuhan University of Science and Technology 38CrMoAl $ A \cdot \dfrac{r}{f} $ A is about 0.17 when the grains grow normally. Moon and Lee[35] Korea Institute of Materials TiN Steel $ 1.33 \cdot \dfrac{r}{f} $ The second-phase particles must be fine and have a high volume fraction to effectively pin the grains. Xu et al.[9] Daye Special Steel SAE4320 $ A \cdot \dfrac{r}{f} $ When the temperature is kept below Ac3 temperature, the precipitated second-phase particles will not dissolve, and Ostwald will ripen. As a result, grain growth is inhibited. Ma et al.[36] Beijing University of Science and Technology 20CrMnTi $ 0.1694 \cdot \dfrac{r}{f} $ The grain radius is controlled to be less than the critical radius, and the grain grows normally. Qi and Li[37] Hebei Iron and Steel 20MnCr5 $ A \cdot \dfrac{r}{f} $ With the increase in temperature and holding time, the number of second-phase particles decreases, and the pinning effect on the grain boundary gradually weakens. Guo et al.[38] Zhengzhou University X80M Steel $ \pi \cdot \left(\dfrac{1}{4} - \dfrac{1}{{3Z}}\right) \cdot \dfrac{r}{f} $ The normal Z value of general metal materials is about 1.7.

Li et al.[39] Beijing University of Science and Technology 20CrMnTi $ \dfrac{{\pi r}}{{6f}} \cdot \left(\dfrac{3}{2} - \dfrac{2}{Z}\right) $ The grain boundary is pinned by the precipitated second-phase nanoparticles. 表 4 元素對奧氏體晶粒長大的作用

Table 4. Effect of various elements on austenite grain growth

Element Effect C, Mn and P Promote growth Si, N and Cu Weak inhibition Mo, Cr and W Moderate inhibition Nb, V, Ti, Al, Zr, N and O Strong inhibition 表 5 Al含量對奧氏體晶粒尺寸的影響

Table 5. Effect of Al content on austenite grain size

Author and publication Unit Steel Brief description Dong et al.[44] Henan University of Science and Technology 20Cr2Ni4A When the mass fraction of Al is 0.007%, the coarsening temperature is

850 ℃; When the mass fraction of Al is 0.041%, the coarsening

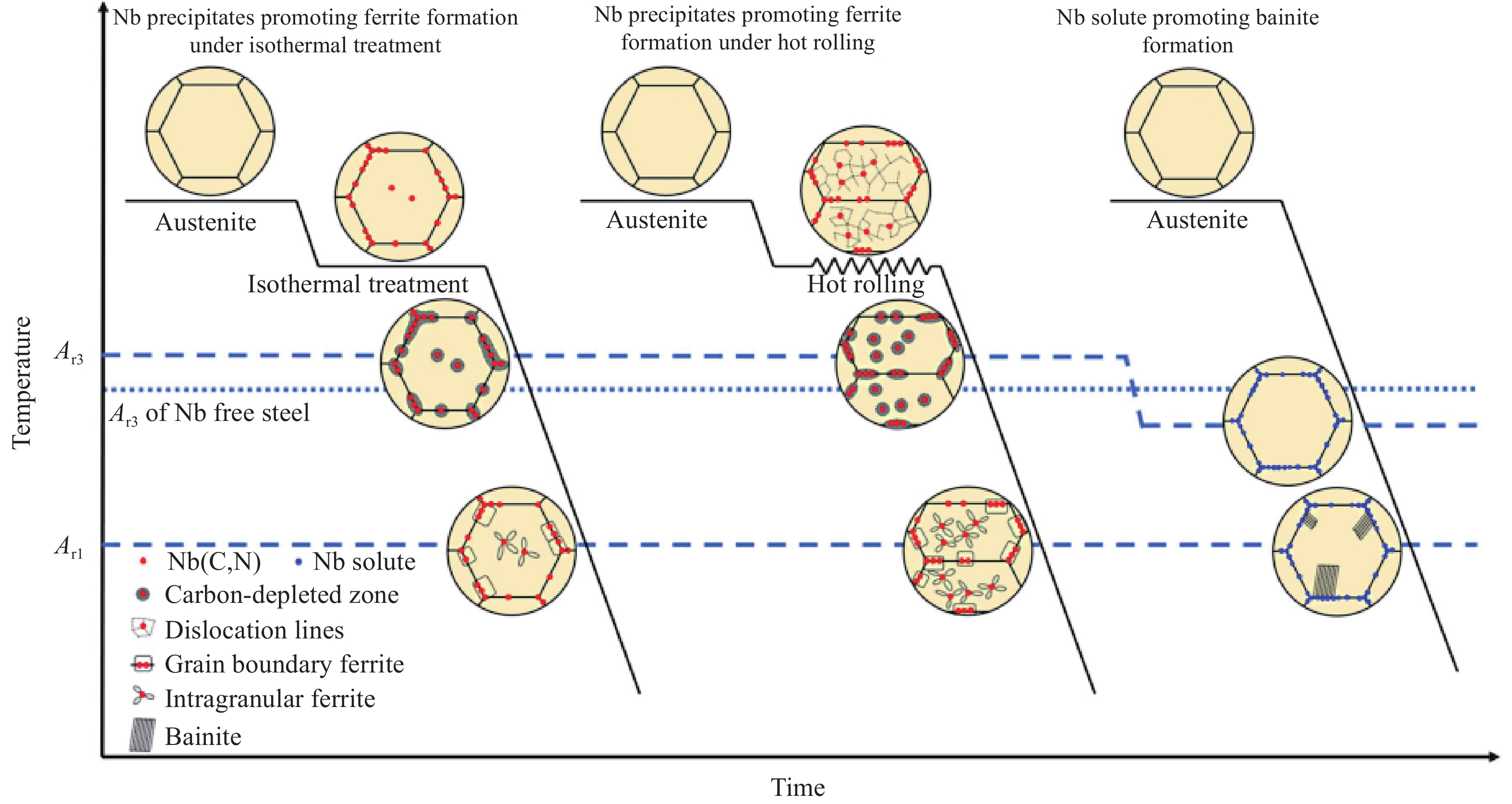

temperature is 1030 ℃.Li et al.[45] Beijing University of Science and Technology L45 When mass fraction of Al ≥ 0.03%, the grain coarsening temperature can reach 1000 ℃ under the condition of long heating time. Kubota and Ochi[46] Nippon Steel Carburized anti-coarsening steel With the increase in Al addition, the grain coarsening temperature increases. However, when the amount of Al is too large, the grain coarsening temperature decreases. Sun et al.[47] Shouguang Juneng Special Steel 22CrMoH When the mass fraction of Al is low at 0.011%, less AlN will be formed, leading to the weakening of the pinning effect. The grain boundary will migrate at the position with less AlN, and the grains will grow. Qi and Li[37] Hebei Shigang 20MnCr5 When mass fraction of Al ≥ 0.025% and mass fraction ratio of Al/N≥3, no mixed crystal is formed at 930 ℃ for 6 h. Liu et al.[48] Beijing University of Science and Technology 20Cr When Nb is microalloyed and mass fraction of Al≥0.025%, the comprehensive pinning is the strongest. Li et al.[49] Fushun Special Steel 20MnCr5 When the mass fraction of Al ≥ 0.02% and mass fraction ratio of Al/N ≥ 2, the grain boundary can be effectively pinned to prevent grain growth and prolong the austenitization. State of Nb Mechanism Affecting stage Precipitated phase/

Solute (segregation)Pinning/Dragging

grain boundaryAustenitizing stage Precipitated phase/

Solute (segregation)Inhibit austenite recrystallization Recrystallization stage Precipitated phase Ferrite nucleation Solid-state transformation stage 表 7 未溶解粒子的化學成分

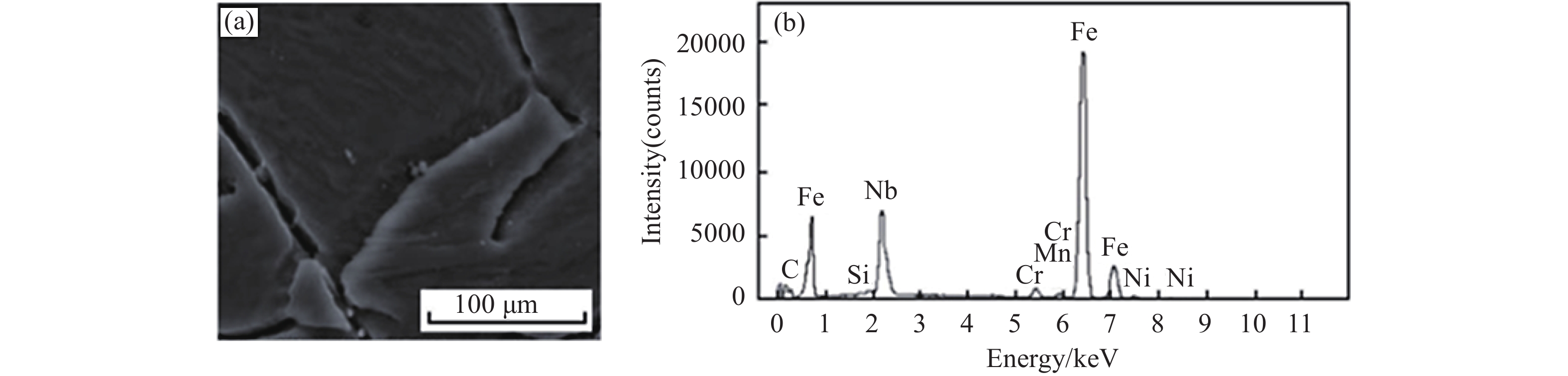

Table 7. Chemical composition of undissolved particles

Element Mass fraction/% Atomic fraction/% C 4.96 25.40 Ti 14.03 18.02 V 3.98 4.81 Cr 1.53 1.80 Nb 75.49 49.97 Total 100 100 表 8 Nb含量對奧氏體晶粒的影響

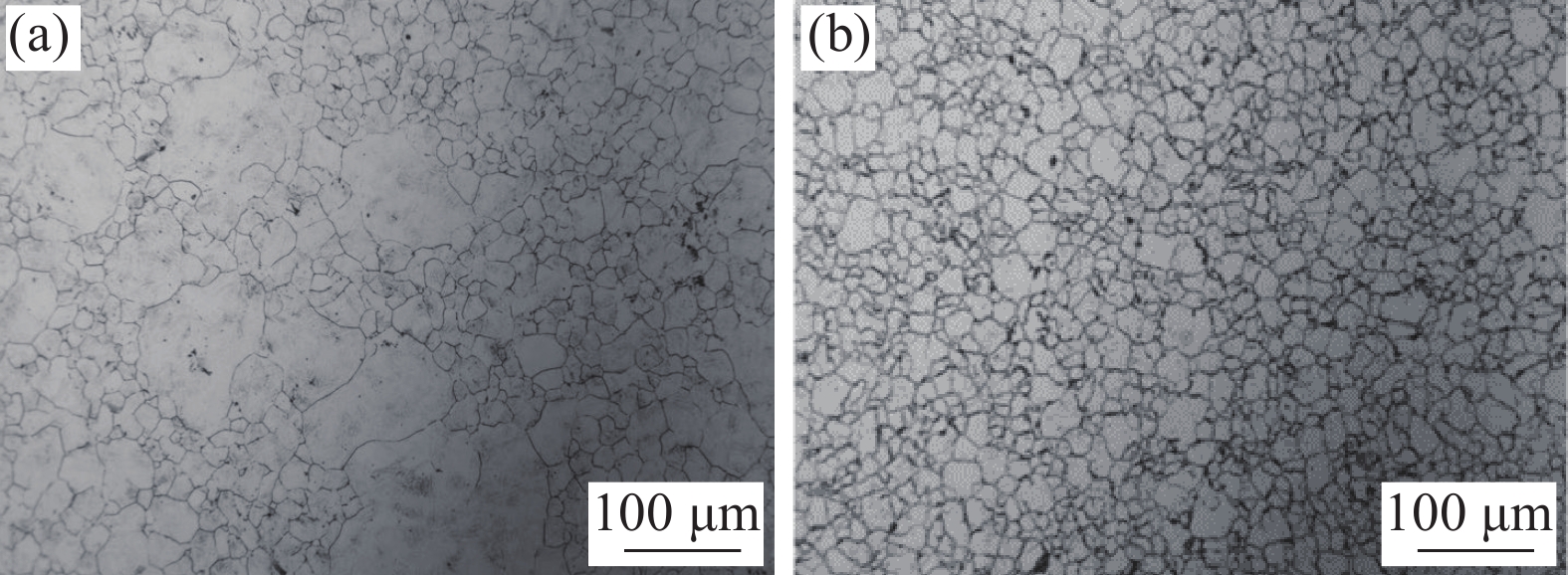

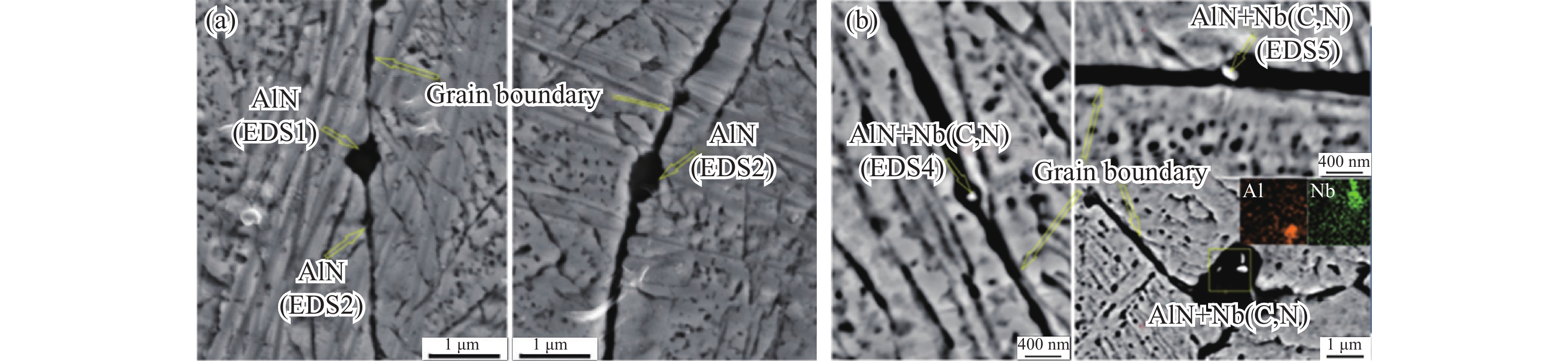

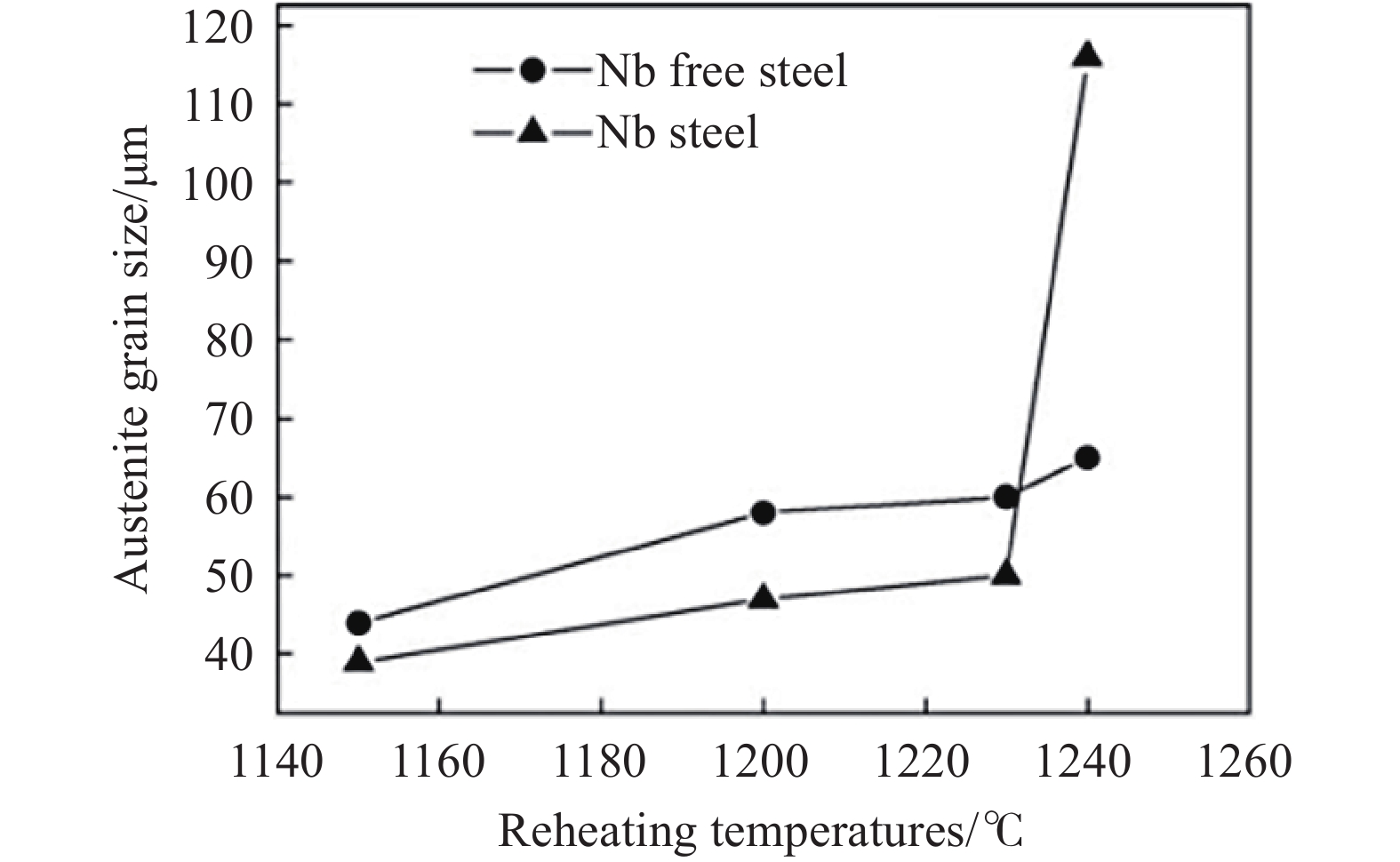

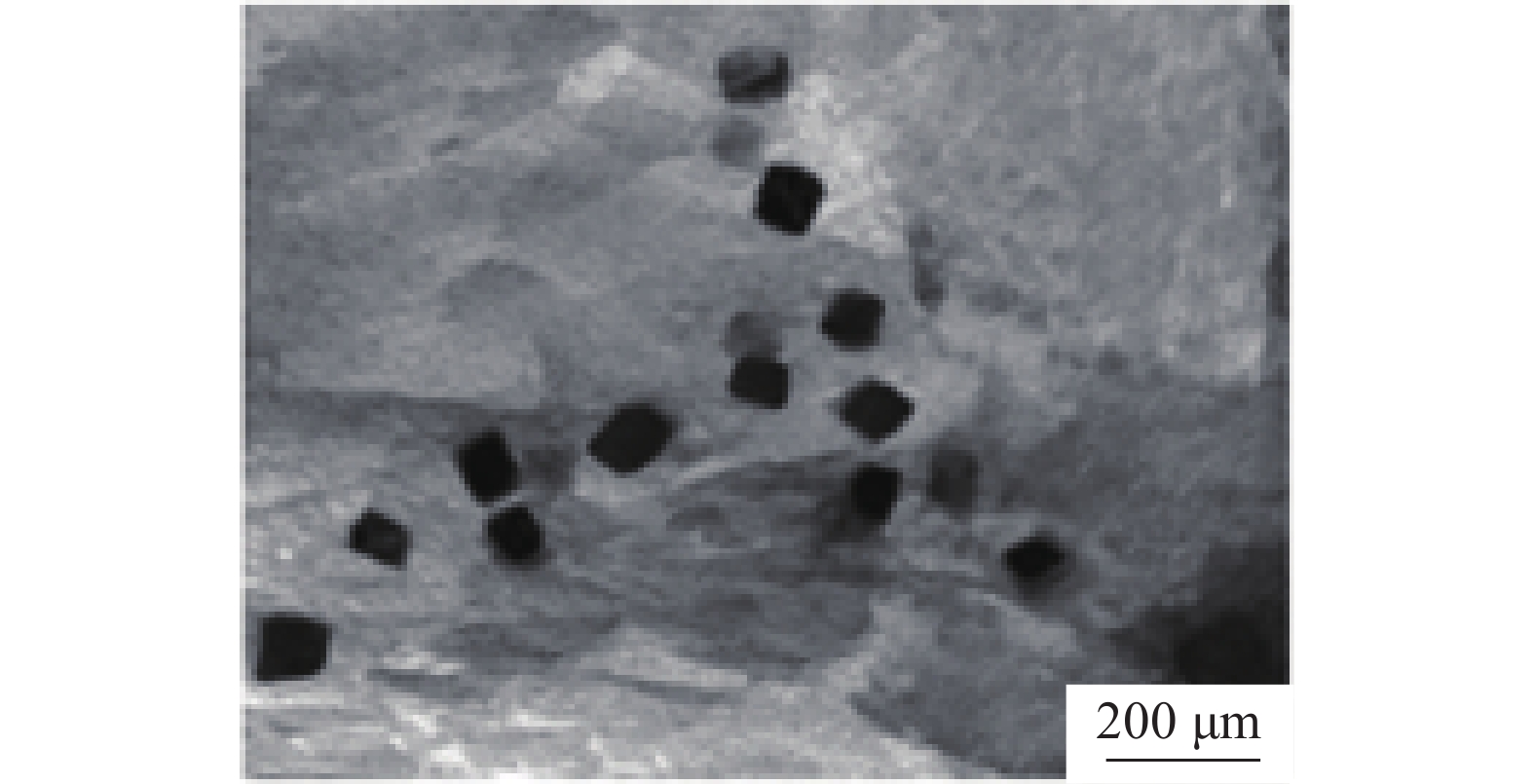

Table 8. Effect of Nb content on austenite grain

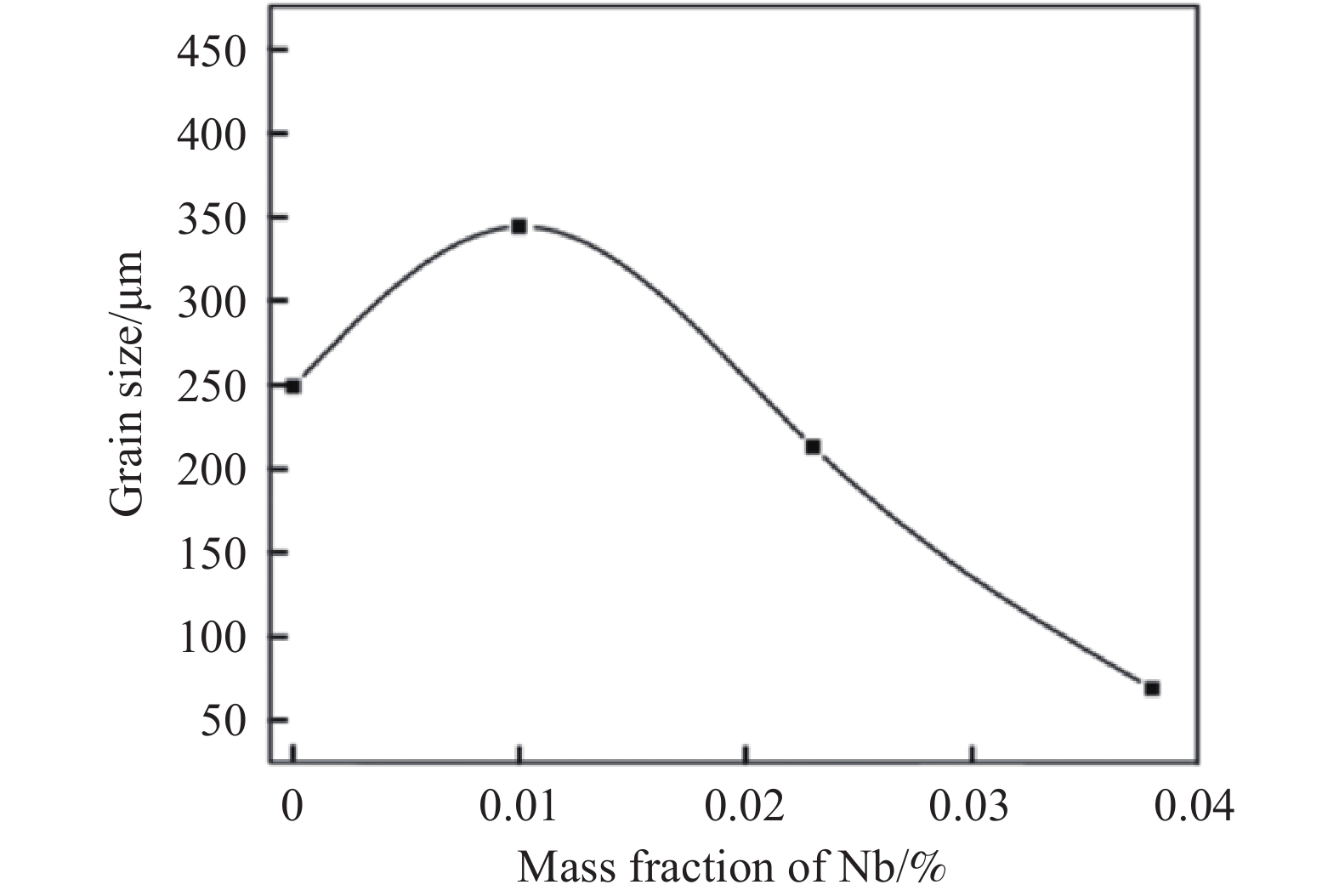

Author and publication Unit Steel Brief description Liu et al.[59] Central Iron & Steel

Research Institute0.065%C?1.15%Mn?0.055%Nb Steel When mass fraction of Nb ≤ 0.025%, no mixed structure appears. When mass fraction of Nb = 0.030%, a slightly mixed crystal structure appears. When mass fraction of Nb ≥ 0.035%, mixed crystals appear. The degree of mixed crystals increases with the Nb content. Yuan et al.[60] Northeast University C?Mn Steel With the increase in Nb content, the average size of austenite grains is refined from 248 nm to 69 nm, as shown in Figure 14. Kubota and Ochi[46] Nippon Steel Carburized anti-coarsening steel With the increase in Nb content, the grain coarsening temperature tends to increase. However, when the mass fraction of Nb exceeds 0.02%, the grain coarsening temperature does not increase further. Liu et al.[61] Kunming University of Science and Technology 17CrNiMo6 At a high temperature, the grain refining effect of AlN particles is not as significant as that of NbC particles. With the increase in Nb content, many undissolved NbC particles at high temperatures can play a strong role in inhibiting grain growth, as shown in Figure 15. Ma et al.[62] Central Iron & Steel

Research Institute20CrMoH The addition of Nb with a mass fraction of 0.04% can effectively refine grains, and the effect of controlling grain growth is not evident when the added mass fraction of Nb is 0 or 0.08%. Tong et al.[63] Shougang Group 20CrMnTi When the holding time is 1 h, the grain coarsening temperature increases by 50 ℃ for every 0.03% increase in mass fraction of Nb. Zhang et al.[57] Central Iron & Steel

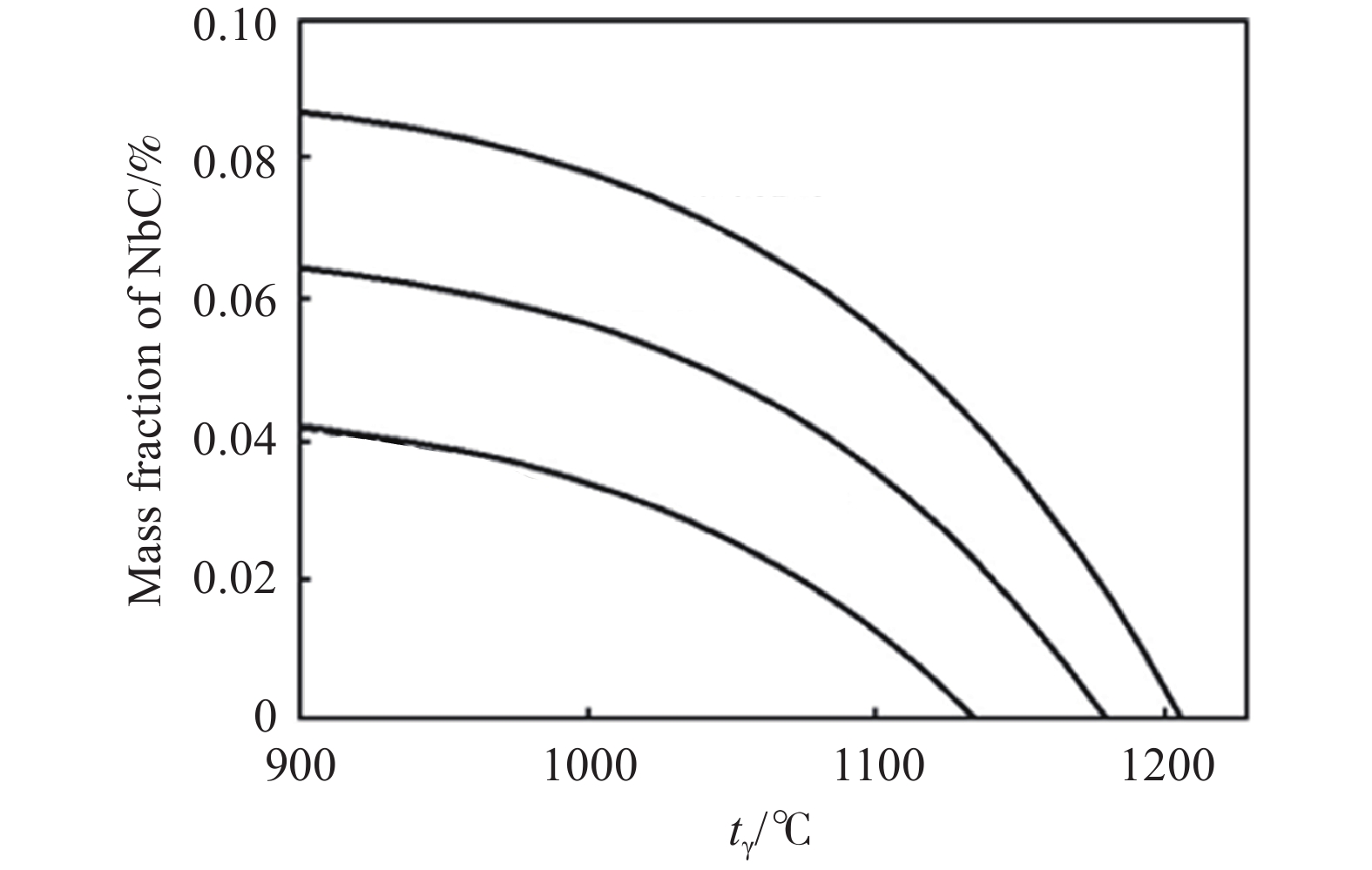

Research Institute18Cr2Ni2Mo With the addition of Nb with a mass fraction of 0.01%, the gear steel becomes suitable for long-term carburization at 980 ℃, and the average grain size is about 26 μm. Jia et al.[64] Xining Special Steel 20MnCr5 After adding Nb with a mass fraction of 0.28%, the steel can meet the requirements of carburization at 1000 ℃ and no mixed crystal is formed. Table 9. Dissolution temperature formula and dissolution temperature of different precipitated particles[65?66]

Precipitated particle Dissolution temperature formula Starting solution temperature/℃ Complete solution temperature/℃ AlN $ \log [{\text{Al}}][{\text{N}}] = - \dfrac{{7550}}{T} + 1.93 $ 900–950 >1150 NbC $ \log [{\text{Nb}}][{\text{C}}] = - \dfrac{{7290}}{T} + 3.04 $ 950–1000 >1150 Nb(C, N) $ \log [{\text{Nb}}][{\text{C + N}}] = - \dfrac{{5860}}{T} + 1.54 $ >1050 >1300 表 10 釘扎力模型的發展

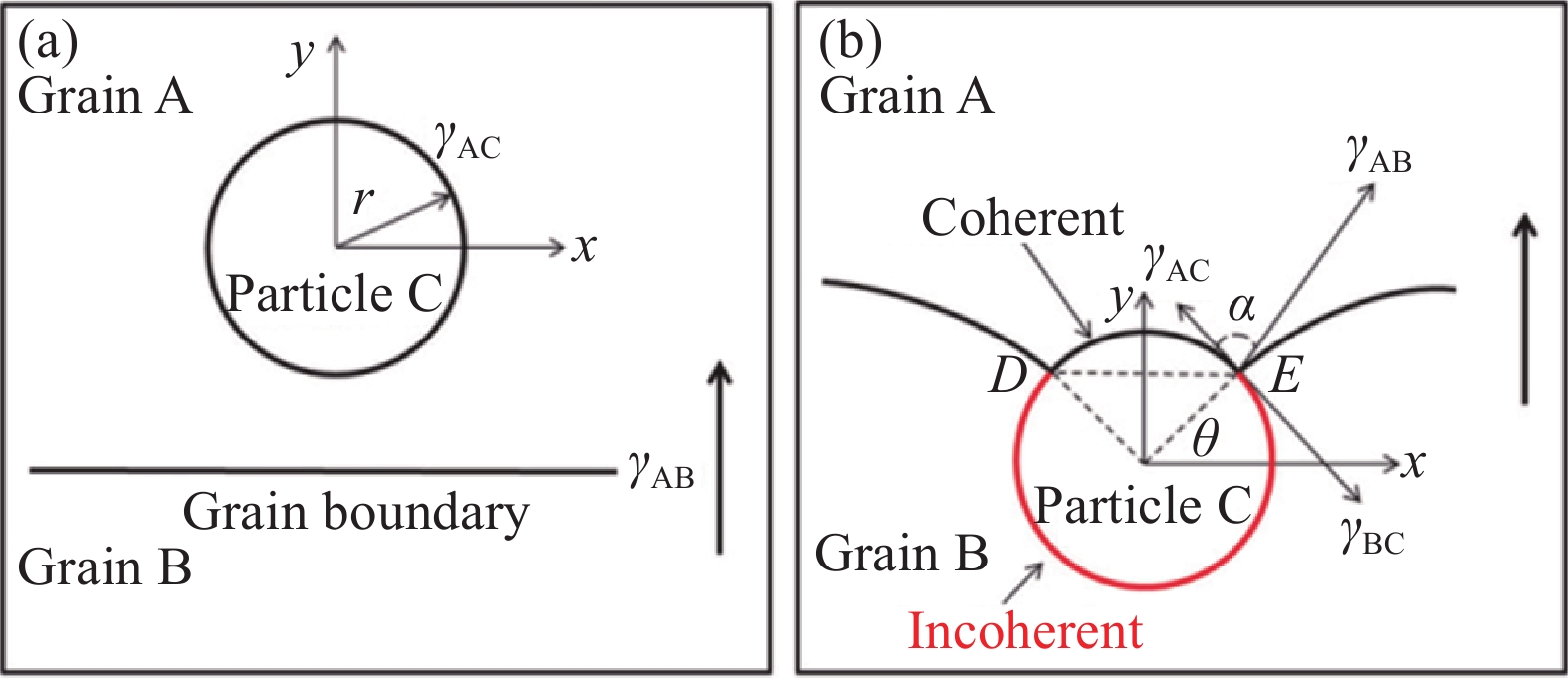

Table 10. Development of pinning force model

Author and publication Unit Material Equation (Pz=) Brief description Smith[27] University of Chicago High purity aluminum $ \dfrac{{3\gamma f}}{{4r}} $ Original equation Gladman[26] United Steel $ \dfrac{{3\gamma f}}{{2r}} $ Only the particles behind the boundary affect the forward motion of the boundary, and the particles in front of the boundary increase the driving force. W?rner and Hazzledine[70] University of Valparaiso Electrical steel $ 1.38 \cdot \dfrac{{\gamma {f^{0.5}}}}{r} $ Influence of grain boundary migration mechanism on grains Nes et al.[29] Norwegian Institute of Technology $ 1.3 \cdot \dfrac{{\gamma {f^{0.92}}}}{r} $ When particles interact with the boundary, they produce a pinning effect and change the shape of the grain boundary. Wang et al.[71] Northeast University 20CrMoNb $ \dfrac{{6f\sigma }}{{\pi r}} $ Gladman equation, σ is the crystal plane energy Maalekian et al.[72] Columbia University Ti/Nb microalloyed Steel $ \beta \cdot \dfrac{{\gamma f}}{r} $ β is the grain boundary energy and an infinite constant determined by particle shape. Zhang et al.[73] Hokkaido University Hot rolled low alloy steel $ \dfrac{{3\gamma f}}{{2r}} $ Pinning force exerted by random particle distribution Gu et al.[74] Yanshan University X100 pipeline steel $ 12\gamma \displaystyle\sum\limits_i^{} {\dfrac{{{f_i}}}{{{r_i}}}} $

$ 12\gamma \displaystyle\sum\limits_{i = 0}^n {\dfrac{{{f_i}}}{{{r_i}}}} $A model with different types of particles (i represents all current precipitation phase types) Jiang et al.[75] Xining Special Steel Non-quenched and tempered steel $ \beta \cdot \dfrac{{\gamma f}}{r} $ Fine and dispersed MnS particles play a pinning role that can prevent grain growth. Liu et al.[76] Beijing University of Science and Technology 20Cr $ \beta \cdot \dfrac{{\gamma f}}{r} $ When $ f \geqslant 1.56 \times {10^{ - 4}} $,

abnormal grain growth can be avoided.Luo et al.[77] Kunming University of Science and Technology Ti-microalloyed steel $ \dfrac{{3\gamma fI}}{{2\pi {r^2}}} $ I is affected by $\displaystyle \sum\limits_{}^{} {f(r)} /r \cdot \displaystyle \sum\limits_0^n {f(r)} /r $ 表 11 加熱溫度對第二相粒子的影響

Table 11. Effect of heating temperature on second-phase particles

Author and publication Unit Steel Particle Brief description Yang et al.[78] Liaoning Special Steel FAS3220H-1 Nb(C, N) When the temperature exceeds 1000 ℃, grain growth is accelerated. Tong et al.[63] Shougang Group 20CrMnTiH NbC When the heating temperature is higher than 1000 ℃, some of the second-phase particles are dissolved. Meanwhile, the undissolved particles are coarsened. Liu et al.[79] Shougang Group 20CrMnTiH NbC, TiN High carburization temperature and time affect the coarsening of precipitated phase particles. Dong et al.[80] Shanghai Jiaotong University SA508-III AlN When the heating temperature is higher than 1050 ℃, grain coarsening occurs due to the dissolution of pinned particles.

Sun et al.[47] Shouguang Juneng Special Steel 22CrMoH AlN The coarsening temperature is 920–930 ℃. With the increase in temperature, AlN particles aggregates and dissolve, and the pinning effect weakens. Yang et al.[22] Angang 18CrNiMo7-6 NbC, AlN The optimal coarsening temperature is 1000 ℃. 表 12 前人對混晶的研究結果

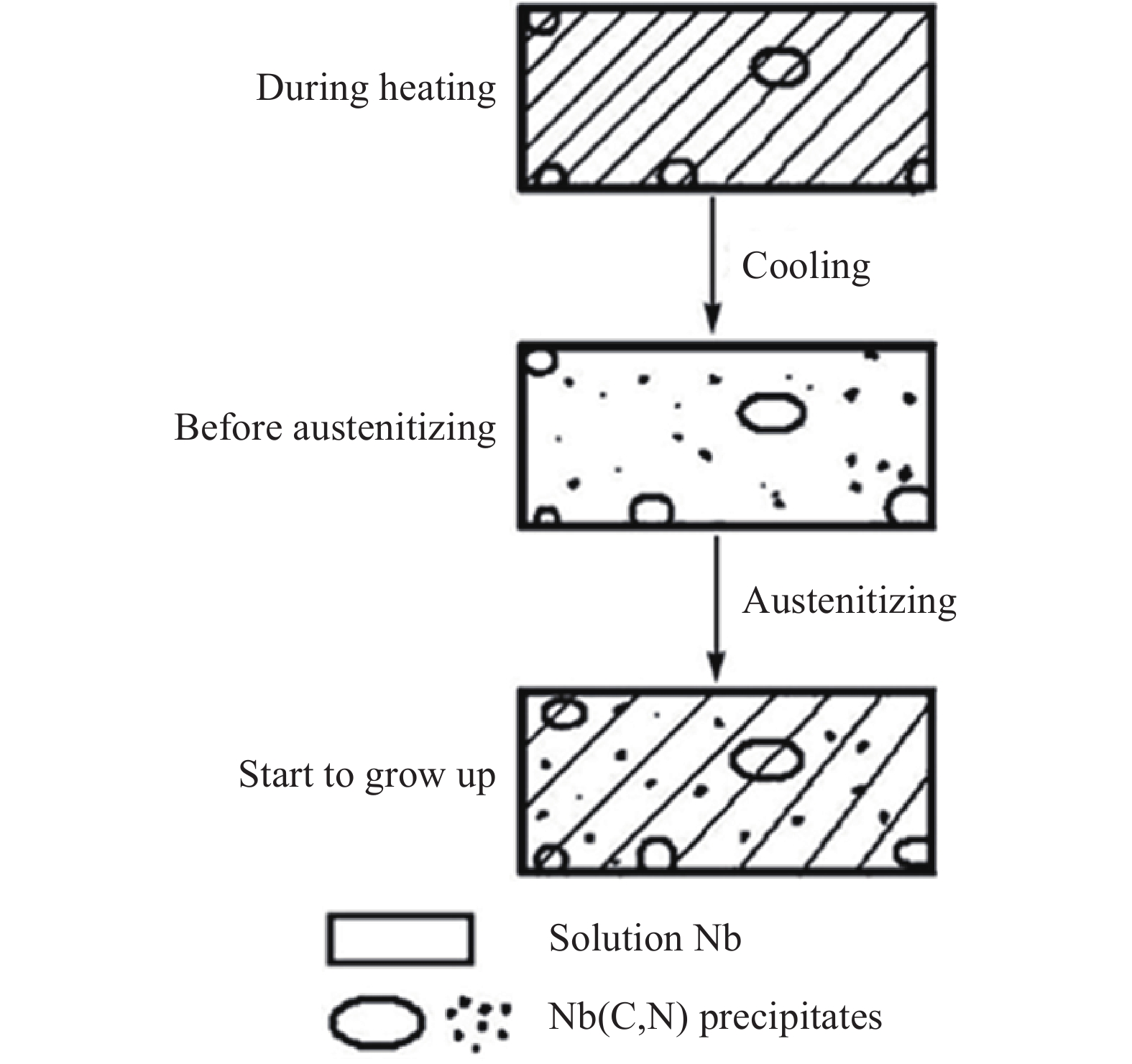

Table 12. Research results on mixed crystals in previous works

Author and publication Unit Steel Brief description Shen and Wu[82] Shougang Guiyang Special Steel 20CrMnTi The mixed crystal is caused by uneven temperature in the furnace and high local temperature, which results in abnormal coarse grains in the local part of the sample that form mixed crystals. Gao et al.[83] Luoyang Bearing Science & Technology Co., Ltd. Cr4Mo4V The uneven distribution of carbides easily occurs in metallurgical processes, and the mixed crystal structures are mainly caused by uneven primary carbides. Song[84] Hengye Forging F91 The alloying degree is relatively high, causing the structural heredity of the mixed crystal. During heat preservation, the increase in nonuniformity factor Z also increases the degree of crystal mixing. Liu et al.[85] Harbin Bearing Company 8Cr4Mo4V The mixed crystal structure after quenching is closely related to the grain size of raw materials. Ye et al.[86] Xining Special Steel 16MnCrS5+H When mixed crystals appear after rolling, AlN can be fully precipitated after annealing at 760 ℃ in the two-phase zone, thus strengthening the role of AlN in pinning grains. Huang et al.[87] Anhui University of Technology 16MnCr5H The coarsening of austenite grains and the appearance of mixed grains are closely related to the aggregation and dissolution of the second-phase AlN particles. www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] He L L. The effect of Nb microalloying on the microstructure and properties of 20MnCr5 low carbon alloy steel // 2019 Papers Compilation of Shaanxi Mechanical Engineering Society. Xian, 2022: 169何亮亮. Nb微合金化對20MnCr5低碳合金鋼組織及性能的影響//陜西省機械工程學會2019年論文匯編. 西安, 2022:169 [2] Zhang X Y, Zhao M H, Zhu Q B, et al. Analysis of three-dimensional morphology of sulfides in continuous casting billet of 20MnCr5 gear steel. Metall Anal, 2022, 42(8): 13張曉宇, 趙夢豪, 朱強斌, 等. 20MnCr5齒輪鋼連鑄坯中硫化物三維形貌的解析. 冶金分析, 2022, 42(8):13 [3] Shi Y, Dai G W, Huang Y X, et al. Microstructure evolution of 20MnCr5 gear steel during continuous cooling transformation. Heat Treat Met, 2017, 42(9): 128 doi: 10.13251/j.issn.0254-6051.2017.09.028史遠, 戴觀文, 黃艷新, 等. 20MnCr5齒輪鋼連續冷卻過程中的組織變化. 金屬熱處理, 2017, 42(9):128 doi: 10.13251/j.issn.0254-6051.2017.09.028 [4] Chen H, Zhou X Y. Research progress of gear steel for automobiles. J Mater Sci Eng, 2011, 29(3): 478 doi: 10.14136/j.cnki.issn1673-2812.2011.03.016陳暉, 周細應. 汽車齒輪鋼的研究進展. 材料科學與工程學報, 2011, 29(3):478 doi: 10.14136/j.cnki.issn1673-2812.2011.03.016 [5] Cheng L J. Overview of grain size standards at home and abroad. Phys Test Chem Anal(Part A), 2019, 55 (8): 515程麗杰. 國內外晶粒度標準綜述. 理化檢驗(物理分冊), 2019, 55(8):515 [6] Mao W M. Recrystallization and Grain Growth of Metals. Beijing: Metallurgical Industry Press, 1994毛衛民. 金屬的再結晶與晶粒長大. 北京:冶金工業出版社, 1994 [7] Wang Q S, Jiao Z G, Fan H S. Study on spheroidizing annealing mechanism of steel. Spec Steel, 1982, 3(3): 1王全山, 焦作光, 樊邯生. 鋼的球化退火機理的研究. 特殊鋼, 1982, 3(3):1 [8] Gao Y J, Jin X, Su Y Y, et al. Monte Carlo simulation of abnormal grain growth. J Guangxi Univ Nat Sci, 2009, 34(2): 220 doi: 10.3969/j.issn.1001-7445.2009.02.022高英俊, 金星, 蘇義勇, 等. 異常晶粒長大的Monte Carlo模擬方法. 廣西大學學報(自然科學版), 2009, 34(2):220 doi: 10.3969/j.issn.1001-7445.2009.02.022 [9] Xu S C, Zhou L X, Zhang Z C, et al. Effect of heat treatment process on austenite grain size of SAE4320 steel. Heat Treat Met, 2014, 39(11): 111徐尚呈, 周立新, 張志成, 等. 熱處理工藝對SAE4320鋼奧氏體晶粒度的影響. 金屬熱處理, 2014, 39(11):111 [10] Novikov V Y. Microstructure evolution during grain growth in materials with disperse particles. Mater Lett, 2012, 68: 413 doi: 10.1016/j.matlet.2011.10.101 [11] Bréchet Y, Militzer M. A note on grain size dependent pinning. Scr Mater, 2005, 52(12): 1299 doi: 10.1016/j.scriptamat.2005.02.021 [12] Beck P A, Kremer J C, Demer L. Grain growth in high purity aluminum. Phys Rev, 1947, 71(8): 555 [13] Hillert M. On the theory of normal and abnormal grain growth. Acta Metall, 1965, 13(3): 227 doi: 10.1016/0001-6160(65)90200-2 [14] Sellars C M, Whiteman J A. Recrystallization and grain growth in hot rolling. Met Sci, 1979, 13(3-4): 187 doi: 10.1179/msc.1979.13.3-4.187 [15] Lee S J, Lee Y K. Prediction of austenite grain growth during austenitization of low alloy steels. Mater Des, 2008, 29(9): 1840 doi: 10.1016/j.matdes.2008.03.009 [16] Hu H, Rath B B. On the time exponent in isothermal grain growth. Metall Trans, 1970, 1(11): 3181 doi: 10.1007/BF03038435 [17] Nishizawa T. Grain growth in single-and dual-phase steels. Tetsu-to-Hagane, 1984, 70(15): 1984 doi: 10.2355/tetsutohagane1955.70.15_1984 [18] Jiao S, Penning J, Leysen F, et al. The modeling of the grain growth in a continuous reheating process of a low carbon Si?Mn bearing TRIP steel. ISIJ Int, 2000, 40(10): 1035 doi: 10.2355/isijinternational.40.1035 [19] Moon J, Lee J, Lee C. Prediction for the austenite grain size in the presence of growing particles in the weld HAZ of Ti-microalloyed steel. Mater Sci Eng A, 2007, 459(1-2): 40 doi: 10.1016/j.msea.2006.12.073 [20] Yue C X, Zhang L W, Liao S L, et al. Research on austenite grain growth behavior of GCr15 steel. Trans Mater Heat Treat, 2008, 29(1): 94 doi: 10.13289/j.issn.1009-6264.2008.01.036岳重祥, 張立文, 廖舒綸, 等. GCr15鋼奧氏體晶粒長大規律研究. 材料熱處理學報, 2008, 29(1):94 doi: 10.13289/j.issn.1009-6264.2008.01.036 [21] Zhu X X, Wang B Y, Fu X B. Evolution of austenite grain growth in gear steel SAE8620H. Trans Mater Heat Treat, 2015, 32(Suppl 2): 242朱小星, 王寶雨, 付曉斌. 齒輪鋼SAE8620H奧氏體晶粒長大演化規律. 材料熱處理學報, 2015, 32(S2):242 [22] Yang S P, Yu W C, Hu F Z, et al. The austenite grain growth behavior of low carbon gear steel 18CrNiMo7-6. Mater Rep, 2021, 35(8): 8179 doi: 10.11896/cldb.20020030楊少朋, 尉文超, 胡芳忠, 等. 低碳齒輪鋼18CrNiMo7-6奧氏體晶粒度長大規律. 材料導報, 2021, 35(8):8179 doi: 10.11896/cldb.20020030 [23] Yang Y H, Wang M Q, Wang C F, et al. Austenite grain growth in Ti and Nb microalloyed gear steels. J Iron Steel Res, 2012, 24(12): 32 doi: 10.13228/j.boyuan.issn1001-0963.2012.12.011楊延輝, 王毛球, 王春芳, 等. 鈦鈮微合金化齒輪鋼的奧氏體晶粒長大研究. 鋼鐵研究學報, 2012, 24(12):32 doi: 10.13228/j.boyuan.issn1001-0963.2012.12.011 [24] Bao S, Yang G W, Xu Y W, et al. Austenite grain growth behavior of medium manganese martensitic NM500 steel. Steel, 2022, 57(8): 152包爽, 楊庚蔚, 徐耀文, 等. 中錳馬氏體NM500鋼奧氏體晶粒長大行為. 鋼鐵, 2022, 57(8):152 [25] He G, Zhu X, Jiang B, et al. Grain growth behavior of niobium microalloyed 20MnCr5 steel and the effect of boron. Materialwiss Werkstofftech, 2022, 53(5): 547 doi: 10.1002/mawe.202100065 [26] Gladman T. On the theory of the effect of precipitate particles on grain growth in metals. Proc R Soc Lond A, 1966, 294(1438): 298 doi: 10.1098/rspa.1966.0208 [27] Smith C S. Grains, phases, and interfaces: An introduction of microstructure. Trans AIME, 1948, 175: 15 [28] Haroun N A, Budworth D W. Modifications to the Zener formula for limitation of grain size. J Mater Sci, 1968, 3(3): 326 doi: 10.1007/BF00741970 [29] Nes E, Ryum N, Hunderi O. On the zener drag. Acta Metall, 1985, 33(1): 11 doi: 10.1016/0001-6160(85)90214-7 [30] Elst R, van Humbeeck J, Delaey L. Evaluation of grain growth criteria in particle-containing materials. Acta Metall, 1988, 36(7): 1723 doi: 10.1016/0001-6160(88)90240-4 [31] Rios P R. On the relationship between pinning force and limiting grain radius. Scr Mater, 1996, 34(8): 1185 doi: 10.1016/1359-6462(95)00641-9 [32] Kad B K, Hazzledine P M. Monte Carlo simulations of grain growth and Zener pinning. Mater Sci Eng A, 1997, 238(1): 70 doi: 10.1016/S0921-5093(97)00435-8 [33] Moon J, Kim S, Lee J, et al. Limiting austenite grain size of TiN-containing steel considering the critical particle size. Scr Mater, 2007, 56(12): 1083 doi: 10.1016/j.scriptamat.2007.02.025 [34] Zhou C, Wang M Q, Dong H, et al. Investigation on kinetics of austenite grain growth of 38CrMoAl steel. Steel, 2010, 45(12): 73 doi: 10.13228/j.boyuan.issn0449-749x.2010.12.004周超, 王毛球, 董瀚, 等. 38CrMoAl鋼奧氏體晶粒長大動力學研究. 鋼鐵, 2010, 45(12):73 doi: 10.13228/j.boyuan.issn0449-749x.2010.12.004 [35] Moon J, Lee C. Pinning efficiency of austenite grain boundary by a cubic shaped TiN particle in hot rolled HSLA steel. Mater Charact, 2012, 73: 31 doi: 10.1016/j.matchar.2012.07.003 [36] Ma W J, Bao Y P, Zhao L H, et al. Control of the precipitation of TiN inclusions in gear steels. Intl J Miner Metall Mater, 2014, 21(3): 234 doi: 10.1007/s12613-014-0900-2 [37] Qi J J, Li S J. Effect of Al-N ratio on grain blending of carburized steel for cars. Hebei Metall, 2015(2): 1 doi: 10.13630/j.cnki.13-1172.2015.0201齊建軍, 李紹杰. 鋁氮比對轎車用滲碳鋼晶粒混晶的影響. 河北冶金, 2015(2):1 doi: 10.13630/j.cnki.13-1172.2015.0201 [38] Guo H B, Zuo X R, Zhang X L, et al. Austenite grain coarsening and Nb/Ti solution precipitation behavior of X80M pipeline steel. Hot Work Technol, 2016, 45(10): 1 doi: 10.14158/j.cnki.1001-3814.2016.10.001郭海濱, 左秀榮, 張新理, 等. X80M管線鋼奧氏體晶粒粗化及Nb/Ti的固溶析出行為. 熱加工工藝, 2016, 45(10):1 doi: 10.14158/j.cnki.1001-3814.2016.10.001 [39] Li Y, Cheng G G, Lu J L, et al. Effect of TiN precipitation on hardenability of 20CrMnTi gear steel. Steel, 2021, 56(1): 75李堯, 成國光, 魯金龍, 等. 20CrMnTi齒輪鋼中TiN析出相對淬透性的影響. 鋼鐵, 2021, 56(1):75 [40] Yong Q L. The Second Phase in Steel Materials. Beijing: Metallurgical Industry Press, 2006雍岐龍. 鋼鐵中的第二相. 北京:冶金工業出版社, 2006 [41] Huang Y, Zhang M. Influence of different factors on the grain growth trend of C?Mn steel // The Third Annual Meeting of the Fifth Steel Pipe Academic Committee of the Steel Rolling Society of the Chinese Society of Metals. Xi’an, 2007: 391黃英, 張珉. 不同因素對C?Mn鋼晶粒長大趨勢的影響//中國金屬學會軋鋼學會鋼管學術委員會五屆三次年會. 西安, 2007:391 [42] Cui Z H. Metallography and Heat Treatment. Beijing: China Machine Press, 2000崔忠坼. 金屬學與熱處理. 北京:機械工業出版社, 2000 [43] Zhang C L, Shao Z H, Li J, et al. Application and development of niobium microalloying technology in medium and high carbon steel. Mater Rep, 2021, 35 (5): 5102 doi: 10.11896/cldb.20010139張朝磊, 邵洙浩, 李戩, 等. 鈮微合金化技術在中高碳鋼中的應用現狀與發展. 材料導報, 2021, 35(5):5102 doi: 10.11896/cldb.20010139 [44] Dong Q M, Li Y, Jiang X T, et al. A preliminary study on the mixed crystal mechanism of 20Cr2Ni4A steel. J Luoyang Inst Technol, 1987(2): 1董企銘, 李炎, 江錫堂, 等. 20Cr2Ni4A鋼混晶機理的初步研究. 洛陽工學院學報, 1987(2):1 [45] Li W Q, Zhang X H, Gao N, et al. The effect of Al, Ti, V and Nb on austenite grain size of medium carbon steels. J Univ Scie Technol Beijing, 1990, 12(5): 437李文卿, 張小紅, 高寧, 等. 鋁、鈦、釩和鈮對中碳鋼奧氏體晶粒度的影響. 北京科技大學學報, 1990, 12(5):437 [46] Kubota M, Ochi T. Development of anti-coarsening steel for carburizing. Mater Sci Forum, 2007, 539: 4855 [47] Sun H J, Zhang Y A, Zhang S P. Analysis of influencing factors on austenite grain size of 22CrMoH gear steel and reasons for mixed grain. Shandong Metallurgy, 2019, 41(6): 29 doi: 10.16727/j.cnki.issn1004-4620.2019.06.011孫后金, 張永安, 張三平. 22CrMoH齒輪鋼奧氏體晶粒度影響因素及混晶原因分析. 山東冶金, 2019, 41(6):29 doi: 10.16727/j.cnki.issn1004-4620.2019.06.011 [48] Liu H S, Dong Y N, Zheng H G, et al. Effect of Nb microalloying on austenite grain size of high temperature carburized gear steel. J Iron Steel Res, 2021, 33(8): 828劉華松, 董延楠, 鄭宏光, 等. Nb微合金化對齒輪鋼高溫滲碳奧氏體晶粒度的影響. 鋼鐵研究學報, 2021, 33(8):828 [49] Li R X, Yu S Y, Wang Y. Factors of grain size for automobile gear steel 20MnCr5. Met World, 2022(4): 72李潤霞, 喻書贏, 王宇. 汽車齒輪用滲碳鋼20MnCr5晶粒度的影響因素. 金屬世界, 2022(4):72 [50] Bepari M A. Effects of second-phase particles on coarsening of austenite in 0.15 Pct carbon steels. Metall Trans A, 1989, 20(1): 13 [51] Liu Z Y, Bao Y P, Wang M, et al. Austenite grain growth of medium-carbon alloy steel with aluminum additions during heating process. Int J Miner Metall Mater, 2019, 26(3): 282 doi: 10.1007/s12613-019-1736-6 [52] Sun L Y, Liu X, Xu X, et al. Review on niobium application in microalloyed steel. J Iron Steel Res Int, 2022, 29(10): 1513 doi: 10.1007/s42243-022-00789-1 [53] Yu Q B, Sun Y. Abnormal growth of austenite grain of low-carbon steel. Mater Sci Eng A, 2006, 420(1-2): 34 doi: 10.1016/j.msea.2006.01.027 [54] Cheng S H, Zhou D, Kong X T, et al. Effect of Nb microalloying on austenite grain growth of high carbon steel. Heat Treat Met, 2014, 39(5): 54 doi: 10.13251/j.issn.0254-6051.2014.05.014程四華, 周德, 孔祥濤, 等. Nb微合金化對高碳鋼奧氏體晶粒生長的影響. 金屬熱處理, 2014, 39(5):54 doi: 10.13251/j.issn.0254-6051.2014.05.014 [55] Gray J M, Yeo R B G. Niobium carbonitride precipitation in low-alloy steels with particular emphasis on precipitate-row formation. ASM-Trans, 1968, 61(2): 255 [56] Xiao R T, Yu H, Zhou P. Abnormal grain growth mechanism of austenite in high-strength welded steel Q103. J Univ Sci Technol Beijing, 2011, 33(12): 1458 doi: 10.13374/j.issn1001-053x.2011.12.006肖榮亭, 于浩, 周平. Q1030焊接高強鋼的奧氏體晶粒異常長大機理. 北京科技大學學報, 2011, 33(12):1458 doi: 10.13374/j.issn1001-053x.2011.12.006 [57] Zhang G Q, He X F, Wei W C, et al. Grain coarsening behavior of high temperature carburized gear steel. Steel, 2019, 54(5): 68 doi: 10.13228/j.boyuan.issn0449-749x.20180369張國強, 何肖飛, 尉文超, 等. 高溫滲碳齒輪鋼的晶粒粗化行為. 鋼鐵, 2019, 54(5):68 doi: 10.13228/j.boyuan.issn0449-749x.20180369 [58] Ma F J, Wen G H, Wang W L. Effect of cooling rates on the second-phase precipitation and proeutectoid phase transformation of a Nb-Ti microalloyed steel slab. Steel Res Int, 2013, 84(4): 370 doi: 10.1002/srin.201200161 [59] Liu Q Y, Dong H, Sun X J, et al. Mixed grain problem of Nb containing steel in CSP process and its improvement method. Steel, 2003(8): 16 doi: 10.3321/j.issn:0449-749X.2003.08.003劉清友, 董瀚, 孫新軍, 等. CSP工藝中含Nb鋼的混晶問題及改善方法. 鋼鐵, 2003(8):16 doi: 10.3321/j.issn:0449-749X.2003.08.003 [60] Yuan X Q, Liu Z Y, Jiao S H, et al. The onset temperatures of γ to α-phase transformation in hot deformed and non-deformed Nb micro-alloyed steels. ISIJ Int, 2006, 46(4): 579 doi: 10.2355/isijinternational.46.579 [61] Liu Y, Wang M Q, Fan G, et al. Grain growth kinetics of niobium bearing gear steel. J Iron Steel Res, 2008(11): 37 doi: 10.13228/j.boyuan.issn1001-0963.2008.11.010劉燕, 王毛球, 樊剛, 等. 含鈮齒輪鋼的晶粒長大動力學. 鋼鐵研究學報, 2008(11):37 doi: 10.13228/j.boyuan.issn1001-0963.2008.11.010 [62] Ma L, Wang M Q, Xu X Q, et al. Austenite grain size and hardenability of Nb-B microalloyed gear steels. Trans Mater Heat Treat, 2009, 30(5): 74 doi: 10.13289/j.issn.1009-6264.2009.05.034馬莉, 王毛球, 徐香秋, 等. 鈮硼微合金化齒輪鋼的晶粒尺寸及淬透性. 材料熱處理學報, 2009, 30(5):74 doi: 10.13289/j.issn.1009-6264.2009.05.034 [63] Tong Q, Cui J Y, Liu Y B, et al. Effect of Nb content on austenite grain growth behavior of 20CrMnTiH steel. Heat Treat Met, 2014, 39(7): 39 doi: 10.13251/j.issn.0254-6051.2014.07.009佟倩, 崔京玉, 柳洋波, 等. Nb含量對20CrMnTiH鋼奧氏體晶粒長大行為的影響. 金屬熱處理, 2014, 39(7):39 doi: 10.13251/j.issn.0254-6051.2014.07.009 [64] Jia Y, Fang G J, Shi W H, et al. Analysis and study on grain coarsening behavior of 20MnCr5?Nb steel. Gansu Metallurgy, 2020, 42(5): 45 doi: 10.3969/j.issn.1672-4461.2020.05.013賈羽, 方光錦, 史文輝, 等. 20MnCr5?Nb鋼的晶粒粗化行為分析與研究. 甘肅冶金, 2020, 42(5):45 doi: 10.3969/j.issn.1672-4461.2020.05.013 [65] Gu Tie. Research on AlN solution behavior of carburized gear steel. Eng Technol Res, 2021, 3(9): 161 doi: 10.3969/j.issn.1671-3818.2021.09.077顧鐵. 滲碳齒輪鋼AlN固溶行為的研究. 工程技術研究, 2021, 3(9):161 doi: 10.3969/j.issn.1671-3818.2021.09.077 [66] Zhang Y Q, Yang X, Lu L Y, et al. Research on heating temperature of Nb microalloyed HRB400 steel bars // Proceedings of 2007 China Iron and Steel Annual Conference. Chengdu, 2007: 832張永青, 楊雄, 魯麗燕, 等. Nb微合金化HRB400鋼筋加熱溫度的研究//2007中國鋼鐵年會論文集. 成都, 2007:832 [67] Yang Y H, Wang M Q, Chen J C, et al. Research progress of high temperature carburized gear steel. Spec Steel, 2013, 34(1): 22 doi: 10.3969/j.issn.1003-8620.2013.01.006楊延輝, 王毛球, 陳敬超, 等. 高溫滲碳齒輪鋼的研究進展. 特殊鋼, 2013, 34(1):22 doi: 10.3969/j.issn.1003-8620.2013.01.006 [68] Huang K, Logé R E. Zener Pinning. Elsevier, 2016 [69] Huang J. Investigation on Abnormal Grain Growth Phenomenon During Carburizing Heat Treatment of Gear Steel [Dissertation]. Shenyang: Dongbei University, 2010黃健. 齒輪鋼滲碳熱處理過程中的晶粒異常長大現象研究[學位論文]. 沈陽:東北大學, 2020 [70] W?rner Dr Fia C H, Hazzledine P M. Grain growth stagnation by inclusions or pores. JOM, 1992, 44(9): 16 doi: 10.1007/BF03222320 [71] Wang B X, Liu X H, Wang G D, et al. Austenite grain size and continuous cooling transformation behavior in gear steel 20CrMoNb gear steel. Mater Sci Technol, 2009, 17(5): 620王秉新, 劉相華, 王國棟, 等. 齒輪鋼20CrMoNb奧氏體晶粒尺寸及相變行為. 材料科學與工藝, 2009, 17(5):620 [72] Maalekian M, Radis R, Militzer M, et al. In situ measurement and modelling of austenite grain growth in a Ti/Nb microalloyed steel. Acta Mater, 2012, 60(3): 1015 doi: 10.1016/j.actamat.2011.11.016 [73] Zhang X G, Matsuura K, Ohno M. Abnormal grain growth in austenite structure reversely transformed from ferrite/pearlite-banded structure. Metall Mater Trans A, 2014, 45(10): 4623 doi: 10.1007/s11661-014-2364-4 [74] Gu Y, Tian P, Wang X, et al. Non-isothermal prior austenite grain growth of a high-Nb X100 pipeline steel during a simulated welding heat cycle process. Mater Des, 2016, 89: 589 doi: 10.1016/j.matdes.2015.09.039 [75] Jiang B, Wu M, Sun H, et al. Prediction model of austenite growth and the role of MnS inclusions in non-quenched and tempered steel. Met Mater Int, 2018, 24(1): 15 doi: 10.1007/s12540-017-7012-2 [76] Liu H S, Dong Y N, Zheng H G, et al. Precipitation criterion for inhibiting austenite grain coarsening during carburization of Al-containing 20Cr gear steels. Metals, 2021, 11(3): 504 doi: 10.3390/met11030504 [77] Luo H Y, Cao J C, Zeng M, et al. Effect of Zr on deformed austenite recrystallization and precipitates in austenite in Ti-microalloyed low carbon steel. Chin J Mater Res, 2022, 36(2): 123羅瀚宇, 曹建春, 曾敏, 等. Zr對Ti微合金化低碳鋼形變奧氏體再結晶和析出相的影響. 材料研究學報, 2022, 36(2):123 [78] Yang L, Shao L, Qiao B, et al. The study on grain size of Nb gear steel. Automob Technol Mater, 2004(7): 5 doi: 10.3969/j.issn.1003-8817.2004.07.002楊林, 邵亮, 喬兵, 等. 含Nb齒輪鋼晶粒度研究. 汽車工藝與材料, 2004, (7):5 doi: 10.3969/j.issn.1003-8817.2004.07.002 [79] Liu Y B, Cui J Y, Tong Q, et al. Effect of Nb on grain coarsening behavior of 20CrMnTi steel during carburizing. Trans Mater Heat Treat, 2015, 36(1): 124 doi: 10.13289/j.issn.1009-6264.2015.01.025柳洋波, 崔京玉, 佟倩, 等. 鈮對20CrMnTi鋼滲碳過程中晶粒粗化行為的影響. 材料熱處理學報, 2015, 36(1):124 doi: 10.13289/j.issn.1009-6264.2015.01.025 [80] Dong D Q, Chen F, Cui Z S. Modeling of austenite grain growth during austenitization in a low alloy steel. J of Materi Eng and Perform, 2016, 25(1): 152 doi: 10.1007/s11665-015-1810-9 [81] Zhang L C, Wen X L, Liu Y Z. Effect of precipitates on austenite grain growth behavior in a low-carbon Nb–V microalloyed steel. Mater Sci Forum, 2017, 898: 783 doi: 10.4028/www.scientific.net/MSF.898.783 [82] Shen Q F, Wu S B. “Mixed crystal” analysis of 20CrMnTi. Mod Mach, 2011(3): 90 doi: 10.3969/j.issn.1002-6886.2011.03.032申群芳, 吳少斌. 20CrMnTi“混晶”分析. 現代機械, 2011(3):90 doi: 10.3969/j.issn.1002-6886.2011.03.032 [83] Gao Y A, Ye J Y, Wang Z Y, et al. The reason and elimination of mixed crystal structure in Cr4Mo4V steel ball quenching. Bearing, 2013(10): 40 doi: 10.3969/j.issn.1000-3762.2013.10.014高元安, 葉健熠, 王智勇, 等. Cr4Mo4V鋼球淬火產生混晶組織的原因與消除措施. 軸承, 2013(10):40 doi: 10.3969/j.issn.1000-3762.2013.10.014 [84] Song H G. Causes and elimination methods of mixed crystal of F91 steel. China Mel Bull, 2017(8): 71宋海剛. F91鋼的混晶原因以及消除方法. 中國金屬通報, 2017(8):71 [85] Liu X L, Ban J, Luo Y, et al. Experimental study on eliminating "mixed crystal" of 8Cr4Mo4V steel. Hot Working Process, 2018, 47(14): 165 doi: 10.14158/j.cnki.1001-3814.2018.14.043劉秀蓮, 班君, 羅燕, 等. 消除8Cr4Mo4V鋼“混晶”試驗研究. 熱加工工藝, 2018, 47(14):165 doi: 10.14158/j.cnki.1001-3814.2018.14.043 [86] Ye T Q, Yang G, Ma H C, et al. Effect of heat treatment process on austenite grain size of 16MnCrS5+H steel. Gansu Metallurgy, 2020, 42(5): 59 doi: 10.3969/j.issn.1672-4461.2020.05.016冶廷全, 楊國, 馬恒春, 等. 熱處理工藝對16MnCrS5+H鋼奧氏體晶粒度的影響. 甘肅冶金, 2020, 42(5):59 doi: 10.3969/j.issn.1672-4461.2020.05.016 [87] Huang D L, Wu X Y, Hou Q Y, et al. Effect of heating process on austenite grain size of 16MnCr5H steel. Heat Treat, 2022, 37(2): 46 doi: 10.3969/j.issn.1008-1690.2022.02.011黃道龍, 吳翔云, 侯清宇, 等. 加熱工藝對16MnCr5H鋼奧氏體晶粒度的影響. 熱處理, 2022, 37(2):46 doi: 10.3969/j.issn.1008-1690.2022.02.011 -

下載:

下載: