-

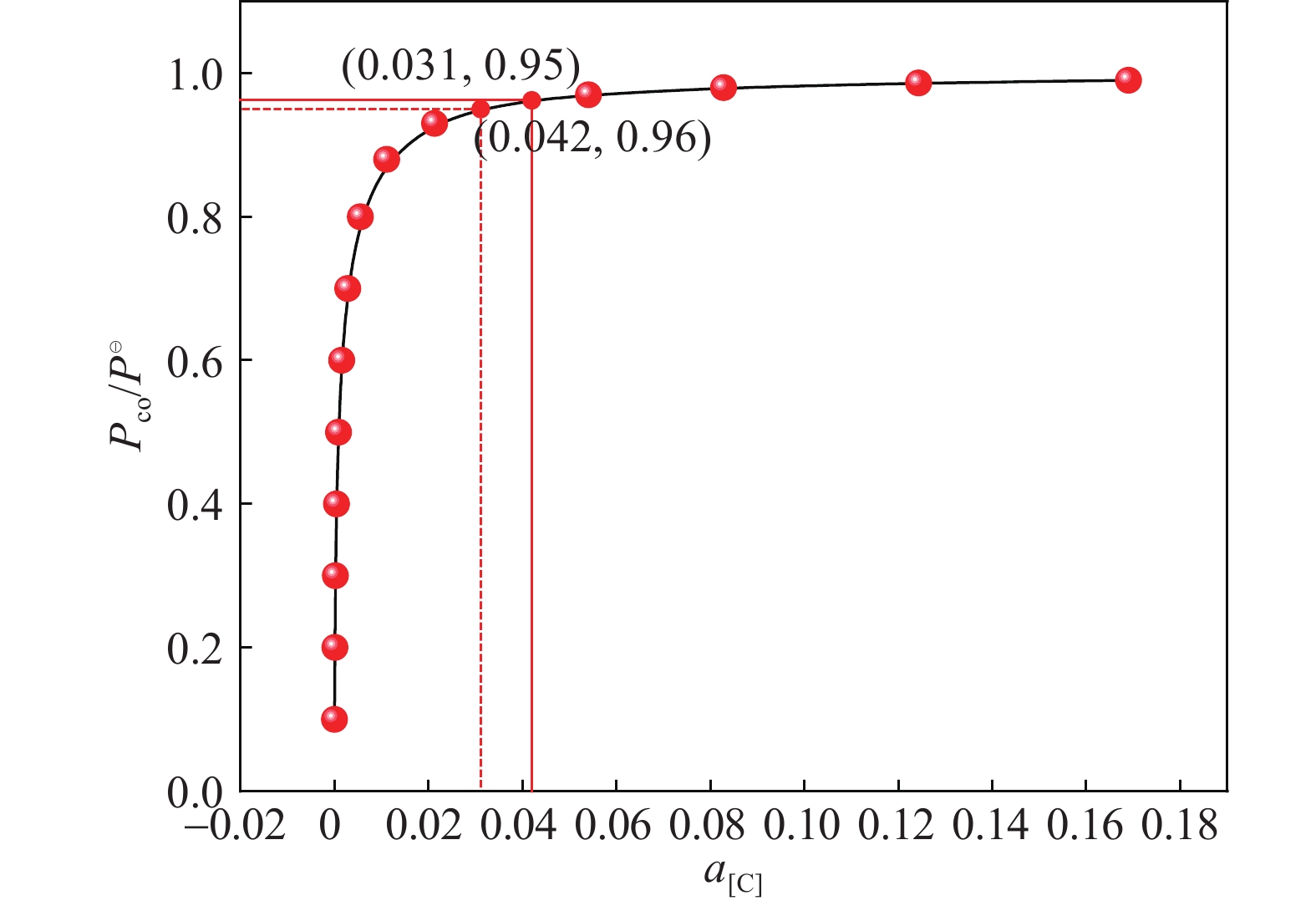

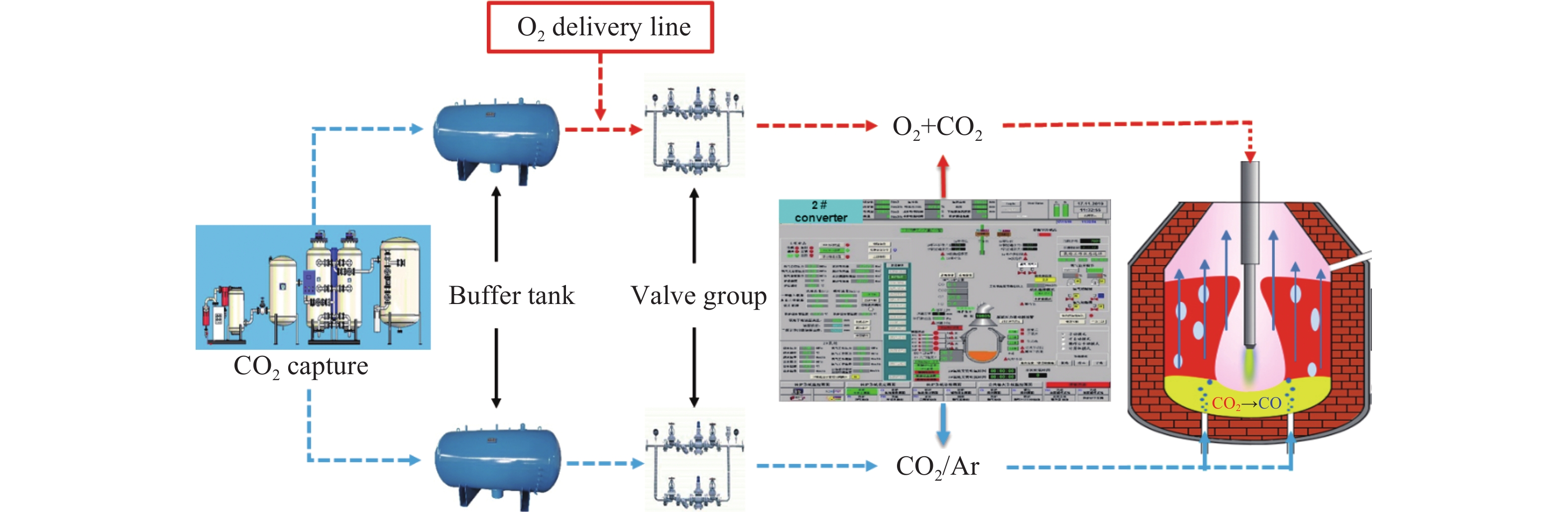

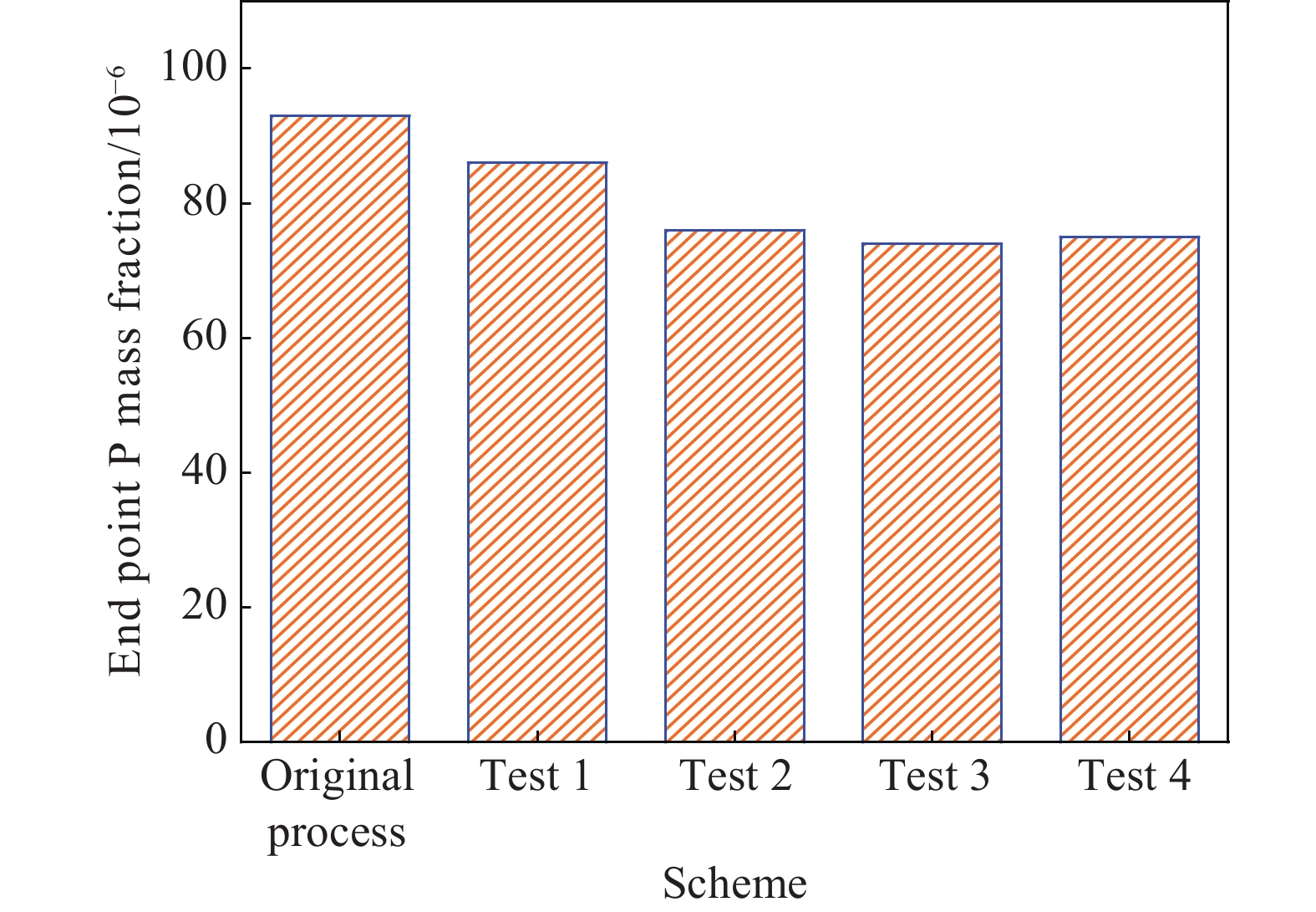

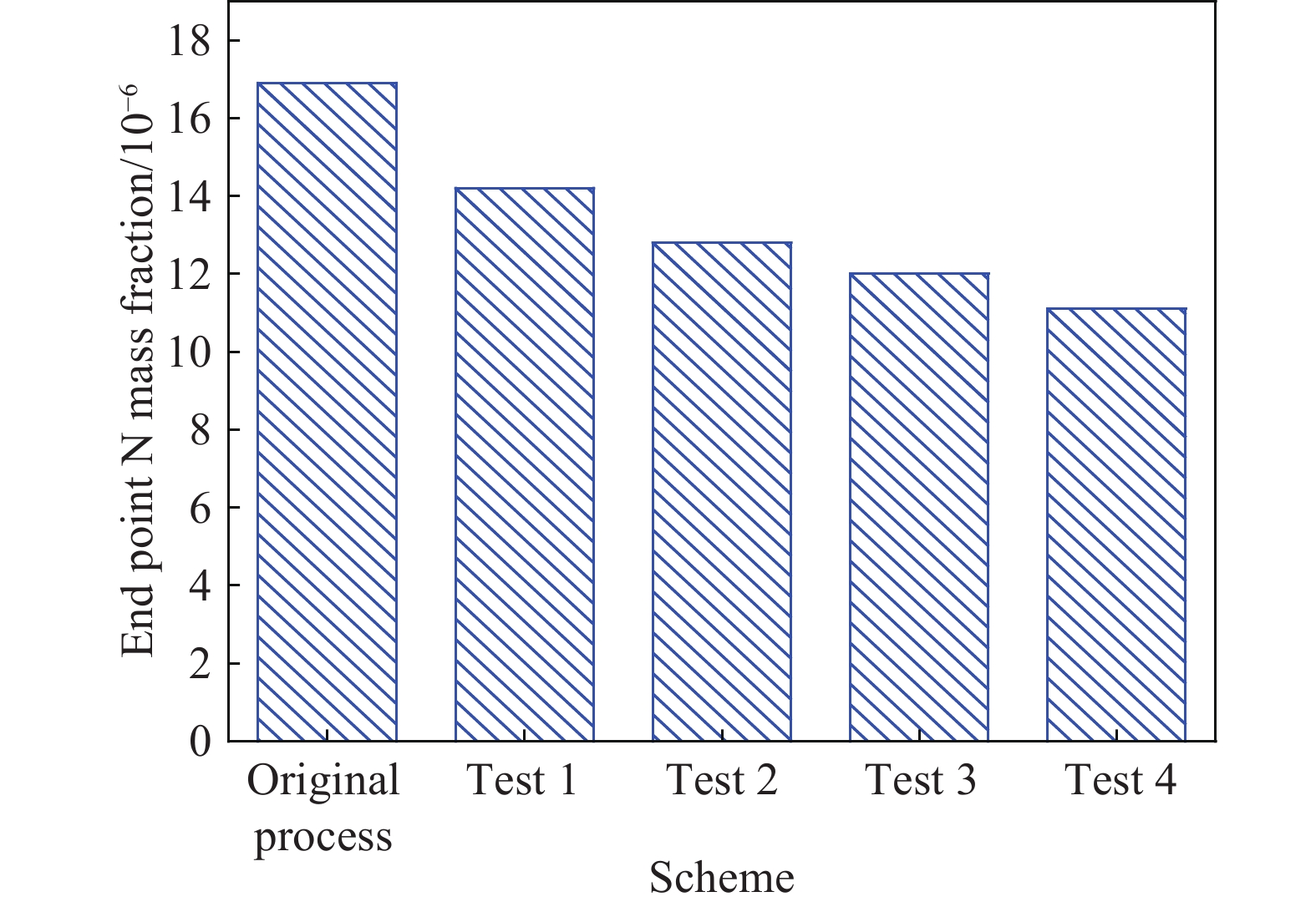

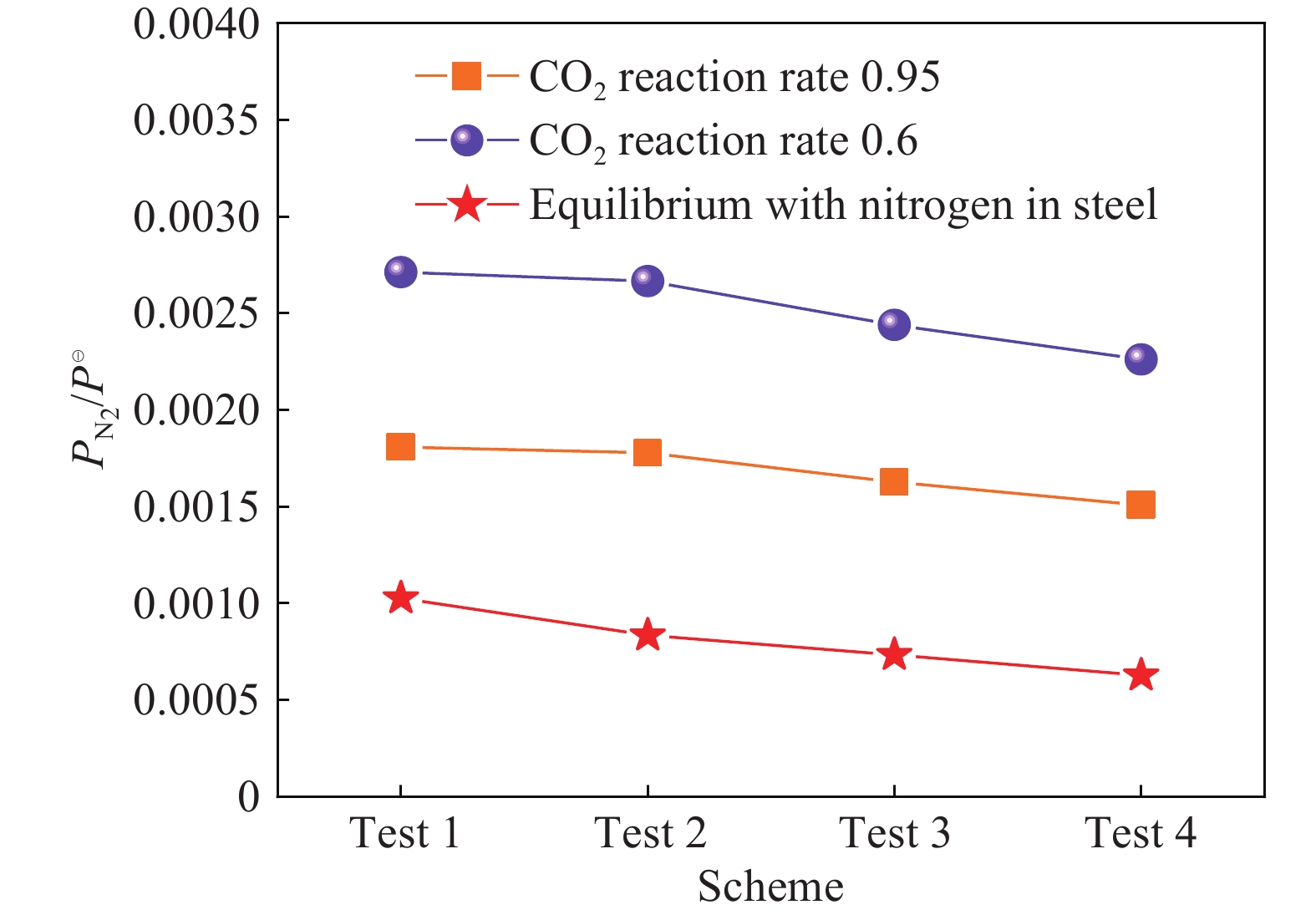

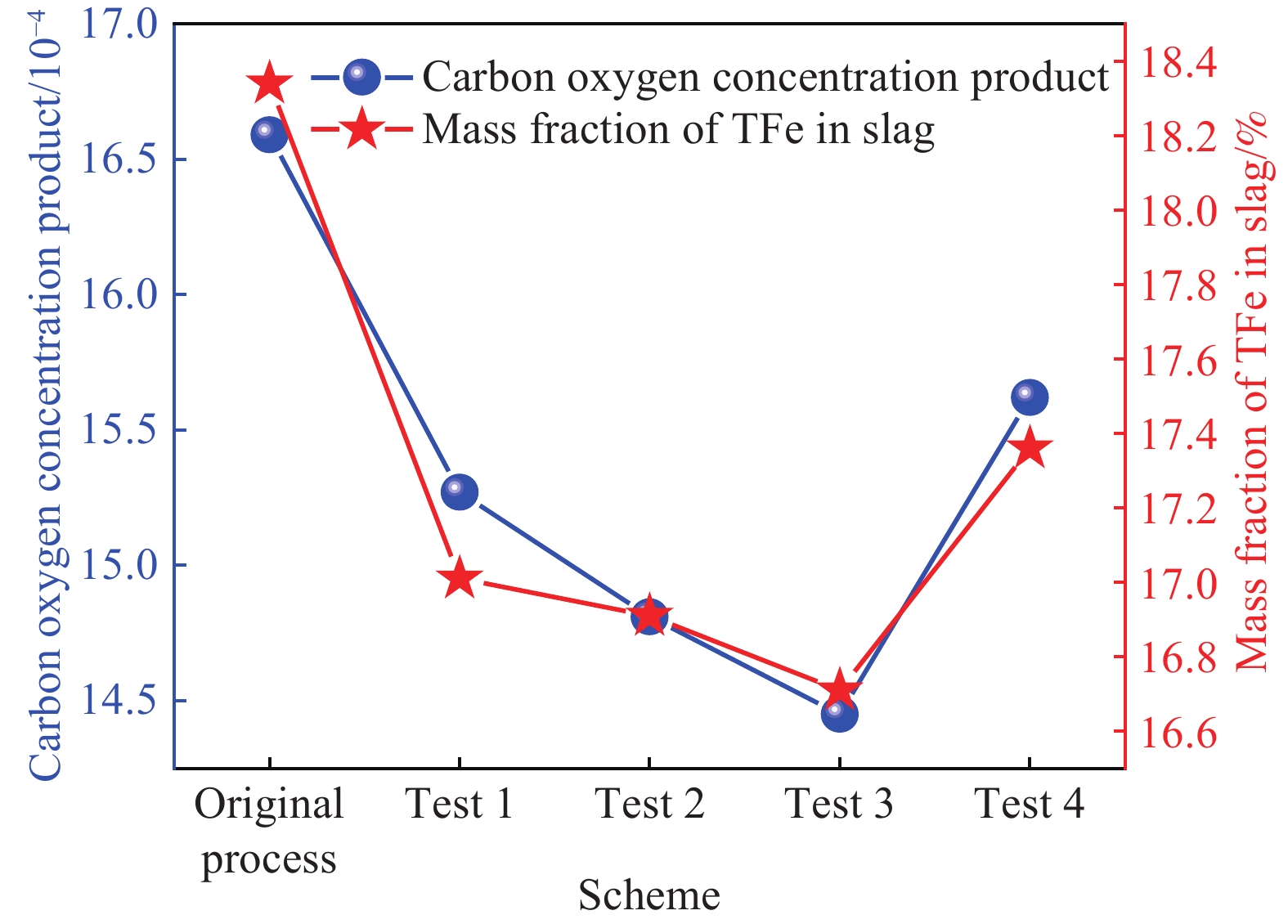

摘要: 結合CO2的高溫反應特性,針對性地制定了CO2冶煉工藝,并對轉爐頂吹CO2比例對終點磷、氮和碳氧濃度積的影響進行了工業試驗研究。結果表明:隨著轉爐冶煉前中期CO2頂吹比例由4.84%逐漸提高到9.68%,轉爐終點磷的質量分數先下降后基本不變,氮的質量分數逐漸下降,碳氧濃度積與渣中TFe變化趨勢基本相同,均為先降低后增加,對于不同指標最佳頂吹CO2比例不同。試驗轉爐終點磷、氮的質量分數、碳氧濃度積與渣中TFe均下降,下降比例最高分別為20.4%、34.3%、12.92%和8.89%。Abstract: When combined with the high-temperature reaction characteristics of carbon dioxide—that is, the weak oxidation, endothermic, or weak exothermic effect compared with oxygen and the bubble increment effect of reacting with carbon to produce twice the gas—the carbon dioxide smelting process was targeted according to the different tasks in different periods of converter smelting. Before temperature measurement, sampling, and carbon determination using the sublance system, carbon dioxide is blown into the converter from the upper oxygen gun and the bottom blowing element of the converter. By changing the ratio of carbon dioxide and oxygen in the oxygen gun, an industrial experimental study was conducted on the effect of the carbon dioxide ratio blown from the upper oxygen gun on the endpoint of the mass fraction of phosphorus and nitrogen and the carbon–oxygen concentration product. The results show that with the gradual increase of the carbon dioxide top blowing ratio from 4.84% to 9.68% in the early and middle stages of converter smelting, the mass fraction of phosphorus at the end of the converter first decreases and then basically remains unchanged. The mass fraction of nitrogen also decreases gradually, but the decreasing range becomes smaller, and the changing trend of carbon–oxygen concentration product is the same as that of TFe in slag, which first decreases and then increases. The optimal carbon dioxide top-blowing ratio varies with the index. Furthermore, the test also shows that even if all the blown carbon dioxide reacts to generate additional carbon monoxide gas and the nitrogen is removed by the additional carbon monoxide gas generated compared with the original process, the partial pressure of nitrogen in the additional gas is much higher than the partial pressure in equilibrium with the mass fraction of nitrogen in the liquid steel. This indicates that the improvement of the denitrification effect is due to the additional gas generated by the reaction of blowing in carbon dioxide; it improves the denitrification effect of the original gas, and the generation of additional gas improves the kinetic conditions of the molten pool and facilitates the mass transfer of nitrogen. The highest decreasing ratio of the endpoint mass fraction of phosphorus, nitrogen, carbon–oxygen concentration product, and TFe in the slag of the test converter was 20.4%, 34.3%, 12.92%, and 8.89%, respectively.

-

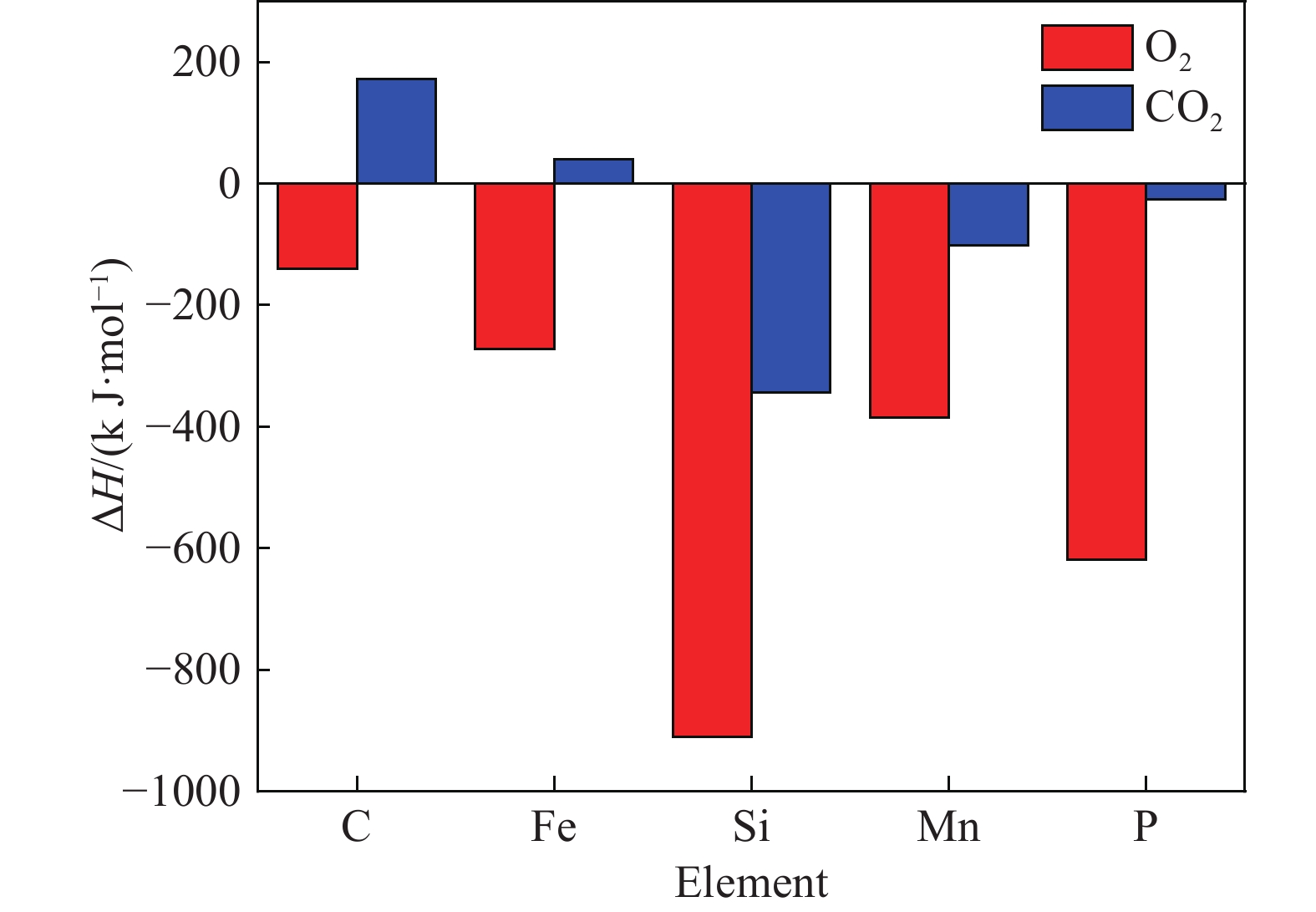

表 1 CO2與鋼液中元素反應的熱力學數據[19]

Table 1. Thermodynamic data of reactions between CO2 and elements in molten steel[19]

Element Reaction equation $\Delta {G^{\circleddash} }$/(J·mol?1) T=1873 K,

$\Delta {G^{\circleddash} }$/(kJ·mol?1)C 1/2O2 + [C]=CO(g) ?140580?42.09T ?219.41 O2 + [C]=CO2(g) ?419050+42.34T ?339.75 CO2(g) + [C]=2CO(g) 137890?126.52T ?99.08 Fe 1/2O2(g) + Fe(l)=(FeO) ?229490+43.81T ?147.43 CO2(g) + Fe(l)=

(FeO)+CO(g)48980?40.62T ?27.10 Si O2 + [Si]=(SiO2) ?804880+210.04T ?411.48 2CO2(g) + [Si]=

(SiO2)+2CO(g)?247940+41.18T ?170.81 Mn 1/2O2 + [Mn]=(MnO) ?412230+126.94T ?174.47 CO2(g) + [Mn]=

(MnO)+CO(g)?133760+42.51T ?54.14 P 4/5[P] + O2(g) =

2/5P2O5(g)?375040+134.23T ?123.63 2/5[P]+CO2(g)=

1/5(P2O5)+CO(g)91555?16.86T 59.98 表 2 工業試驗方案

Table 2. Industrial test scheme

Scheme Stage Top blowing O2 (standard status) /(m3·h?1) Top blowing CO2 (standard status) /(m3·h?1) Top blowing

CO2 ratio/%Bottom blowing CO2/Ar (standard status) /(m3·h?1) Original process Early and middle stage 62000 0 0 800/0 Later stage 62000 0 0 0/1200 Test 1 Early and middle stage 59000 3000 4.84 800/0 Later stage 62000 0 0 0/1200 Test 2 Early and middle stage 58000 4000 6.45 800/0 Later stage 62000 0 0 0/1200 Test 3 Early and middle stage 57000 5000 8.06 800/0 Later stage 62000 0 0 0/1200 Test 4 Early and middle stage 56000 6000 9.68 800/0 Later stage 62000 0 0 0/1200 Note: the early and middle stage, in the top blowing refers to the stage before TSC, and in the bottom blowing refers to the stage when the top blowing oxygen supply is less than 9000 m3 (standard status); the later stage, in the top blowing refers to the stage after the TSC, in the bottom blowing refers to the stage when the top blowing oxygen supply is greater than 9000 m3 (standard status). Top blowing means that the converter injects O2 and CO2 through the oxygen gun, bottom blowing means that the converter injects Ar or CO2 through the bottom blowing element, and TSC means that the converter measures temperature and samples carbon through the auxiliary gun. 表 3 試驗碳、溫度與補熱劑加入情況

Table 3. Industrial test carbon, temperature, and heat compensating material

Scheme Element mass fraction of molten iron/% Mass fraction of end carbon/% Endpoint temperature/ ℃ Heat compensating material (per ton)/kg Number of furnaces C Si Mn P Ferrosilicon Coke High efficiency heat compensating material Original process 4.30 0.29 0.11 0.069 0.0361 1651.8 1.127 0.644 2.672 85 Test 1 4.31 0.29 0.10 0.068 0.0377 1649.7 1.821 1.597 3.577 47 Test 2 4.36 0.29 0.10 0.071 0.0359 1653.1 2.138 0.893 1.308 116 Test 3 4.36 0.29 0.11 0.073 0.0360 1656.2 1.044 0.981 1.424 269 Test 4 4.30 0.28 0.12 0.072 0.0369 1658.3 2.361 1.279 2.557 127 www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Lü M, Zhu R, Bi X R, et al. Application research of carbon dioxide in BOF steelmaking process. J Univ Sci Technol Beijing, 2011, 33(Suppl 1): 126呂明, 朱榮, 畢秀榮, 等. 二氧化碳在轉爐煉鋼中的應用研究. 北京科技大學學報, 2011, 33(增刊1): 126 [2] Wang Z L, Bao Y P, Wang D Z, et al. Leaching rule of phosphorus element in high phosphorus converter slag with different acids. Iron Steel, 2021, 56(4): 103王仲亮, 包燕平, 王達志, 等. 高磷轉爐渣中磷元素在不同酸中的浸出規律. 鋼鐵, 2021, 56(4):103 [3] Wang L Z, Bao Y P, Li X. Comparison of two-stage dephosphorization during remaining slag-double slag process in converter. Iron Steel, 2019, 54(8): 37王林珠, 包燕平, 李翔. 轉爐留渣雙渣工藝兩階段脫磷對比. 鋼鐵, 2019, 54(8):37 [4] Xing Y, Zhang W B, Su W, et al. Research of ultra-low emission technologies of the iron and steel industry in China. Chin J Eng, 2021, 43(1): 1邢奕, 張文伯, 蘇偉, 等. 中國鋼鐵行業超低排放之路. 工程科學學報, 2021, 43(1):1 [5] Lin W H, Jiao S Q, Sun J K, et al. Modified exponential model for carbon prediction in the end blowing stage of basic oxygen furnace converter. Chin J Eng, 2020, 42(7): 854林文輝, 焦樹強, 孫建坤, 等. 轉爐吹煉后期碳含量預報的改進指數模型. 工程科學學報, 2020, 42(7):854 [6] Wei G S, Han B C, Zhu R. Metallurgical reaction behavior of CO2 as RH lifting gas. Chin J Eng, 2020, 42(2): 203魏光升, 韓寶臣, 朱榮. CO2作為RH提升氣的冶金反應行為研究. 工程科學學報, 2020, 42(2):203 [7] Feng C, Zhu R, Liu R Z, et al. Industrial application of bottom-blown CO2 in basic oxygen furnace steelmaking process. Steel Res Int, 2021, 92(10): 2000704 doi: 10.1002/srin.202000704 [8] Li Z, Zhu R, Ma G, et al. Laboratory investigation into reduction the production of dust in basic oxygen steelmaking. Ironmak Steelmak, 2017, 44(8): 601 doi: 10.1080/03019233.2016.1223906 [9] Li Z Z, Zhu R, Liu R Z, et al. Comparison of smelting effects by bottom blowing different gases. Iron Steel, 2016, 51(9): 40李智崢, 朱榮, 劉潤藻, 等. 煉鋼過程底吹氣體的冶煉效果對比. 鋼鐵, 2016, 51(9):40 [10] Jin R J, Zhu R, Feng L X, et al. Experimental study of steelmaking with CO2 and O2 mixed blowing. J Univ Sci Technol Beijing, 2007, 29(Suppl 1): 77靳任杰, 朱榮, 馮立新, 等. 二氧化碳-氧氣混合噴吹煉鋼實驗研究. 北京科技大學學報, 2007, 29(增刊1): 77 [11] Yin Z J, Zhu R, Yi C, et al. Fundamental research on controlling BOF dust by COMI steel-making process. Iron Steel, 2009, 44(10): 92 doi: 10.3321/j.issn:0449-749X.2009.10.021尹振江, 朱榮, 易操, 等. 應用COMI煉鋼工藝控制轉爐煙塵基礎研究. 鋼鐵, 2009, 44(10):92 doi: 10.3321/j.issn:0449-749X.2009.10.021 [12] Li Z Z, Zhu R, Liu R Z, et al. Study on the characteristics of CO2 and the effect of CO2 on material and energy in steelmaking process. Ind Heat, 2015, 44(6): 27 doi: 10.3969/j.issn.1002-1639.2015.06.007李智崢, 朱榮, 劉潤藻, 等. CO2的高溫特性及對煉鋼物料和能量的影響研究. 工業加熱, 2015, 44(6):27 doi: 10.3969/j.issn.1002-1639.2015.06.007 [13] Zhang W, Li Z Z, Zhu R, et al. Experimental study of CO2 blowing in steelmaking process. Ind Heat, 2015, 44(2): 41 doi: 10.3969/j.issn.1002-1639.2015.02.012張偉, 李智崢, 朱榮, 等. 煉鋼過程噴吹CO2的實驗研究. 工業加熱, 2015, 44(2):41 doi: 10.3969/j.issn.1002-1639.2015.02.012 [14] Yi C, Zhu R, Chen B Y, et al. Experimental research on reducing the dust of BOF in CO2 and O2 mixed blowing steelmaking process. ISIJ Int, 2009, 49(11): 1694 doi: 10.2355/isijinternational.49.1694 [15] Zhu R, Bi X R, Lv M, et al. Research on steelmaking dust based on difference of Mn, Fe and Mo vapor pressure. Adv Mater Res, 2011, 284-286: 1216 doi: 10.4028/www.scientific.net/AMR.284-286.1216 [16] Yi C, Zhu R, Yin Z J, et al. Experimental research of COMI steelmaking process based on 30 t converter. Chin J Process Eng, 2009, 9(Suppl 1): 222易操, 朱榮, 尹振江, 等. 基于30t轉爐的COMI煉鋼工藝實驗研究. 過程工程學報, 2009, 9(增刊1): 222 [17] Ning X J, Yin Z J, Yi C, et al. Experimental research on dust reduction in steelmaking by CO2. Steelmaking, 2009, 25(5): 32寧曉鈞, 尹振江, 易操, 等. 利用CO2減少煉鋼煙塵的實驗研究. 煉鋼, 2009, 25(5):32 [18] Lv M, Zhu R, Wei X Y, et al. Research on top and bottom mixed blowing CO2 in converter steelmaking process. Steel Res Int, 2012, 83(1): 11 doi: 10.1002/srin.201100166 [19] Zhang J Y. Physical Chemistry of Metallurgy. Beijing: Metallurgical Industry Press, 2004張家蕓. 冶金物理化學. 北京: 冶金工業出版社, 2004 [20] Liu Y, Liu L, Tong P Q, et al. Process control of dephosphorization in initial smelting period of combined blowing BOF for clean steel. Steelmaking, 2006, 22(2): 27 doi: 10.3969/j.issn.1002-1043.2006.02.009劉躍, 劉瀏, 佟溥翹, 等. 優質高碳鋼高拉碳前期脫磷過程控制. 煉鋼, 2006, 22(2):27 doi: 10.3969/j.issn.1002-1043.2006.02.009 [21] Li Z Z. Investigations on Fundamental Theory of CO2 Applied in Steelmaking Processes [Dissertation]. Beijing: University of Science and Technology Beijing, 2017李智崢. CO2應用于煉鋼的基礎理論研究[學位論文]. 北京: 北京科技大學, 2017 [22] Li Z Z, Zhu R, Zhu Y Q. Effect of CO2 on material and energy in dephosphorization converters. Chin J Eng, 2016, 38(Suppl 1): 232李智崢, 朱榮, 朱益強. CO2對脫磷轉爐物料和能量的影響. 工程科學學報, 2016, 38(增刊1): 232 [23] Guo H J. Metallurgical Physical Chemistry Course. 2nd Ed. Beijing: Metallurgical Industry Press, 2006郭漢杰. 冶金物理化學教程. 2版. 冶金工業出版社, 2006 [24] Wu X, Bao Y P, Yue F, et al. Study on factors to affect the product of carbon content and oxygen content at blowing end-point of BOF steelmaking. Res Iron Steel, 2010, 38(2): 26武珣, 包燕平, 岳峰, 等. 影響轉爐終點碳氧積的因素分析. 鋼鐵研究, 2010, 38(2):26 [25] Zhan D P, Qiu G X, Niu B, et al. Thermodynamics and kinetics research of nitrogen dissolution in steel. Steelmaking, 2015, 31(5): 7戰東平, 邱國興, 牛奔, 等. 氮在鋼液中溶解的熱力學及動力學研究. 煉鋼, 2015, 31(5):7 -

下載:

下載: