Strengthening mechanism of the mechanical properties of micro/nano-laminated composites

-

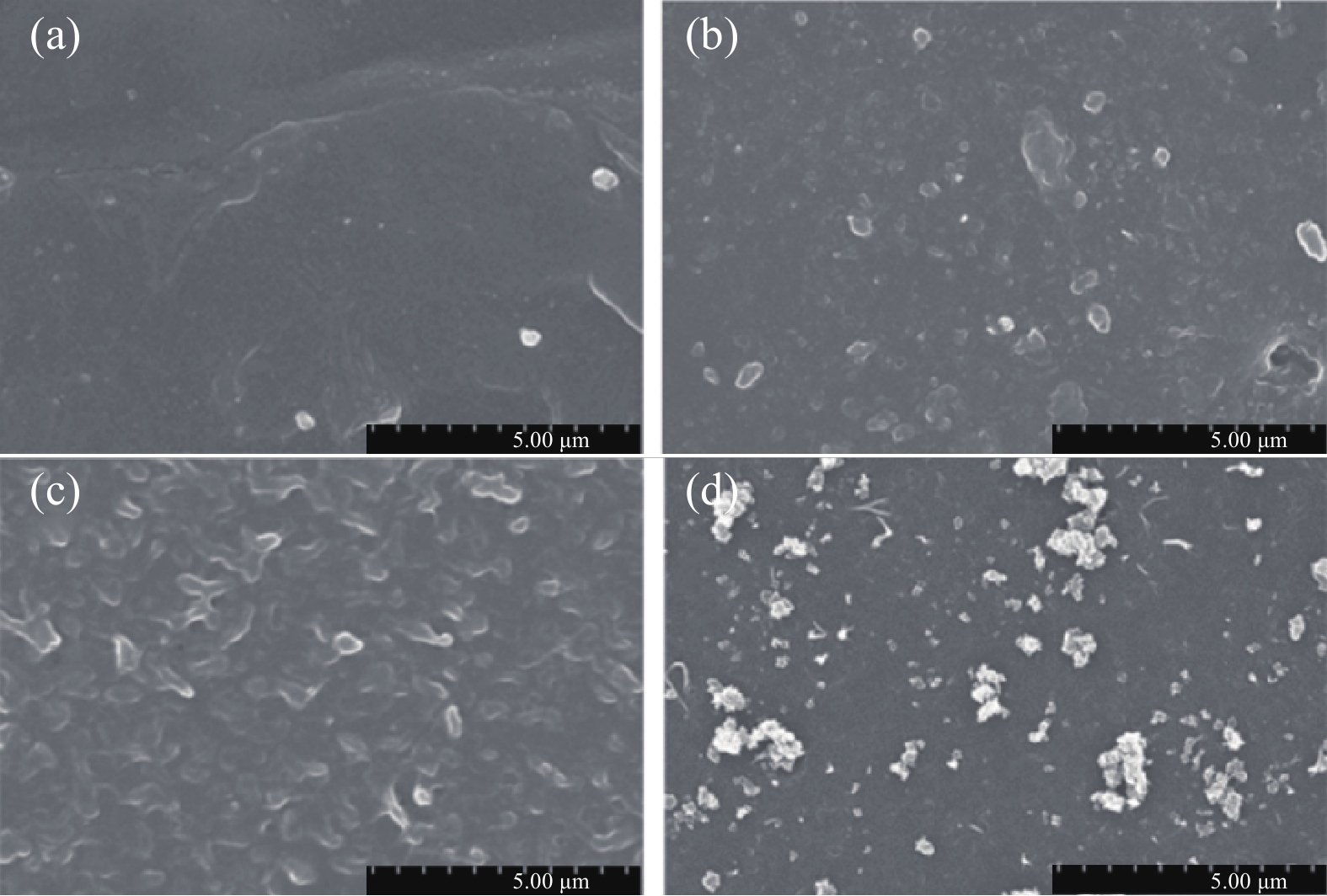

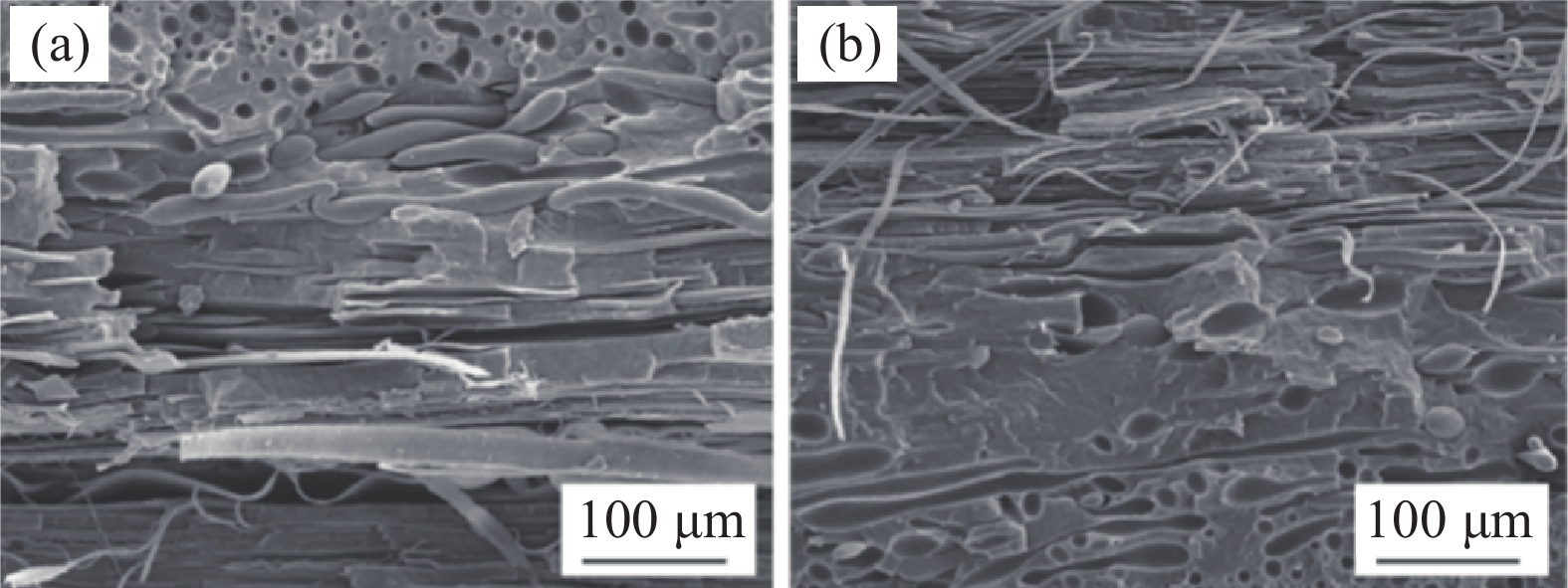

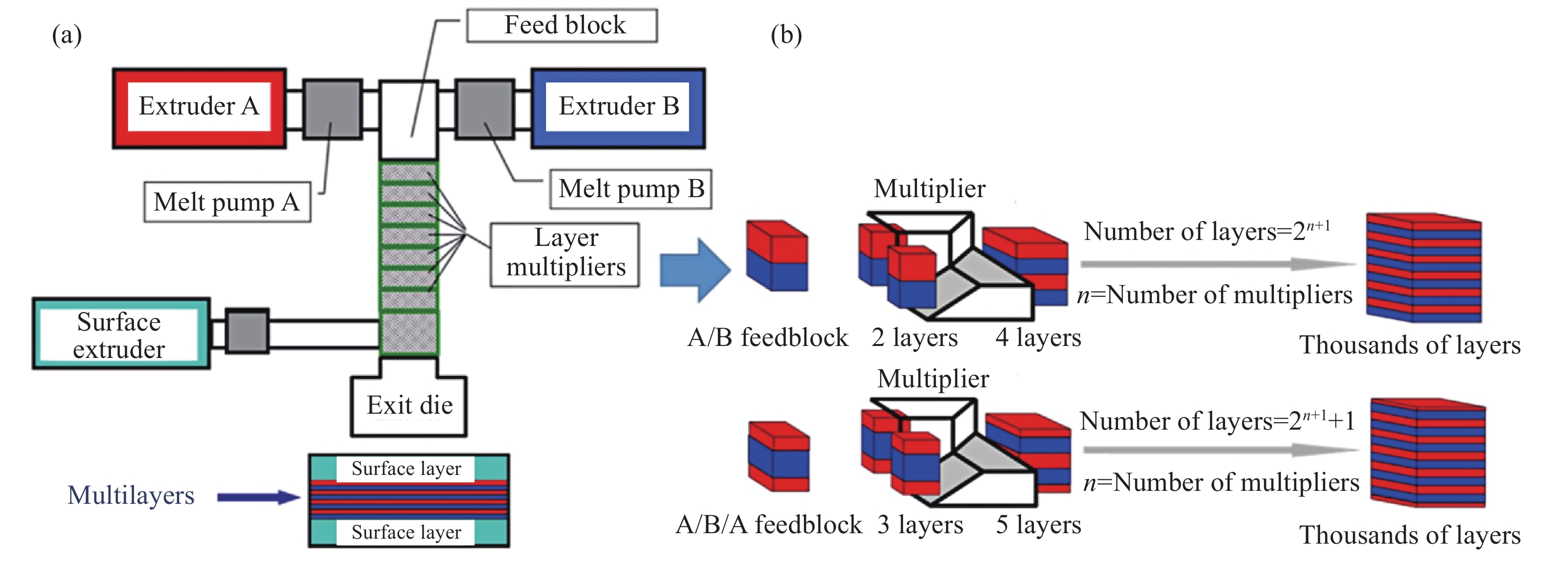

摘要: 微納層疊技術是層層組裝(LbL)技術中的一種,能夠將兩種或多種不同的聚合物組合生成具有交替層狀結構的復合材料。與浸涂、旋涂和噴涂等傳統組裝方法相比,該技術是一種不含溶劑的熔體連續加工技術,具有經濟環保的優點。本文簡要總結了微納層疊技術的研究現狀,概述了微納層疊技術的原理與工藝,重點介紹了多層交替復合材料力學性能的增強機理,包括層界面相互作用、層界面誘導結晶、調控聚合物相形態、調控無機粒子的分散取向和原位成纖,并對該技術的未來研究方向進行展望。Abstract: Offering the advantages of easy preparation and low cost, polymer systems account for many of the high-performance materials used in industry. With the widespread application of polymer materials, higher requirements for the properties of polymer products have been proposed. Recently, polymer-based functional composites have been a worldwide research focus, and the structure of the composites directly affects their properties. The special multilayer structure of shells and trees often brings excellent performance or special functions. Discussing the strength and toughness mechanism of natural materials helps guide new functional composite preparation. In recent decades, a novel micro/nano-lamination technology has attracted the interest of academia and industry. Micro/nano-lamination technology is a layer-by-layer assembly (LbL) technology, which can combine two or more types of polymers into tens of thousands of layers alternately arranged, and each microlayer thickness can reach nanometer level to form composite materials with an alternating layered structure. Compared with solution LbL assembly methods, such as dip coating, spin coating, and spray coating, it is a continuous melt processing technique that involves no solvent, which has the advantages of flexibility, versatility, economy, and eco-friendliness. Compared with the composites prepared by blending melt extrusion or with fewer layers, the shape memory properties, electrical properties, barrier properties, and mechanical properties of composites prepared by micro/nano-lamination technology are considerably improved. As an application of biomimetic materials in the polymer research field, multilayer alternating composites prepared using micro/nano-lamination have a special multilayer structure, rich layer interface, and micro/nano-scale layer confined space. The multilayer composites prepared by micro/nano-lamination have an important positive synergistic effect on mechanical properties, and the unique multilayer structure can adjust stress distribution, stress transfer, and microcrack propagation. In this paper, according to the research status of micro/nano-lamination, the principle and process of micro/nano-lamination are briefly introduced. The mechanical property enhancement mechanism of multilayer alternating composites is reviewed, including interlayer interface interaction, layer interface-induced crystallization, regulation of polymer phase morphology, regulation of the dispersion orientation of inorganic particles, and in situ fiber formation. Micro/nano-lamination technology can coordinate the properties of different materials, integrate the excellent properties of many types of polymer materials, and make composite materials with good comprehensive properties. This model of high-performance functional materials has a broad market application prospect.

-

表 1 微納層疊復合材料應用

Table 1. Application of micro/nano-lamination composites

Composition Number of layers Single layer thickness/μm Total thickness/mm Typical performance Application direction Ref. IIR/EP 8–16 250 2–5 Damp Rail transit, ships, household appliances [37] PC/PMMA 64–256 4–16 — Toughness, hardness, rigidity Mobile phone back panel, touch display panel [38] PVDF/PMMA 32 20–70 1.5 Scratch resistance Protective film, sewage pretreatment [39] PCL/PVA 33 — 1.0 Barrier, tensile Food fresh-keeping film [40] PP/POE 64 — 1.8 Stretching, shock Polypropylene substrate, sheet and membrane materials [41] www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Chen W Z, Li W, Xu K, et al. Functionalizing titanium surface with PAMAM dendrimer and human BMP2 gene via layer-by-layer assembly for enhanced osteogenesis. J Biomed Mater Res A, 2018, 106(3): 706 doi: 10.1002/jbm.a.36273 [2] Huang Z Q, Shi X B, Chen S T, et al. Mechanical properties of HDPE (HD5502GA) nano-MMT composite material for hollow containers. China Rubber/plastics Technol Equip, 2020, 46(10): 41黃志強, 石行波, 陳商濤, 等. 中空容器專用HDPE(HD5502GA)/nano-MMT復合材料力學性能分析. 橡塑技術與裝備, 2020, 46(10):41 [3] Xiong L Z, Yang W M, Zhou X, et al. Research progress of extrusion technology for micro-nano layer films. China Plast, 2015, 29(8): 9熊良釗, 楊衛民, 周星, 等. 微納層疊擠出技術的研究進展. 中國塑料, 2015, 29(8):9 [4] Sheng T Y, Yang W M, Tan J, et al. Recent advance on micro/nano lamination extrusion technology. New Chem Mater, 2022, 50(2): 6盛天陽, 楊衛民, 譚晶, 等. 微納層疊功能復合材料研究進展. 化工新型材料, 2022, 50(2):6 [5] Guo K, Li W J, Wang X L. Construction and applications of multilayered polymer materials by layer-by-layer assembly. J Southwest Minzu Univ (Nat Sci Ed) , 2020, 46(4): 341郭坤, 李偉杰, 王曉玲. 層層自組裝聚合物材料的制備及應用. 西南民族大學學報(自然科學版), 2020, 46(4):341 [6] Fang W X, Shen J B, Li J, et al. Recent progress of structural development and related properties of polymer materials in confined layer spaces. Polym Bull, 2017(10): 23方文祥, 沈佳斌, 李姜, 等. 聚合物在受限層空間中的形態結構演變及相關性能研究進展. 高分子通報, 2017(10):23 [7] Li Z P, Olah A, Baer E. Micro- and nano-layered processing of new polymeric systems. Prog Polym Sci, 2020, 102: 101210 doi: 10.1016/j.progpolymsci.2020.101210 [8] Yuan B, Jiao Z W, Liu D S, et al. Structural design and flow field analysis of annular laminated mold used for micro-layer extrusion technology. China Plast Ind, 2019, 47(4): 57 doi: 10.3969/j.issn.1005-5770.2019.04.012袁擘, 焦志偉, 劉東升, 等. 環形微納層疊擠出模具的結構設計與流場分析. 塑料工業, 2019, 47(4):57 doi: 10.3969/j.issn.1005-5770.2019.04.012 [9] Li J L. Preparation and Mechanism of High Performance PVC Based on Multilayer Coextrusion [Dissertation]. Beijing: Beijing University of Chemical Technology, 2018李經龍. 基于微納層疊原理的聚氯乙烯高性能化制備及機理研究[學位論文]. 北京: 北京化工大學, 2018 [10] Lu B, Zhang H G, Maazouz A, et al. Interfacial phenomena in multi-micro-/nanolayered polymer coextrusion: A review of fundamental and engineering aspects. Polymers, 2021, 13(3): 417 doi: 10.3390/polym13030417 [11] Luo S S, Wei L Q, Sun J, et al. Crystallization behavior and optical properties of isotactic polypropylene filled with α-nucleating agents of multilayered distribution. RSC Adv, 2020, 10(1): 387 doi: 10.1039/C9RA09485G [12] He W, Luo F, Zhang F S, et al. Preparation and properties of alternating multilayered silicone rubber filled with carbon nanotubes/grapheme. Polym Mater Sci &Eng, 2021, 37(2): 130賀婉, 羅芳, 張風順, 等. 碳納米管/石墨烯復合填充交替多層硅橡膠的結構及性能. 高分子材料科學與工程, 2021, 37(2):130 [13] Li L, Shi M N, Yan H, et al. Preparation and study on properties of NBR/PP thermoplastic elastomer based on micro nano laminated extrusion technology. China Plast Ind, 2021, 49(7): 134 doi: 10.3969/j.issn.1005-5770.2021.07.029李亮, 石美濃, 閻華, 等. 微納層疊擠出技術制備NBR/PP熱塑性彈性體及其性能研究. 塑料工業, 2021, 49(7):134 doi: 10.3969/j.issn.1005-5770.2021.07.029 [14] Zhang C, Shi M N, Zhang Y C, et al. Structure and properties of(APP+PUR-T)/PUR-T alternative multilayer flame retardant based on microlayer coextrusion technology. Eng Plast Appl, 2019, 47(9): 62張超, 石美濃, 張有忱, 等. 基于微納層疊技術制備(APP+PUR-T)/PUR-T交替多層阻燃材料的結構與性能. 工程塑料應用, 2019, 47(9):62 [15] Zhang X L, Xu Y, Zhang X, et al. Progress on the layer-by-layer assembly of multilayered polymer composites: Strategy, structural control and applications. Prog Polym Sci, 2019, 89: 76 doi: 10.1016/j.progpolymsci.2018.10.002 [16] Gu L, Zhu Y T, He J L, et al. Preparation and properties of poly(lactic acid)/polycaprolactone degradable multilayered films based on micro-nano multiplayer coextrusion. China Plast, 2021, 35(11): 7谷琳, 朱鈺婷, 何家隆, 等. 基于微納層疊共擠的PLA/PCL可降解微層薄膜的制備及性能研究. 中國塑料, 2021, 35(11):7 [17] Wu Y Q, Ge Q, Yang F, et al. Improving the low-temperature toughness of PPR pipe by compounding with PERT. J Polym Res, 2021, 28(4): 143 doi: 10.1007/s10965-021-02501-5 [18] Xu Y, Qin J X, Zhang X F, et al. Enhancing scratch damage resistance of PMMA via layer assembly with PVDF: Numerical modeling prediction and experimental verification. Polymer, 2020, 194: 122382 doi: 10.1016/j.polymer.2020.122382 [19] Xu Y, Li D, Shen J B, et al. Scratch damage behaviors of PVDF/PMMA multilayered materials: Experiments and finite element modeling. Polymer, 2019, 182: 121829 doi: 10.1016/j.polymer.2019.121829 [20] Montana J S, Roland S, Richaud E, et al. Nanostructuration effect on the mechanical properties of PMMA toughened by a triblock acrylate copolymer using multilayer coextrusion. Polymer, 2018, 149: 124 doi: 10.1016/j.polymer.2018.06.048 [21] Yang S, Yu H N, Lei F, et al. Formation mechanism and morphology of β-transcrystallinity of polypropylene induced by two-dimensional layered interface. Macromolecules, 2015, 48(12): 3965 doi: 10.1021/acs.macromol.5b00396 [22] He L, Luo S S, Shen J B, et al. Fabrication of multilayered β-form transcrystallinity in isotactic polypropylene for achieving optimized mechanical performances. Ind Eng Chem Res, 2020, 59(50): 21791 doi: 10.1021/acs.iecr.0c04518 [23] Luo S S, Zheng Y, Zheng Z, et al. Competitive growth of α- and β-transcrystallinity in isotactic polypropylene induced by the multilayered distribution of α-nucleating agents: Toward high mechanical performances. Chem Eng J, 2019, 355: 710 doi: 10.1016/j.cej.2018.08.162 [24] Embabi M, Kweon M S, Chen Z L, et al. Tunable tensile properties of polypropylene and polyethylene terephthalate fibrillar blends through micro-/nanolayered extrusion technology. Polymers, 2020, 12(11): 2585 doi: 10.3390/polym12112585 [25] Yi L F, Xu Y, Li D, et al. Fabrication of scratch resistant polylactide with multilayered shish-kabab structure through layer-multiplying coextrusion. Ind Eng Chem Res, 2018, 57(12): 4320 doi: 10.1021/acs.iecr.8b00221 [26] Wang S W. Study on the Preparation and Properties of IIR/PP Thermoplastic Vulcanizate Based on Micro-nano Laminated Extrusion Technology [Dissertation]. Beijing: Beijing University of Chemical Technology, 2021王帥文. 基于微納層疊擠出技術的IIR/PP熱塑性硫化橡膠的制備與性能研究[學位論文]. 北京: 北京化工大學, 2021 [27] Xiong L Z, Yang W M, Li C J, et al. Plasticizer migration from micro-layered flexible poly (vinyl chloride) films prepared by multi-layer co-extrusion technology. J Plast Film Sheeting, 2016, 32(4): 402 doi: 10.1177/8756087915612884 [28] Zhen X S, Zhang L Y, Shi M N, et al. Mechanical behavior of PMMA/SiO2 multilayer nanocomposites: Experiments and molecular dynamics simulation. Macromol Res, 2020, 28(3): 266 doi: 10.1007/s13233-020-8035-y [29] Li J L, Jiang X W, Jiao Z W, et al. Structure and properties of micro layer PVC/nano-SiO2 composites. Plast Sci Technol, 2018, 46(9): 19李經龍, 姜行偉, 焦志偉, 等. 微層聚氯乙烯/納米二氧化硅復合材料的結構與性能. 塑料科技, 2018, 46(9):19 [30] Chen B S, Gao W L, Shen J B, et al. The multilayered distribution of intumescent flame retardants and its influence on the fire and mechanical properties of polypropylene. Compos Sci Technol, 2014, 93: 54 doi: 10.1016/j.compscitech.2013.12.022 [31] Xia L C, Wu H, Guo S Y, et al. Enhanced sound insulation and mechanical properties of LDPE/mica composites through multilayered distribution and orientation of the mica. Compos A Appl Sci Manuf, 2016, 81: 225 doi: 10.1016/j.compositesa.2015.11.023 [32] Zhu Y T, Gu L, He J L, et al. Preparation and properties of PP/PA6/CNTs in-situ microfiber composite films based on microlayer coextrusion. China Plast, 2021, 35(10): 1朱鈺婷, 谷琳, 何家隆, 等. 微納層疊共擠PP/PA6/CNTs原位微纖復合膜的制備及性能研究. 中國塑料, 2021, 35(10):1 [33] Zhu Y J, Wei L Q, Li L Z, et al. PVDF/PA11 in-situ microfiber high dielectric composites prepared by micro-/nano-layer co-extrusion. Eng Plast Appl, 2021, 49(11): 33 doi: 10.3969/j.issn.1001-3539.2021.11.006朱永軍, 韋良強, 李凌洲, 等. 微納層疊共擠制備PVDF/PA11原位微纖高介電復合材料. 工程塑料應用, 2021, 49(11):33 doi: 10.3969/j.issn.1001-3539.2021.11.006 [34] Liu Y, Huang A R, Wei L Q, et al. The effect of viscosity ratio on the morphology and properties of EVA/PP in-situ microfibillar composites. China Plast Ind, 2018, 46(8): 43 doi: 10.3969/j.issn.1005-5770.2018.08.010劉渝, 黃安榮, 韋良強, 等. 黏度比對EVA/PP原位微纖復合材料形態及性能的影響. 塑料工業, 2018, 46(8):43 doi: 10.3969/j.issn.1005-5770.2018.08.010 [35] Sun J, Huang A R, Luo S S, et al. Preparation and properties of PLA/PBAT in-situ microfibrillar composites. China Plast Ind, 2021, 49(5): 33 doi: 10.3969/j.issn.1005-5770.2021.05.005孫靜, 黃安榮, 羅珊珊, 等. PLA/PBAT原位微纖復合材料的制備與性能研究. 塑料工業, 2021, 49(5):33 doi: 10.3969/j.issn.1005-5770.2021.05.005 [36] Sun J, Huang A R, Luo S S, et al. Effect of different processing methods on phase structure and properties of ethylene–octene copolymer/poly(lactic acid)blends. Polym Mater Sci &Eng, 2021, 37(4): 166孫靜, 黃安榮, 羅珊珊, 等. 不同加工方法對乙烯–辛烯共聚物/聚乳酸共混物相結構與性能的影響. 高分子材料科學與工程, 2021, 37(4):166 [37] Zhang J, Yao D, Shen M L, et al. A Light and Wide Temperature Range Laminated Damping Noise Reduction Profile: China Patent, CN212353971U. 2021-1-15張捷, 姚丹, 沈夢露, 等. 一種輕質寬溫域層狀約束阻尼降噪型材: 中國專利, CN212353971U. 2021-1-15 [38] Zhu J M, Xu Y, Guo S Y, et al. A Multilayer Composite Plate with High Strength and Toughness and Its Preparation Method: China Patent, CN112757732A. 2021-5-7朱家銘, 徐楊, 郭少云, 等. 一種高強度高韌性的多層復合板及其制備方法: 中國專利, CN112757732A. 2021-5-7 [39] Shen J B, Xu Y, Guo S Y. A Scratch-resistant Protective Layer and A Scratch-resistant Material Made From It: China Patent, CN110293724A. 2019-10-1沈佳斌, 徐楊, 郭少云. 一種耐刮擦防護層及由其制成的耐刮擦材料: 中國專利, CN110293724A. 2019-10-1 [40] Guo S Y, Han A C, Chen R. A Method for Preparing Alternating Layered Biodegradable Polymer Barrier Materials with Excellent Water Vapor and Oxygen Barrier Properties: China Patent, CN107286607B. 2019-10-18郭少云, 韓艾純, 陳蓉. 一種制備兼具優異水蒸氣和氧氣阻隔性能的交替層狀生物降解高分子阻隔材料的方法: 中國專利, CN107286607B. 2019-10-18 [41] Wu H, Wang J F, Guo S Y, et al. A Preparation Method of Synergically Reinforced and Toughened Polypropylene Matrix Composites: China Patent, CN105398062B. 2018-6-29吳宏, 王建峰, 郭少云, 等. 一種協同增強增韌聚丙烯基復合材料的制備方法: 中國專利, CN105398062B. 2018-6-29 [42] Scholtyssek S, Adhikari R, Seydewitz V, et al. Evaluation of morphology and deformation micromechanisms in multilayered PP/PS films: An electron microscopy study. Macromol Symp, 2010, 294(1): 33 doi: 10.1002/masy.201050804 [43] Bironeau A, Salez T, Miquelard-Garnier G, et al. Existence of a critical layer thickness in PS/PMMA nanolayered films. Macromolecules, 2017, 50(10): 4064 doi: 10.1021/acs.macromol.7b00176 -

下載:

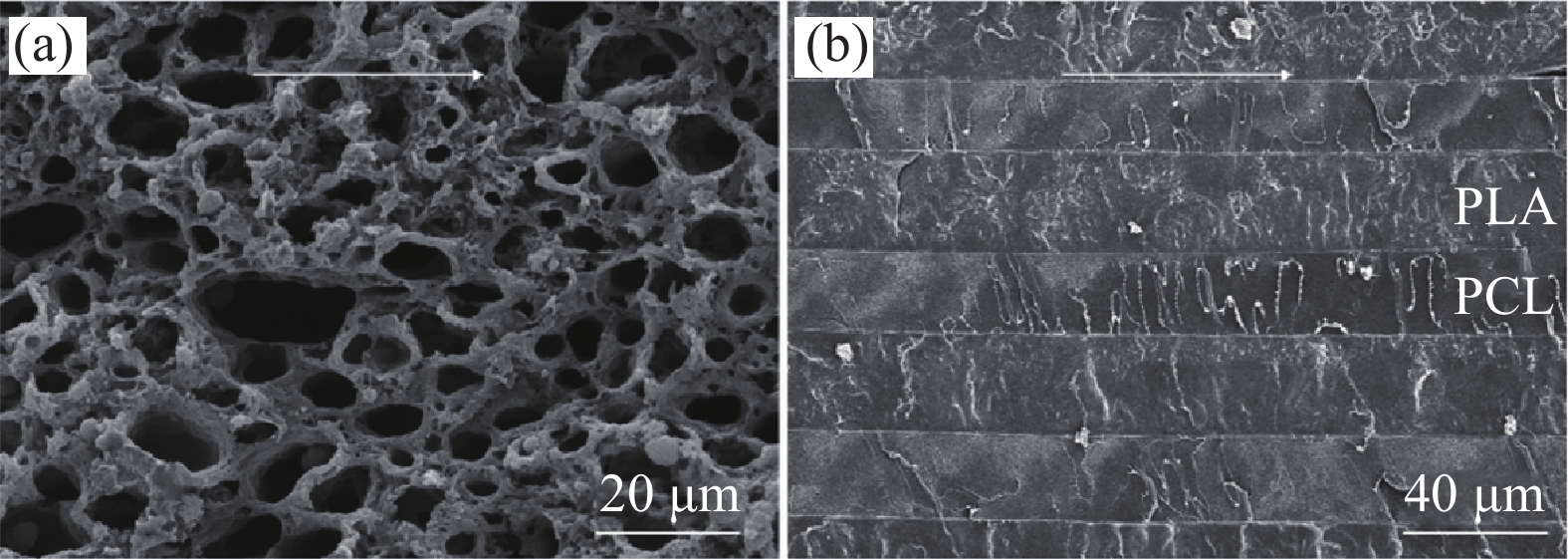

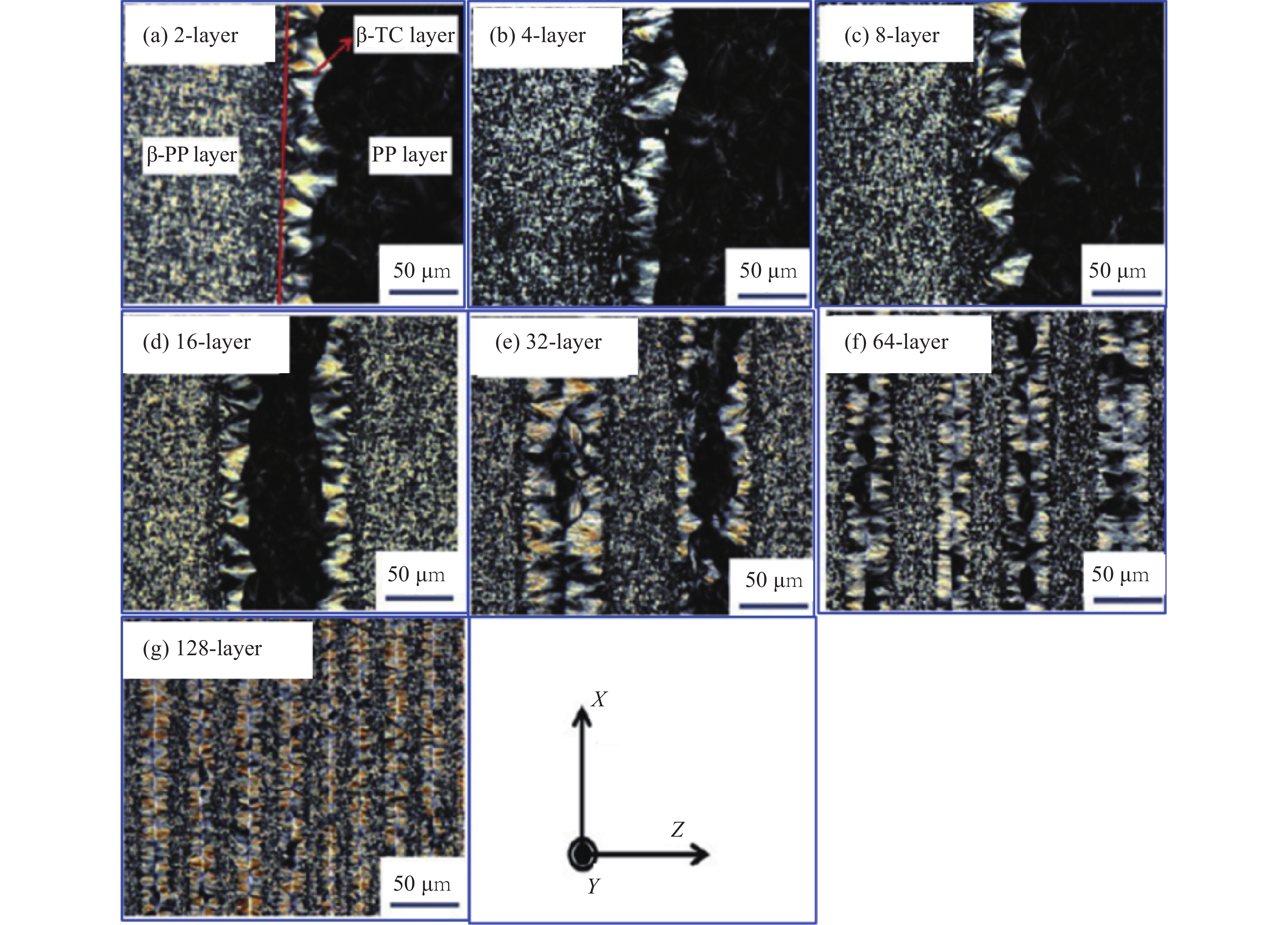

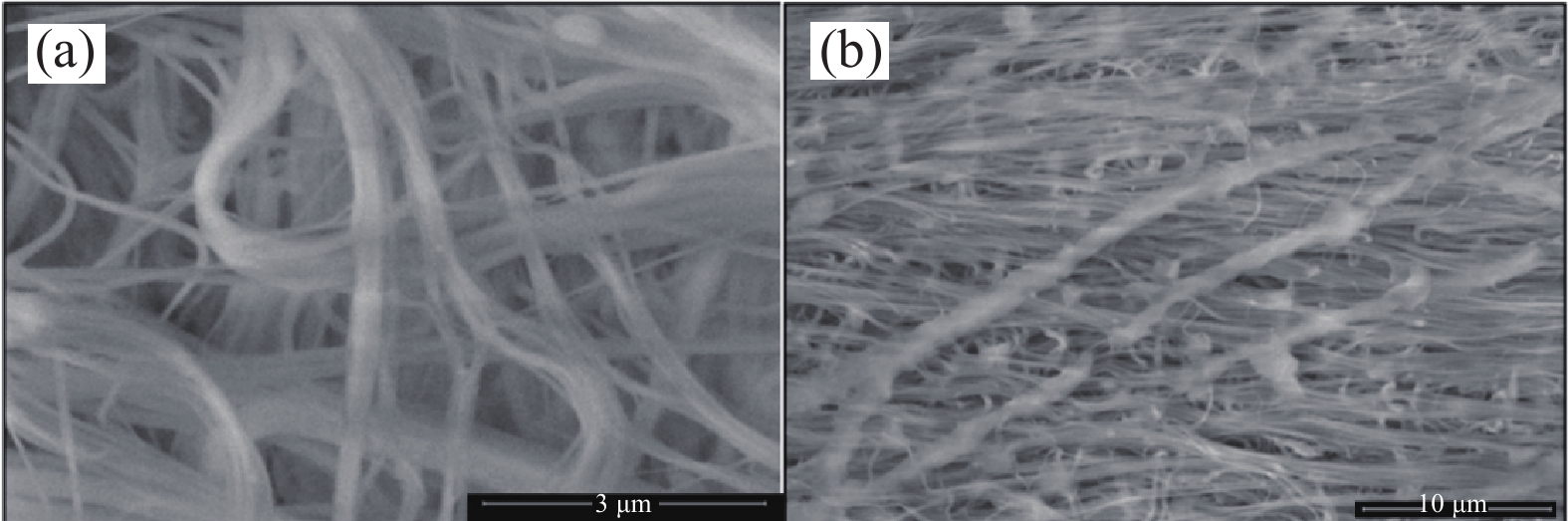

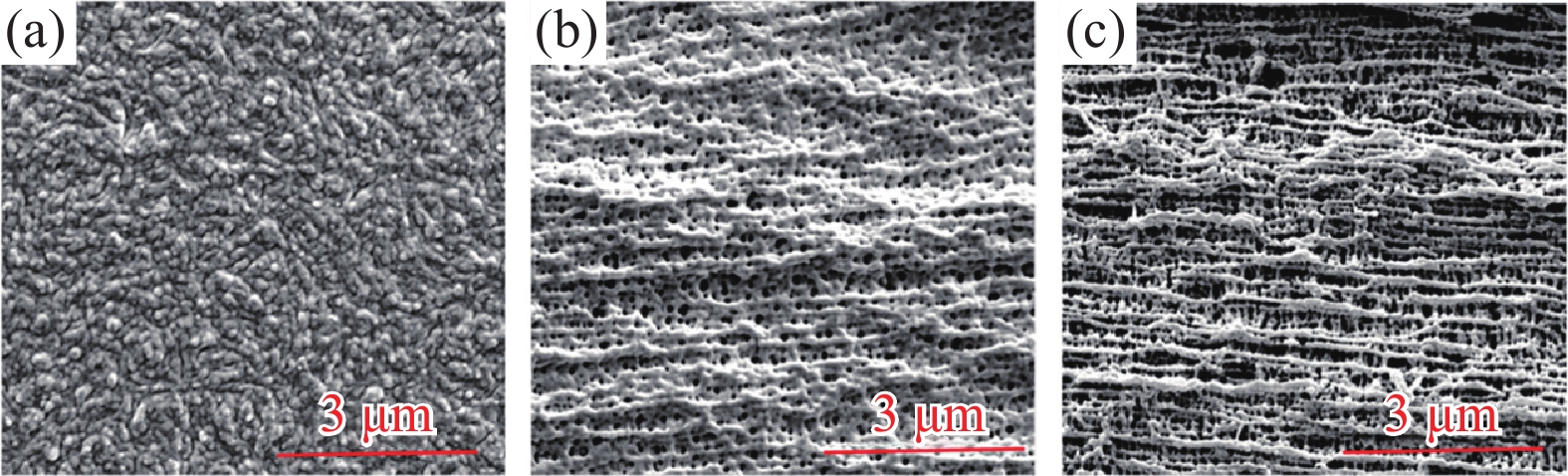

下載: