Key metallurgical technology for high-quality bearing steel production based on the nonaluminum deoxidation process

-

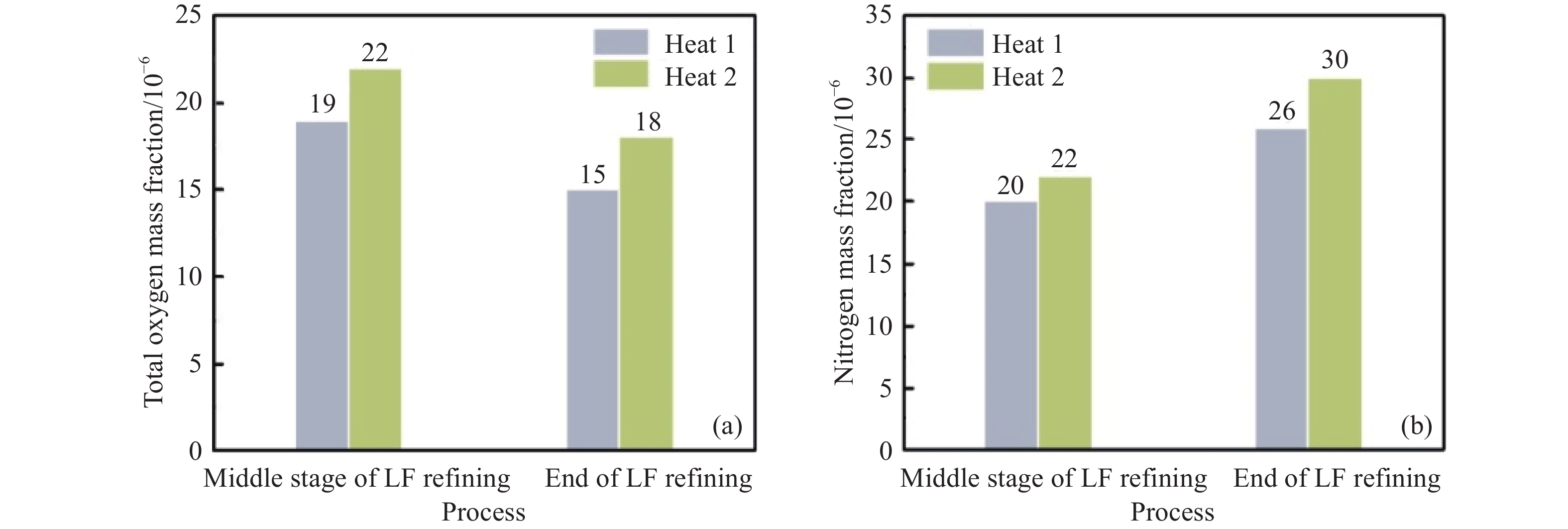

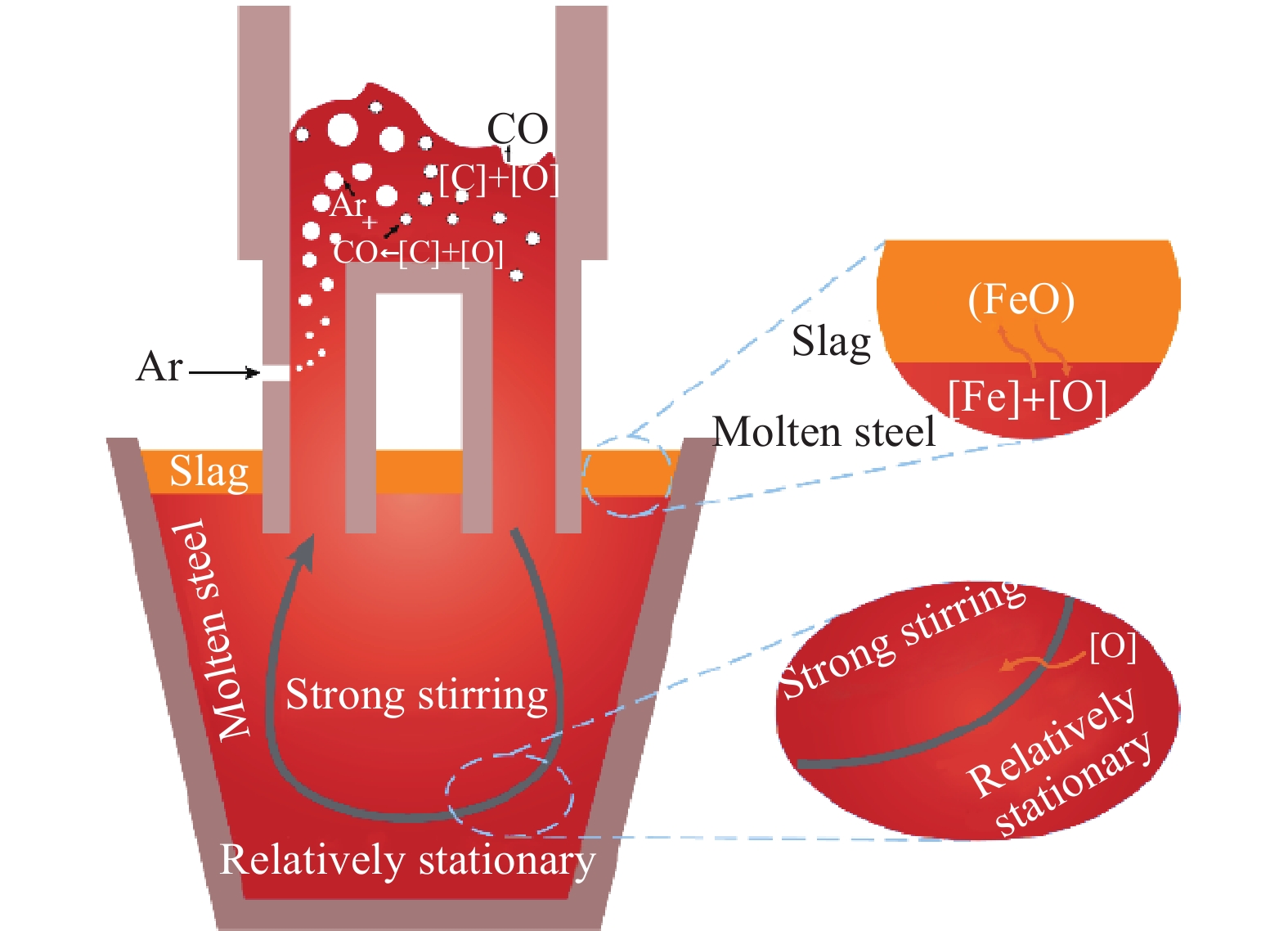

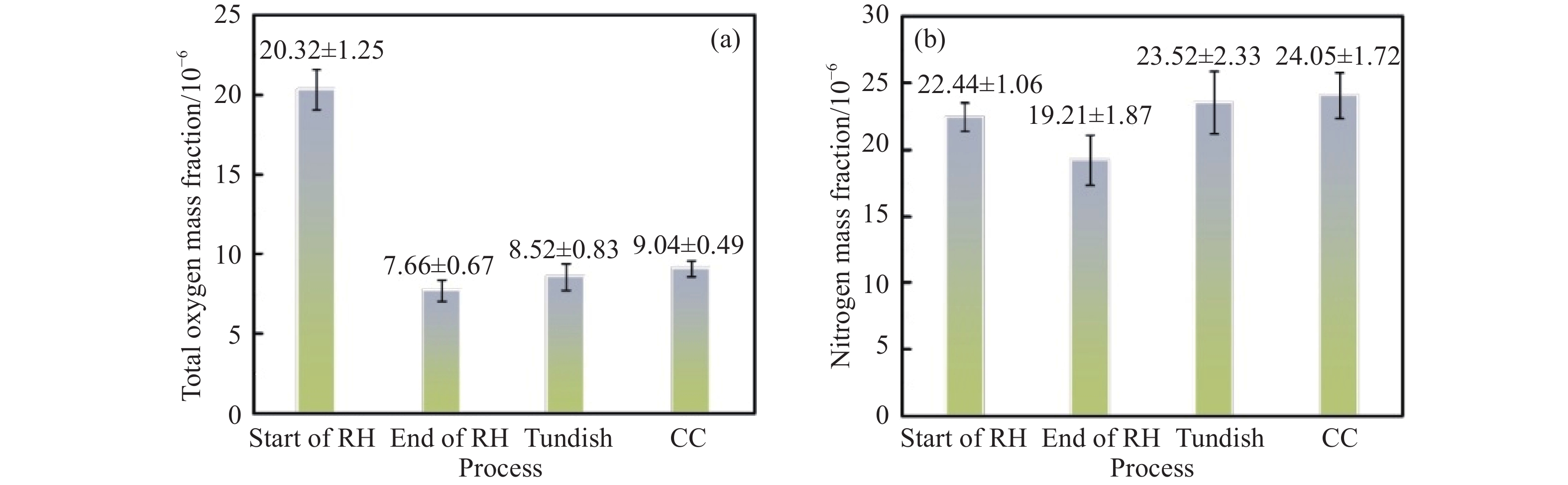

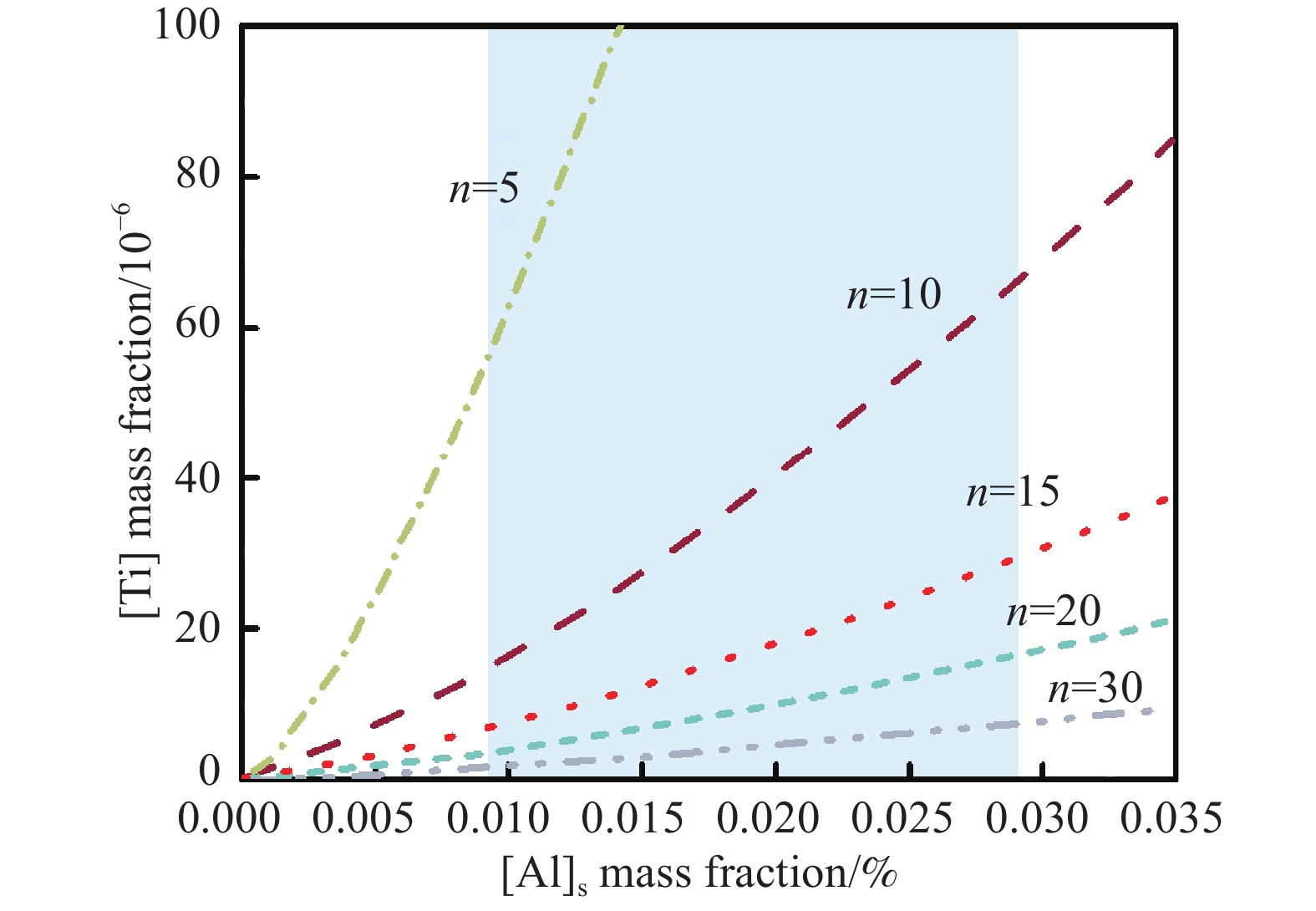

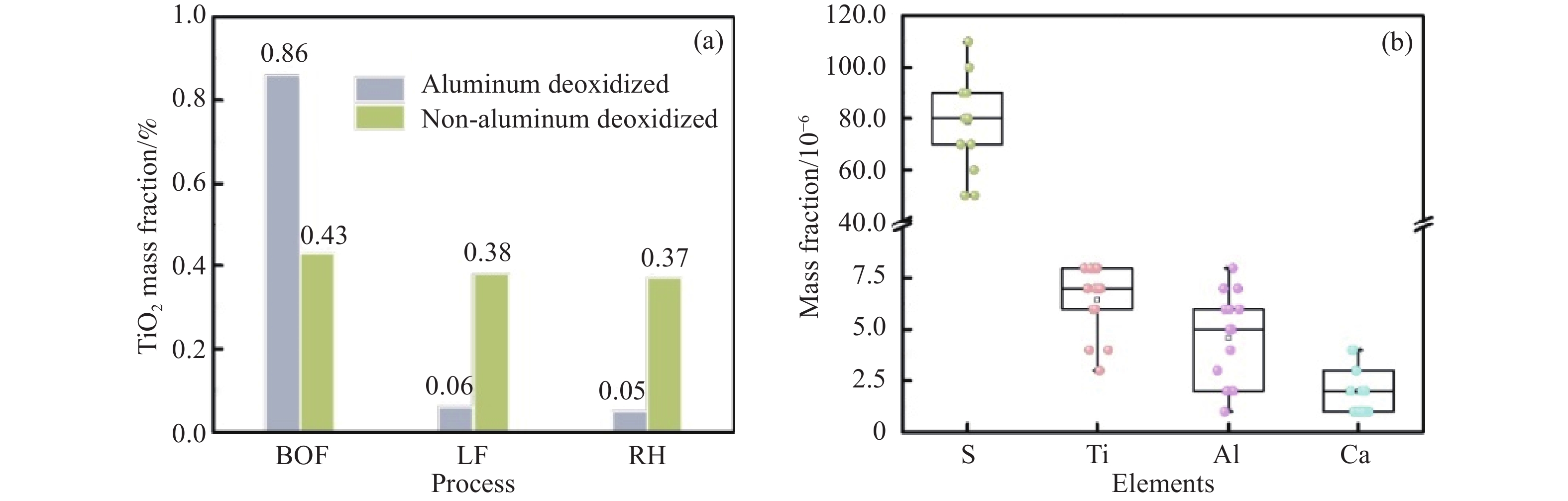

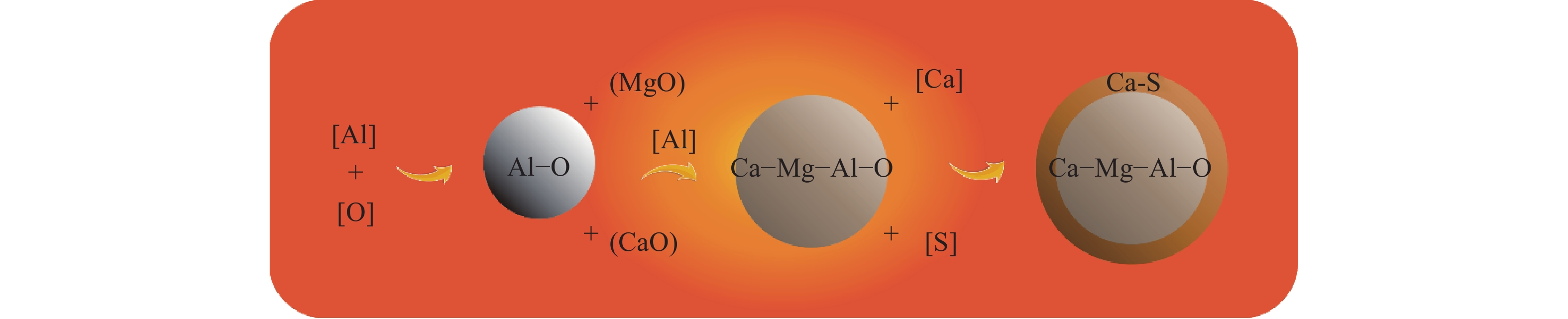

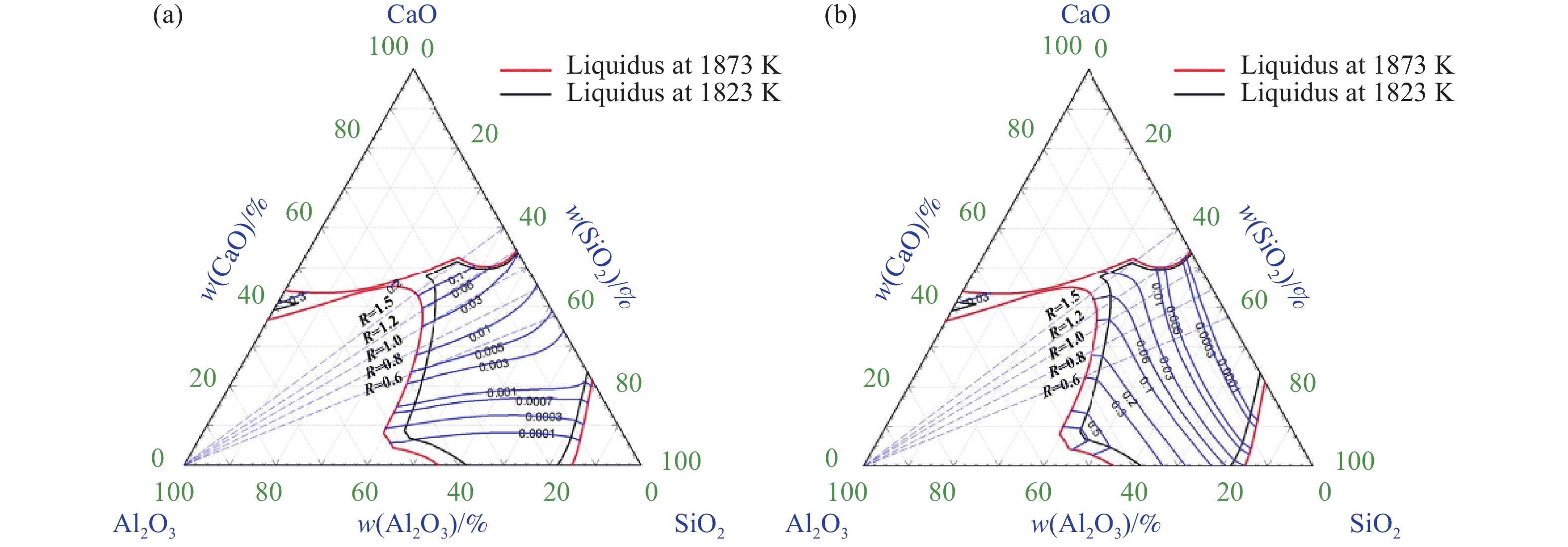

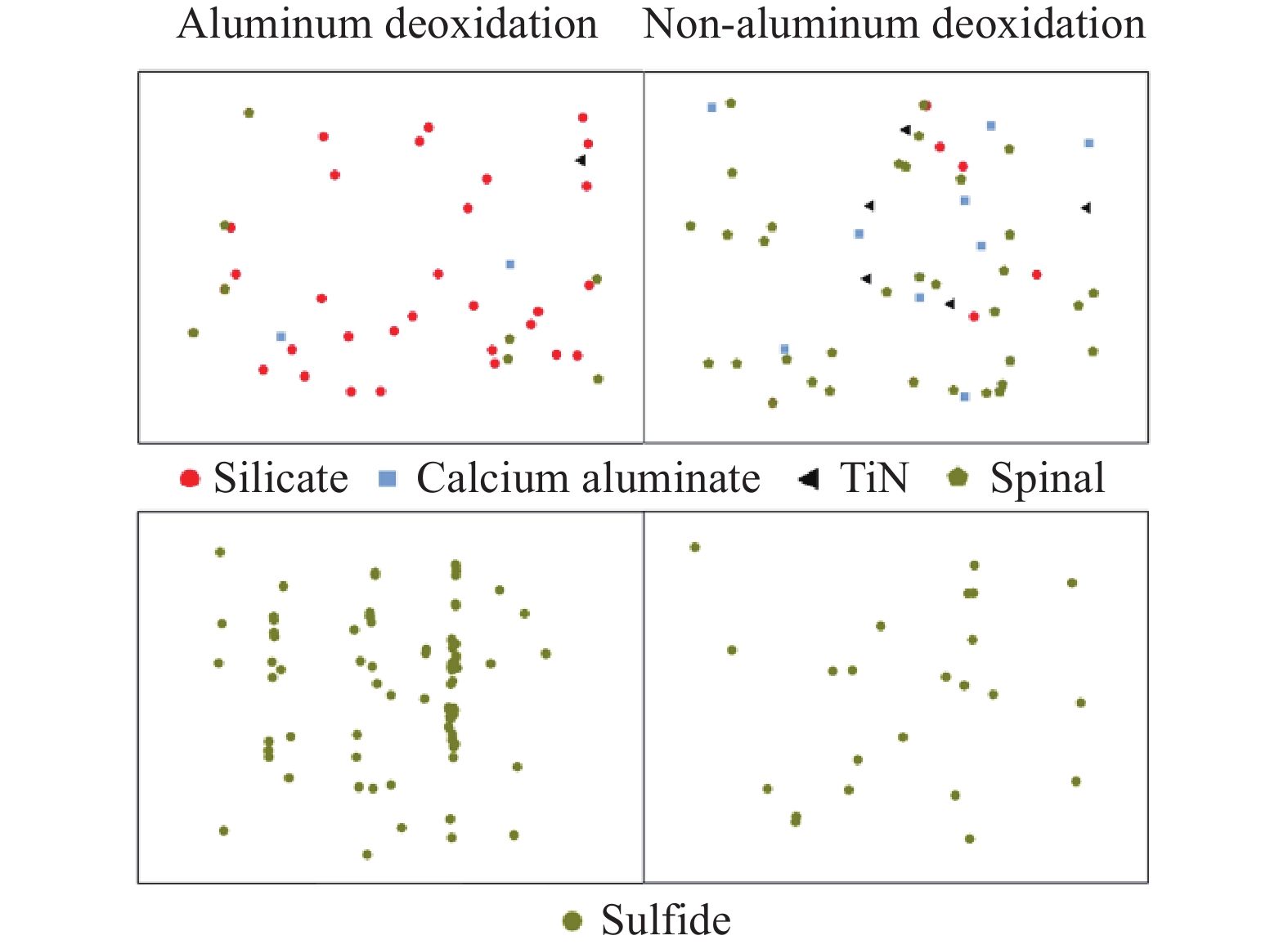

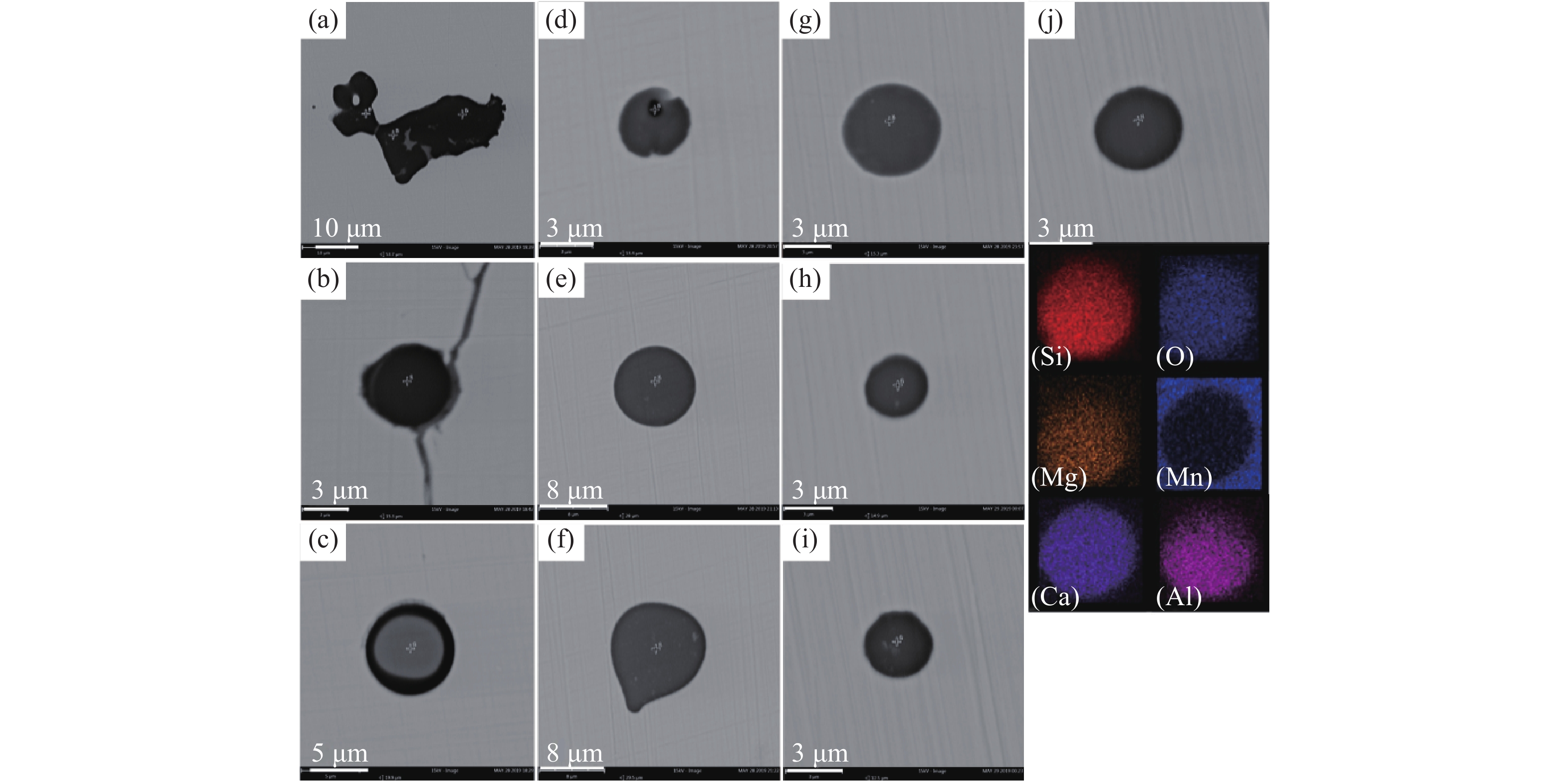

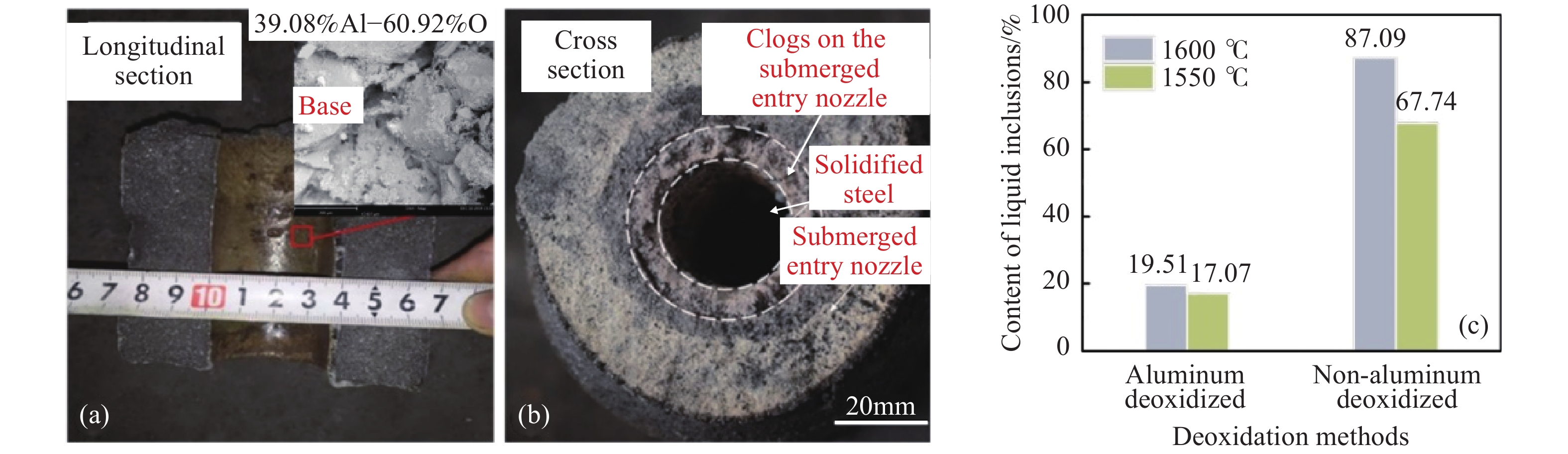

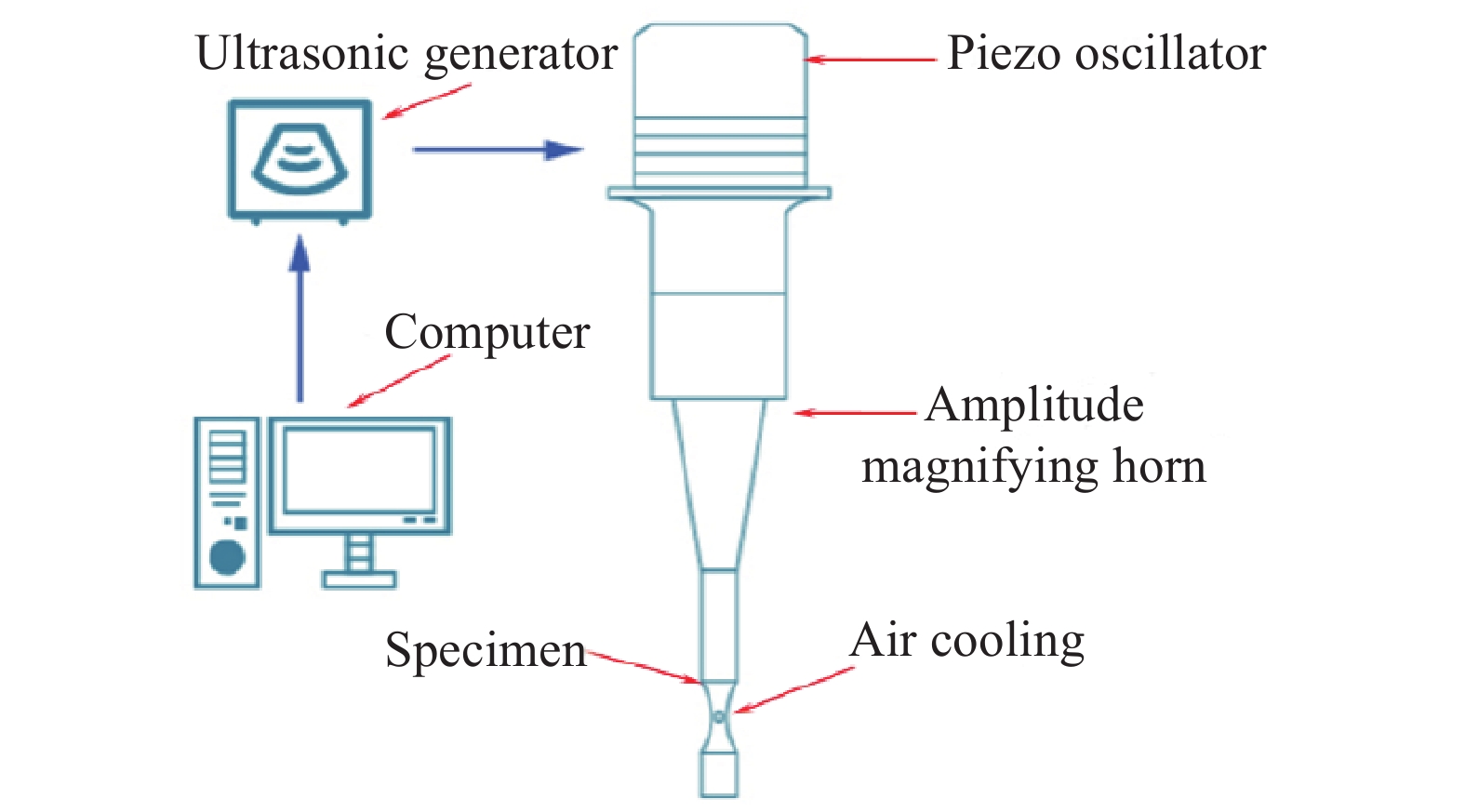

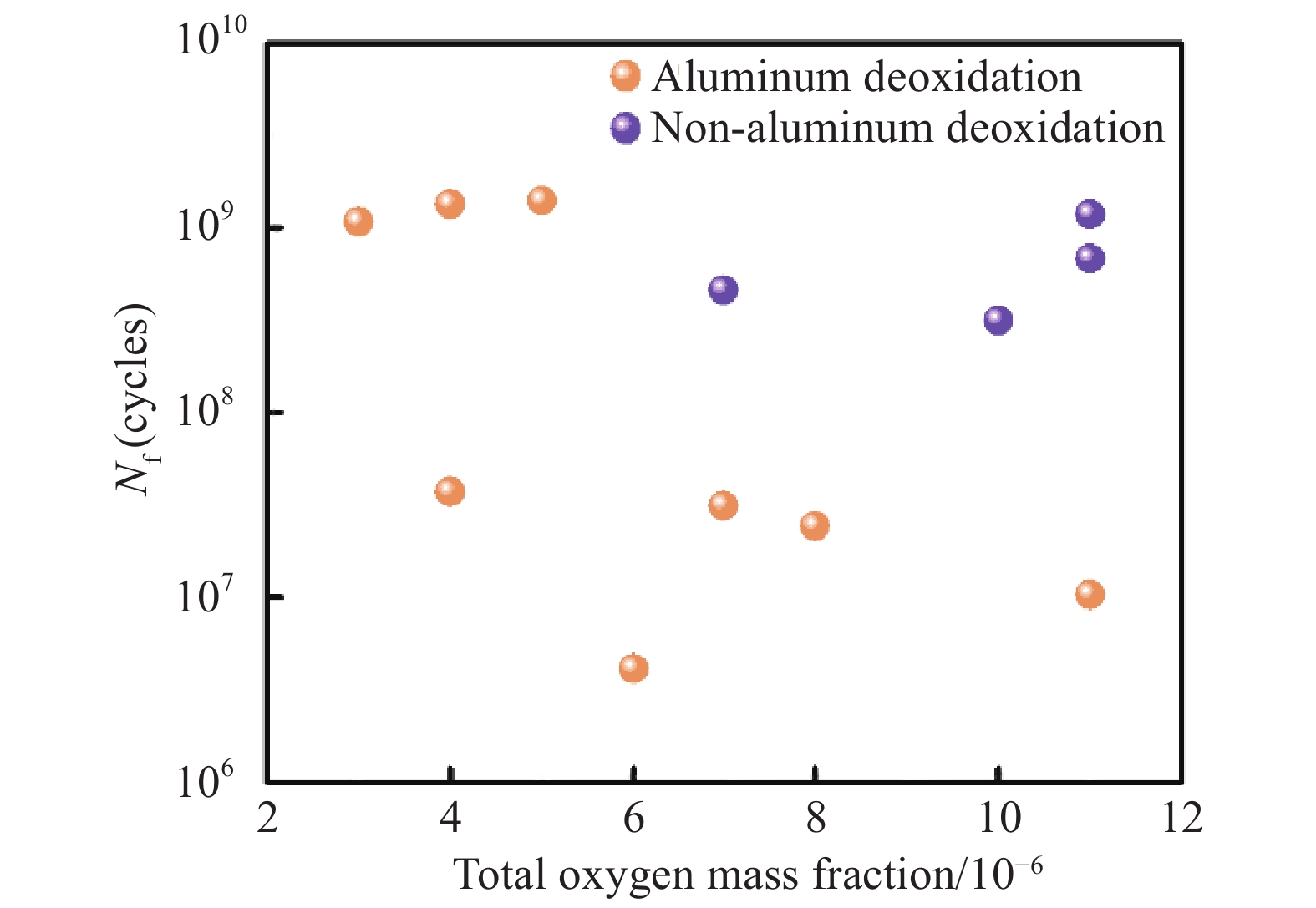

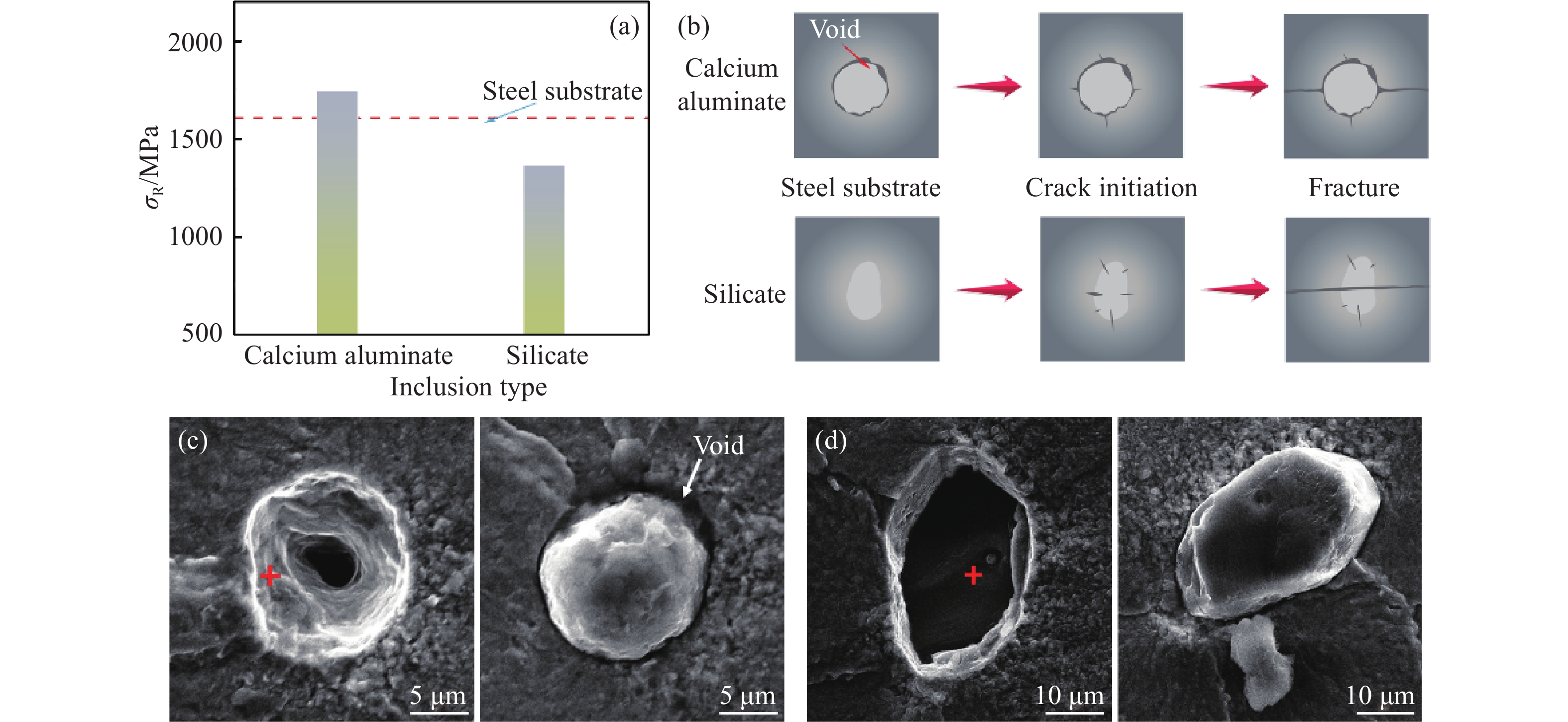

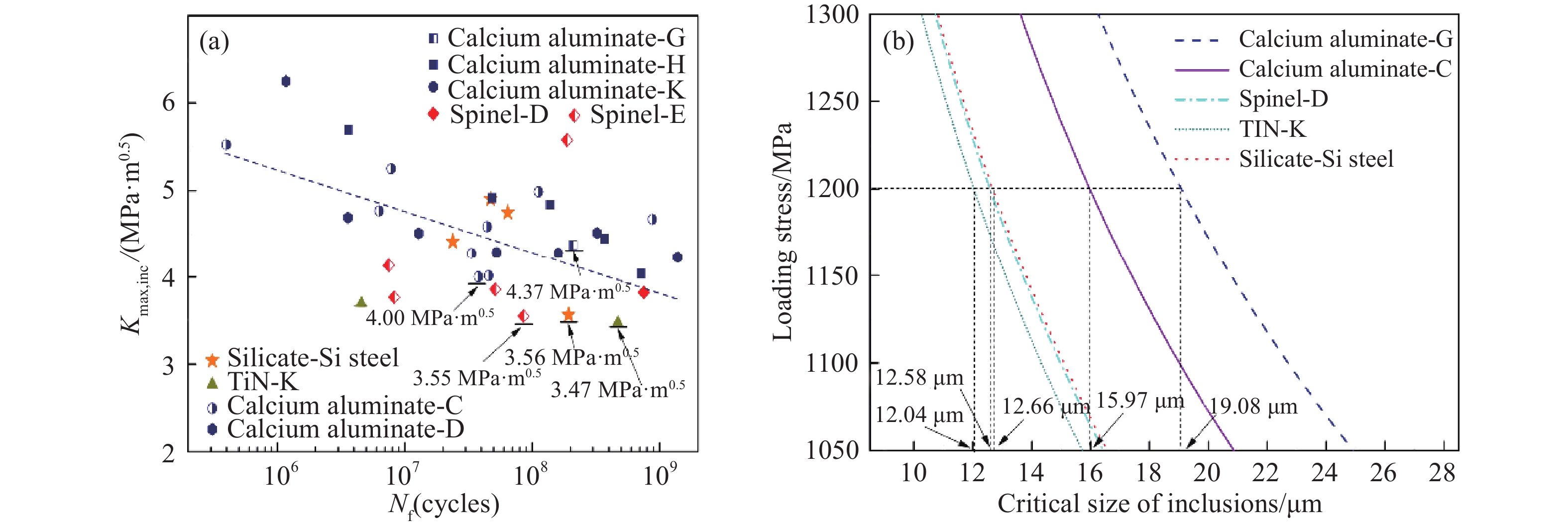

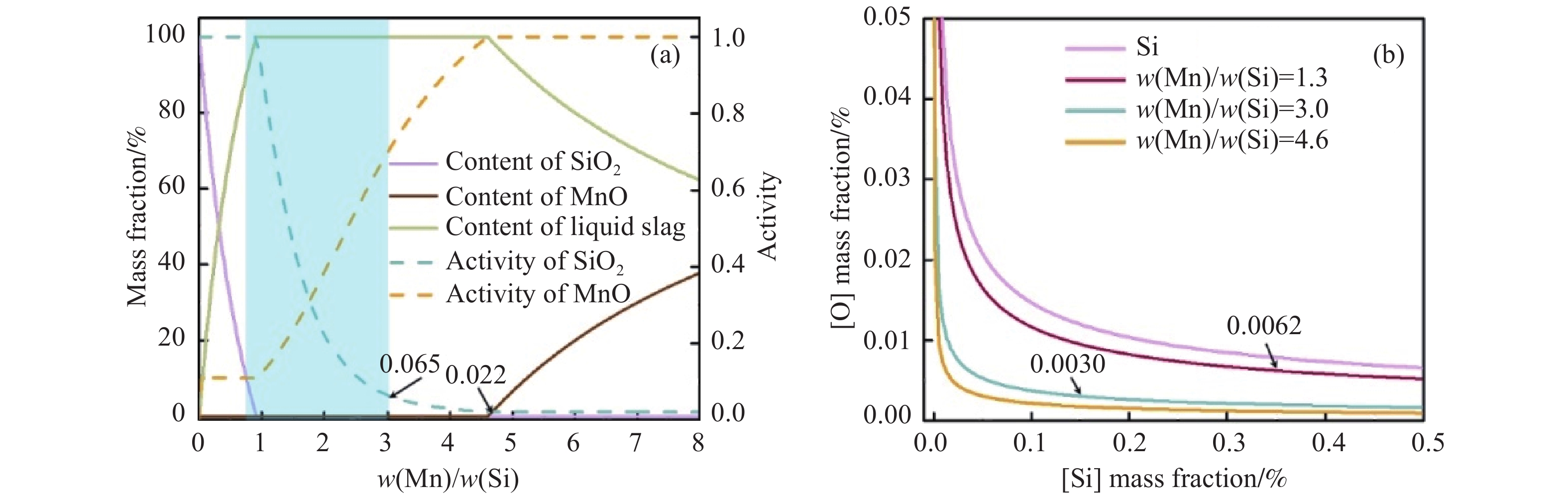

摘要: 我國高品質軸承鋼生產技術已取得了長足進步,部分企業的軸承鋼質量處于世界先進水平,但質量穩定性與世界領先水平仍存在一定差距。目前,國內外主要采用鋁脫氧工藝生產軸承鋼,通過鋁脫氧和造高堿度渣快速降低鋼液中氧含量,高品質軸承鋼中全氧質量分數已經可以控制在5×10?6以下,但仍存在大顆粒球狀(Ds類)類夾雜物導致疲勞失效的難題,以及超低全氧和鈦含量難以穩定控制、小方坯連鑄水口堵塞等問題。針對上述問題,本研究提出了非鋁脫氧工藝生產軸承鋼,即在轉爐出鋼時加入硅錳合金預脫氧,鋼包精煉爐(LF)向渣面加入硅質脫氧劑擴散脫氧,真空循環脫氣精煉(RH)真空深脫氧,保證鋼液全氧質量分數在8×10?6左右。在保證鋼液低鋁低鈦的同時,利用低堿度渣改變夾雜物類型,控制夾雜物塑性化,從而有效地解決鋼液流動性問題。利用超聲疲勞試驗機對兩種工藝軸承鋼疲勞壽命進行測定,闡明了不同類型夾雜物對疲勞性能的影響,剖析了不同工藝軸承鋼的疲勞斷裂機理,研究了引起疲勞裂紋的夾雜物臨界尺寸。Abstract: Bearing steel is subjected to complex alternating stress conditions for a long time which requires excellent service properties such as high hardness, high wear resistance, high elastic limit, and high contact fatigue strength. Therefore, during bearing steel production, it is necessary to strictly control the process and improve the purity of steel to ensure high precision, long service life, and high reliability of bearings. China has made considerable progress in the production technology of high-quality bearing steel, and some enterprises can produce world-class bearing steel. However, the stability of bearing steel still requires improvement. Currently, the aluminum deoxidation process is mainly used to produce bearing steel at home and abroad. Through aluminum deoxidation and the production of high-alkalinity slag, the oxygen content in liquid steel can be rapidly reduced. The total oxygen mass fraction in high-quality bearing steel can be controlled below 5×10?6. However, fatigue failure caused by occasional Ds-type inclusions still occurs. Concurrently, other problems such as blockage of small billet continuous casting nozzle and difficulty in stable control of ultralow total oxygen and titanium content also occur. To circumvent the aforementioned problems, this study proposed a nonaluminum deoxidation process by adding silicon–manganese alloy for pre-deoxidation during converter tapping, adding silicon deoxidizer to the ladle furnace (LF) slag surface for diffusion deoxidation, and Ruhrstahl?Heraeus (RH) vacuum deep deoxidation to ensure that the total oxygen mass fraction of the molten steel was approximately 8×10?6, to produce bearing steel. While ensuring the low aluminum and low titanium contents of liquid steel, low-alkalinity slag is used to change the type of inclusions and control the plasticity of inclusions to effectively solve the problem of liquid steel fluidity. The fatigue life of bearing steels by two kinds of processes was evaluated using the ultrasonic fatigue testing machine, the effects of different types of inclusions on fatigue performance were verified, the fatigue fracture mechanism of bearing steels by different processes was analyzed, and the critical size of inclusions causing fatigue cracks was predicted. The application of the aforementioned key technologies plays a guiding role in the large-scale production of nonaluminum deoxidized high-quality bearing steel. However, its quality still lags behind the most advanced production level of bearing steel worldwide, including the poor desulfurization effect caused by the use of low-basicity slag in the refining process, which needs to be further investigated.

-

Key words:

- bearing steel /

- silicomanganese deoxidation /

- vacuum deep deoxidation /

- inclusion /

- ultrasonic fatigue

-

圖 1 合金元素與脫氧效果關系. (a) 不同錳硅比對脫氧產物占比及活度的影響;(b) [Si]平衡鋼液中[O]質量分數變化

Figure 1. Relationship between alloying elements and deoxidation effect: (a) effects of different manganese–silicon ratios on the proportion and activity of each deoxidation product; (b) variation of [O] mass content in [Si] equilibrium molten steel

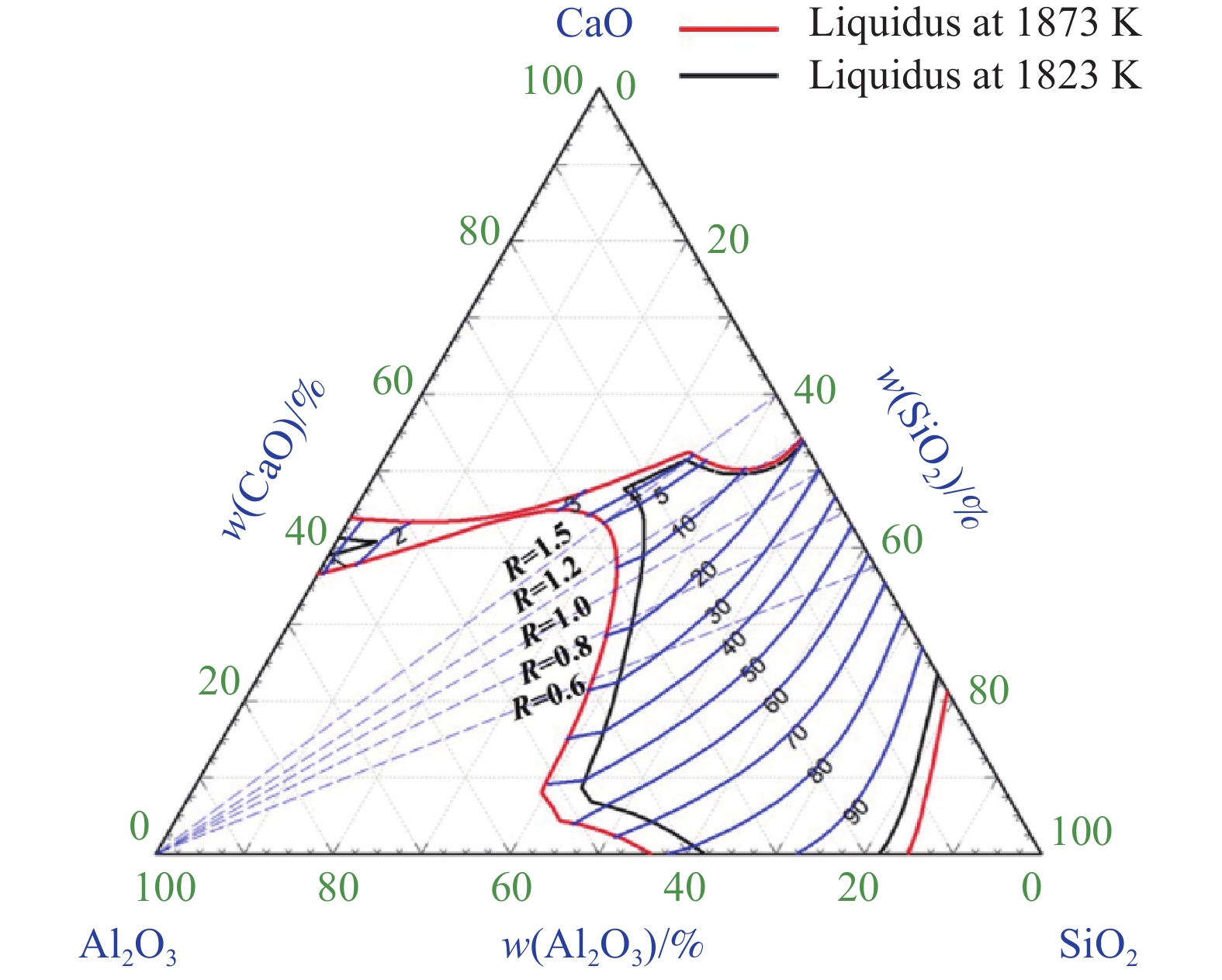

表 1 非鋁脫氧工藝冶煉軸承鋼LF精煉渣成分(質量分數)

Table 1. Composition of LF refining slag for smelting bearing steel by the nonaluminum deoxidation process

% Stage CaO SiO2 Al2O3 MgO MnO FeO R After the BOF 41.2 38.8 3.89 7.16 3.80 2.043 1.06 Start of LF refining 40.9 39.8 4.05 7.30 3.74 1.368 1.03 LF refining

before slagging48.7 34.8 3.74 7.73 0.736 2.133 1.40 LF refining

after slagging47.1 33.5 5.06 11.3 0.413 0.555 1.41 End of LF refining 37.8 42.0 4.71 12.2 0.805 0.900 0.90 表 2 非鋁脫氧工藝冶煉軸承鋼RH鋼包頂渣成分(質量分數)

Table 2. Composition of RH top slag smelting bearing steel by the nonaluminum deoxidation process

% Stage CaO SiO2 Al2O3 MgO MnO FeO R Start of RH 37.2 41.7 4.67 12.5 0.859 1.386 0.89 End of RH 37.6 41.8 4.76 12.4 0.882 0.945 0.90 表 3 不同工藝下Ds類夾雜物評級

Table 3. Ds inclusion ratings under different processes

Grade Aluminum deoxidized Nonaluminum deoxidized Quantity (heats) Proportion/% Quantity (heats) Proportion/% Grade 0 210 45.45 154 91.67 Grade 0.5 178 38.53 14 8.33 Grade 1.0 63 13.64 0 0 Grade 1.5 10 2.16 0 0 Grade 2.0 1 0.22 0 0 表 4 不同工藝下連澆爐數對比

Table 4. Comparison of continuous casting heats under different processes

Deoxidization process CC heats (heats) Average (heats) Total (heats) Nonaluminum 8–17 12.8 231 Low aluminum 5–10 7.9 270 Aluminum 5 5 — 表 5 力學參數和熱物性系數

Table 5. Mechanical parameters and thermophysical coefficients

Materials α/(10?6 ℃?1) E/GPa $\upsilon $ Silicate 2.47 71 0.21 Calcium Aluminate 5.0 113 0.23 Steel substrate 23.0 206 0.50 www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Cao W Q, Yu F, Wang C Y, et al. Status and future development of metallurgical quality and performance of bearing steels for high-end equipment. Special Steel, 2021, 42(1): 1曹文全, 俞峰, 王存宇, 等. 高端裝備用軸承鋼冶金質量性能現狀及未來發展方向. 特殊鋼, 2021, 42(1):1 [2] Gu C, Wang Z L, Xiao W, et al. Research status and progress on cleanliness of high-fatigue-life bearing steels. Chin J Eng, 2021, 43(3): 299顧超, 王仲亮, 肖微, 等. 高疲勞壽命軸承鋼潔凈度現狀及研究進展. 工程科學學報, 2021, 43(3):299 [3] Neishi Y, Makino T, Matsui N, et al. Influence of the inclusion shape on the rolling contact fatigue life of carburized steels. Metall Mater Trans A, 2013, 44(5): 2131 doi: 10.1007/s11661-012-1344-9 [4] Moghaddam S M, Sadeghi F. A review of microstructural alterations around nonmetallic inclusions in bearing steel during rolling contact fatigue. Tribol Trans, 2016, 59(6): 1142 doi: 10.1080/10402004.2016.1141447 [5] Hashimoto K, Fujimatsu T, Tsunekage N, et al. Effect of inclusion/matrix interface cavities on internal-fracture-type rolling contact fatigue life. Mater Des, 2011, 32(10): 4980 doi: 10.1016/j.matdes.2011.06.056 [6] Zong N F, Huang J, Liu J, et al. Present situation and prospect of key metallurgical technologies for improving quality of bearing steel. Bearing, 2020(12): 60宗男夫, 黃健, 劉軍, 等. 軸承鋼質量提升的關鍵冶金技術現狀及展望. 軸承, 2020(12):60 [7] Birat J P. Impact of steelmaking and casting technologies on processing and properties of steel. Ironmak Steelmak, 2001, 28(2): 152 doi: 10.1179/030192301677885 [8] Liu L. Key production-technology for high-quality special steels. Iron Steel, 2018, 53(4): 1劉瀏. 高品質特殊鋼關鍵生產技術. 鋼鐵, 2018, 53(4):1 [9] Xiao W, Bao Y P, Gu C, et al. Ultrahigh cycle fatigue fracture mechanism of high-quality bearing steel obtained through different deoxidation methods. Int J Miner Metall Mater, 2021, 28(5): 804 doi: 10.1007/s12613-021-2253-y [10] Li M, Wang X C, Duan J H, et al. Formation and controlling of Type-D inclusions in bearing steel. Chin J Eng, 2018, 40(Suppl 1): 31李明, 王新成, 段加恒, 等. 軸承鋼中D類夾雜物的形成與控制. 工程科學學報, 2018, 40(S1): 31 [11] Gu C, Bao Y P, Gan P, et al. Effect of main inclusions on crack initiation in bearing steel in the very high cycle fatigue regime. Int J Miner Metall Mater, 2018, 25(6): 623 doi: 10.1007/s12613-018-1609-4 [12] Kamiya T, Mizobe K, Kida K. Effect of observation position of SUJ2 bar specimens on inclusions distribution. IOP Conf Ser:Mater Sci Eng, 2018, 307: 012046 doi: 10.1088/1757-899X/307/1/012046 [13] Gu C, Wang M, Bao Y P, et al. Quantitative analysis of inclusion engineering on the fatigue property improvement of bearing steel. Metals, 2019, 9(4): 476 doi: 10.3390/met9040476 [14] Miao X D, Yu C M, Shi C M, et al. Formation and controlling of calcium-aluminates inclusions in bearing steel. J Univ Sci Technol Beijing, 2007, 29(8): 771 doi: 10.3321/j.issn:1001-053x.2007.08.005繆新德, 于春梅, 石超民, 等. 軸承鋼中鈣鋁酸鹽夾雜物的形成及控制. 北京科技大學學報, 2007, 29(8):771 doi: 10.3321/j.issn:1001-053x.2007.08.005 [15] Xiao W, Bao Y P, Wang M, et al. Inclusions evolution and control of non-aluminum deoxidized GCr15 bearing steel. Iron Steel, 2021, 56(1): 37肖微, 包燕平, 王敏, 等. 非鋁脫氧GCr15軸承鋼的夾雜物演變和控制. 鋼鐵, 2021, 56(1):37 [16] Wang L F, Zhuo X J, Zhang J M, et al. Controlling inclusion composition in steelmaking process for tire cord steel. J Univ Sci Technol Beijing, 2003, 25(4): 308 doi: 10.3321/j.issn:1001-053X.2003.04.005王立峰, 卓曉軍, 張炯明, 等. 冶金過程中簾線鋼夾雜物成分控制. 北京科技大學學報, 2003, 25(4):308 doi: 10.3321/j.issn:1001-053X.2003.04.005 [17] Wang X H. Iron and Steel Metallurgy: Steelmaking. Beijing: Higher Education Press, 2007王新華. 鋼鐵冶金: 煉鋼學. 北京: 高等教育出版社, 2007 [18] Xu Z Y, Zhao Z W, Jiang Y J, et al. Experiment on Nb-bearing microalloyed steel made directly by Nb-bearing hot metal. Iron Steel, 2015, 50(4): 13徐掌印, 趙增武, 姜銀舉, 等. 含鈮鐵水直接冶煉含鈮微合金鋼的試驗. 鋼鐵, 2015, 50(4):13 [19] Song L, Wang M, Li X, et al. Manganese migration behavior in the RH vacuum process of manganese-containing steel. Chin J Eng, 2020, 42(3): 331宋磊, 王敏, 李新, 等. 含錳鋼RH真空過程錳的遷移行為. 工程科學學報, 2020, 42(3):331 [20] Ling H T, Zhang L F. A mathematical model for prediction of carbon concentration during RH refining process. Metall Mater Trans B, 2018, 49(6): 2963 doi: 10.1007/s11663-018-1403-8 [21] Walker P F F. Improving the reliability of highly loaded rolling bearings: The effect of upstream processing on inclusions. Mater Sci Technol, 2014, 30(4): 385 doi: 10.1179/1743284713Y.0000000491 [22] Spriestersbach D, Grad P, Kerscher E. Influence of different non-metallic inclusion types on the crack initiation in high-strength steels in the VHCF regime. Int J Fatigue, 2014, 64: 114 doi: 10.1016/j.ijfatigue.2014.03.003 [23] Xie W X, Bao Y P, Wang M, et al. Relationship between high frequency defect detection and inclusions in GCr15 bearing steel. Iron Steel, 2015, 50(3): 44謝文新, 包燕平, 王敏, 等. GCr15軸承鋼探傷缺陷與夾雜物的關系. 鋼鐵, 2015, 50(3):44 [24] Park J H, Todoroki H. Control of MgO·Al2O3 spinel inclusions in stainless steels. ISIJ Int, 2010, 50(10): 1333 doi: 10.2355/isijinternational.50.1333 [25] Li L, Jiang Y, Wu J Y, et al. Formation and control of blockage at submerged nozzle of mold during GCr15 steel casting. Shanghai Met, 2020, 42(6): 35 doi: 10.3969/j.issn.1001-7208.2020.06.009李林, 江野, 吳建永, 等. GCr15鋼澆注過程浸入式水口結瘤的原因及控制. 上海金屬, 2020, 42(6):35 doi: 10.3969/j.issn.1001-7208.2020.06.009 [26] Sasai K, Mizukami Y. Mechanism of alumina adhesion to continuous caster nozzle with reoxidation of molten steel. ISIJ Int, 2001, 41(11): 1331 doi: 10.2355/isijinternational.41.1331 [27] Hua C J, Wang M, Zhang M Y, et al. Effect of submerged entry nozzle wall surface morphologies on boundary layer structure and alumina inclusions transport. Chin J Eng, 2021, 43(7): 925華承健, 王敏, 張孟昀, 等. 浸入式水口內壁特征對邊界層流場結構和氧化鋁夾雜物運動行為的影響. 工程科學學報, 2021, 43(7):925 [28] Li X S, Li N, Liu G Q, et al. Study on fatigue performance and life prediction of high strength bearing steel GCr15. China Met Equip Manuf Technol, 2020, 55(4): 141李新生, 李囡, 劉國強, 等. 高強軸承鋼GCr15的疲勞性能與壽命預測研究. 鍛壓裝備與制造技術, 2020, 55(4):141 [29] Deng H P, He B L, Yu Y X, et al. Research progress of ultra-high cycle fatigue for ferrous materials. Hot Work Technol, 2017, 46(4): 6鄧海鵬, 何柏林, 于影霞, 等. 鋼鐵材料超高周疲勞的研究進展. 熱加工工藝, 2017, 46(4):6 [30] Teng Z J, Wu H R, Huang Z Y, et al. Effect of mean stress in very high cycle fretting fatigue of a bearing steel. Int J Fatigue, 2021, 149: 106262 doi: 10.1016/j.ijfatigue.2021.106262 [31] Gu C. Microstructure Fatigue Life Prediction Model Based on the Effect of Inclusions in Bearing Steel [Dissertation]. Beijing: University of Science and Technology Beijing, 2019顧超. 高品質軸承鋼疲勞壽命預測模型及夾雜物影響規律研究[學位論文]. 北京: 北京科技大學, 2019 [32] Deng Z Y, Zhu M Y. Evolution mechanism of non-metallic inclusions in Al-killed alloyed steel during secondary refining process. ISIJ Int, 2013, 53(3): 450 doi: 10.2355/isijinternational.53.450 [33] Ma Y, Pan T, Jiang B, et al. Study of the effect of sulfur contents on fracture toughness of railway wheel steels for high speed train. Acta Metall Sin, 2011, 47(8): 978馬躍, 潘濤, 江波, 等. S含量對高速車輪鋼斷裂韌性影響的研究. 金屬學報, 2011, 47(8):978 [34] Gu C, Lian J H, Bao Y P, et al. Numerical study of the effect of inclusions on the residual stress distribution in high-strength martensitic steels during cooling. Appl Sci, 2019, 9(3): 455 doi: 10.3390/app9030455 [35] Gu C, Liu W Q, Lian J H, et al. In-depth analysis of the fatigue mechanism induced by inclusions for high-strength bearing steels. Int J Miner Metall Mater, 2021, 28(5): 826 doi: 10.1007/s12613-020-2223-9 [36] Murakami Y, Usuki H. Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels. II: Fatigue limit evaluation based on statistics for extreme values of inclusion size. Int J Fatigue, 1989, 11(5): 299 [37] Unal O, Maleki E, Varol R. Comprehensive analysis of pulsed plasma nitriding preconditions on the fatigue behavior of AISI 304 austenitic stainless steel. Int J Miner Metall Mater, 2021, 28(4): 657 doi: 10.1007/s12613-020-2097-x -

下載:

下載: