| [1] |

Zhao Y, Zhao T F, Zhang J H, et al. Research progress of refractories for alkali-containing waste liquid incinerator. China Special Equip Saf, 2020, 36(11): 15趙瑩, 趙騰飛, 張家赫, 等. 含堿廢液焚燒爐耐火材料研究進展. 中國特種設備安全, 2020, 36(11):15

|

| [2] |

Wang S N. Progress in treatment and research of high-salt organic wastewater. Chem Eng Des Commun, 2019, 45(12): 239王勝南. 高鹽有機廢水的處理與研究進展. 化工設計通訊, 2019, 45(12):239

|

| [3] |

Cao M L, Li H, Liu F C, et al. Recent development in the treatment process for high salt organic wastewater. Nonferrous Met Sci Eng, 2019, 10(3): 92曹美玲, 李海, 劉佛財, 等. 高鹽有機廢水的處理與研究進展. 有色金屬科學與工程, 2019, 10(3):92

|

| [4] |

Ghazi N M, Lastra A A, Watts M J. Hydroxyl radical (OH) scavenging in young and mature landfill leachates. Water Res, 2014, 56: 148 doi: 10.1016/j.watres.2014.03.001

|

| [5] |

Miao S H, Kong F R, Lai J Y. Reformation and practice of harmless treatment of organic waste liquid from chemical production. Chem Enterp Manag, 2021(27): 30繆樹輝, 孔繁榮, 來繼云. 化工生產有機廢液無害化處理的改造與實踐. 化工管理, 2021(27):30

|

| [6] |

Wang J L, Chen G F, Liu F X, et al. Efficiency of ozonation combined with cultivation of vallisneria natans removing organic substances in piggery wastewater. J Ecol Rural Environ, 2017, 33(1): 84王俊力, 陳桂發, 劉福興, 等. 臭氧氧化-苦草深度處理對豬場尾水中有機物的去除效果. 生態與農村環境學報, 2017, 33(1):84

|

| [7] |

Tan C Z, Yang Z C. Extraction Chemistry. Guilin: Guangxi Normal University Press, 1991覃誠真, 楊子超. 萃取化學. 桂林: 廣西師范大學出版社, 1991

|

| [8] |

Chen H, Zhang F, Wang Z Z, et al. Study on treatment of wastewater with high salinity. Guangzhou Chem Ind, 2017, 45(22): 17陳浩, 張楓, 王中正, 等. 高鹽廢水處理技術研究進展. 廣州化工, 2017, 45(22):17

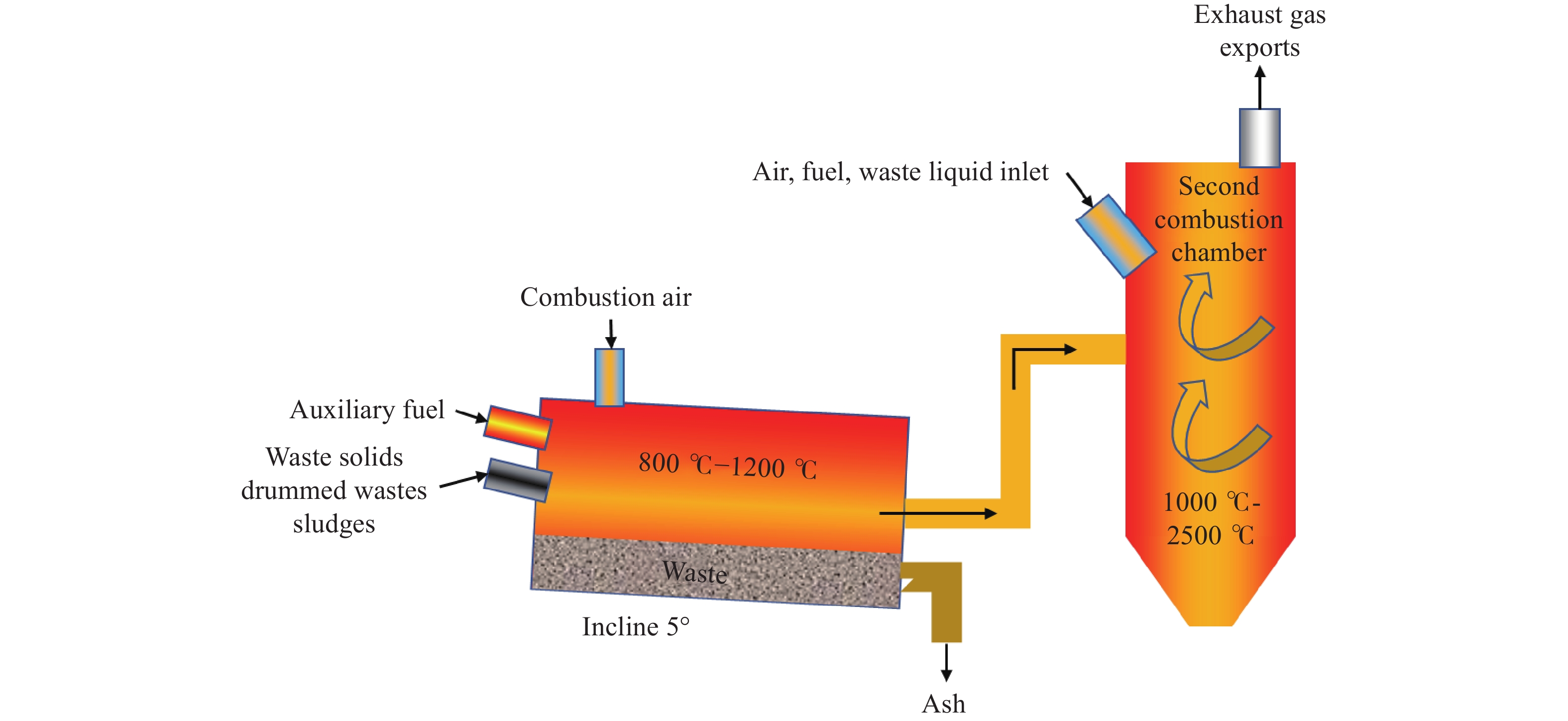

|

| [9] |

Yankov D, Molinier J, Albet J, et al. Lactic acid extraction from aqueous solutions with tri-n-octylamine dissolved in decanol and dodecane. Biochem Eng J, 2004, 21(1): 63 doi: 10.1016/j.bej.2004.03.006

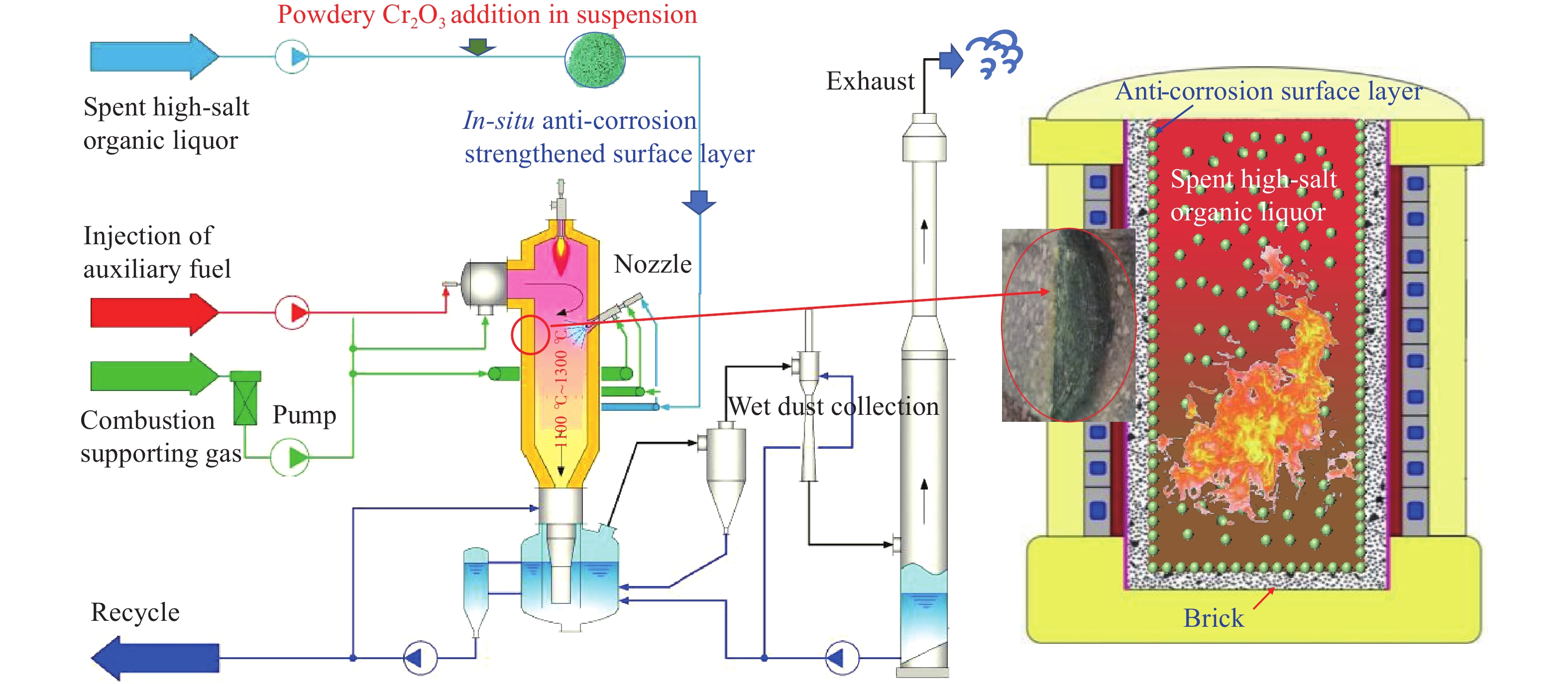

|

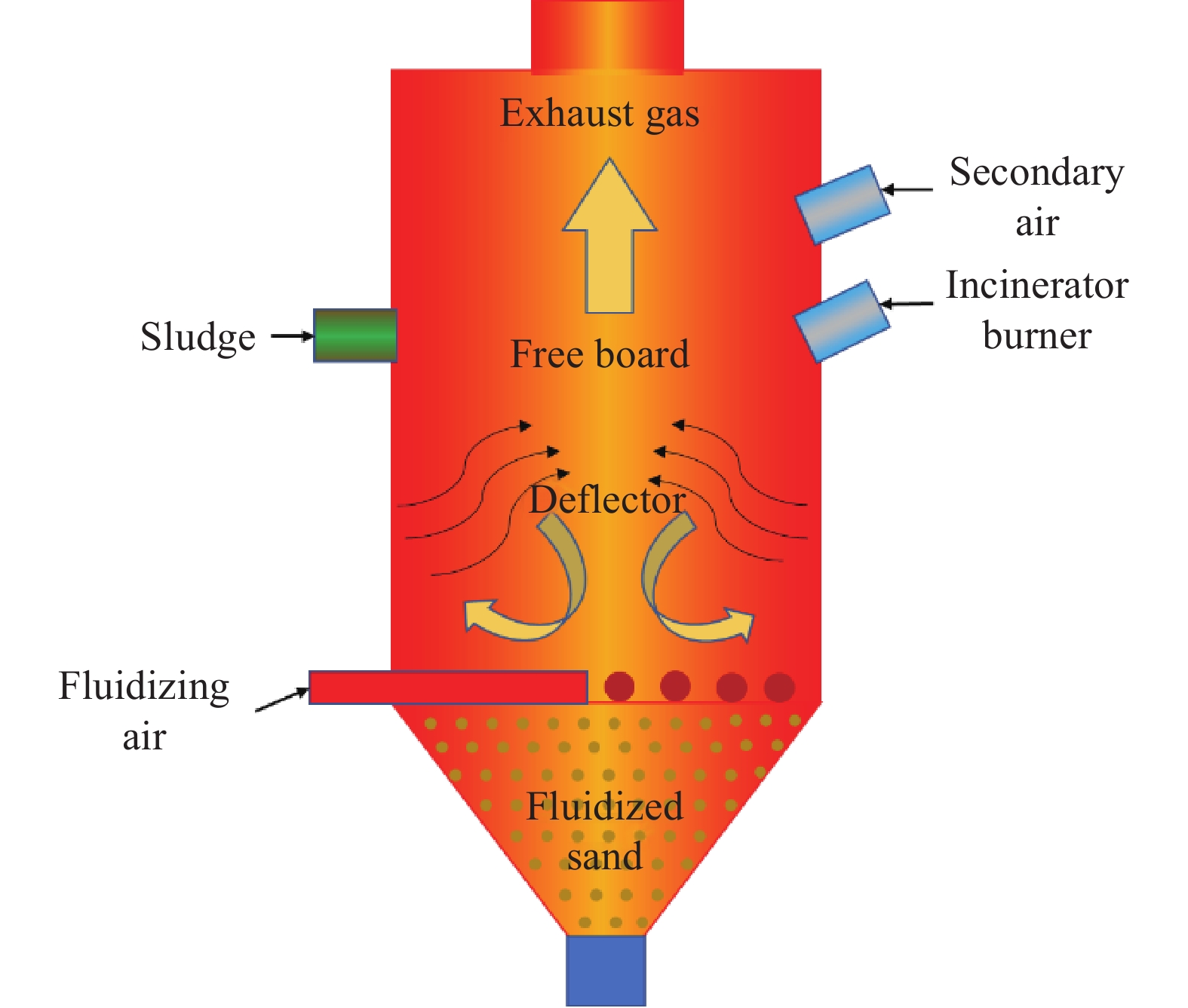

| [10] |

Ferreira A M, Coutinho J A P, Fernandes A M, et al. Complete removal of textile dyes from aqueous media using ionic-liquid-based aqueous two-phase systems. Sep Purif Technol, 2014, 128: 58 doi: 10.1016/j.seppur.2014.02.036

|

| [11] |

Tang L, Xie H J, Xu H Y, et al. Development prospect of treatment technology of high salinity organic wastewater. Chlor Alkali Ind, 2021, 57(8): 18唐林, 謝濠江, 徐慧遠, 等. 有機高鹽廢水處理技術與發展展望. 氯堿工業, 2021, 57(8):18

|

| [12] |

Wang B, Shi B, Lai J H, et al. Research status and application of high-salt organic wastewater treatment. Technol Water Treat, 2020, 46(3): 5王兵, 施斌, 來進和, 等. 高鹽有機廢水處理研究現狀及應用. 水處理技術, 2020, 46(3):5

|

| [13] |

Wang Y G, Liu X M. Review on the application and development of red mud-based photocatalytic materials for degradation of organic pollutants in water. Chin J Eng, 2021, 43(1): 22王亞光, 劉曉明. 赤泥基光催化材料降解水中有機污染物的應用現狀及發展趨勢. 工程科學學報, 2021, 43(1):22

|

| [14] |

Li X, Gou M M, Liu X F, et al. Research status and progress on treatment of high-salt wastewater. Technol Water Treat, 2019, 45(5): 6李興, 勾芒芒, 劉學峰, 等. 高鹽廢水處理現狀及研究進展. 水處理技術, 2019, 45(5):6

|

| [15] |

Procházka J, Heyberger A, Volaufová E. Extraction equilibrium of dicarboxylic acids with tertiary amine in single and binary diluents. Sep Sci Technol, 2005, 39(5): 1073 doi: 10.1081/SS-120028572

|

| [16] |

Li B Y, Liu G Q, Wang Y, et al. Formation and treatment of high-salt wastewater. Chem Ind Eng Prog, 2014, 33(2): 493李柄緣, 劉光全, 王瑩, 等. 高鹽廢水的形成及其處理技術進展. 化工進展, 2014, 33(2):493

|

| [17] |

Luo X P, Wei H D, Dong Z M. Design of incinerator for treating BDO/PTMEG devices wastewater. Chem Eng China, 2020, 48(5): 6羅秀朋, 魏宏大, 董志明. 用于處理BDO/PTMEG裝置廢液的焚燒爐設計. 化學工程, 2020, 48(5):6

|

| [18] |

Ye J, Chen Y F. Study on incineration treatment method of high concentration pharmaceutical organic waste liquor. Chem Enterp Manag, 2019(26): 100葉杰, 陳燕芳. 高濃度制藥有機廢液的焚燒處理方法研究. 化工管理, 2019(26):100

|

| [19] |

Zuo W, Zhou Y C, Ge S F, et al. Development of thermal treatment of high-salt organic wastewater. Environ Eng, 2018, 36(4): 47左武, 周尤超, 葛仕福, 等. 高含鹽有機廢液熱處理技術研究進展. 環境工程, 2018, 36(4):47

|

| [20] |

Zhang S K. Research of incineration treatment technology on high-concentration organic wastewater. Ind Furn, 2011, 33(5): 25 doi: 10.3969/j.issn.1001-6988.2011.05.006張紹坤. 焚燒法處理高濃度有機廢液的技術探討. 工業爐, 2011, 33(5):25 doi: 10.3969/j.issn.1001-6988.2011.05.006

|

| [21] |

Sun S J, Zhao J, Duan W X, et al. Engineering application of multi-strand saline organic waste liquid incineration and waste heat recovery device. China Petroleum Chem Stand Qual, 2019, 39(23): 96 doi: 10.3969/j.issn.1673-4076.2019.23.047孫恕堅, 趙娟, 端午祥, 等. 多股含鹽有機廢液焚燒及余熱回收裝置工程應用. 中國石油和化工標準與質量, 2019, 39(23):96 doi: 10.3969/j.issn.1673-4076.2019.23.047

|

| [22] |

Li J Z. Brief introduction of incineration technology of high concentration saline dye wastewater abroad. Ind Water Wastewater, 1993, 24(3): 1李家珍. 簡述國外高濃度含鹽染料廢水焚燒技術. 化工給排水設計, 1993, 24(3):1

|

| [23] |

Lu H J, Guo H M. Process selection on organic waste liquors treated by incinerating method. China Environ Prot Ind, 2005(12): 36 doi: 10.3969/j.issn.1006-5377.2005.12.017呂宏俊, 郭和民. 焚燒法處理有機廢液的工藝選擇. 中國環保產業, 2005(12):36 doi: 10.3969/j.issn.1006-5377.2005.12.017

|

| [24] |

Lin W G, Dam-Johansen K, Frandsen F. Agglomeration in bio-fuel fired fluidized bed combustors. Chem Eng J, 2003, 96(1-3): 171 doi: 10.1016/j.cej.2003.08.008

|

| [25] |

Qian H G. Design of rubbish-burning furnace in revolving tubular kiln-model. Power Eng, 2002, 22(3): 1819錢惠國. 回轉窯式廢棄物焚燒爐的設計. 動力工程, 2002, 22(3):1819

|

| [26] |

Yu C L, Wang Q, Guan X C, et al. Integrated suspension incineration technology for high concentration organic wastewater containing salt. Energy Conserv Technol, 2020, 38(3): 247 doi: 10.3969/j.issn.1002-6339.2020.03.012余傳林, 王祺, 關小川, 等. 一體化懸浮焚燒處理高濃度含鹽有機廢液鍋爐技術. 節能技術, 2020, 38(3):247 doi: 10.3969/j.issn.1002-6339.2020.03.012

|

| [27] |

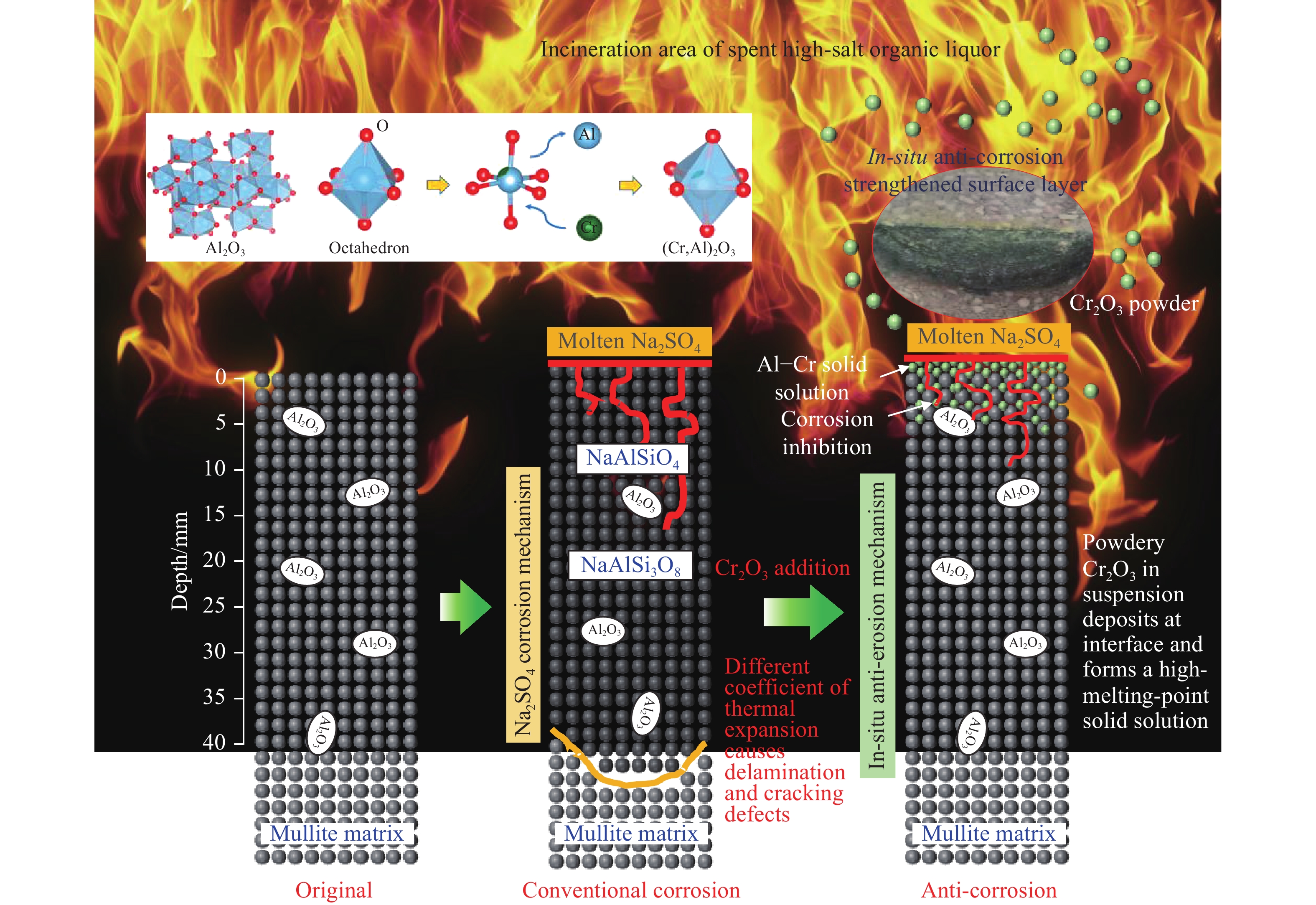

Cen K F, Xu X, Gu Y L, et al. Research of waste incineration technology in the fluidized bed. J Xi’an Jiaotong Univ, 2000, 34(1): 1 doi: 10.3321/j.issn:0253-987X.2000.01.001岑可法, 徐旭, 谷月玲, 等. 工業廢棄物和生活垃圾流化床焚燒技術的研究. 西安交通大學學報, 2000, 34(1):1 doi: 10.3321/j.issn:0253-987X.2000.01.001

|

| [28] |

Chen X P, Zhao C S, Shen L H, et al. The application of fluidized bed incineration technology in the field of organic waste liquid disposal. Boil Technol, 2001, 32(9): 25陳曉平, 趙長遂, 沈來宏, 等. 流化床焚燒技術在有機廢液無害化處理領域的應用. 鍋爐技術, 2001, 32(9):25

|

| [29] |

Chen J S, Jin X, Hu X G. Present research and development trends of organic liquid waste incineration technology. Anhui Chem Ind, 2011, 37(5): 9陳金思, 金鑫, 胡獻國. 有機廢液焚燒技術的現狀及發展趨勢. 安徽化工, 2011, 37(5):9

|

| [30] |

Li B, Yang J L, Jiang X G, et al. Fluidized bed incineration of the high concentration organic waste liquid and the secondary pollutant emission. J Zhejiang Univ Eng Sci, 2000, 34(2): 152李斌, 楊家林, 蔣旭光, 等. 高濃度有機廢液的流化床焚燒技術及二次污染物排放特性研究. 浙江大學學報(工學版), 2000, 34(2):152

|

| [31] |

Sperber J, Burgard R, Duennes F J. Innovative lining concepts for hazardous waste incineration. Refract World Forum, 2012, 4: 85

|

| [32] |

Gui J H. Incinerator and melting furnace for waste treatment and refractory materials thereof. Foreign Refract, 2001, 26(2): 15桂劍紅. 處理廢棄物用焚燒爐和熔融爐及其耐火材料. 國外耐火材料, 2001, 26(2):15

|

| [33] |

Liao J G. Status of refractories used in waste melting furnace. Foreign Refract, 2003, 28(6): 1廖建國. 廢棄物熔融爐及其所用耐火材料. 國外耐火材料, 2003, 28(6):1

|

| [34] |

Ren B, Li Y W, Nath M, et al. Enhanced alkali vapor attack resistance of bauxite-SiC refractories for the working lining of cement rotary kilns via incorporation of andalusite. Ceram Int, 2018, 44(18): 22113 doi: 10.1016/j.ceramint.2018.08.323

|

| [35] |

Chen D, Gu H Z, Huang A, et al. Towards chrome-free lining for plasma gasifiers using the CA6–SiC castable based on high-temperature water vapor corrosion. Ceram Int, 2019, 45(9): 12429 doi: 10.1016/j.ceramint.2019.03.175

|

| [36] |

Gallet-Doncieux A, Bahloul O, Gault C, et al. Investigations of SiC aggregates oxidation: Influence on SiC castables refractories life time at high temperature. J Eur Ceram Soc, 2012, 32(4): 737 doi: 10.1016/j.jeurceramsoc.2011.10.044

|

| [37] |

Heuer A H, Lou V L K. Volatility diagrams for silica, silicon nitride, and silicon carbide and their application to high-temperature decomposition and oxidation. J Am Ceram Soc, 1990, 73(10): 2789 doi: 10.1111/j.1151-2916.1990.tb06677.x

|

| [38] |

Xie J. The Research on the Composition and Alkali Resistance of Chrome Free Refractory for Alkali Recovery Furnace [Dissertation]. Wuhan: Wuhan University of Science and Technology, 2014謝靜. 堿回收爐用無鉻耐火材料組成及抗堿性能的研究[學位論文]. 武漢: 武漢科技大學, 2014

|

| [39] |

Yu Y L. Research on Chrome Free Refractory and Lining Structure Design for Coal Catalytic Gasifier [Dissertation]. Wuhan: Wuhan University of Science and Technology, 2017余亞蘭. 煤催化氣化爐用無鉻耐火材料研究及爐襯結構設計[學位論文]. 武漢: 武漢科技大學, 2017

|

| [40] |

Maity M, Al-Zahrani E. Performance of high alumina refractory lining in caustic waste incinerator // International Conference on Refractory Materials. Zhengzhou, 2012: 242Maity M, Al-Zahrani E. 苛性垃圾焚燒爐中高鋁耐火材料爐襯的性能 // 國際耐火材料會議. 鄭州, 2012: 242

|

| [41] |

Fan M X, Hou X J. Hot corrosion resistance of aluminosilicate refractories-comparative tests in the secondary combustion chamber of a hazardous waste incinerator. Refract &Lime, 2019, 44(3): 41范沐旭, 侯曉靜. 危廢焚燒爐二次燃燒室用鋁硅系耐火材料耐高溫侵蝕性對比試驗. 耐火與石灰, 2019, 44(3):41

|

| [42] |

Chen Z Y. Chemical Thermodynamics of Refractories. Beijing: Metallurgical Industry Press, 2005陳肇友. 化學熱力學與耐火材料. 北京: 冶金工業出版社, 2005

|

| [43] |

Bondioli F, Ferrari A M, Leonelli C, et al. Reaction mechanism in alumina/chromia (Al2O3–Cr2O3) solid solutions obtained by coprecipitation. J Am Ceram Soc, 2004, 83(8): 2036 doi: 10.1111/j.1151-2916.2000.tb01508.x

|

| [44] |

Lim K H. Investigations and design considerations for the refractory lining of coal gasifiers. Int Ceram Rev, 1983, 32(4): 34

|

| [45] |

Manfredo L J, McNally R N. Solubility of refractory oxides in soda-lime glass. J Am Ceram Soc, 1984, 67(8): C-155

|

| [46] |

Jiang M X, Li Y, Chen K X. Selected Papers on Refractories by Chen Zhaoyou. Revised Ed. Beijing: Metallurgical Industry Press, 2011蔣明學, 李勇, 陳開獻. 陳肇友耐火材料論文選. 增訂版. 北京: 冶金工業出版社, 2011

|

| [47] |

Funari V, Gomes H I, Coppola D, et al. Opportunities and threats of selenium supply from unconventional and low-grade ores: A critical review. Resour Conserv Recycl, 2021, 170: 105593 doi: 10.1016/j.resconrec.2021.105593

|

| [48] |

Zhang G H. On the development of refractory industry in China. China Build Mater, 2007, 56(2): 63 doi: 10.3969/j.issn.1000-0836.2007.02.023張光輝. 淺談我國耐火材料工業的發展. 中國建材, 2007, 56(2):63 doi: 10.3969/j.issn.1000-0836.2007.02.023

|

| [49] |

Xu W Z. Refractories. Beijing: Metallurgical Industry Press, 2002徐維忠. 耐火材料. 北京: 冶金工業出版社, 2002

|

| [50] |

Huang A, Wang Y J, Zou Y S, et al. Dynamic interaction of refractory and molten steel: Corrosion mechanism of alumina-magnesia castables. Ceram Int, 2018, 44(12): 14617 doi: 10.1016/j.ceramint.2018.05.085

|

| [51] |

Jiang D L, Yuan W K, Qian F. Sci-tech Development Strategy Research on Energy Saving of High Energy Consuming Industrial Heating Equipment in China. Beijing: Science Press, 2017江東亮, 袁渭康, 錢鋒. 我國高耗能工業高溫熱工裝備節能科技發展戰略研究. 北京: 科學出版社, 2017

|

| [52] |

Wang S Z, Gu J, Miao W, et al. Heat transfer analysis of several industrial furnace lining refractory structures. Rare Met Mater Eng, 2009, 38(Suppl 2): 1259王壽增, 顧靜, 苗蔚, 等. 工業窯爐中幾種爐襯耐火材料結構的傳熱分析. 稀有金屬材料與工程, 2009, 38(增刊 2):1259

|

| [53] |

Luo X D. Review on the use and damage mechanism of refractory lining for copper smelting process (1). Refract &Lime, 2015, 40(3): 21羅旭東. 銅冶煉工藝用耐火材料內襯的使用及損毀機理回顧 (1). 耐火與石灰, 2015, 40(3):21

|

| [54] |

Huang F, Liu C, Maruoka N, et al. Dissolution behaviour of MgO based refractories in CaO–Al2O3–SiO2 slag. Ironmak Steelmak, 2015, 42(7): 553 doi: 10.1179/1743281215Y.0000000003

|

| [55] |

Li Z P. The Study of Corrosion Mechanism of Refractory used in Copper Converter Furnace [Dissertation]. Xi'an: Xi'an University of Architecture and Technology, 2003李正平. 煉銅轉爐用耐火材料損毀機理研究[學位論文]. 西安: 西安建筑科技大學, 2003

|

| [56] |

Ren B, Li Y W, Nath M, et al. Abrasion resistance and thermal conductivity of ZrO2-containing bauxite refractories in the transition zone of a cement kiln. Ceram Int, 2018, 44(15): 18942 doi: 10.1016/j.ceramint.2018.07.132

|

| [57] |

Chen G H, Deng J X. Nano Thin Film Technology and Application. Beijing: Chemical Industry Press, 2004陳光華, 鄧金祥. 納米薄膜技術與應用. 北京: 化學工業出版社, 2004

|

| [58] |

Kumar K, Singh R K, Datta R. Water wettable graphite through nanotechnology and its application in refractories. Interceram-Int Ceram Rev, 2017, 66(1): 30

|

| [59] |

Bi Y B, Wang H F, Wang M, et al. Synthesis of SiC modified graphite in molten salts by microwave heating. Refractories, 2017, 51(6): 418 doi: 10.3969/j.issn.1001-1935.2017.06.004畢玉保, 王慧芳, 王銘, 等. 微波熔鹽法制備SiC改性石墨. 耐火材料, 2017, 51(6):418 doi: 10.3969/j.issn.1001-1935.2017.06.004

|

| [60] |

Ye J K, Zhang S W, Lee W E. Molten salt synthesis and characterization of SiC coated carbon black particles for refractory castable applications. J Eur Ceram Soc, 2013, 33(10): 2023 doi: 10.1016/j.jeurceramsoc.2013.02.011

|

| [61] |

Aboutalebi M R, Isac M, Guthrie R I L. The behaviour of selenium impurities during the addition of Se-containing manganese to steel melt. Steel Res Int, 2004, 75: 366 doi: 10.1002/srin.200405782

|

| [62] |

Braulio M, Martinez A T, Luz A, et al. Basic slag attack of spinel-containing refractory castables. Ceram Int, 2011, 37(6): 1935 doi: 10.1016/j.ceramint.2011.02.007

|

| [63] |

Dai Y X, Li J, Yan W, et al. Corrosion mechanism and protection of BOF refractory for high silicon hot metal steelmaking process. J Mater Res Technol, 2020, 9(3): 4292 doi: 10.1016/j.jmrt.2020.02.055

|

| [64] |

Weinberg V A, Varona C, Chaucherie X, et al. Corrosion of Al2O3?SiO2 refractories by sodium and sulfur vapors: A case study on hazardous waste incinerators. Ceram Int, 2017, 43(7): 5743 doi: 10.1016/j.ceramint.2017.01.116

|

| [65] |

Chen Q Y, Bai X Q. Erosion of Al-Cr-Zr bricks for incinerators by incineration slag with different potassium and sodium contents. Refractories, 2013, 47(5): 382 doi: 10.3969/j.issn.1001-1935.2013.05.017陳清艷, 白曉琴. 不同鉀鈉含量的焚燒爐渣對焚燒爐用鋁鉻鋯磚的侵蝕. 耐火材料, 2013, 47(5):382 doi: 10.3969/j.issn.1001-1935.2013.05.017

|

| [66] |

Chen D, Huang A, Gu H Z, et al. Corrosion of Al2O3–Cr2O3 refractory lining for high-temperature solid waste incinerator. Ceram Int, 2015, 41(10): 14748 doi: 10.1016/j.ceramint.2015.07.202

|

| [67] |

Shi X G, Li B S, Liu H Y, et al. The corrosion resistance mechanisms of the cr-coated SiC in molten Na2SO4 salt: Strengthened boundaries and protective scales. Corros Sci, 2021, 185: 109421 doi: 10.1016/j.corsci.2021.109421

|

| [68] |

Liu J K, Hao Z, Cui Z X, et al. Oxidation behavior, thermal stability, and the coating/substrate interface evolution of CrN-coated Zircaloy under high-temperature steam. Corros Sci, 2021, 185: 109416 doi: 10.1016/j.corsci.2021.109416

|

| [69] |

Kim H B, Oh M S. Changes in microstructure of a high chromia refractory due to interaction with infiltrating coal slag in a slagging gasifier environment. Ceram Int, 2008, 34(8): 2107 doi: 10.1016/j.ceramint.2007.08.010

|

| [70] |

Pérez I, Moreno-Ventas I, Parra R, et al. Comparative analyses of the infiltration of Al–Cr–O and Mg–Cr–O refractories by molten phases in the copper-making process using the sessile drop technique. Boletín De La Sociedad Espa?ola De Cerámica Y Vidrio, 2020, 59(1): 15

|

| [71] |

Kaiser A, Lobert M, Telle R. Thermal stability of zircon (ZrSiO4). J Eur Ceram Soc, 2008, 28(11): 2199 doi: 10.1016/j.jeurceramsoc.2007.12.040

|

| [72] |

Riu D H, Kong Y M, Kim H E. Effect of Cr2O3 addition on microstructural evolution and mechanical properties of Al2O3. J Eur Ceram Soc, 2000, 20(10): 1475 doi: 10.1016/S0955-2219(00)00023-6

|

| [73] |

Gómez-Rodríguez C, Antonio-Zárate Y, Revuelta-Acosta J, et al. Research and development of novel refractory of MgO doped with ZrO2 nanoparticles for copper slag resistance. Materials, 2021, 14(9): 2277 doi: 10.3390/ma14092277

|

| [74] |

Kwong K, Petty A, Bennett J, et al. Wear mechanisms of chromia refractories in slagging gasifiers. Int J Appl Ceram Technol, 2007, 4(6): 503 doi: 10.1111/j.1744-7402.2007.02175.x

|

| [75] |

Peng G C, Jia W C, Qiao Q Q, et al. Research progress on the preparation and corrosion resistance of layered double hydroxides film on aluminum alloys. Chin J Eng, 2020, 42(1): 1彭光春, 賈文超, 喬芊芊, 等. 鋁合金表面水滑石薄膜的制備及其耐蝕性研究進展. 工程科學學報, 2020, 42(1):1

|

| [76] |

Kenneth Kaneko T, Zhu J X, Howell N, et al. The effects of gasification feedstock chemistries on the infiltration of slag into the porous high chromia refractory and their reaction products. Fuel, 2014, 115: 248 doi: 10.1016/j.fuel.2013.06.052

|

| [77] |

Zhang P, Fu Q G, Cheng C Y, et al. Microstructure evolution of in-situ SiC–HfB2–Si ternary coating and its corrosion behaviors at ultra-high temperatures. J Eur Ceram Soc, 2021, 41(13): 6223 doi: 10.1016/j.jeurceramsoc.2021.05.058

|

| [78] |

Li Y H, Meng F P, Ge F F, et al. Improved oxidation resistance through an in-situ formed diffusion barrier: Oxidation behavior of amorphous multi-component FeCrAlMoSiY-coated Zr in high-temperature steam. Corros Sci, 2021, 189: 109566 doi: 10.1016/j.corsci.2021.109566

|

| [79] |

Han G H, Wang Z X, Liu B B, et al. In-situ improved corrosion resistance of corundum-mullite refractory for the incineration of hazardous spent high-salt organic liquor by Cr2O3: Interfacial anti-erosion mechanism. Ceram Int, 2022, 48(9): 12395 doi: 10.1016/j.ceramint.2022.01.104

|

下載:

下載: