Advances and trends in high-temperature modification–crystallization control detoxification of stainless steel slag

-

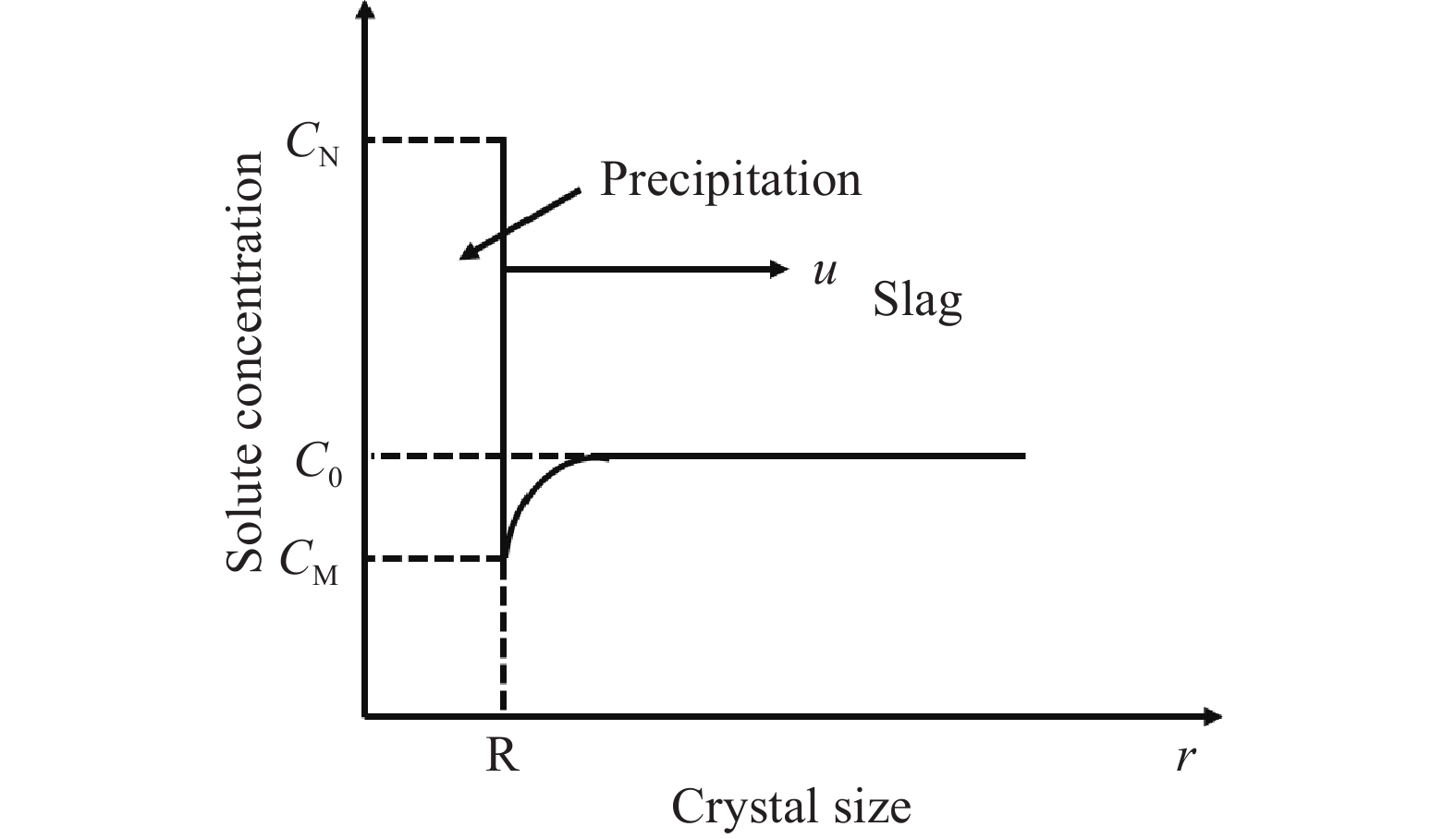

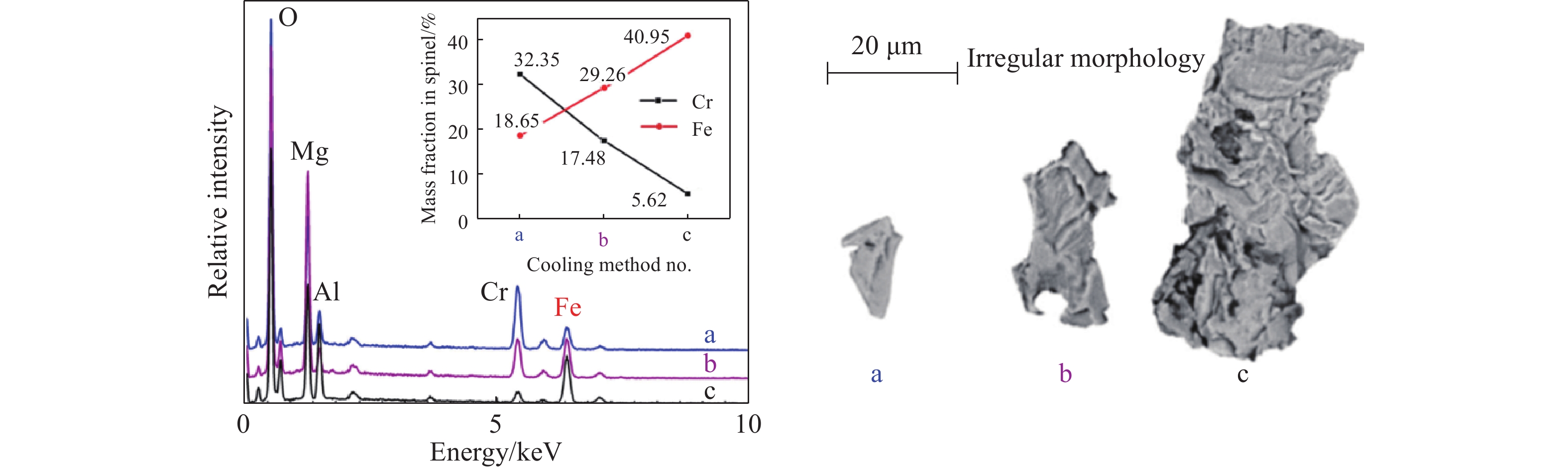

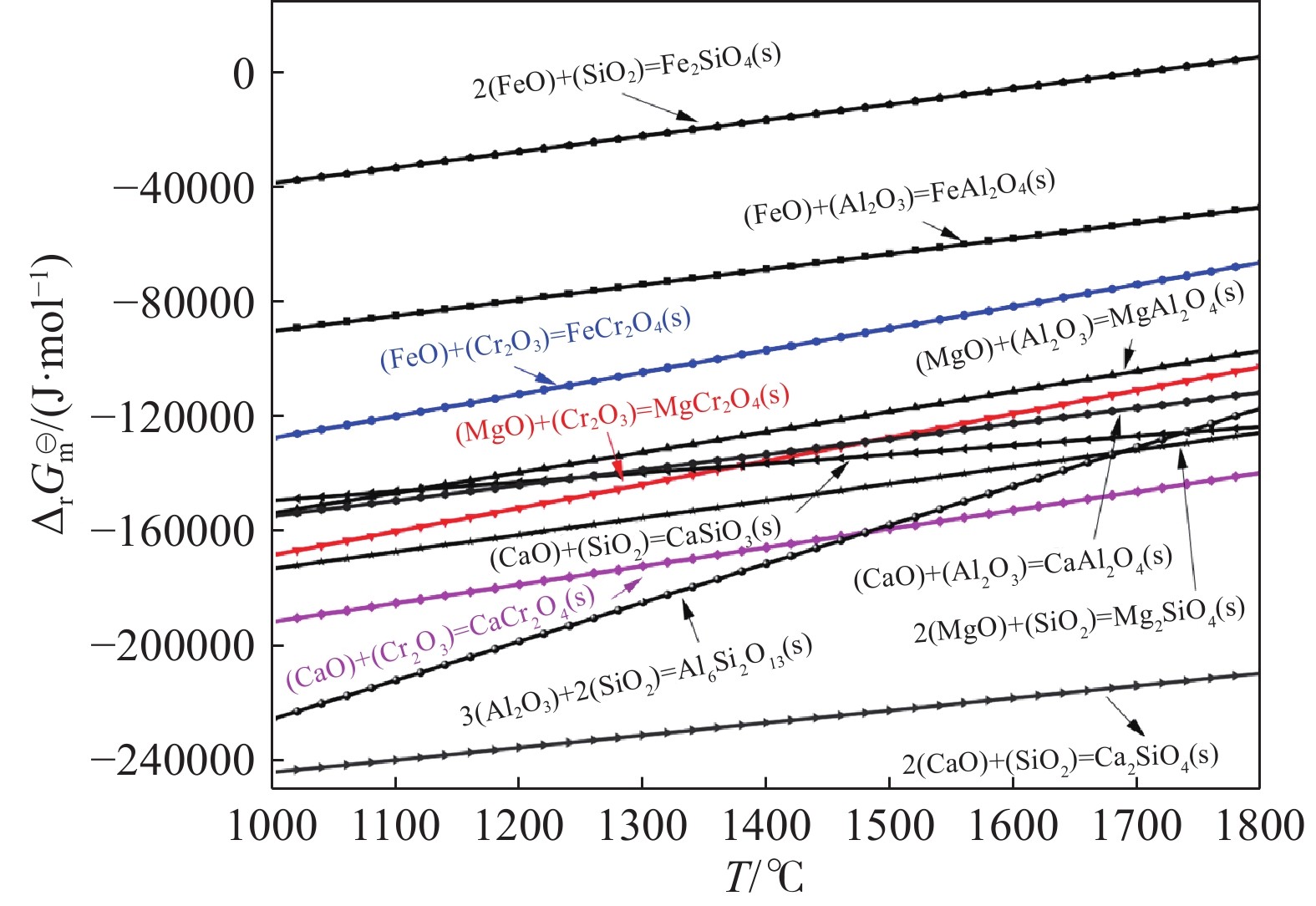

摘要: 截止到目前,鋼鐵工業普通固廢(高爐鐵渣)循環利用技術取得了重要進展,但仍存在固廢頑疾亟需處理。不銹鋼冶煉產生的含鉻(Cr)渣長期以來缺乏有效的無害化處置方法,環境隱患巨大。國內外專家學者通過添加還原物質、高溫調質及調節冷卻方式等以改變渣中鉻元素的賦存狀態,控制Cr6+的溶出,進而實現不銹鋼渣的解毒。其中,高溫改性?析晶調控方法可以通過調整鋼渣組分和控制溫度制度促進含鉻尖晶石相的形成和長大,提高鉻元素在尖晶石相中的富集程度,有望成為最有效且安全的無害化處理技術,在近些年得到快速發展。本文從不銹鋼渣高溫改性?析晶調控解毒的熱力學機理和結晶動力學原理出發,針對不銹鋼渣的高溫調質改性、解毒方面的研究進展進行了綜述。基于高溫調質?選擇性析晶的核心問題,重點闡述了改善解毒效果的方法和措施。另外,針對不銹鋼渣高溫改性?析晶調控解毒存在的問題提出了今后的發展方向。Abstract: To date, the recycling technology of common solid waste (blast furnace iron slag) in the iron and steel industry has made important progress. However, persisting, stubborn solid waste problems urgently need to be solved. With the continuous growth of stainless steel production in China, the total amount of stainless steel slag has reached more than 10 million tons. This slag contains a lot of CaO, MgO, and SiO2, which are suitable building material additives. However, the harmful element chromium (Cr) in the slag and the dissolution characteristics of Cr6+ ions limit its large-scale application. For a long time, no effective, harmless disposal method has been available for Cr-containing slag, which brings great hidden danger to the environment. Given the characteristics of stainless steel slag, the current detoxification methods mainly include the solidification method, wet reduction, high-temperature ferrosilicon reduction, and high-temperature modification–crystallization control processes. Among these methods, high-temperature modification–crystallization control can promote Cr-containing spinel phase formation by adjusting steel slag compositions (e.g., basicity and oxidation-reduction properties) to improve the enrichment degree of Cr in the spinel phase. At the same time, by adjusting the slag cooling system (e.g., the quenching temperature and holding time) and reducing the slag viscosity, the nucleation and growth of the Cr-containing spinel phase can be improved, the precipitation amounts of the spinel phase are increased, and the occurrence probability of chromium in the matrix phase is reduced; thus, the detoxification of stainless steel slag can be achieved. Compared with the other three detoxification treatment methods, high-temperature modification–crystallization control has the advantages of a simple process, stable treatment effect, and large scale. In particular, solid wastes containing silicon, aluminum, and magnesium can be used as additives to adjust the composition of steel slag to realize a coordinated treatment of various solid wastes, which has very high economic value. In addition, using waste heat to modify steel slag directly after slag picking can substantially reduce energy consumption, should become one of the most promising harmless treatment approaches, and has recently attracted extensive attention. In this paper, the research progress of high-temperature modification and detoxification of stainless steel slag is reviewed according to its thermodynamic mechanism and crystallization kinetics principles. On the basis of the core problem of melt modification-selective crystallization, the methods and measures for improving the detoxification effect are emphasized. In addition, aiming at the existing problems in the high-temperature modification–crystallization control detoxification of stainless steel slag, development directions are proposed.

-

表 1 EAF渣和AOD渣的主要化學成分(質量分數)[18-24]

Table 1. Main chemical compositions and contents of EAF and AOD slags (mass fraction)[18-24]

% Slag CaO SiO2 MgO FetO Cr2O3 Al2O3 MnO B EAF Slag 38.64?50.39 24.01?34.73 4.80?12.63 0.54?4.30 2.92?6.40 2.30?9.55 0.20?6.00 1.20?1.76 AOD Slag 54.10?66.10 24.67?26.50 2.06?6.30 0.20?1.81 0.25?1.83 1.07?4.91 0.16?1.02 2.04?2.49 表 2 EAF渣和AOD渣的主要礦相組成及Cr的賦存形式[18-24]

Table 2. Main mineral compositions of EAF/AOD slags and the existence form of Cr[18-24]

Slag Main mineral phase Other mineral phases Cr-containing phase EAF slag Ca2SiO4, Ca3MgSi2O8 Ca2(Al,Mg)[(Si,Al)SiO7], Al2SiO5, Fe3O4, (Fe,Mg)(Fe,Cr,Al)2O4,

Cr2O3, CaCr2O4, CaCrO4(Fe,Mg)(Fe,Cr,Al)2O4,

Cr2O3, CaCr2O4, CaCrO4AOD slag Ca2SiO4,Ca3MgSi2O8 (Fe,Mg)(Fe,Cr,Al)2O4, MgO, Fe-Cr-Ni (Fe,Mg)(Fe,Cr,Al)2O4, MgO, Fe-Cr-Ni 表 3 不銹鋼渣生成二元復合氧化物的化學反應方程及熱力學數據[29-32]

Table 3. Chemical reaction equations and thermodynamic data of slag[29-32]

Chemical reaction equation Standard reaction Gibbs free energy variation/ (J·mol?1) $ \left( {{\text{FeO}}} \right){\text{ + }}\left( {{\text{A}}{{\text{l}}_{\text{2}}}{{\text{O}}_{\text{3}}}} \right){\text{ = FeA}}{{\text{l}}_{\text{2}}}{{\text{O}}_{\text{4}}}\left( {\text{s}} \right) $ ${\Delta _{\text{r} } }{G_{\rm{m}}^{\ominus}}= - 144225 + 53.847T$ $ \left( {{\text{FeO}}} \right){\text{ + }}\left( {{\text{C}}{{\text{r}}_{\text{2}}}{{\text{O}}_{\text{3}}}} \right){\text{ = FeC}}{{\text{r}}_{\text{2}}}{{\text{O}}_{\text{4}}}\left( {\text{s}} \right) $ ${\Delta _{\text{r} } }{G_{\rm{m}}^{\ominus}} = - 204144 + 76.479T$ $ \left( {{\text{MgO}}} \right){\text{ + }}\left( {{\text{A}}{{\text{l}}_{\text{2}}}{{\text{O}}_{\text{3}}}} \right){\text{ = MgA}}{{\text{l}}_{\text{2}}}{{\text{O}}_{\text{4}}}\left( {\text{s}} \right) $ ${\Delta _{\text{r} } }{G_{\rm{m}}^{\ominus}} = - 224507 + 70.710T$ $ \left( {{\text{MgO}}} \right){\text{ + }}\left( {{\text{C}}{{\text{r}}_{\text{2}}}{{\text{O}}_{\text{3}}}} \right){\text{ = MgC}}{{\text{r}}_{\text{2}}}{{\text{O}}_{\text{4}}}\left( {\text{s}} \right) $ ${\Delta _{\text{r} } }{G_{\rm{m}}^{\ominus}} = - 250426 + 82.002T$ $ \left( {{\text{CaO}}} \right){\text{ + }}\left( {{\text{C}}{{\text{r}}_{\text{2}}}{{\text{O}}_{\text{3}}}} \right){\text{ = CaC}}{{\text{r}}_{\text{2}}}{{\text{O}}_{\text{4}}}\left( {\text{s}} \right) $ ${\Delta _{\text{r} } }{G_{\rm{m}}^{\ominus}} = - {\text{256506} } + {\text{82} }{\text{.002} }T$ $ \left( {{\text{CaO}}} \right){\text{ + }}\left( {{\text{Si}}{{\text{O}}_{\text{2}}}} \right){\text{ = CaSi}}{{\text{O}}_{\text{3}}}\left( {\text{s}} \right) $ ${\Delta _{\text{r} } }{G_{\rm{m}}^{\ominus}} = - {\text{181562} } + {\text{32} }{\text{.136} }T$ $ {\text{2}}\left( {{\text{CaO}}} \right){\text{ + }}\left( {{\text{Si}}{{\text{O}}_{\text{2}}}} \right){\text{ = C}}{{\text{a}}_{\text{2}}}{\text{Si}}{{\text{O}}_{\text{4}}}\left( {\text{s}} \right) $ ${\Delta _{\text{r} } }{G_{\rm{m}}^{\ominus}} = - {\text{287358} } + {\text{43} }{\text{.179} }T$ $ \left( {{\text{CaO}}} \right){\text{ + }}\left( {{\text{A}}{{\text{l}}_{\text{2}}}{{\text{O}}_{\text{3}}}} \right){\text{ = CaA}}{{\text{l}}_{\text{2}}}{{\text{O}}_{\text{4}}}\left( {\text{s}} \right) $ ${\Delta _{\text{r} } }{G_{\rm{m}}^{\ominus}} = - {\text{208581} } + {\text{53} }{\text{.750} }T$ $ {\text{2}}\left( {{\text{MgO}}} \right){\text{ + }}\left( {{\text{Si}}{{\text{O}}_{\text{2}}}} \right){\text{ = M}}{{\text{g}}_{\text{2}}}{\text{Si}}{{\text{O}}_{\text{4}}}\left( {\text{s}} \right) $ ${\Delta _{\text{r} } }{G_{\rm{m}}^{\ominus}}= - {\text{232410} } + {\text{59} }{\text{.229} }T$ $ {\text{2}}\left( {{\text{FeO}}} \right){\text{ + }}\left( {{\text{Si}}{{\text{O}}_{\text{2}}}} \right){\text{ = F}}{{\text{e}}_{\text{2}}}{\text{Si}}{{\text{O}}_{\text{4}}}\left( {\text{s}} \right) $ ${\Delta _{\text{r} } }{G_{\rm{m}}^{\ominus}} = - {\text{93882} } + {\text{55} }{\text{.045} }T$ $ {\text{3}}\left( {{\text{A}}{{\text{l}}_{\text{2}}}{{\text{O}}_{\text{3}}}} \right){\text{ + 2}}\left( {{\text{Si}}{{\text{O}}_{\text{2}}}} \right){\text{ = A}}{{\text{l}}_{\text{6}}}{\text{S}}{{\text{i}}_{\text{2}}}{{\text{O}}_{{\text{13}}}}\left( {\text{s}} \right) $ ${\Delta _{\text{r} } }{G_{\rm{m}}^{\ominus}} = - {\text{360987} } + {\text{135} }{\text{.387} }T$ 表 4 不銹鋼渣二元堿度對于選擇性富集、析出含鉻尖晶石相的影響

Table 4. Effect of the binary basicity of stainless steel slag on selective enrichment and formation of Cr-containing spinel

Slag system B Crystallization

temperature/ ℃Heating

time /hCr-containing

phaseCr mass fractionin

spinel phase /%CaO?SiO2?Cr2O3?MgO Synthetic slag [37] 1.0?2.0 1600 24 (CaMg)Cr2O4, Ca3MgSi2O8, Ca2SiO4,CaSiO3 32.27 CaO?SiO2?Cr2O3?MgO?FeO Synthetic slag [38] 0.6?2.2 1550 0.5 (Mg,Fe)(Fe,Cr)2O4 CaO?SiO2?Cr2O3?MgO?Al2O3 Synthetic slag [39] 1.1?1.5 1400 12 Mg(Al,Cr)2O4, Ca2MgSi2O7 46.70 CaO?SiO2?Al2O3?Cr2O3?MgO-CaF2?FeO

Synthetic slag[40]1.0?2.0 1300 0.5 Mg(Cr,Al)2O4, glass, MgO, Ca2SiO4 35.23 CaO?SiO2?Al2O3?CrOx?MgO?FetO Industrial slag [41] 0.96?1.96 1200 12 (Fe,Mg)(Cr,Al)2O4, CaSiO3, Ca2MgSi2O7 46.06 表 5 不銹鋼渣的化學成分(FetO、MgO、Al2O3)對于選擇性富集及析出含鉻尖晶石相的影響

Table 5. Effect of the chemical composition (FetO, MgO, Al2O3) of stainless steel slag on the selective enrichment and formation of Cr-containing spinel

Slag system Added compound

(mass fraction/%)Crystallization

temperature /℃Heating

time /hCr-containing

phaseCr content in

spinel phase/%CaO?SiO2?Al2O3?Cr2O3?MgO?

CaF2?FeO Synthetic slag[44]FeO (0?6.00) 1300 1 (Fe,Mg)(Cr,Fe,Al)2O4,MeO 27.21 (atom fraction) CaO?SiO2?Al2O3?Cr2O3?MgO?

FeO Synthetic slag[45]FeO (0?20.00) 1550 0.5 (Mg,Fe)(Cr,Fe,Al)2O4 27.38 (mass fraction) CaO?SiO2?Al2O3?Cr2O3?MgO?

Fe2O3 Synthetic slag[46]Fe2O3 (0?20.00) 1550 0.5 (Mg,Fe)(Cr,Fe,Al)2O4 CaO?SiO2?Al2O3?Cr2O3?MgO?FeO?Fe2O3

Synthetic slag[47]Fe2O3 (2.00?12.00) 1550 0.5 (Mg,Fe,Ca)(Cr,Fe,Al)2O4 12.79 (atom fraction) CaO?SiO2?Cr2O3?MgO

Synthetic slag[48]MgO (0?12.00) 1600 24 MgCr2O4,Cr2O3,CrO 63.98 (mass fraction) CaO?SiO2?Cr2O3?MgO?CaF2

Synthetic slag[35]MgO (0?9.00) 1600 0 CaCr2O4,CaCrO4,Ca5(CrO4)3F,

MgCr2O433.00 (mass fraction) CaO?SiO2?Al2O3?Cr2O3?MgO

Synthetic slag[51]Al2O3 (3.00?12.00) 1400 0.5 Mg(Al,Cr)2O4,Ca2SiO4,Melilite 10.94 (atom fraction) CaO?SiO2?Al2O3?Cr2O3?MgO?

FeO?CaF2 Synthetic slag[33]Al2O3 (4.00?16.00) 1300 0.5 Mg(Al,Cr)2O4,Ca2SiO4 18.23(atom fraction) CaO?SiO2?Al2O3?Cr2O3?MgO

Synthetic slag[34]Al2O3 (5.56?25.00) 1400?1600 48 Mg(Al,Cr)2O4 www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Zhao P. China's stainless steel output reached 30.139 million tons in 2020 [N/OL]. www. csteelnews. com (2021-1-27) [2022-2-10]. http://www.csteelnews.com/sjzx/gsfx/202101/t20210127_46237.html趙萍. 2020年中國不銹鋼產量達3013.9萬噸[N/OL]. 中國鋼鐵新聞網 (2021-1-27) [2022-2-10]. http://www.csteelnews.com/sjzx/gsfx/202101/t20210127_46237.html [2] Shen H T, Forssberg E, Nordstr?m U. Physicochemical and mineralogical properties of stainless steel slags oriented to metal recovery. Resour Conserv Recycl, 2004, 40(3): 245 doi: 10.1016/S0921-3449(03)00072-7 [3] Kim G, Sohn I. Selective metal cation concentration during the solidification of stainless steel EAF dust and slag mixtures from high temperatures for increased Cr recovery. J Hazard Mater, 2018, 359: 174 doi: 10.1016/j.jhazmat.2018.07.053 [4] Ouyang S L, Zhang Y X, Chen Y X, et al. Preparation of glass-ceramics using chromium-containing stainless steel slag: Crystal structure and solidification of heavy metal chromium. Sci Rep, 2019, 9: 1964 doi: 10.1038/s41598-018-37996-4 [5] Cheng Z W, Xu Y. Process technology of stainless steel smelting. Special Steel Technol, 2011, 17(1): 1程志旺, 許勇. 不銹鋼冶煉工藝技術. 特鋼技術, 2011, 17(1):1 [6] Cao L H. Study on the Enrichment and Stabilization of Chromium in Stainless Steel Slag [Dissertation]. Shenyang: Northeastern University, 2018操龍虎. 不銹鋼渣中鉻的富集及穩定化控制研究[學位論文]. 沈陽: 東北大學, 2018 [7] Bai Z T. Preparation and Characterization on the High-Carbon Ferrochromium Slag-based Glass-ceramics [Dissertation]. Beijing: University of Science and Technology Beijing, 2017白智韜. 高碳鉻鐵渣制備微晶玻璃及其性能的基礎研究[學位論文]. 北京: 北京科技大學, 2017 [8] Jia Z H. Study on the Occurrence State and Distribution Behavior of Chromium in the Preparation of Chromium Containing Glass Ceramics [Dissertation]. Ganzhou: Jiangxi University of Science and Technology, 2020賈志恒. 含鉻微晶玻璃制備過程中鉻的賦存狀態及分布行為研究[學位論文]. 贛州: 江西理工大學, 2020 [9] Zhang Y X. Study on the Effect of the Crystallization and Curing Effect of Heavy Metal Cr in the Slag Glass-Ceramics [Dissertation]. Baotou: Inner Mongolia University of Science & Technology, 2020張宇軒. 礦渣微晶玻璃中重金屬鉻固化效果及其對析晶影響的研究[學位論文]. 包頭: 內蒙古科技大學, 2020 [10] Bai Z T, Qiu G B, Peng B, et al. Synthesis and characterization of glass-ceramics prepared from high-carbon ferrochromium slag. RSC Adv, 2016, 6(58): 52715 doi: 10.1039/C6RA06245H [11] Huang Q F, Yang Y F, Wang Q. Potential for serious environmental threats from uncontrolled Co-processing of wastes in cement kilns. Environ Sci Technol, 2012, 46(24): 13031 doi: 10.1021/es3042274 [12] Lind B B, F?llman A M, Larsson L B. Environmental impact of ferrochrome slag in road construction. Waste Manage, 2001, 21(3): 255 doi: 10.1016/S0956-053X(00)00098-2 [13] Sheen Y N, Wang H Y, Sun T H. A study of engineering properties of cement mortar with stainless steel oxidizing slag and reducing slag resource materials. Constr Build Mater, 2013, 40: 239 doi: 10.1016/j.conbuildmat.2012.09.078 [14] Park D, Lim S R, Lee H W, et al. Mechanism and kinetics of Cr(VI) reduction by waste slag generated from iron making industry. Hydrometallurgy, 2008, 93(1-2): 72 doi: 10.1016/j.hydromet.2008.03.003 [15] Wang T G, Li Z H. Some thermodynamic properties of calcium chromate. J Chem Eng Data, 2004, 49(5): 1300 doi: 10.1021/je049968r [16] Estokova A, Palascakova L, Kanuchova M. Study on Cr(VI) leaching from cement and cement composites. Int J Environ Res Public Health, 2018, 15(4): 824 doi: 10.3390/ijerph15040824 [17] Rosales J, Cabrera M, Agrela F. Effect of stainless steel slag waste as a replacement for cement in mortars. Mechanical and statistical study. Constr Build Mater, 2017, 142: 444 doi: 10.1016/j.conbuildmat.2017.03.082 [18] Zhao Q Z, Li J G, Zeng Y N, et al. Thermodynamics of chromium oxidation of stainless steel slag under alkaline condition. Environ Prot Sci, 2020, 46(6): 173 doi: 10.16803/j.cnki.issn.1004-6216.2020.06.029趙慶忠, 李俊國, 曾亞南, 等. 堿性條件下不銹鋼渣中鉻的氧化行為熱力學. 環境保護科學, 2020, 46(6):173 doi: 10.16803/j.cnki.issn.1004-6216.2020.06.029 [19] Gao Z Y, Li J G, Liu B, et al. Mineralogical composition of EAF slag and its short-term leaching characteristics. Ind Saf Environ Prot, 2017, 43(11): 80 doi: 10.3969/j.issn.1001-425X.2017.11.021高志遠, 李俊國, 劉寶, 等. EAF渣礦相組成及其短期淋溶特性. 工業安全與環保, 2017, 43(11):80 doi: 10.3969/j.issn.1001-425X.2017.11.021 [20] Adegoloye G, Beaucour A L, Ortola S, et al. Mineralogical composition of EAF slag and stabilised AOD slag aggregates and dimensional stability of slag aggregate concretes. Constr Build Mater, 2016, 115: 171 doi: 10.1016/j.conbuildmat.2016.04.036 [21] Engstr?m F, Adolfsson D, Yang Q, et al. Crystallization behaviour of some steelmaking slags. Steel Res Int, 2010, 81(5): 362 doi: 10.1002/srin.200900154 [22] Mostafaee S, Andersson M, J?nsson P G. Petrographical study of microstructural evolution of EAF duplex stainless steelmaking slags. Ironmak Steelmak, 2011, 38(2): 90 doi: 10.1179/030192310X12731438631769 [23] Wang Y J, Li J G, Zheng N. Mineral compositions and microstructures of AOD stainless steel slag. Iron Steel Vanadium Titanium, 2013, 34(4): 68 doi: 10.7513/j.issn.1004-7638.2013.04.013王亞軍, 李俊國, 鄭娜. AOD不銹鋼渣礦相組成及其顯微形貌. 鋼鐵釩鈦, 2013, 34(4):68 doi: 10.7513/j.issn.1004-7638.2013.04.013 [24] Li J G, Liu B, Zeng Y N, et al. Maximum availability and mineralogical control of chromium released from AOD slag. Environ Monit Assess, 2017, 189(3): 113 doi: 10.1007/s10661-017-5843-4 [25] Han Z J, Holappa L. Bubble bursting phenomenon in gas/metal/slag systems. Metall Mater Trans B, 2003, 34(5): 525 doi: 10.1007/s11663-003-0020-2 [26] Han Z J, Holappa L. Mechanisms of iron entrainment into slag due to rising gas bubbles. ISIJ Int, 2003, 43(3): 292 doi: 10.2355/isijinternational.43.292 [27] Lee Y M, Nassaralla C L. Standard free energy of formation of calcium chromate. Mater Sci Eng A, 2006, 437(2): 334 doi: 10.1016/j.msea.2006.08.010 [28] Zhao Q, Liu C J, Li B K, et al. Decomposition mechanism of chromite in sulfuric acid-dichromic acid solution. Int J Miner Metall Mater, 2017, 24(12): 1361 doi: 10.1007/s12613-017-1528-9 [29] Yang X M, Duan J P, Shi C B, et al. A thermodynamic model of phosphorus distribution ratio between CaO?SiO2?MgO?FeO?Fe2O3?MnO?Al2O3?P2O5 slags and molten steel during a top-bottom combined blown converter steelmaking process based on the ion and molecule coexistence theory. Metall Mater Trans B, 2011, 42(4): 738 doi: 10.1007/s11663-011-9491-8 [30] Duan S C, Guo X L, Guo H J, et al. A manganese distribution prediction model for CaO?SiO2?FeO?MgO?MnO?Al2O3 slags based on IMCT. Ironmak Steelmak, 2017, 44(3): 168 doi: 10.1080/03019233.2016.1198859 [31] Liu X, Diao J, Ke Z Q, et al. Experimental investigation and thermodynamic modeling of vanadium, chromium and phosphorus distributions between FeO?SiO2?CaO?V2O3?Cr2O3?P2O5?MnO slag and semi-steel. Metall Res Technol, 2016, 113(4): 407 doi: 10.1051/metal/2016023 [32] Yang X M, Shi C B, Zhang M, et al. A thermodynamic model of phosphate capacity for CaO?SiO2?MgO?FeO?Fe2O3?MnO?Al2O3?P2O5 slags equilibrated with molten steel during a top-bottom combined blown converter steelmaking process based on the ion and molecule coexistence theory. Metall Mater Trans B, 2011, 42(5): 951 doi: 10.1007/s11663-011-9527-0 [33] Wang Z J, Sohn I. Understanding the solidification and leaching behavior of synthesized Cr-containing stainless steel slags with varying Al2O3/SiO2 mass ratios. Ceram Int, 2021, 47(8): 10918 doi: 10.1016/j.ceramint.2020.12.211 [34] García-Ramos E, Romero-Serrano A, Zeifert B, et al. Immobilization of chromium in slags using MgO and Al2O3. Steel Res Int, 2008, 79(5): 332 doi: 10.1002/srin.200806135 [35] Cabrera-Real H, Romero-Serrano A, Zeifert B, et al. Effect of MgO and CaO/SiO2 on the immobilization of chromium in synthetic slags. J Mater Cycles Waste Manag, 2012, 14(4): 317 doi: 10.1007/s10163-012-0072-y [36] Samada Y, Miki T, Hino M. Prevention of chromium elution from stainless steel slag into seawater. ISIJ Int, 2011, 51(5): 728 doi: 10.2355/isijinternational.51.728 [37] Albertsson G J, Teng L, Bj?rkman B. Effect of basicity on chromium partition in CaO?MgO?SiO2?Cr2O3 synthetic slag at 1873 K. Miner Process Extr Metall, 2014, 123(2): 116 doi: 10.1179/1743285513Y.0000000038 [38] Li J L, Zeng Q, Mou Q Q, et al. Effect of basicity on precipitation of spinel crystals in a CaO?SiO2?MgO?Cr2O3?FeO system. High Temp Mater Process, 2019, 38(2019): 867 doi: 10.1515/htmp-2019-0043 [39] Shu Q F, Luo Q Y, Wang L J, et al. Effects of MnO and CaO/SiO2 mass ratio on phase formations of CaO?Al2O3?MgO?SiO2?CrOx Slag at 1673 K and PO2 = 10-10 atm. Steel Res Int, 2014, 86(4): 391 [40] Cao L H, Liu C J, Zhao Q, et al. Analysis on the stability of chromium in mineral phases in stainless steel slag. Metall Res Technol, 2018, 115(1): 114 doi: 10.1051/metal/2017071 [41] Li W L, Xue X X. Effects of silica addition on chromium distribution in stainless-steel slag. Ironmak Steelmak, 2018, 45(10): 929 doi: 10.1080/03019233.2017.1412386 [42] Beukes J P, Guest R N. Technical note Cr(VI) generation during milling. Miner Eng, 2001, 14(4): 423 doi: 10.1016/S0892-6875(01)00022-X [43] Li J L, Xu A J, He D F, et al. Effect of FeO on the formation of spinel phases and chromium distribution in the CaO?SiO2?MgO?Al2O3?Cr2O3 system. Int J Miner Metall Mater, 2013, 20(3): 253 doi: 10.1007/s12613-013-0720-9 [44] Yu Y, Wang D, Li J L, et al. Thermodynamic calculation of FeO effect on precipitation of spinel containing chromium in CaO?SiO2?MgO?Al2O3?Cr2O3 system. J Wuhan Univ Sci Technol, 2018, 41(1): 15余岳, 王迪, 李建立, 等. FeO影響CaO?SiO2?MgO?Al2O3?Cr2O3體系中含鉻尖晶石晶體析出的熱力學分析. 武漢科技大學學報, 2018, 41(1):15 [45] Zeng Q, Li J L, Mou Q Q, et al. Effect of FeO on spinel crystallization and chromium stability in stainless steel-making slag. JOM, 2019, 71(7): 2331 doi: 10.1007/s11837-019-03465-0 [46] Mou Q Q, Li J L, Zeng Q, et al. Effect of Fe2O3 on the size and components of spinel crystals in the CaO?SiO2?MgO?Al2O3?Cr2O3 system. Int J Miner Metall Mater, 2019, 26(9): 1113 doi: 10.1007/s12613-019-1822-9 [47] Zeng Q, Li J L, Yu Y, et al. Occurrence and leaching behavior of chromium in synthetic stainless steel slag containing FetO. Minerals, 2021, 11(10): 1055 doi: 10.3390/min11101055 [48] Arredondo-Torres V, Romero-Serrano A, Zeifert B, et al. Stabilization of MgCr2O4 spinel in slags of the SiO2?CaO?MgO?Cr2O3 system. Rev Metal, 2006, 42(6): 417 [49] Morita K, Inoue A, Takayama N, et al. The solubility of MgO?Cr2O3 in MgO?Al2O3?SiO2?CaO slag at 1600 ℃ under reducing conditions. Tetsu-to-Hagane, 1988, 74(6): 999 doi: 10.2355/tetsutohagane1955.74.6_999 [50] Morita K, Shibuya T, Sano N. The solubility of the chromite in MgO?Al2O3?SiO2?CaO melts at 1600 ℃ in air. Tetsu-to-Hagane, 1988, 74(4): 632 doi: 10.2355/tetsutohagane1955.74.4_632 [51] Albertsson G, Teng L D, Bj?rkman B, et al. Effect of low oxygen partial pressure on the chromium partition in CaO?MgO?SiO2?Cr2O3?Al2O3 synthetic slag at elevated temperatures. Steel Res Int, 2013, 84(7): 670 doi: 10.1002/srin.201200214 [52] Cao L H, Liu C J, Zhao Q, et al. Effect of Al2O3 modification on enrichment and stabilization of chromium in stainless steel slag. J Iron Steel Res Int, 2017, 24(3): 258 doi: 10.1016/S1006-706X(17)30038-9 [53] Freij S J, Parkinson G M. Surface morphology and crystal growth mechanism of gibbsite in industrial Bayer liquors. Hydrometallurgy, 2005, 78(3-4): 246 doi: 10.1016/j.hydromet.2005.04.001 [54] Zhang L J, Chen Z Y, Hu Q M, et al. On the abnormal fast diffusion of solute atoms in α-Ti: A first-principles investigation. J Alloys Compd, 2018, 740: 156 doi: 10.1016/j.jallcom.2017.12.359 [55] Li J L, Mou Q Q, Zeng Q, et al. Experimental study on precipitation behavior of spinels in stainless steel-making slag under heating treatment. Processes, 2019, 7(8): 487 doi: 10.3390/pr7080487 [56] Sakai Y, Yabe Y, Takahashi M, et al. Elution of hexavalent chromium from molten sewage sludge slag: Influence of sample basicity and cooling rate. Ind Eng Chem Res, 2013, 52(10): 3903 doi: 10.1021/ie303354j [57] Albertsson G J, Engstr?m F, Teng L D. Effect of the heat treatment on the chromium partition in Cr-containing industrial and synthetic slags. Steel Res Int, 2014, 85(10): 1418 doi: 10.1002/srin.201300231 [58] Cao L H, Liu C J, Zhao Q, et al. Growth behavior of spinel in stainless steel slag during cooling process. J Iron Steel Res Int, 2018, 25(11): 1131 doi: 10.1007/s42243-018-0058-7 [59] Li W L, Xue X X. Effect of cooling regime on phase transformation and chromium enrichment in stainless-steel slag. Ironmak Steelmak, 2019, 46(7): 642 doi: 10.1080/03019233.2018.1436890 [60] Chan C, Young J. Physical stabilization of the beta to gamma transformation in dicalcium silicate. J Am Ceram Soc, 2005, 75(6): 1621 [61] Ghose A, Chopra S, Young J F. Microstructural characterization of doped dicalcium silicate polymorphs. J Mater Sci, 1983, 18(10): 2905 doi: 10.1007/BF00700771 [62] Klyuev V P, Pevzner B Z. The influence of aluminum oxide on the thermal expansion, glass transition temperature, and viscosity of lithium and sodium aluminoborate glasses. Glass Phys Chem, 2002, 28(4): 207 doi: 10.1023/A:1019954010719 [63] Klyuev V P, Pevzner B Z. Structural interpretation of the glass transition temperature and thermal expansion of glasses in the system BaO?Al2O3?B2O3. Phys Chem Glasses, 2000, 41(6): 380 [64] Klyuev V P, Pevzner B Z. Thermal expansion and transition temperature of glasses in the systems BeO?Al2O3?B2O3 and MgO?Al2O3?B2O3. J Non Cryst Solids, 2007, 353(18-21): 2008 doi: 10.1016/j.jnoncrysol.2007.01.065 [65] Lin Y, Luo Q Y, Yan B J, et al. Effect of B2O3 addition on mineralogical phases and leaching behavior of synthetic CaO?SiO2?MgO?Al2O3?CrOx slag. J Mater Cycles Waste Manag, 2020, 22(4): 1208 doi: 10.1007/s10163-020-01015-4 [66] Wang W, Liao W, Wu X R, et al. Study on occurrence and concentrating behavior of chromium in stainless steel slag. Multipurp Util Miner Resour, 2012(3): 42 doi: 10.3969/j.issn.1000-6532.2012.03.011王偉, 廖偉, 武杏榮, 等. 不銹鋼渣中鉻的賦存狀態與鉻的富集行為研究. 礦產綜合利用, 2012(3):42 doi: 10.3969/j.issn.1000-6532.2012.03.011 [67] Wu X R, Zhong Q B, Shen X M, et al. Influence of B2O3 on crystallization behavior of Cr-bearing phase in stainless steel slag // 2018 4th International Conference on Green Materials and Environmental Engineering (GMEE). Beijing, 2018: 1 [68] Li W L, Xue X X. Effects of boron oxide addition on chromium distribution and emission of hexavalent chromium in stainless-steel slag. Ind Eng Chem Res, 2018, 57(13): 4731 doi: 10.1021/acs.iecr.8b00499 -

下載:

下載: