-

摘要: 近年來,微生物誘導碳酸鈣沉積技術(MICP)成為巖土工程領域的熱點方向,其中島礁背景下的MICP加固技術更是具有廣闊前景。本文系統總結了微生物礦化作用基本原理以及島礁工程建設中的MICP技術最新進展,得出了以下結論:MICP反應產物是碳酸鈣,與鈣質砂成分相同,滿足島礁生態需求;島礁溫度、pH條件適宜MICP反應,仍需深入研究輻射、波流條件等島礁特殊環境因素對MICP反應的影響;島礁微生物技術能大幅提升鈣質地層強度、剛度、樁基承載力、岸坡抗波流侵蝕能力,對于固島強島意義重大,需進一步通過現場原位加固試驗驗證該技術在島礁環境下的適用性。目前,MICP數值模型研究尚處于起步階段,主要通過單元試驗、模型試驗驗證,需開發可考慮島礁環境(溫度、pH、波流等)的MICP多過程數值理論模型,基于現場原位尺度試驗驗證其準確性。研究工作可為島礁環境下的MICP加固提供參考。Abstract: Being an environmentally friendly technology, Microbially Induced Calcium Carbonate Precipitation (MICP) has become a popular research topic in the field of geotechnical and environmental engineering, among which island microbial technology is a promising direction. This paper systematically summarizes the basic principles of microbial mineralization and the progress made in the use of MICP in construction work done on islands, such as the reinforcement of calcareous sand, protection of island slopes from erosion, and reinforcement of pile foundations, and the numerical modeling performed in island engineering. The following conclusions can be drawn: MICP produces calcium carbonate, which is the same as calcareous sand, and thus MICP can be used to meet the ecological reinforcement requirements of islands. The temperature and soil pH of the islands are suitable for MICP. Urease activity in soil nonlinearly increases as environmental temperature increases in the range from 5 ℃ to 40 ℃, and the soil pH influences pore solution concentrations, which in turn affects the deposition rate, yield, and morphology of calcium carbonate. The optimal pH value required for the mineralization caused by Sporosarcina pasteurii is approximately 9. However, the influence of the special environmental characteristics of islands, such as radiation, waves and currents, on MICP requires further study. Island microbial technology can be used to greatly enhance the strength and stiffness of calcareous sand in islands, the bearing capacity of pile foundations constructed in islands, and the erosion resistance of island slopes against waves and currents. The verification of the applicability of MICP in an island environment and the determination of the efficiency of bacterial urease activity, morphology and deposition rate of calcium carbonate in calcareous sand, physical and mechanical properties and uniformity of cemented calcareous sand layers in that environment require in-situ reinforcement tests. Most of the previous research on MICP is laboratory experiments. The spatiotemporal evolutions of the chemical substances used in various processes of MICP cannot be determined in real-time. The labor and other resources used in field experiments, which are highly dependent on field conditions, are expensive. Therefore, a reliable numerical model is highly important to understand the biochemical processes associated with MICP. However, research on MICP numerical models is still in its infancy, and currently, the MICP models are verified mainly using element and model tests. The development of a numerical model for the multiple processes of MICP suitable for the environmental conditions, such as temperature, soil pH, waves, and currents, of an island and verification of the accuracy of the model based on in situ reinforcement tests is extremely important. The findings can provide a reference for soil reinforcement in an island environment using MICP.

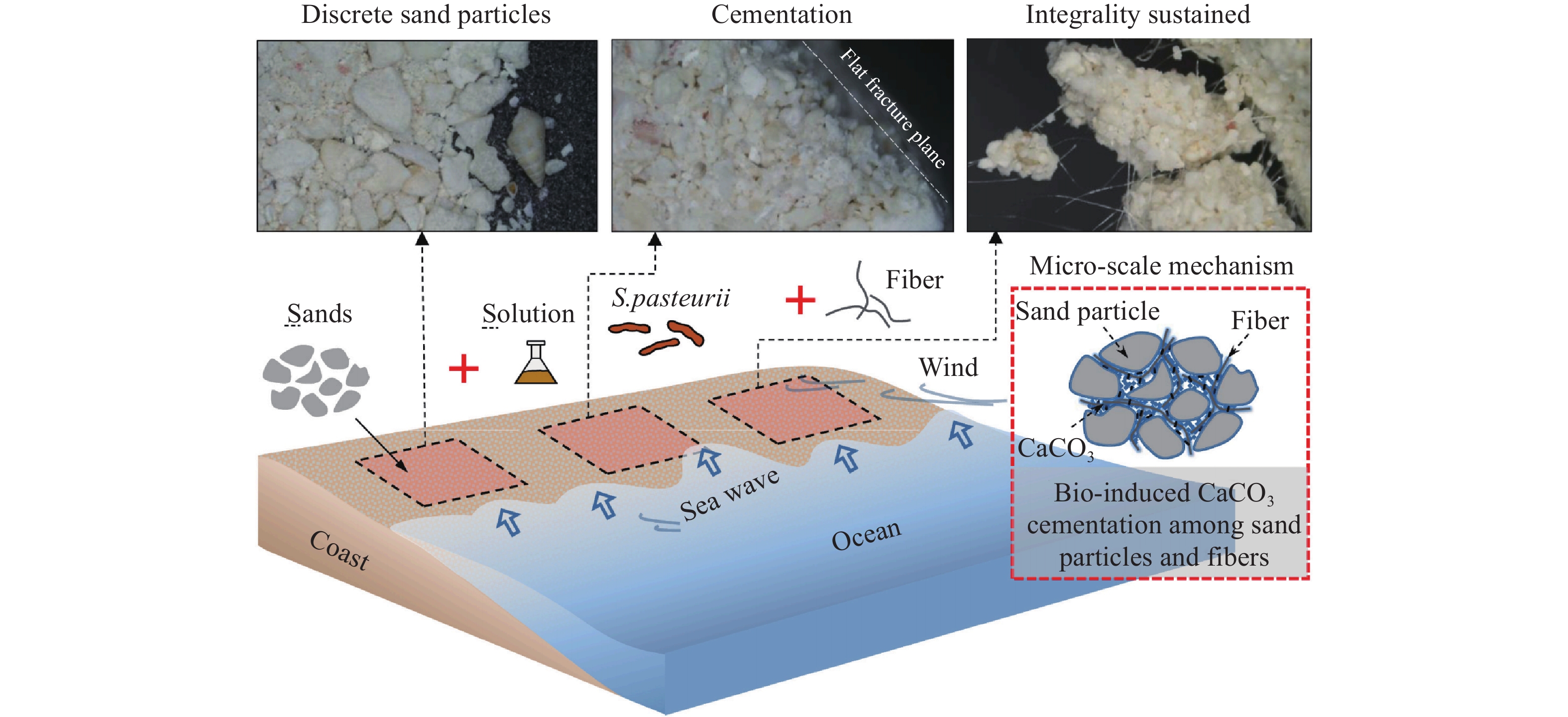

-

Key words:

- island construction /

- MICP /

- calcareous sand /

- island environment /

- ground reinforcement /

- numerical model

-

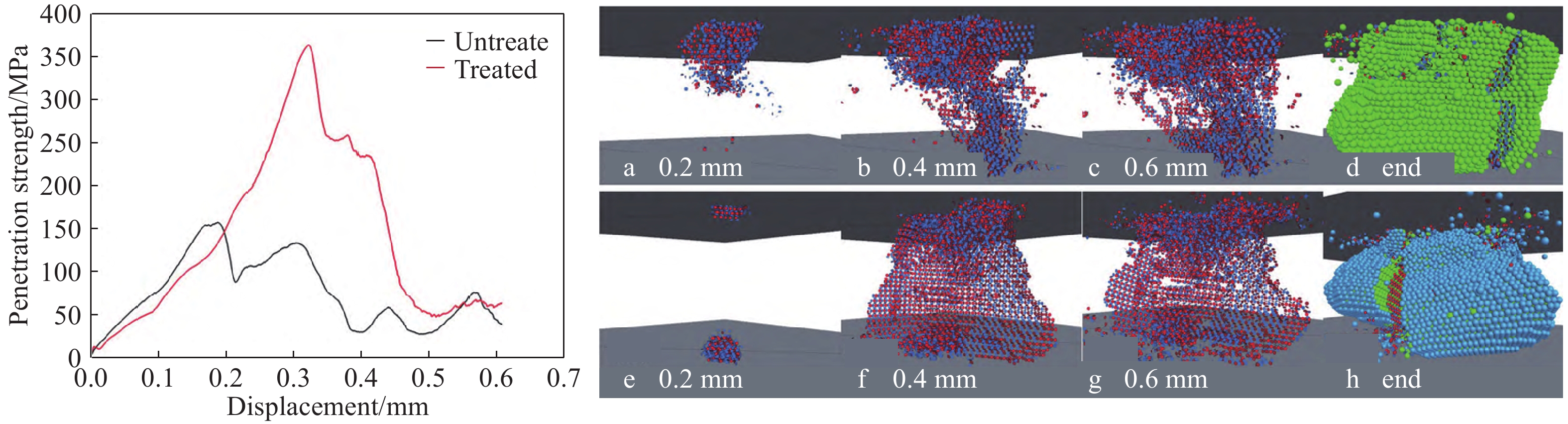

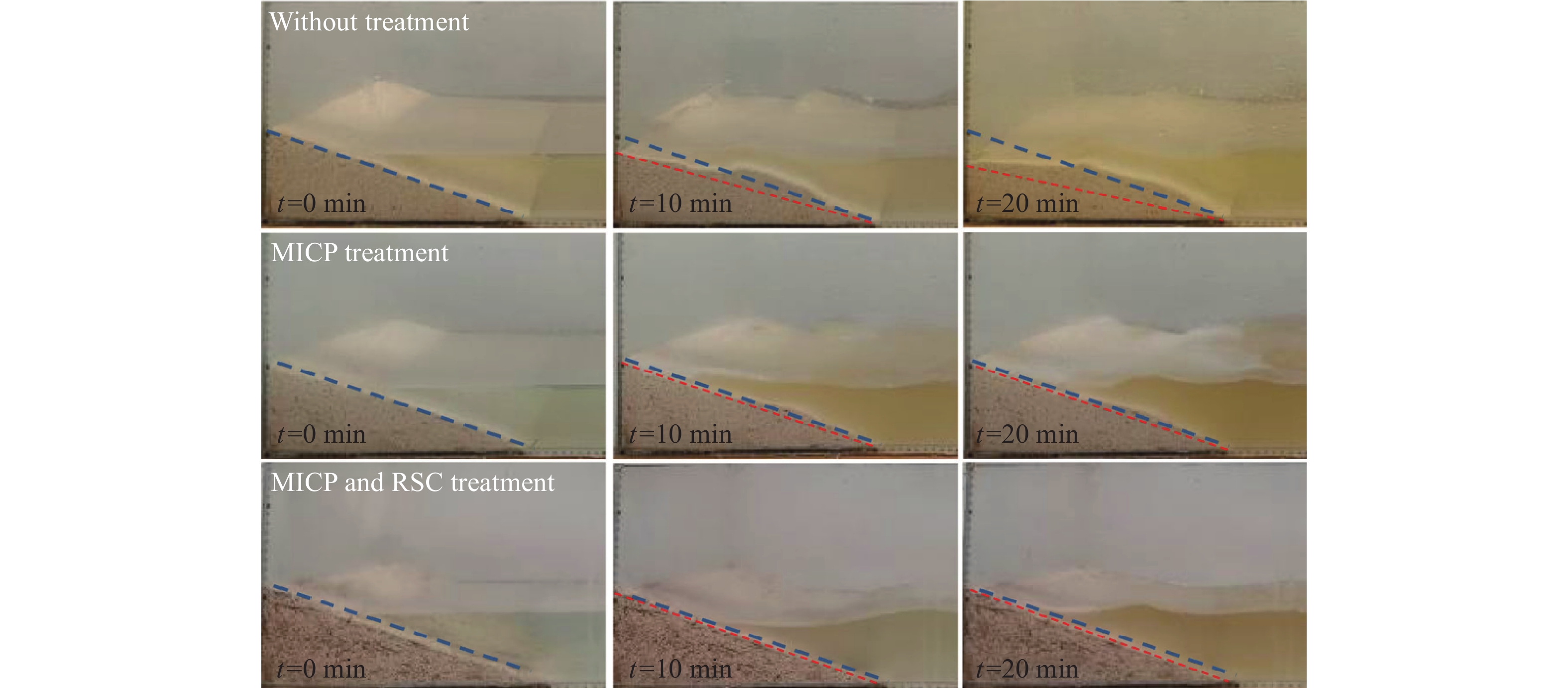

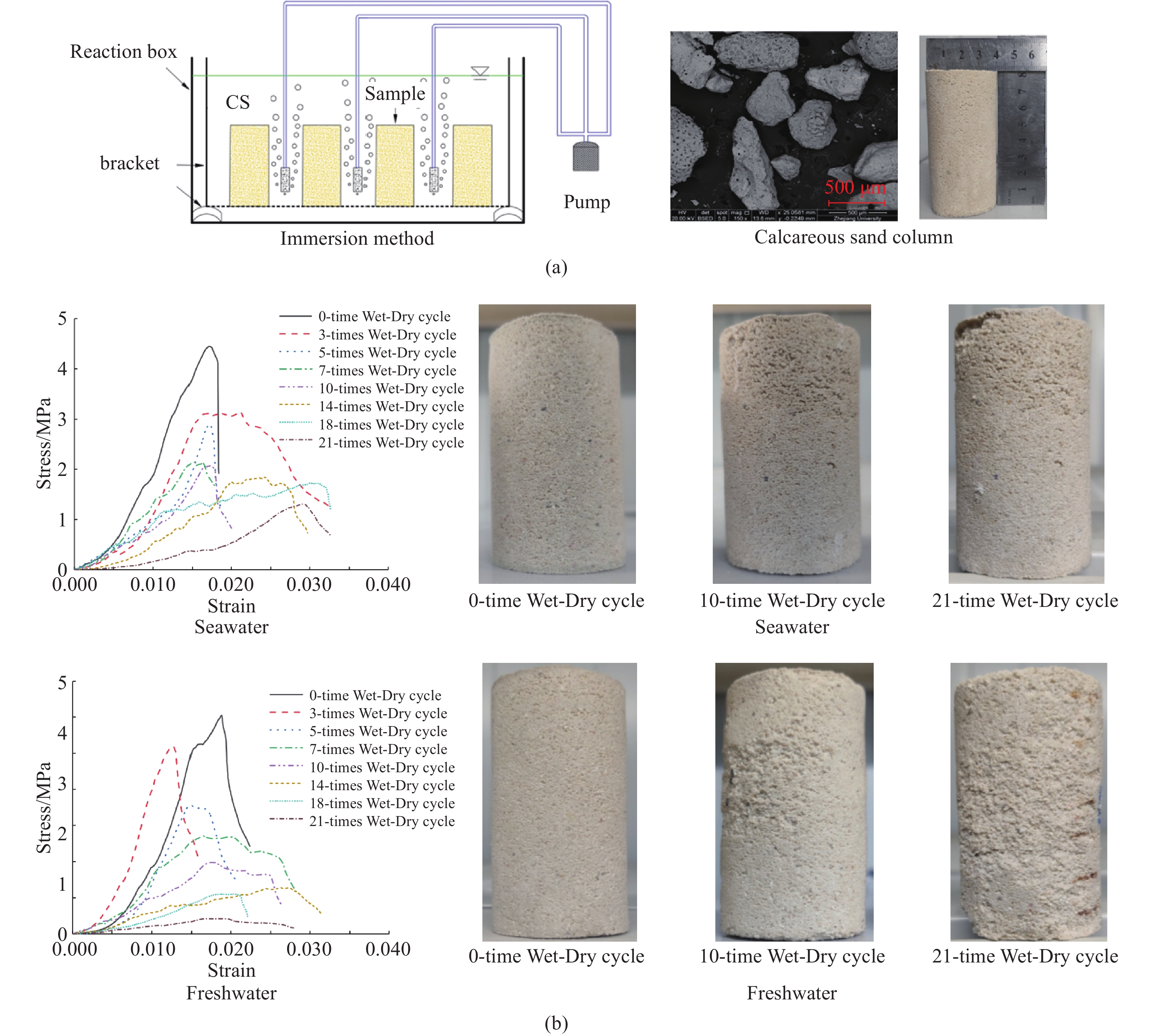

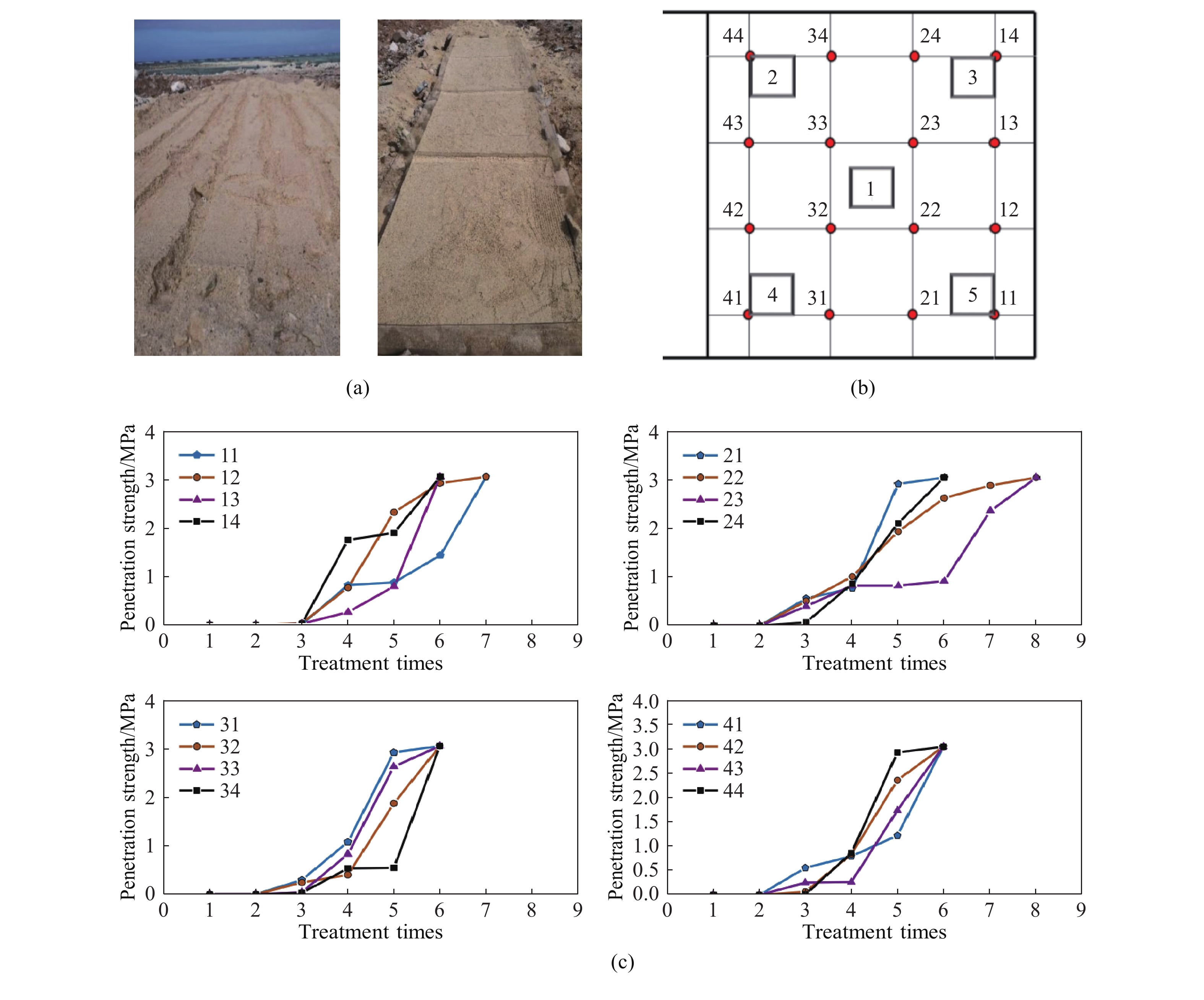

圖 1 島礁地層MICP現場加固試驗[19]. (a) 島礁現場試驗照片; (b) 貫入強度測點; (c) 鈣質砂地層貫入強度與處理次數之間的關系

Figure 1. MICP field reinforcement test of island formations[19]: (a) island field test image; (b) measuring points of the penetration strength; (c) relationship between the penetration strength of the calcareous sand formation and number of treatments

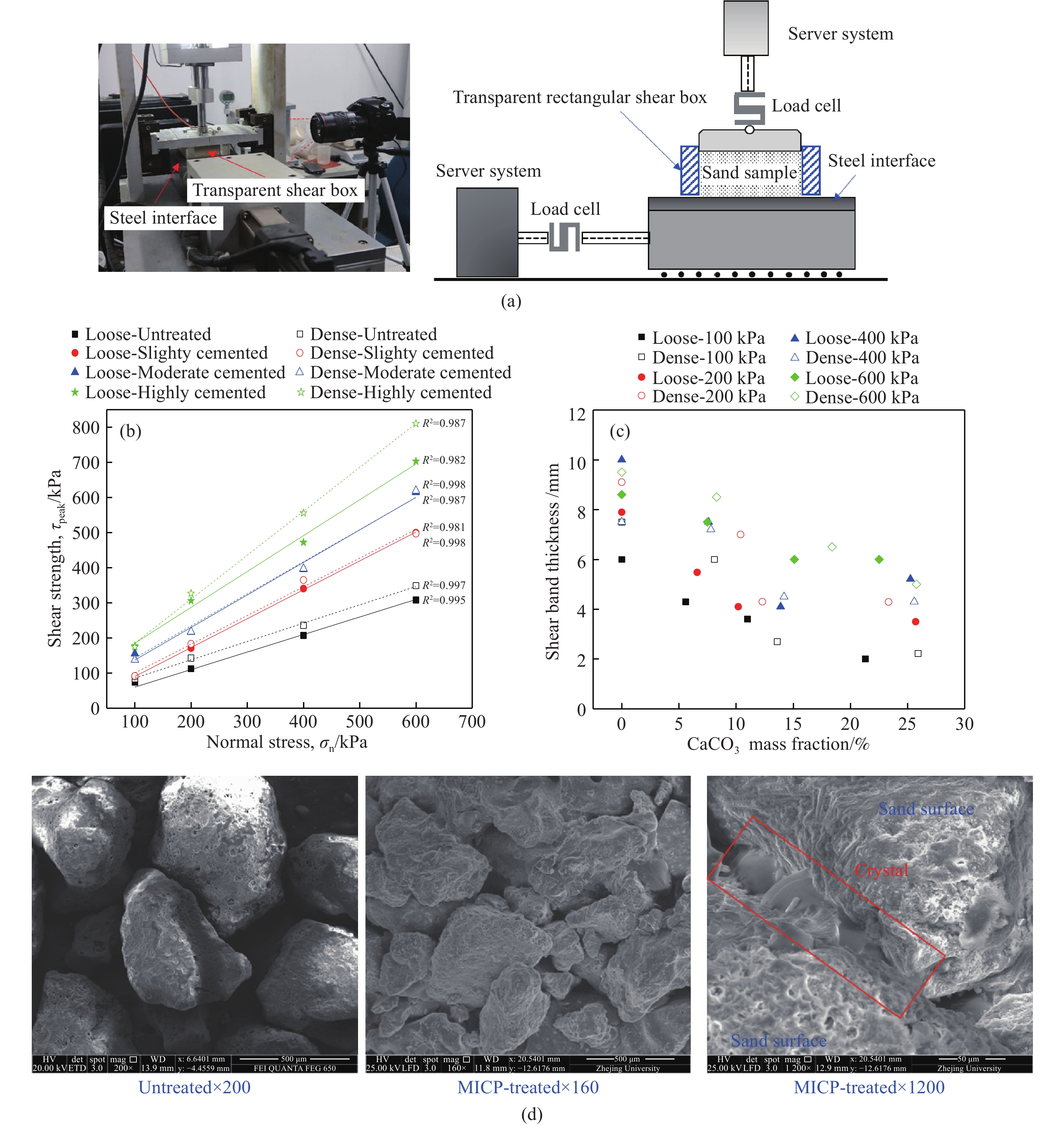

圖 4 MICP加固界面剪切試驗結果[33]. (a) 多功能界面剪切設備; (b) MICP膠結界面摩爾庫倫強度規律;(c) MICP膠結界面剪切帶厚度與碳酸鈣含量之間的關系; (d) MICP膠結機理(放大200、160、1200倍)

Figure 4. Interface shear test results for MICP reinforcement[33]: (a) multifunctional interface shear device; (b) molar Coulomb strength law of the MICP cemented interface; (c) the relationship between the shear band thickness and the calcium carbonate content at the MICP cemented interface; (d) MICP cementing mechanism (magnify 200, 160, 1200 times)

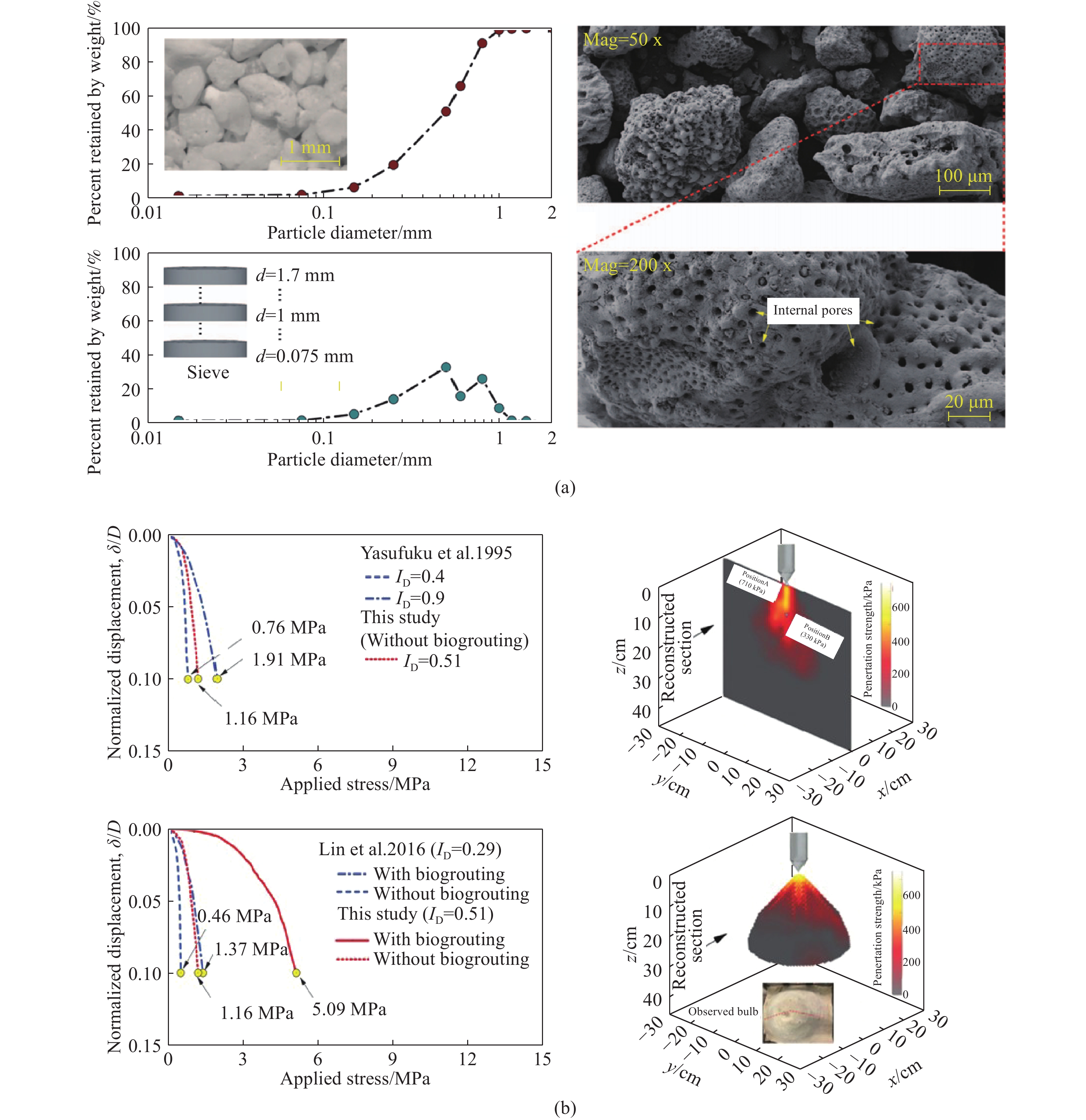

圖 5 MICP加固鈣質地層中樁基試驗結果[37]. (a) 鈣質砂級配與微觀形貌(d代表顆粒粒徑); (b) 樁基承載特性與貫入強度分布(δ,D和ID分別代表樁頂位移、模型樁樁徑和鈣質砂土相對密實度)

Figure 5. Test results of MICP reinforced pile foundation in calcareous sand formation[37]: (a) gradation distribution and microscopic morphology of the calcareous sand (d represents the particle size); (b) bearing characteristics of pile foundation and distribution of penetration strength (δ, D and ID represent the displacement of the pile top, the diameter of the model pile and the relative density of the calcareous sand, respectively)

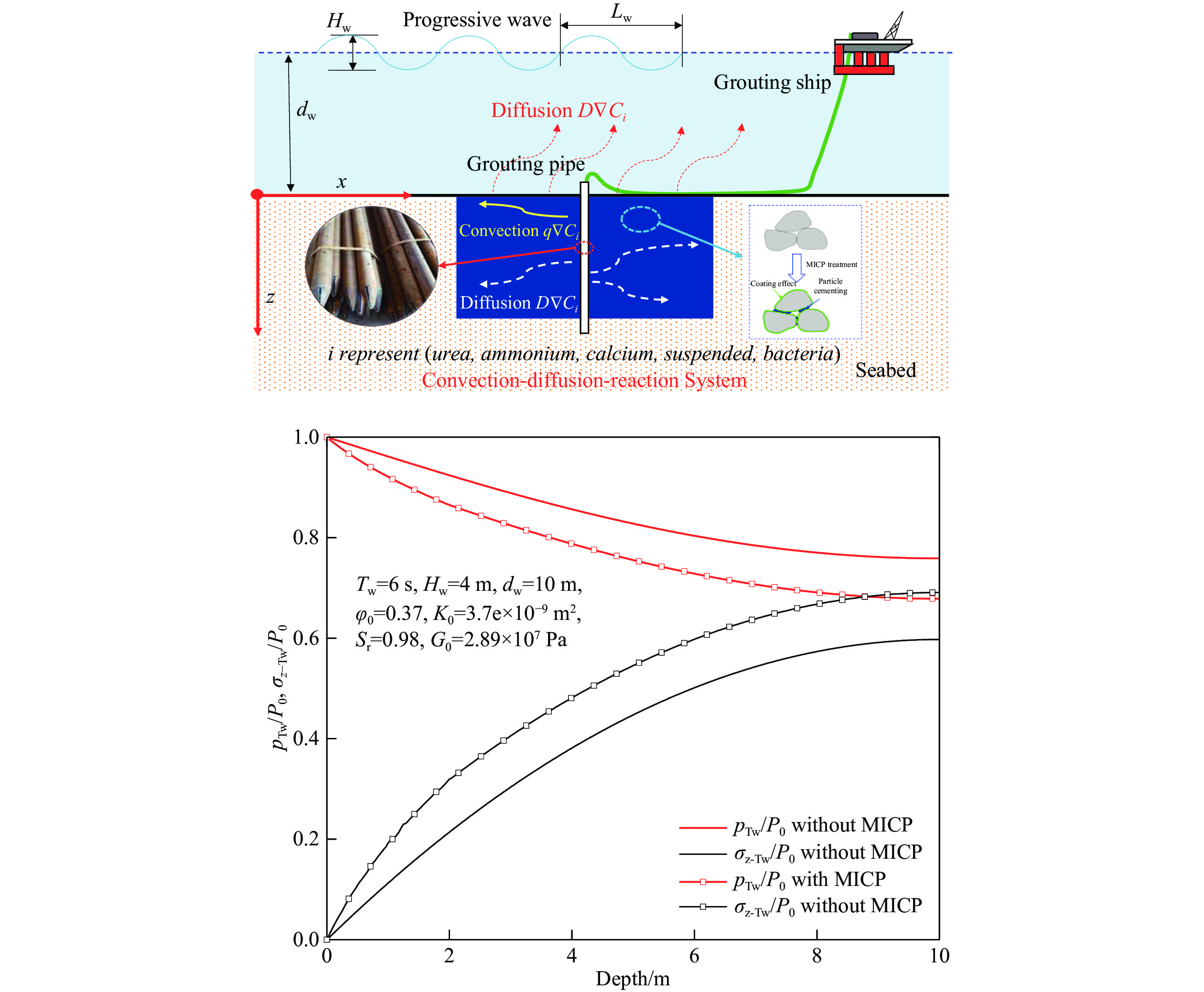

圖 9 考慮波浪作用的MICP加固海床與響應(其中pTw/P0和σz-Tw/P0分別代表一個波浪周期內超孔壓幅值、豎向有效應力幅值與海床表面波壓力P0之比)

Figure 9. Seabed reinforcement by MICP and the dynamic response with the consideration of the waves (pTw/P0 and σ,z-Tw/P0 represent the ratio of excess pore pressure amplitude, vertical effective stress amplitude to the wave pressure at the seabed surface P0)

www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Wu Y, Li N, Wang X Z, et al. Experimental investigation on mechanical behavior and particle crushing of calcareous sand retrieved from South China Sea. Eng Geol, 2021, 280: 105932 doi: 10.1016/j.enggeo.2020.105932 [2] Wang X Z, Jiao Y Y, Wang R, et al. Engineering characteristics of the calcareous sand in Nansha Islands, South China Sea. Eng Geol, 2011, 120(1-4): 40 doi: 10.1016/j.enggeo.2011.03.011 [3] DeJong J T, Mortensen B M, Martinez B C, et al. Bio-mediated soil improvement. Ecol Eng, 2010, 36(2): 197 doi: 10.1016/j.ecoleng.2008.12.029 [4] Martinez B C, DeJong J T, Ginn T R, et al. Experimental optimization of microbial-induced carbonate precipitation for soil improvement. J Geotech Geoenviron Eng, 2013, 139(4): 587 doi: 10.1061/(ASCE)GT.1943-5606.0000787 [5] Al Qabany A, Soga K, Santamarina C. Factors affecting efficiency of microbially induced calcite precipitation. J Geotech Geoenviron Eng, 2012, 138(8): 992 doi: 10.1061/(ASCE)GT.1943-5606.0000666 [6] van Paassen L A, Daza C M, Staal M, et al. Potential soil reinforcement by biological denitrification. Ecol Eng, 2010, 36(2): 168 doi: 10.1016/j.ecoleng.2009.03.026 [7] O’Donnell S T, Kavazanjian E Jr, Rittmann B E. MIDP: Liquefaction mitigation via microbial denitrification as a two-stage process. II: MICP. J Geotech Geoenviron Eng, 2017, 143(12): 04017095 [8] Gao X Y. Study on the Technology of Solidifying Coral Sand with Struvite Induced by Microorganisms in High Salt Environment [Dissertation]. Quanzhou: Huaqiao University, 2020高歆雨. 高鹽環境下微生物誘導鳥糞石固化珊瑚砂技術研究[學位論文]. 泉州: 華僑大學, 2020 [9] Yu X N, Qian C X, Xue B. Loose sand particles cemented by different bio-phosphate and carbonate composite cement. Constr Build Mater, 2016, 113: 571 doi: 10.1016/j.conbuildmat.2016.03.105 [10] Boquet E, Boronat A, Ramos-Cormenzana A. Production of calcite (calcium carbonate) crystals by soil bacteria is a general phenomenon. Nature, 1973, 246(5434): 527 doi: 10.1038/246527a0 [11] Whiffin V S. Microbial CaCO3 Precipitation for the Production of Biocement [Dissertation]. Perth: Murdoch University, 2004 [12] van Paassen L A. Bio-mediated ground improvement: From laboratory experiment to pilot applications // Geo-Frontiers Congress 2011. Dallas, 2011: 4099 [13] Fang X W, Li J X, Li J, et al. Damage constitutive model of biocemented coral sand columns under unconfined compression. Chin J Undergr Space Eng, 2018, 14(5): 1234方祥位, 李晶鑫, 李捷, 等. 珊瑚砂微生物固化體單軸損傷本構模型. 地下空間與工程學報, 2018, 14(5):1234 [14] Fang X W, Li J X, Li J, et al. Study of triaxial compression test and damage constitutive model of biocemented coral sand columns. Rock Soil Mech, 2018, 39(Suppl 1): 1 doi: 10.16285/j.rsm.2017.2101方祥位, 李晶鑫, 李捷, 等. 珊瑚砂微生物固化體三軸壓縮試驗及損傷本構模型研究. 巖土力學, 2018, 39(Suppl 1):1 doi: 10.16285/j.rsm.2017.2101 [15] Ou Y X, Fang X W, Shen C N, et al. Influence of particle sizes of coral sand on bio-cementation. J Water Resour Archit Eng, 2016, 14(2): 35 doi: 10.3969/j.issn.1672-1144.2016.02.007歐益希, 方祥位, 申春妮, 等. 顆粒粒徑對微生物固化珊瑚砂的影響. 水利與建筑工程學報, 2016, 14(2):35 doi: 10.3969/j.issn.1672-1144.2016.02.007 [16] Li J, Fang X W, Shen C N, et al. Influence of grain composition on coral sand bio-cementation. J Water Resour Archit Eng, 2016, 14(6): 7 doi: 10.3969/j.issn.1672-1144.2016.06.002李捷, 方祥位, 申春妮, 等. 顆粒級配對珊瑚砂微生物固化影響研究. 水利與建筑工程學報, 2016, 14(6):7 doi: 10.3969/j.issn.1672-1144.2016.06.002 [17] Guo H X, Li D R, Ma R N, et al. Oedometer test of calcareous sands solidified using the MICP mixing method. J Tsinghua Univ (Sci Technol) , 2019, 59(8): 593 doi: 10.16511/j.cnki.qhdxxb.2019.21.018郭紅仙, 李東潤, 馬瑞男, 等. MICP拌和固化鈣質砂一維固結試驗. 清華大學學報(自然科學版), 2019, 59(8):593 doi: 10.16511/j.cnki.qhdxxb.2019.21.018 [18] Khan M N H, Amarakoon G G N N, Shimazaki S, et al. Coral sand solidification test based on microbially induced carbonate precipitation using ureolytic bacteria. Mater Trans, 2015, 56(10): 1725 doi: 10.2320/matertrans.M-M2015820 [19] Liu H L, Ma G L, Xiao Y, et al. In situ experimental research on calcareous foundation stabilization using MICP technique on the reclaimed coral reef islands. J Ground Improv, 2019, 1(1): 26劉漢龍, 馬國梁, 肖楊, 等. 微生物加固島礁地基現場試驗研究. 地基處理, 2019, 1(1):26 [20] Li Y Y, Fang X W, Ou Y X, et al. Impacts of different substrate solution ratio in biocementation of coral sand. J Water Resour Archit Eng, 2017, 15(6): 52 doi: 10.3969/j.issn.1672-1144.2017.06.011李洋洋, 方祥位, 歐益希, 等. 底物溶液配比對微生物固化珊瑚砂的影響研究. 水利與建筑工程學報, 2017, 15(6):52 doi: 10.3969/j.issn.1672-1144.2017.06.011 [21] Ou Y X, Fang X W, Zhang N, et al. Influence of solution salinity on microbial biocementation of coral sand. J Logist Eng Univ, 2016, 32(1): 78 doi: 10.3969/j.issn.1672-7843.2016.01.015歐益希, 方祥位, 張楠, 等. 溶液鹽度對微生物固化珊瑚砂的影響. 后勤工程學院學報, 2016, 32(1):78 doi: 10.3969/j.issn.1672-7843.2016.01.015 [22] Li H, Tang C S, Liu B, et al. Mechanical behavior of MICP-cemented calcareous sand in simulated seawater environment. Chin J Geotech Eng, 2020, 42(10): 1931李昊, 唐朝生, 劉博, 等. 模擬海水環境下MICP固化鈣質砂的力學特性. 巖土工程學報, 2020, 42(10):1931 [23] Liu Y, Zhang Y L, Hu J N, et al. MICP-cemented coastal fine sand in simulated seawater environment. Nat Sci J Hainan Univ, 2021, 39(4): 390 doi: 10.15886/j.cnki.hdxbzkb.2021.0049劉淵, 張友良, 胡晉寧, 等. 模擬海水環境下MICP固化濱海粉細砂的試驗研究. 海南大學學報(自然科學版), 2021, 39(4):390 doi: 10.15886/j.cnki.hdxbzkb.2021.0049 [24] Xiao Y, Deng H F, Li J L, et al. Study on the domestication of Sporosarcina pasteurii and strengthening effect of calcareous sand in seawater environment. Rock Soil Mech, 2022, 43(2): 395肖瑤, 鄧華鋒, 李建林, 等. 海水環境下巴氏芽孢桿菌馴化及鈣質砂固化效果研究. 巖土力學, 2022, 43(2):395 [25] Dong B W, Liu S Y, Yu J, et al. Evaluation of the effect of natural seawater strengthening calcareous sand based on MICP. Rock Soil Mech, 2021, 42(4): 1104董博文, 劉士雨, 俞縉, 等. 基于微生物誘導碳酸鈣沉淀的天然海水加固鈣質砂效果評價. 巖土力學, 2021, 42(4):1104 [26] Xiao P. Study on Dynamic and Liquefaction Charcteristics of Temperature Controlled MICP-Treated Calcareous Sand [Dissertation]. Chongqing: Chongqing University, 2020肖鵬. 微生物溫控加固鈣質砂動力與液化特性研究[學位論文]. 重慶: 重慶大學, 2020 [27] Shen J W, Zhou B, Zhang X, et al. Study on the effect of MICP on the crushing behavior of calcareous sand particles. Geol J China Univ, 2021, 27(6): 655 doi: 10.16108/j.issn1006-7493.2020056申嘉偉, 周博, 張星, 等. MICP對鈣質砂單顆粒的破碎行為影響研究. 高校地質學報, 2021, 27(6):655 doi: 10.16108/j.issn1006-7493.2020056 [28] Wang Y J, Jiang N J. Direct shear and compressibility behavior of bio-stimulated MICP treated calcareous sand. Geol J China Univ, 2021, 27(6): 662 doi: 10.16108/j.issn1006-7493.2020094王逸杰, 蔣寧俊. 原位激發微生物成礦加固鈣質砂的剪切與壓縮特性研究. 高校地質學報, 2021, 27(6):662 doi: 10.16108/j.issn1006-7493.2020094 [29] Yin L Y. Experimental Study on the Mechanical Behavior of Fiber Reinforcement Calcareous Sand Cemented by MICP Technology [Dissertation]. Nanjing: Nanjing University, 2019尹黎陽. 基于微生物誘導碳酸鈣沉淀技術固化纖維加筋鈣質砂的力學性能研究[學位論文]. 南京: 南京大學, 2019 [30] Lin S Q, Lei X W, Meng Q S, et al. Influence of fiber contents on dynamic behavior of MICP-treated calcareous sand. Yangtze River, 2020, 51(7): 181 doi: 10.16232/j.cnki.1001-4179.2020.07.031林勝強, 雷學文, 孟慶山, 等. 纖維摻量對MICP固化鈣質砂動力特性的影響. 人民長江, 2020, 51(7):181 doi: 10.16232/j.cnki.1001-4179.2020.07.031 [31] Zhao J T, Tong H W, Shan Y, et al. Effects of different types of fibers on the physical and mechanical properties of MICP-treated calcareous sand. Materials, 2021, 14(2): 268 doi: 10.3390/ma14020268 [32] Zeng H, Yin L Y, Tang C S, et al. Tensile behavior of bio-cemented, fiber-reinforced calcareous sand from coastal zone. Eng Geol, 2021, 294: 106390 doi: 10.1016/j.enggeo.2021.106390 [33] Li Y J, Guo Z, Wang L Z, et al. Interface shear behavior between MICP-treated calcareous sand and steel. J Mater Civ Eng, 2021, 33(2): 04020455 doi: 10.1061/(ASCE)MT.1943-5533.0003549 [34] Li Y J, Guo Z, Wang L Z, et al. Shear resistance of MICP cementing material at the interface between calcareous sand and steel. Mater Lett, 2020, 274: 128009 doi: 10.1016/j.matlet.2020.128009 [35] Lin H, Suleiman M, Jabbour H, et al. Enhancing the axial compression response of pervious concrete ground improvement piles using biogrouting. J Geotech Geoenvironmental Eng, 2016, 142(10): 04016045 doi: 10.1061/(ASCE)GT.1943-5606.0001515 [36] Lin H, Suleiman M, Jabbour H, et al. Bio-grouting to enhance axial pull-out response of pervious concrete ground improvement piles. Can Geotech J, 2017, 55(4): 1 [37] Xiao Y, Stuedlein A, Pan Z Y, et al. Toe bearing capacity of precast concrete piles through biogrouting improvement. J Geotech Geoenvironmental Eng, 2020, 146(12): 06020026 doi: 10.1061/(ASCE)GT.1943-5606.0002404 [38] Tao J L, Li J H, Wang X R, et al. Nature-inspired bridge scour countermeasures: Streamlining and biocementation. J Test Eval, 2018, 46(4): 20170517 doi: 10.1520/JTE20170517 [39] Montoya B M, Do J, Gabr M A. Distribution and properties of microbially induced carbonate precipitation in underwater sand bed. J Geotech Geoenviron Eng, 2021, 147(10): 04021098 doi: 10.1061/(ASCE)GT.1943-5606.0002607 [40] Li Y J, Guo Z, Wang L Z, et al. An innovative eco-friendly method for scour protection around monopile foundation. Appl Ocean Res, 2022, 123: 103177 doi: 10.1016/j.apor.2022.103177 [41] Kou H L, Wu C Z, Ni P P, et al. Assessment of erosion resistance of biocemented sandy slope subjected to wave actions. Appl Ocean Res, 2020, 105: 102401 doi: 10.1016/j.apor.2020.102401 [42] Salifu E, MacLachlan E, Iyer K R, et al. Application of microbially induced calcite precipitation in erosion mitigation and stabilisation of sandy soil foreshore slopes: A preliminary investigation. Eng Geol, 2016, 201: 96 doi: 10.1016/j.enggeo.2015.12.027 [43] Kou H L, Liu J H, Zhang P, et al. Ecofriendly improvement of coastal calcareous sandy slope using recycled shredded coconut coir (RSC) and bio-cement. Acta Geotech, 2022: 1 [44] Li Y L, Guo Z, Xu Q, et al. Experimental research on wet-dry cycle of MICP cemented calcareous sand in seawater environment. J Zhejiang Univ (Eng Sci) , 2022, 56(9): 1740 doi: 10.3785/j.issn.1008-973X.2022.09.007李藝隆, 國振, 徐強, 等. 海水環境下MICP膠結鈣質砂干濕循環試驗研究. 浙江大學學報(工學版), 2022, 56(9):1740 doi: 10.3785/j.issn.1008-973X.2022.09.007 [45] Martinez B C, DeJong J T, Ginn T R. Bio-geochemical reactive transport modeling of microbial induced calcite precipitation to predict the treatment of sand in one-dimensional flow. Comput Geotech, 2014, 58: 1 doi: 10.1016/j.compgeo.2014.01.013 [46] Fauriel S, Laloui L. A bio-chemo-hydro-mechanical model for microbially induced calcite precipitation in soils. Comput Geotech, 2012, 46: 104 doi: 10.1016/j.compgeo.2012.05.017 [47] Wang X R, Nackenhorst U. A coupled bio-chemo-hydraulic model to predict porosity and permeability reduction during microbially induced calcite precipitation. Adv Water Resour, 2020, 140: 103563 doi: 10.1016/j.advwatres.2020.103563 [48] Tang C S, Pan X H, Lyu C, et al. Bio-geoengineering technology and the applications. Geol J China Univ, 2021, 27(6): 625 doi: 10.16108/j.issn1006-7493.2021011唐朝生, 泮曉華, 呂超, 等. 微生物地質工程技術及其應用. 高校地質學報, 2021, 27(6):625 doi: 10.16108/j.issn1006-7493.2021011 [49] Yin L Y, Tang C S, Xie Y H, et al. Factors affecting improvement in engineering properties of geomaterials by microbial-induced calcite precipitation. Rock Soil Mech, 2019, 40(7): 2525 doi: 10.16285/j.rsm.2018.0520尹黎陽, 唐朝生, 謝約翰, 等. 微生物礦化作用改善巖土材料性能的影響因素. 巖土力學, 2019, 40(7):2525 doi: 10.16285/j.rsm.2018.0520 [50] Peng J, Feng Q P, Sun Y C. Influences of temperatures on MICP-treated soils. Chin J Geotech Eng, 2018, 40(6): 1048 doi: 10.11779/CJGE201806010彭劼, 馮清鵬, 孫益成. 溫度對微生物誘導碳酸鈣沉積加固砂土的影響研究. 巖土工程學報, 2018, 40(6):1048 doi: 10.11779/CJGE201806010 [51] van Paassen L A V. Biogrout, Ground Improvement by Microbial Induced Carbonate Precipitation [Dissertation]. Delft: Delft University of Technology, 2009 [52] Cheng L, Shahin M A, Cord-Ruwisch R, et al. Soil stabilisation by microbial-induced calcite precipitation (MICP): investigation into some physical and environmental aspects // 7th International Congress on Environmental Geotechnics. Melbourne, 2014, 64(12): 1105 [53] Keykha H A, Asadi A, Zareian M. Environmental factors affecting the compressive strength of microbiologically induced calcite precipitation-treated soil. Geomicrobiol J, 2017, 34(10): 889 doi: 10.1080/01490451.2017.1291772 [54] Cheng L, Shahin M A, Chu J. Soil bio-cementation using a new one-phase low-pH injection method. Acta Geotech, 2019, 14(3): 615 doi: 10.1007/s11440-018-0738-2 -

下載:

下載: