Low-carbon development strategy analysis of the domestic and foreign steel industry

-

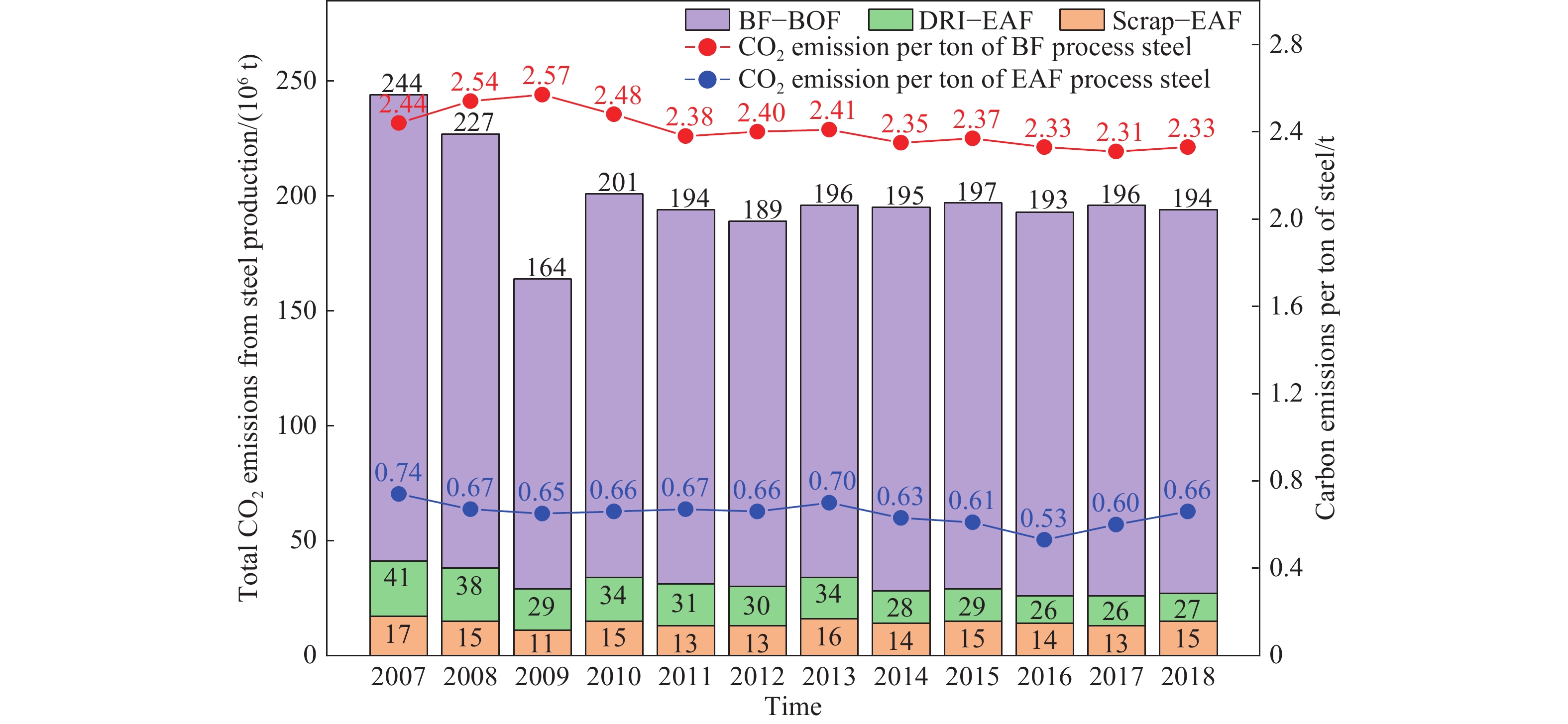

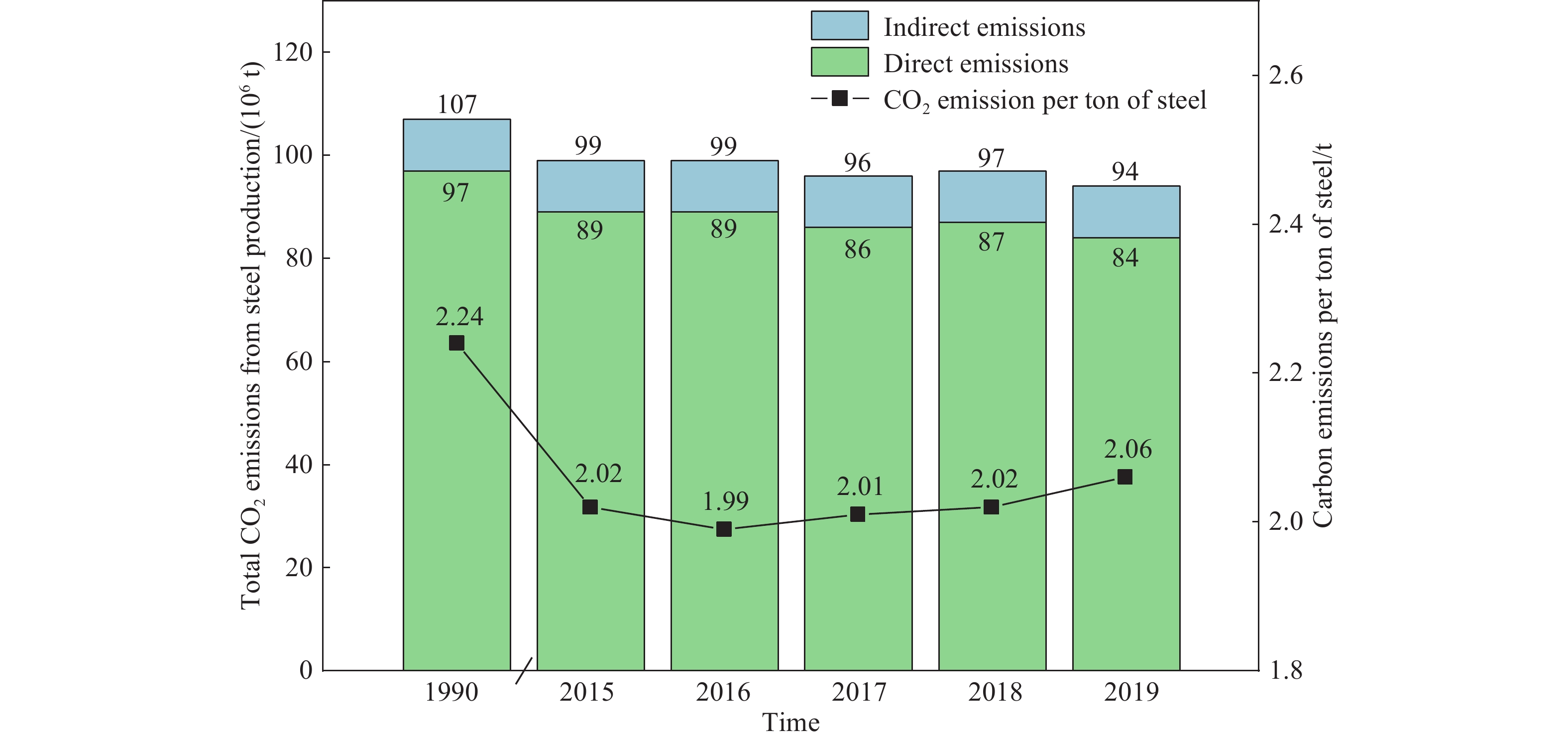

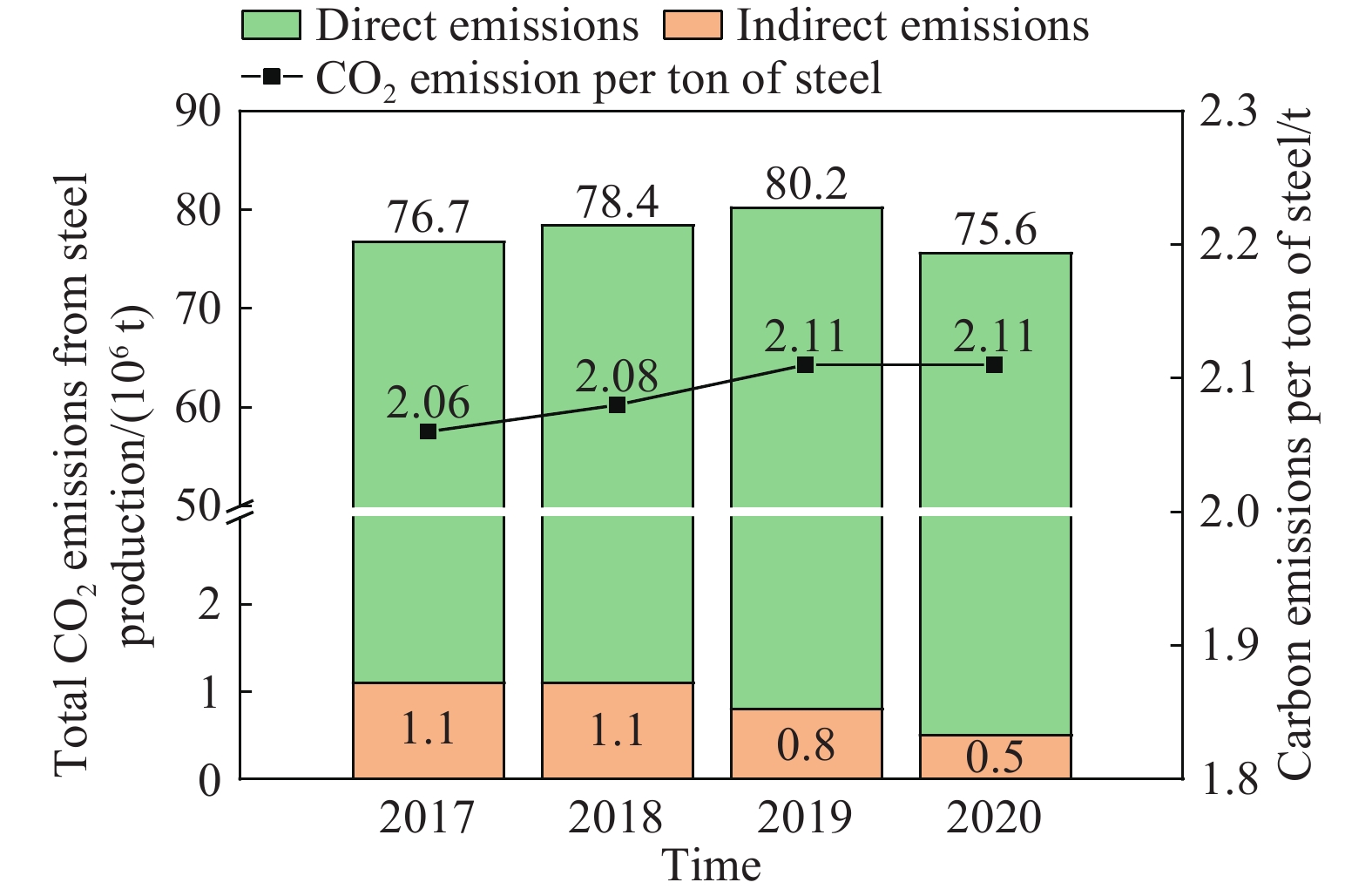

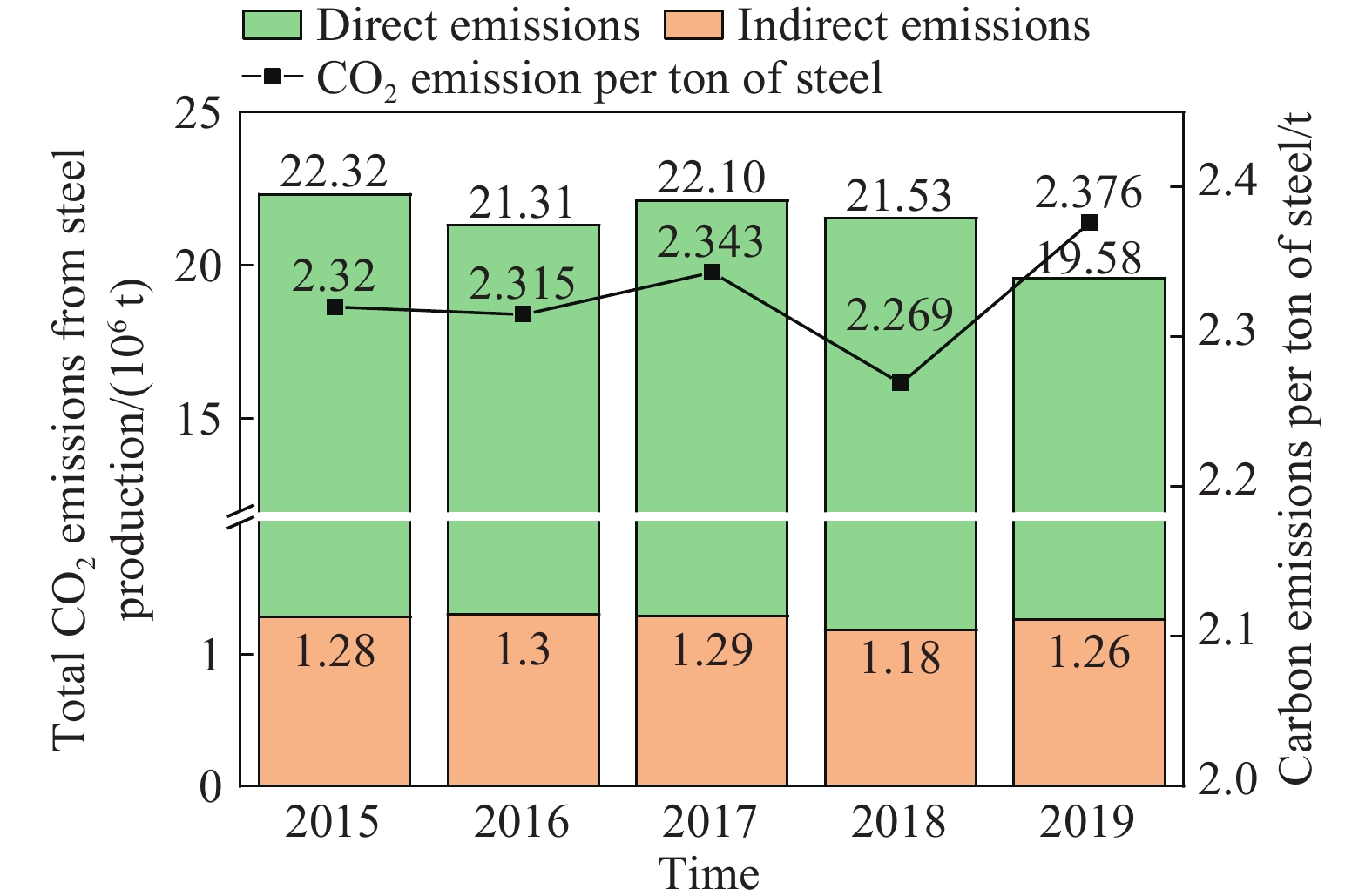

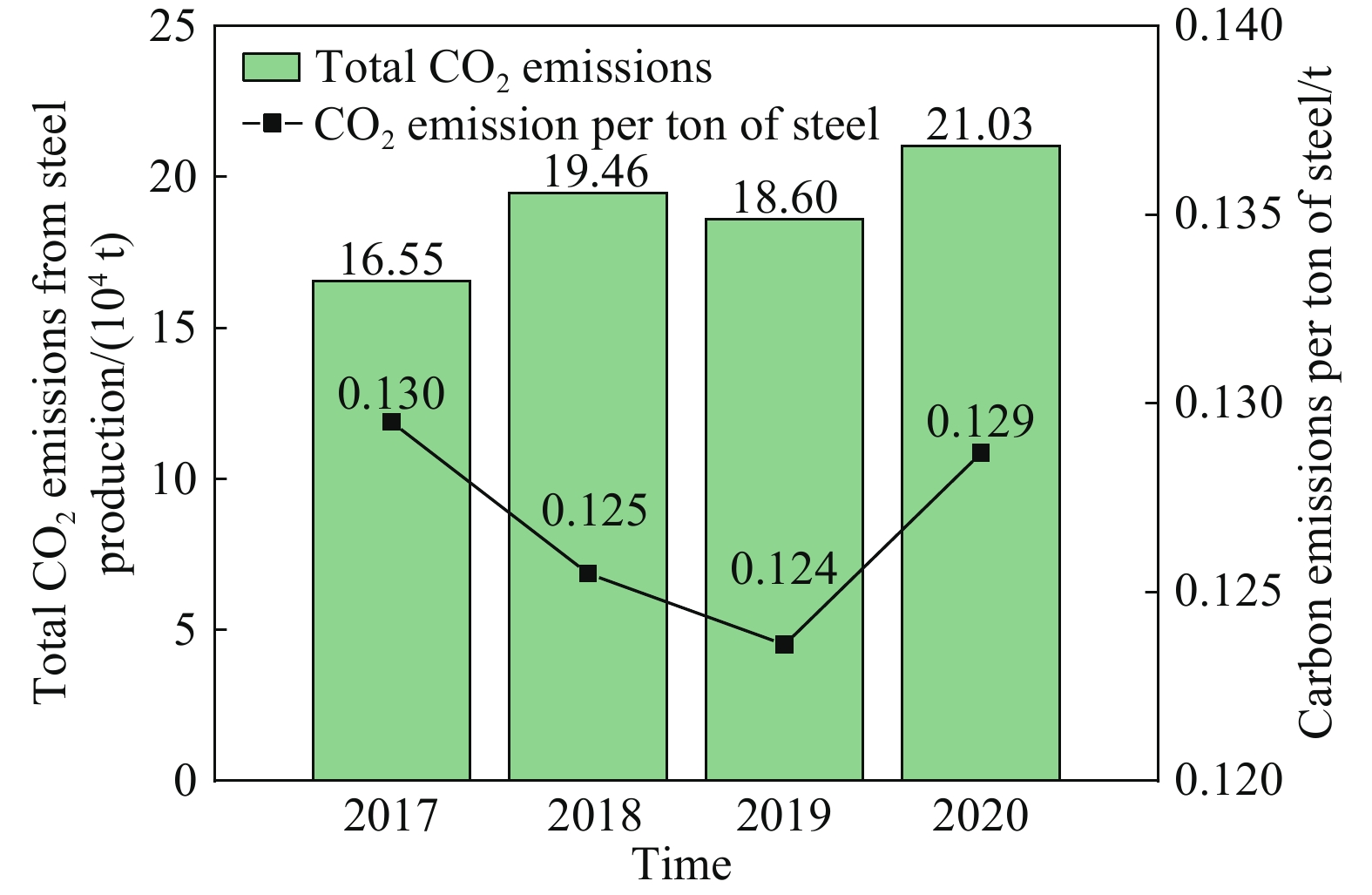

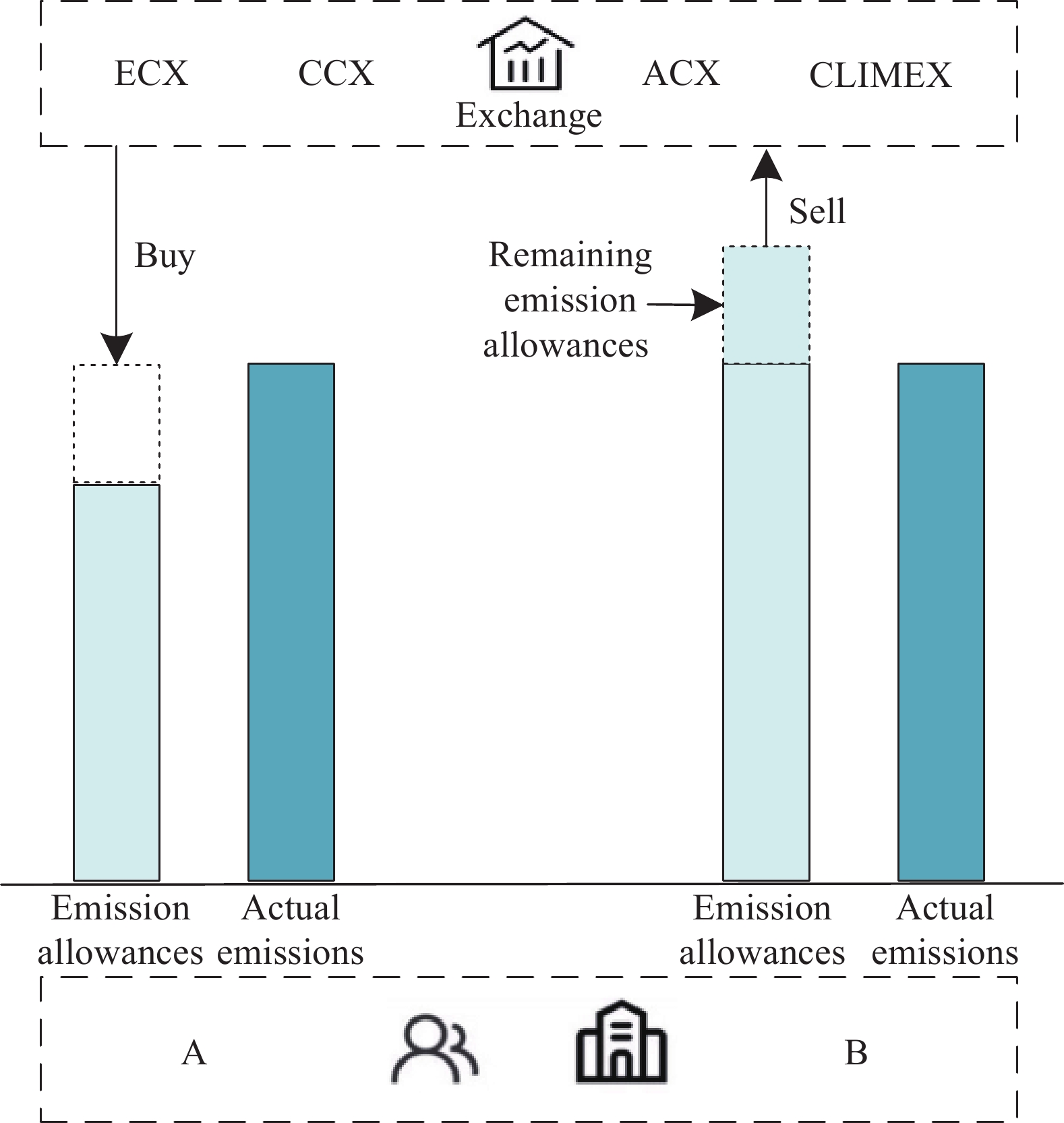

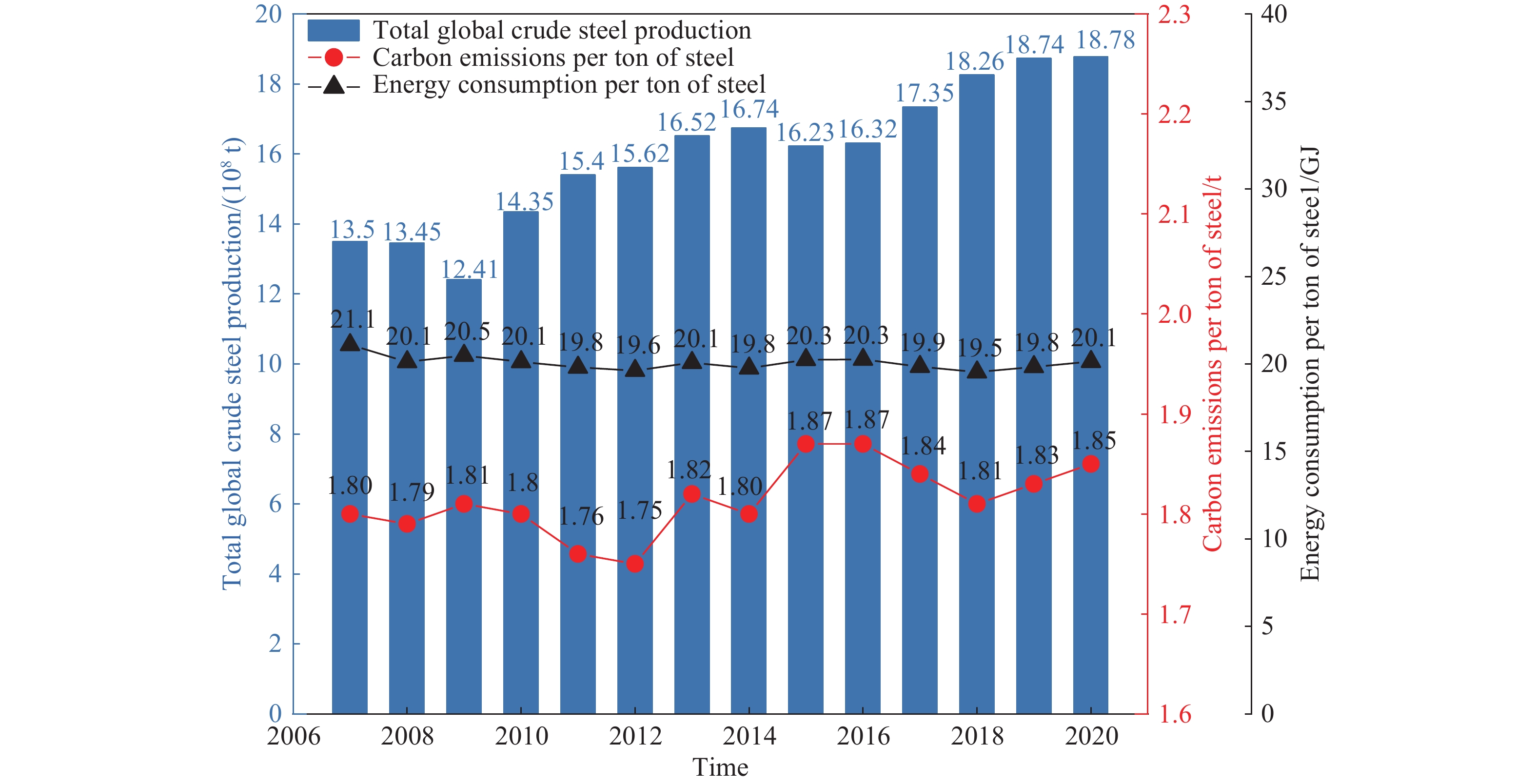

摘要: 在綠色化、低碳化發展的時代背景下,全球鋼鐵行業紛紛開展低碳研究工作,各類低碳技術層出不窮。首先概述了全球鋼鐵行業CO2排放現狀,以及主要產鋼國家的碳減排目標,并對其低碳策略進行詳細的分析,指出國際鋼鐵行業的低碳發展方向主要聚焦于發展電爐流程、氫冶金、碳捕集利用與封存和清潔能源利用等方面。隨后聚焦我國鋼鐵行業碳排放現狀,梳理了中國鋼鐵行業實現“雙碳”目標的應對策略,指出減量化發展、流程結構調整是未來我國鋼鐵行業低碳發展的主攻方向。最后,為了使前文所提的宏觀策略更加具體化,又選取我國某一典型鋼鐵企業,以其技術特點、地理位置、資源稟賦、發展規劃為主要依據,針對性地分析并提出了7條適合該企業的減排路徑,為其綠色低碳發展指明方向。Abstract: In an era of green and low-carbon development, the global steel industry has conducted low-carbon research, and various low-carbon technologies have continuously emerged. This paper summarizes the CO2 emission status of the global steel industry and international steel enterprises, such as ArcelorMittal, Nippon Steel, POSCO, and Big River Steel, and summarizes the carbon emission reduction targets and low-carbon development projects of major steel-producing countries, such as the United States and Japan. Based on this, the low-carbon strategy is analyzed in detail, noting that the low-carbon development direction of the international iron and steel industry is mainly focused on developing electric furnace processes, hydrogen metallurgy technology, carbon capture, utilization and storage (CCUS) technology, and clean energy utilization. In addition, the EU is actively building a carbon emission trading system and achieving carbon reduction using policies and regulations such as a carbon tax and carbon border tax. After analyzing the low-carbon development situation of the international steel industry, this paper focuses on the low-carbon green development of the domestic steel industry. Firstly, combined with the total output of crude steel, total CO2 emissions, CO2 emissions per ton of steel, and other data of China’s iron and steel industry, this paper analyzes the status quo of carbon emissions in China’s iron and steel industry. Secondly, it summarizes the carbon emission reduction targets of Baosteel, HBIS, and other large state-owned iron and steel enterprises. Thirdly, the countermeasures for China’s steel industry to achieve a “carbon peak and carbon neutrality” are summarized as follows: implement crude steel output control, adjust the production process structure, conduct research and development of low-carbon energy-saving technology, and build a carbon trading system; among them, reduction development and process structure adjustment are the main future directions of low-carbon development of China’s iron and steel industry, while low-carbon energy-saving technology and a carbon trading system are important guarantees for China’s iron and steel industry to achieve carbon neutrality. Finally, to make the four macro strategies proposed above more specific and visualized, a typical steel enterprise in China is selected based on its technical characteristics, geographical location, resource endowment, and development planning. Seven emission reduction paths, including iron resource optimization, process optimization and reconstruction, system energy efficiency improvement, energy consumption structure optimization, low-carbon technology transformation, industrial coordination, and carbon reduction management enhancement, are analyzed and proposed to point out the direction of green and low-carbon development for the enterprise.

-

Key words:

- CO2 emission /

- carbon peak /

- carbon neutrality /

- low-carbon technology /

- steel

-

圖 7 碳交易基本原理圖

Figure 7. Basic principles of carbon trading

Note: ECX: European climate exchange; CCX: Chicago climate exchange; ACX: Asia carbon exchange; CLIMEX: Dutch climate exchange[24]

表 1 主要產鋼國及鋼鐵企業低碳發展戰略目標一覽表

Table 1. List of low-carbon development strategic goals of major steel-producing countries and steel companies

Country/Industry Low carbon development strategic goals Related policy documents United States On the basis of greenhouse gas emissions in 2005, strive to reduce

emissions by 30% in 2025, 42% in 2030, and 83% in 2050《American Clean Energy and Security Act》 United States Steel

CorporationReduce greenhouse gas emission intensity by 20% by 2030 Nucor Corporation 35% reduction in 2015 total CO2 emissions by 2030 《Nucor 2020 Corporate Sustainability Report》 Japan On the basis of 2008 greenhouse gas emissions, strive to

achieve a reduction of 60% to 80% by 2050《Striving For A Low Carbon Society In Japan》

《Action Plan For Realizing Low

Carbon Society》Nippon Steel

CorporationBy 2030, CO2 emissions will be reduced by

30% from 2013 to 70 million tonsKorea On the basis of 2017 greenhouse gas emissions, strive to achieve

a 24.4% reduction in 2030 and carbon neutrality in 2050《Basic Law On Low Carbon Green Growth》

《2050 Long Term Low Greenhouse Gas

Emission Development Strategy》POSCO Short-term goal: 20% CO2 reduction in 2030

Intermediate-term goal: 50% CO2 reduction in 2040

Long-term goal: carbon neutrality by 2050

Emission reduction baseline: Average CO2 emission of

enterprises from 2017 to 2019 (78.8 million tons)Hyundai Steel 80% CO2 reduction by 2050 European Union Greenhouse gas emissions by 2030 are based on a 55%

reduction in 1990 and full carbon neutrality by 2050《European Green New Deal》

《2030 Climate Target Plan》ArcelorMittal CO2 emissions from European operations in 2030 are reduced

by 30% based on 2018 (194 million tons),

Achieving net-zero carbon emissions overall by 2050ThyssenKrupp 30% reduction in CO2 emissions by 2030,

The total output of green steel reaches 3 million tonsTata Steel Europe CO2 emissions will be reduced by 30% to 40% in 2030,

Achieving carbon neutrality by 2050表 2 主要產鋼國低碳項目/技術一覽表

Table 2. List of low-carbon projects/technologies in major steel-producing countries

Country/Region Participating units Low carbon project/ Technical name United States U.S. Department of Energy

American Iron and Steel Institute1. Research project on new technologies of CO2 emission in steel

production and low carbon steelmaking

2. Iron Ore Melting Oxidation Electrolysis Technology

3. Hydrogen-based Reduction Ironmaking Flash Melting TechnologyNucor Corporation 100% Wind Energy Powered Steelmaking Project Evraz Group、American Electric Power Company 100% Solar Powered Steelmaking Project Japan Japan Iron and Steel Federation COURSE50 Japan Iron and Steel Institute Zero emission power generation technology Korea Ministry of Trade, Industry and Energy of Korea COOLSTAR European Union European Steel Technology Platform (ESTEP) ULCOS Germany ThyssenKrupp Carbon2Chem Salzgitter、Tenova SALCOS ArcelorMittal MIDREX H2 Sweden SSAB、LKAB、Vattenfall HYBRIT Austria Voestalpine、Siemens AG、Verbund H2FUTURE 表 3 各制氫技術成本一覽表[21]

Table 3. List of Costs of various hydrogen production technologies

Types of hydrogen production Hydrogen production method Energy price Hydrogen production cost Hydrogen production from

water electrolysisValley Electricity Electrolysis Hydrogen Production 0.3 ¥·(kW·h)?1 20 ¥·kg?1 Industrial Electricity Electrolysis Hydrogen Production 0.6 ¥·(kW·h)?1 38 ¥·kg?1 Green Electricity Electrolysis Hydrogen Production 0.1 ¥·(kW·h)?1 10 ¥·kg?1 Hydrogen production

from fossil fuelsCoal hydrogen production 550 ¥·t?1 10 ¥·kg?1 Hydrogen production from natural gas 3 ¥·m?3 13 ¥·kg?1 表 4 國內部分鋼鐵企業碳達峰、碳中和行動規劃

Table 4. Action plan for carbon peak and carbon neutrality of some domestic steel companies

Steel Company Proposed Carbon Peaking, Carbon Neutrality Target Plan China Baowu Steel Group

Corporation LimitedCarbon peak in 2023 By 2025, have the technological ability to reduce carbon by 30% 30% carbon reduction from peak carbon emissions by 2035 Carbon neutrality in 2050 HBIS Group Corporation

LimitedCarbon peak in 2022 Reduce carbon emissions by more than 10% from peak carbon emissions by 2025 Reduce carbon emissions by more than 30% from peak carbon emissions by 2030 Carbon neutrality in 2050 Baotou Iron and Steel Group

Corporation LimitedCarbon peak in 2023 By 2030, have the technological ability to reduce carbon by 30% 50% carbon reduction from peak carbon emissions by 2042 Carbon neutrality in 2050 Anshan Iron and Steel Group

Corporation LimitedCarbon peak by 2025 Achieve breakthroughs in the industrialization of cutting-edge

low-carbon metallurgical technology by 203030% carbon reduction from peak carbon emissions by 2035 www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] International Energy Agency. Global Energy Review 2020 [R/OL]. Report Online (2020-04-27) [2022-01-05].https://iea.blob.core.windows.net/assets/7e802f6a-0b30-4714-abb1-46f21a7a9530/Global_Energy_Review_2020.pdf [2] Zhao Y J. Study on Carbon Emission Cost Accounting and Evaluation of Iron and Steel Enterprises [Dissertation]. Changsha: Central South University, 2012趙雅敬. 鋼鐵企業碳排放成本核算與評價研究[學位論文]. 長沙: 中南大學, 2012 [3] World Steel Association. Climate change and the production of iron and steel [R/OL]. Report Online (2021-05-19) [2022-01-05].https://worldsteel.org/wp-content/uploads/Climate-change-and-the-production-of-iron-and-steel.pdf [4] World Steel Association. Global crude steel output decreases by 0.9% in 2020 [R/OL]. Report Online (2021-01-26) [2022-01-05].https://www.worldsteel.org/media-centre/press-releases/2021/Global-crude-steel-output-decreases-by-0.9--in-2020.html [5] International Energy Agency. Iron and steel technology roadmap [R/OL]. Report Online (2020-10-08) [2022-01-05].https://www.iea.org/reports/iron-and-steel-technology-roadmap [6] World Steel Association. Sustainability Indicators 2021 Report [R/OL] Report Online (2021-11-13) [2022-01-05]https://worldsteel.org/wp-content/uploads/Sustainability-Indicators-2021-Report.pdf [7] ArcelorMittal. Climate Action Report (2019) [R/OL]. Report Online (2019-05-29) [2022-01-05].https://storagearcelormittalprod.blob.core.windows.net/media/hs4nmyya/am_climateactionreport_1.pdf [8] Nippon Steel Corporation. 2020 Sustainability Report [R/OL]. Report Online (2020-10-09) [2022-01-05].https://www.nipponsteel.com/common/secure/en/csr/report/nsc/pdf/report2020.pdf [9] POSCO. POSCO Corporate Citizenship Report 2020 [R/OL]. Report Online (2021-06-04) [2022-01-05].https://www.posco.co.kr/docs/eng6/jsp/dn/irinfo/posco_report_2020.pdf [10] China Steel Corporation. 2020 Corporate Social Responsibility Report [R/OL]. Report Online (2021-05-11) [2022-01-05]. https: //www. csc. com. tw/csc/hr/e/hr-2020.pdf中國鋼鐵股份有限公司. 2020年企業社會責任報告[R/OL]. 在線報道 (2021-05-11) [2022-01-05].https://www.csc.com.tw/csc/hr/e/hr-2020.pdf [11] Big River Steel. Corporate Social Responsibility Report (2019) [R/OL]. (2021-05-24) [2022-01-05].https://bigriversteel.com/wp-content/uploads/2021/05/BRS2106-CSR-Report-Update-052421-Final.pdf [12] Energy Information Administration. How much carbon dioxide is produced per kilowatt-hour of U. S. electricity generation? [EB/OL]. Question Online (2021-11-04) [2022-01-05].https://www.eia.gov/tools/faqs/faq.php?id=74&t=11 [13] China Electricity Council. China Electricity Council Releases Annual Development Report of China's Electric Power Industry 2020 [R/OL]. Report Online (2020-06-12) [2022-01-05]. https://cec.org.cn/detail/index. html?3-284175中國電力企業聯合會. 中電聯發布《中國電力行業年度發展報告2020》[R/OL]. 報告在線 (2020-06-12) [2022-01-05]. https://cec.org.cn/detail/index.html?3-284175 [14] Xue Q G, Yang F, Zhang X X, et al. Development of an oxygen blast furnace and its research progress in University of Science and Technology Beijing. Chin J Eng, 2021, 43(12): 1579薛慶國, 楊帆, 張欣欣, 等. 氧氣高爐的發展歷程及其在北京科技大學的研究進展. 工程科學學報, 2021, 43(12):1579 [15] Zhang J L, Liu Z J, Jiao K X, et al. Progress of new technologies and fundamental theory about ironmaking. Chin J Eng, 2021, 43(12): 1630(張建良, 劉征建, 焦克新, 等. 煉鐵新技術及基礎理論研究進展. 工程科學學報, 2021, 43(12):1630 [16] Yan J J. Progress and future of ultra-low CO2 steel making program. China Metall, 2017, 27(2): 6 doi: 10.13228/j.boyuan.issn1006-9356.20160169嚴珺潔. 超低二氧化碳排放煉鋼項目的進展與未來. 中國冶金, 2017, 27(2):6 doi: 10.13228/j.boyuan.issn1006-9356.20160169 [17] Wang D Y. Breaking-through iron-making technologies in ULCOS project. World Iron Steel, 2011, 11(2): 7 doi: 10.3969/j.issn.1672-9587.2011.02.002王東彥. 超低碳煉鋼項目中的突破型煉鐵技術. 世界鋼鐵, 2011, 11(2):7 doi: 10.3969/j.issn.1672-9587.2011.02.002 [18] Hu J G, Guo Y L, Zhou W T, et al. Analysis of the progress and application prospects of new low-carbon ironmaking technology in the united states. China Steel Focus, 2011(2): 51胡俊鴿, 郭艷玲, 周文濤, 等. 美國低碳煉鐵新技術的進展及應用前景分析. 冶金管理, 2011(2):51 [19] Zhang L N, Li H, Cheng L, et al. Overview of low-carbon technology development in foreign steel industry. Yejin Jingji Yu Guanli, 2018(5): 30 doi: 10.3969/j.issn.1002-1779.2018.05.009張利娜, 李輝, 程琳, 等. 國外鋼鐵行業低碳技術發展概況. 冶金經濟與管理, 2018(5):30 doi: 10.3969/j.issn.1002-1779.2018.05.009 [20] Zhang J L, Li K J, Liu Z J, et al. Primary Exploration of Hydrogen Metallurgy. Beijing: Metallurgical Industry Press, 2021張建良, 李克江, 劉征建, 等. 氫冶金初探. 北京: 冶金工業出版社, 2021 [21] Zhong Dian Jing Wei. Cost analysis of China’s main hydrogen production technologies: Coal production has obvious advantages [EB/OL]. Sohu Website Online (2021-02-29) [2022-01-05]. https://www.sohu.com/a/449697033_121028641中電經緯. 中國主要制氫技術成本分析: 煤制氫優勢明顯 [EB/OL]. 搜狐網頁在線 (2021-02-29) [2022-01-05]. https://www.sohu.com/a/449697033_121028641 [22] Xie H P, Liu H, Wu G. China’s carbon dioxide emissions technology should be developed in the direction of CCU. Energy China, 2012, 34(10): 15 doi: 10.3969/j.issn.1003-2355.2012.10.003謝和平, 劉虹, 吳剛. 中國未來二氧化碳減排技術應向CCU方向發展. 中國能源, 2012, 34(10):15 doi: 10.3969/j.issn.1003-2355.2012.10.003 [23] Duan M S, Pang T. Basic elements of emission trading scheme. China Popul Resour Environ, 2013, 23(3): 110 doi: 10.3969/j.issn.1002-2104.2013.03.018段茂盛, 龐韜. 碳排放權交易體系的基本要素. 中國人口·資源與環境, 2013, 23(3):110 doi: 10.3969/j.issn.1002-2104.2013.03.018 [24] Li X P, ShangGuan F Q, Zhou J C, et al. Carboniferous Flow Operation and CO2 Emission Reduction in Steel Manufacturing Process. Beijing: Metallurgical Industry Press, 2020酈秀萍, 上官方欽, 周繼程, 等. 鋼鐵制造流程中碳素流運行與碳減排途徑. 北京: 冶金工業出版社, 2020 [25] Emissions-EUETS. EU ETS Product Benchmarks [EB/OL]. Website Online (2013-09-15) [2022-01-05].https://www.emissions-euets.com/product-benchmarks [26] International Energy Agency. CO2 Emissions from fuel combustion 2019 highlights [R/OL]. Report Online (2019-11-23) [2022-01-05]. https://iea.blob.core.windows.net/assets/eb3b2e8d-28e0-47fd-a8ba-160f7ed42bc3/CO2_Emissions_from_Fuel_Combustion_2019_Highlights.pdf [27] International Energy Agency. Material efficiency in clean energy transitions [R/OL]. Report Online (2019-03-22) [2022-01-05].https://www.iea.org/reports/material-efficiency-in-clean-energy-transitions [28] ShangGuan F Q, Zhang C X, Li X P, et al. Discussion on the CO2 emission calculation method & its application in the steel plants // Proceedings of the 2011 National Metallurgical Energy Conservation, Emission Reduction and Low-Carbon Technology Development Seminar. Tangshan, 2011: 6上官方欽, 張春霞, 酈秀萍, 等. 鋼鐵企業CO2排放計算方法及其應用探討 // 2011年全國冶金節能減排與低碳技術發展研討會文集. 唐山, 2011: 6 [29] Department of Energy Statistics, National Bureau of Statistics. China Energy Statistical Yearbook (2018). Beijing: China Statistics Press, 2019國家統計局能源統計司. 中國能源統計年鑒(2018). 北京: 中國統計出版社, 2019 [30] Shangguan F Q, Liu Z D, Yin R Y. Study on implementation path of “carbon peak” and “carbon neutrality” in steel industry in China. China Metall, 2021, 31(9): 15 doi: 10.13228/j.boyuan.issn1006-9356.20210393上官方欽, 劉正東, 殷瑞鈺. 鋼鐵行業“碳達峰”“碳中和”實施路徑研究. 中國冶金, 2021, 31(9):15 doi: 10.13228/j.boyuan.issn1006-9356.20210393 [31] Yang T. The development of low-carbon technology in the iron and steel industry abroad and China's CO2 emission reduction strategy. China Steel, 2011(6): 12 doi: 10.3969/j.issn.1672-5115.2011.06.003楊婷. 國外鋼鐵工業低碳技術發展與我國減排CO2策略. 中國鋼鐵業, 2011(6):12 doi: 10.3969/j.issn.1672-5115.2011.06.003 [32] Shangguan F Q. Study on the Optimization of Full Scrap EAF Process—City Steel Plants & Decarbonization of Steel Industry [Dissertation]. Beijing: Central Iron & Steel Research Institute, 2021上官方欽. 全廢鋼電爐流程優化研究——城市鋼廠與鋼鐵工業脫碳化[學位論文]. 北京: 鋼鐵研究總院, 2021 [33] Yin R Y. Metallurgical Process Engineering. Beijing: Metallurgical Industry Press, 2004殷瑞鈺. 冶金流程工程學. 北京: 冶金工業出版社, 2004 -

下載:

下載: