Kinetics and mechanism of the reduction–carburization processes of MoO2 to Mo2C with CO–15% CO2 mixed gases

-

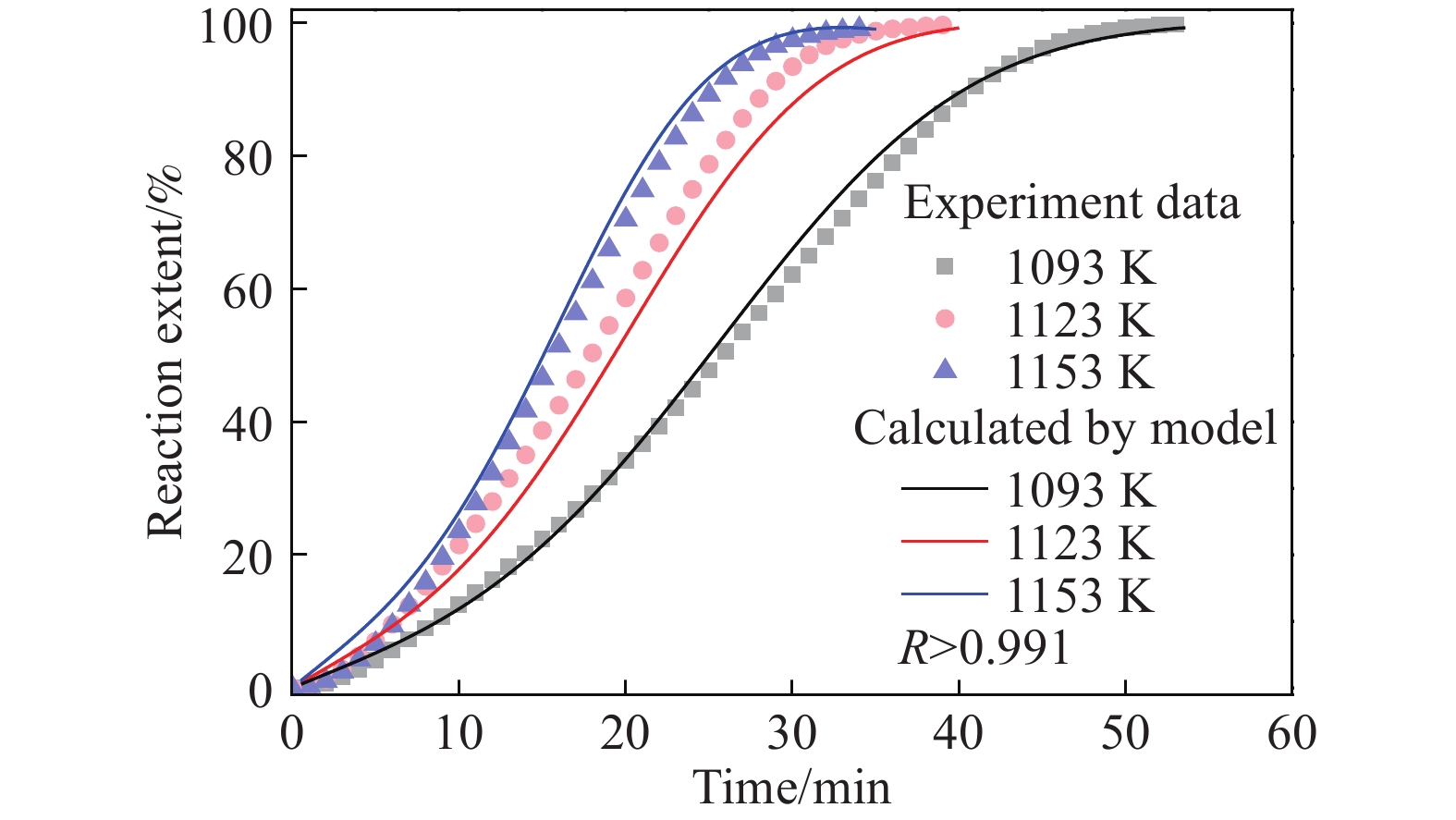

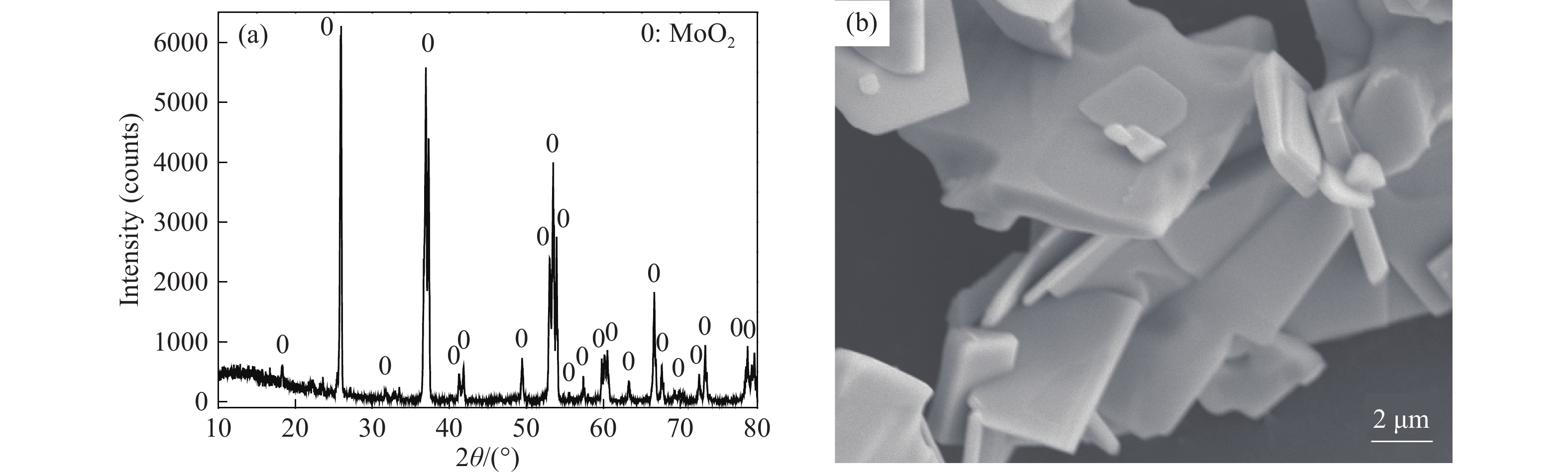

摘要: 對CO–15%CO2混合氣體還原碳化MoO2制備Mo2C的反應機理及其動力學展開研究并采用熱力學軟件FactSage 7.3、場發射掃描電子顯微鏡 (FE-SEM)、X射線衍射(XRD)、熱重(TG)、比表面積測試(BET)和模型擬合等手段和方法對實驗數據進行分析。結果表明:變溫實驗中,升溫速率越快,MoO2的開始反應溫度和完全還原溫度越高;恒溫實驗中,溫度越高,MoO2的還原碳化速率越快;反應前后物相組成表明MoO2是經一步反應直接生成Mo2C,沒有中間產物金屬Mo的生成,并且還發現所得Mo2C基本與MoO2具有一致的片狀形貌,但是由于氣體的進入與逸出、產物摩爾體積的縮小以及沉積碳的減少,Mo2C顆粒表面會產生微孔和裂紋導致比表面積增長近20倍;動力學分析結果表明該還原碳化過程由形核長大與界面化學反應共同控制,其中形核長大過程占比68.9%,表觀活化能為80.651 kJ·mol–1;界面化學反應占比31.1%,表觀活化能為121.002 kJ·mol–1。

-

關鍵詞:

- CO–15%CO2混合氣體 /

- 二氧化鉬 /

- 碳化鉬 /

- 反應機理 /

- 動力學

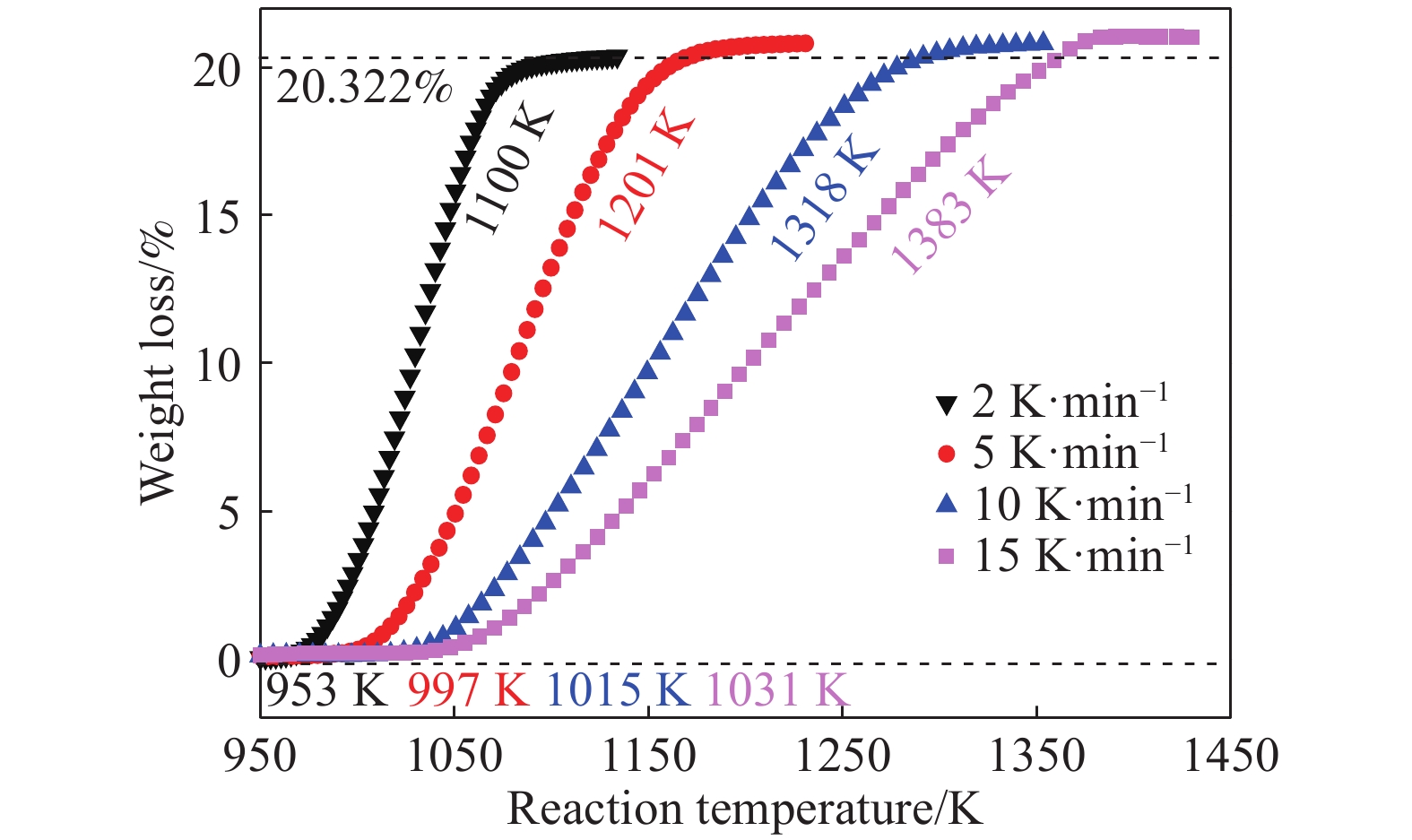

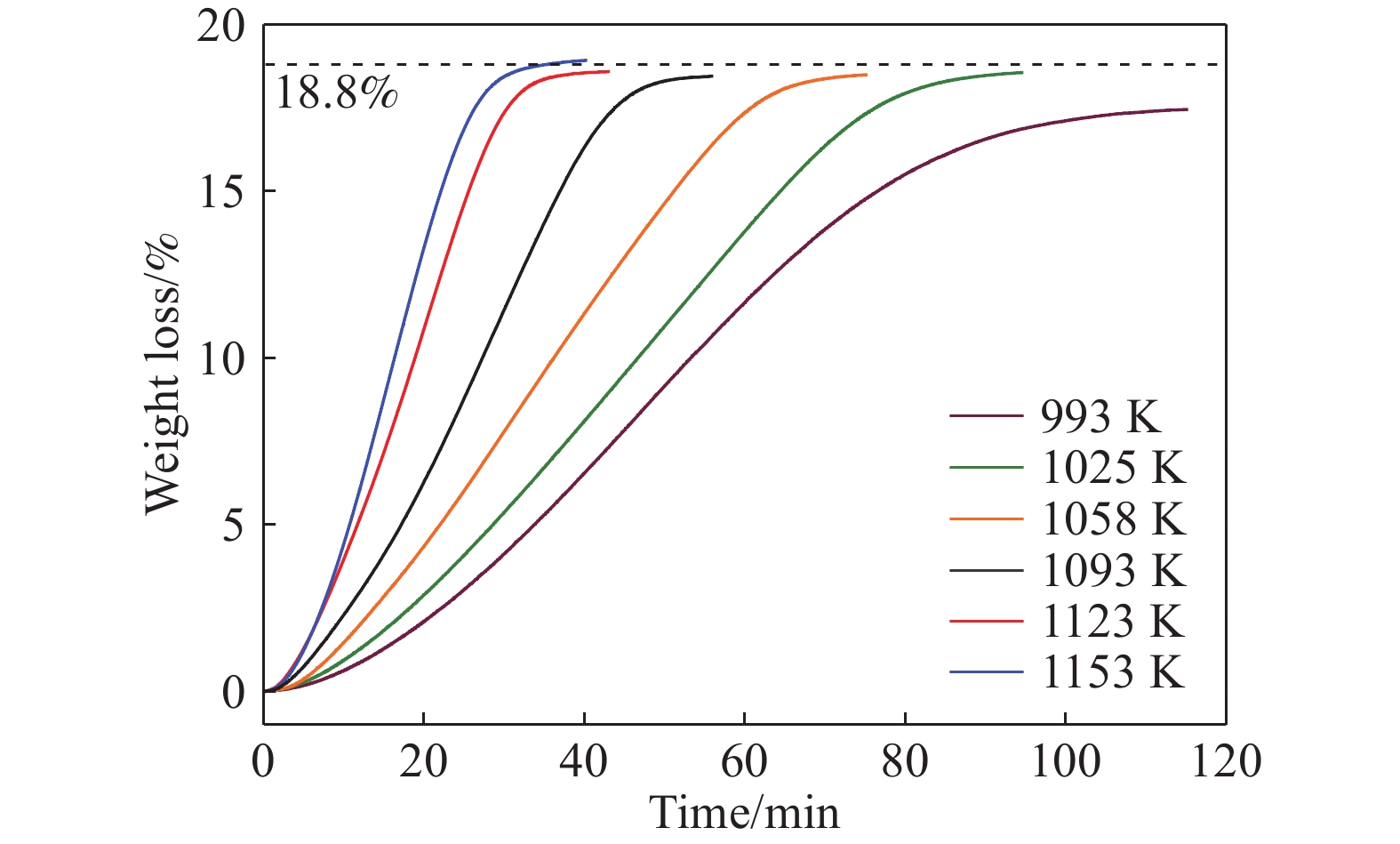

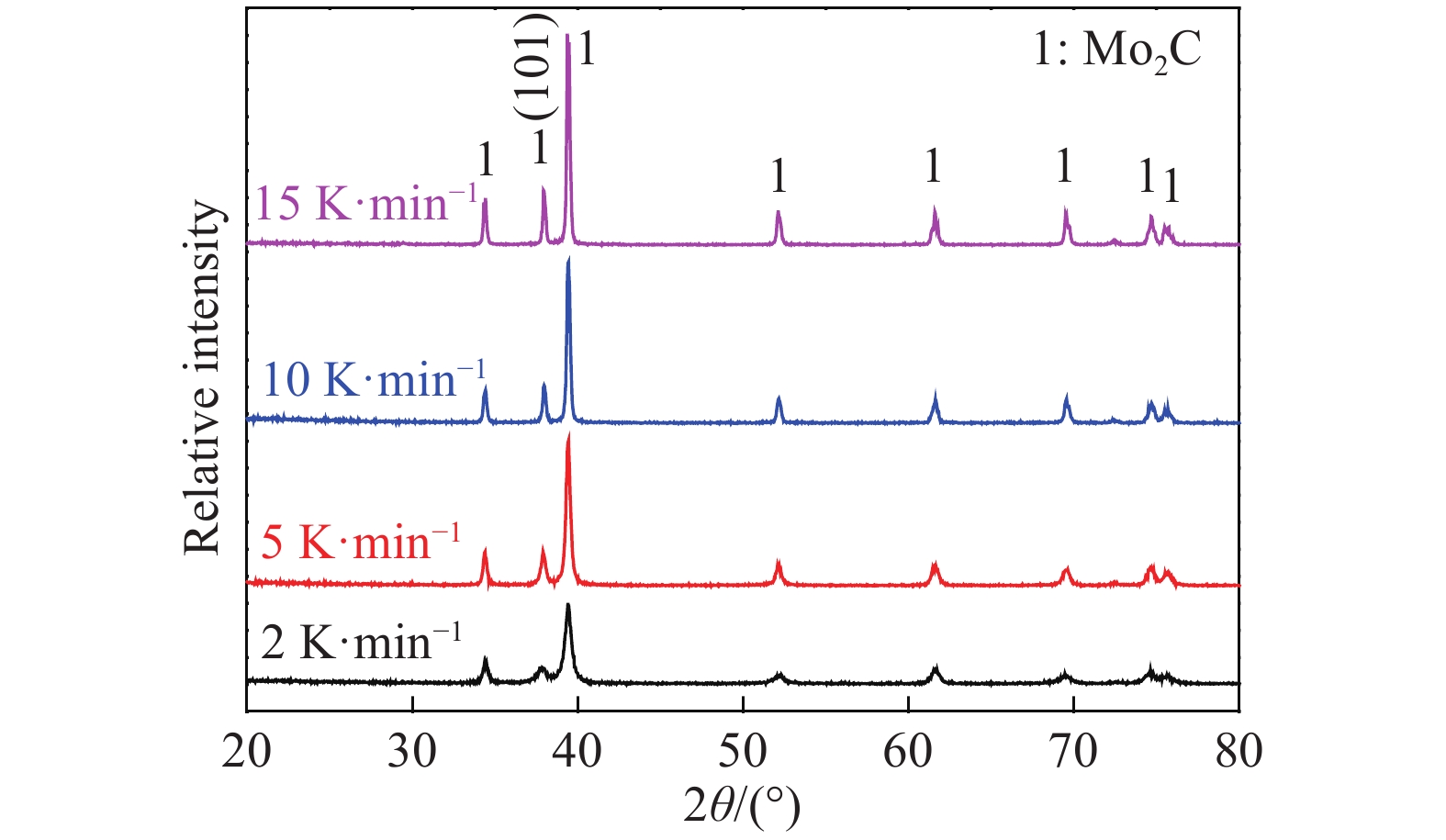

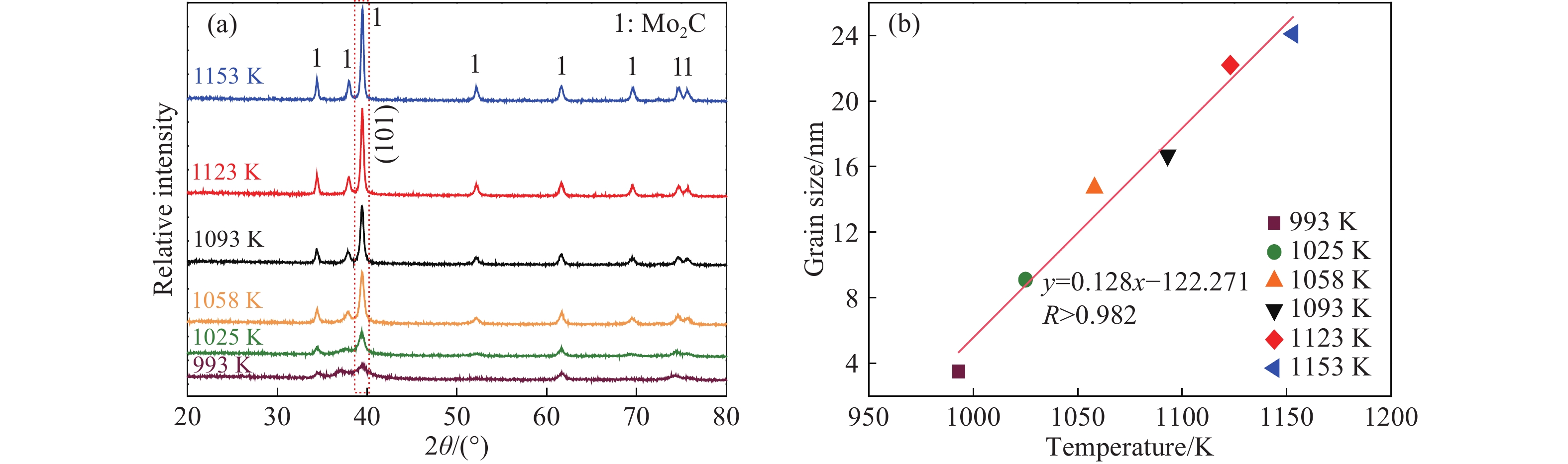

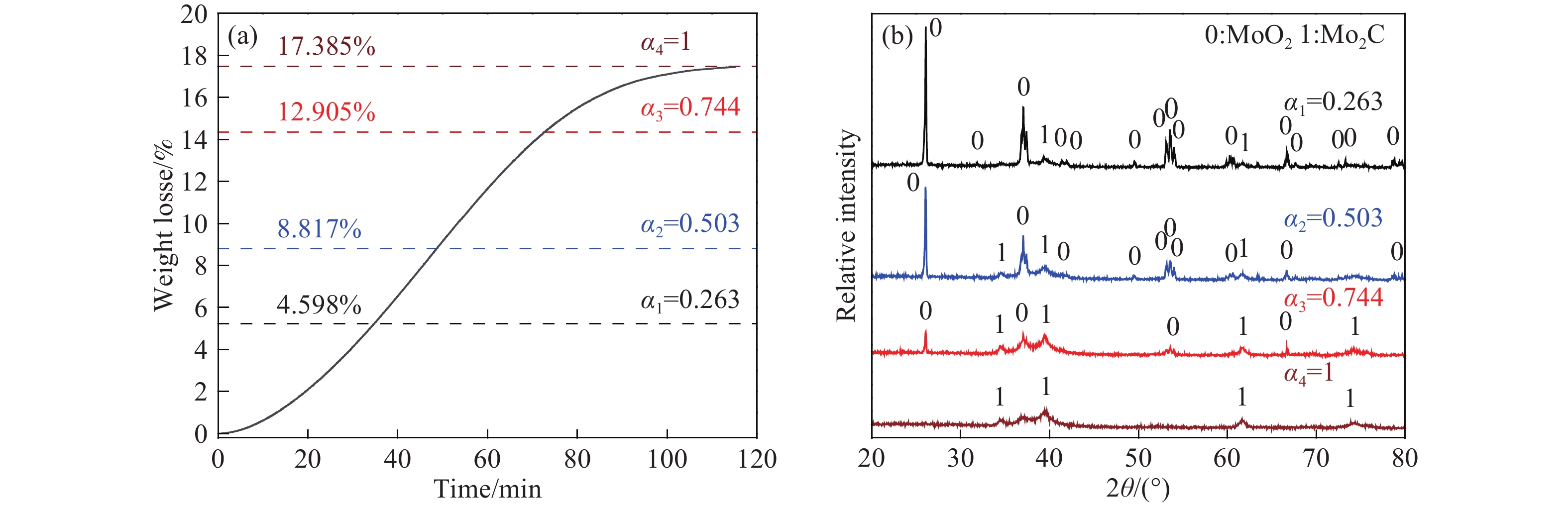

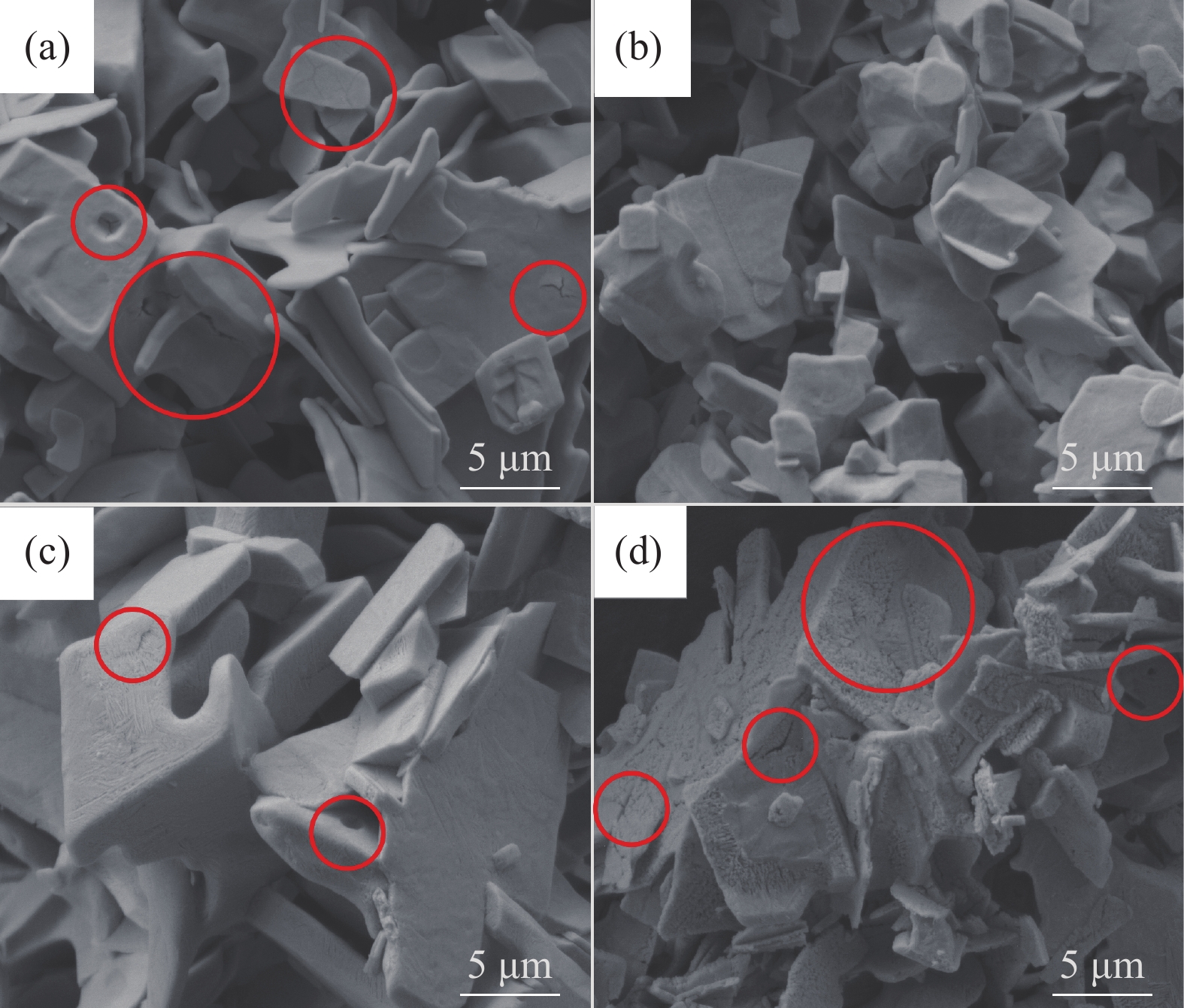

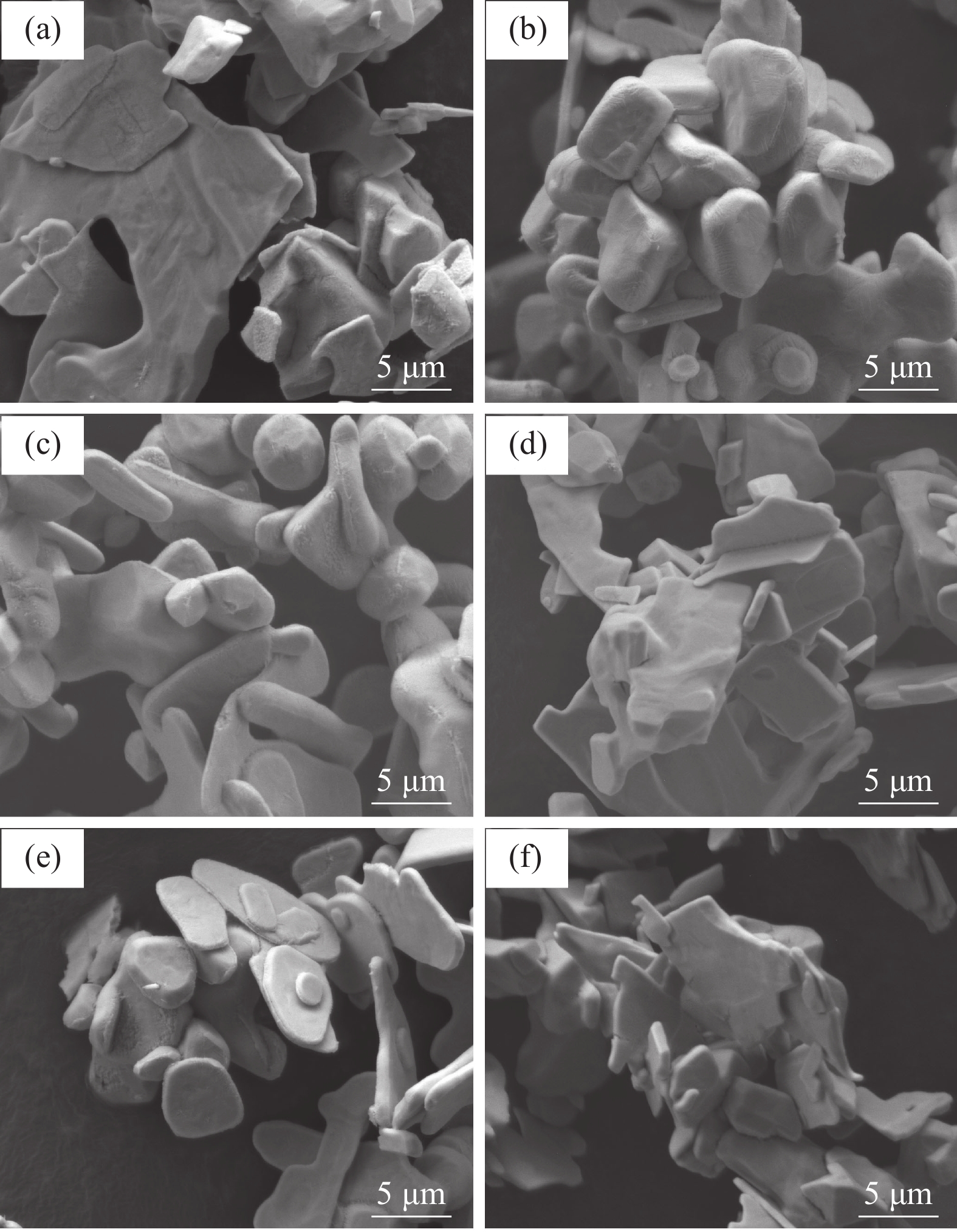

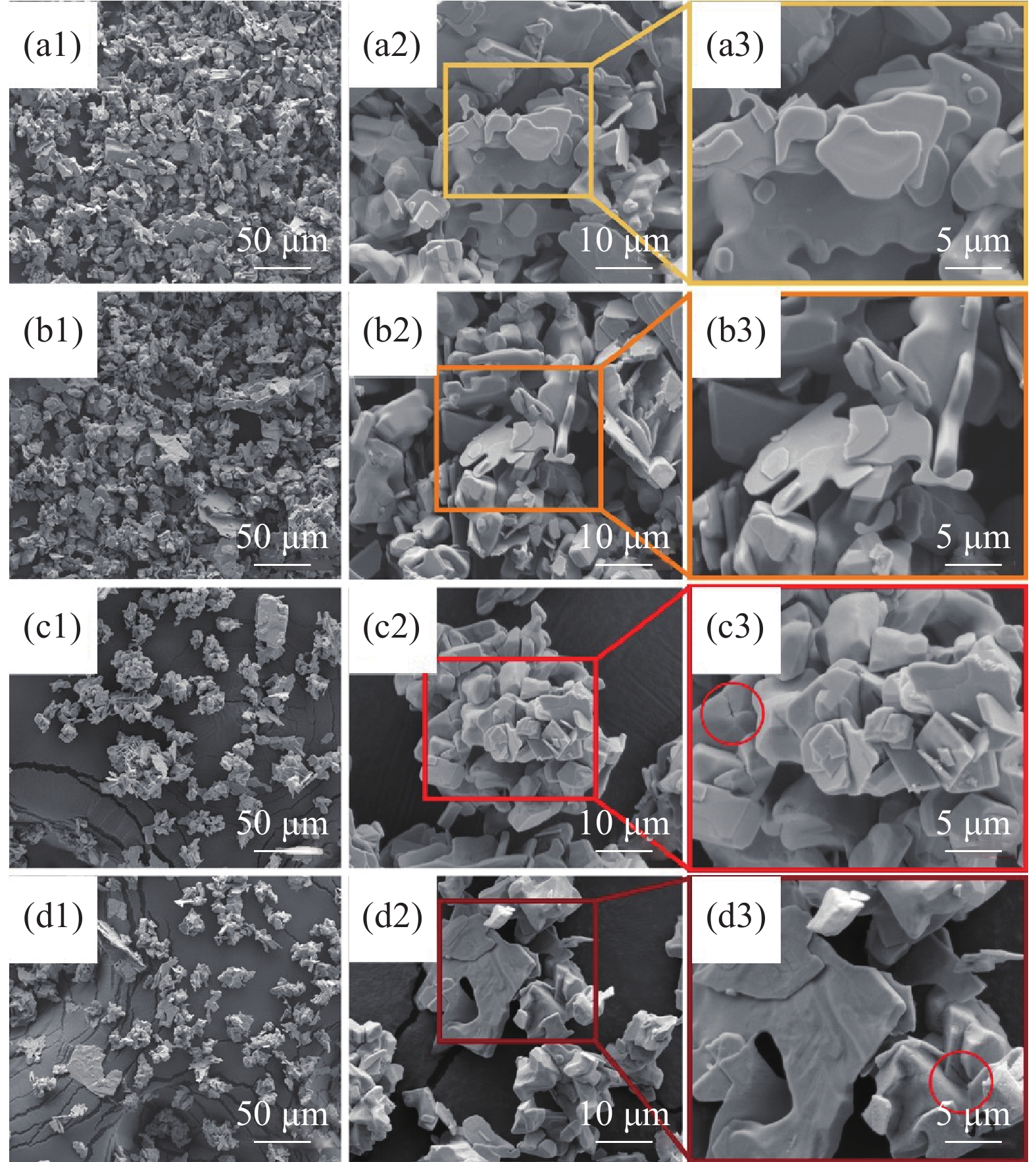

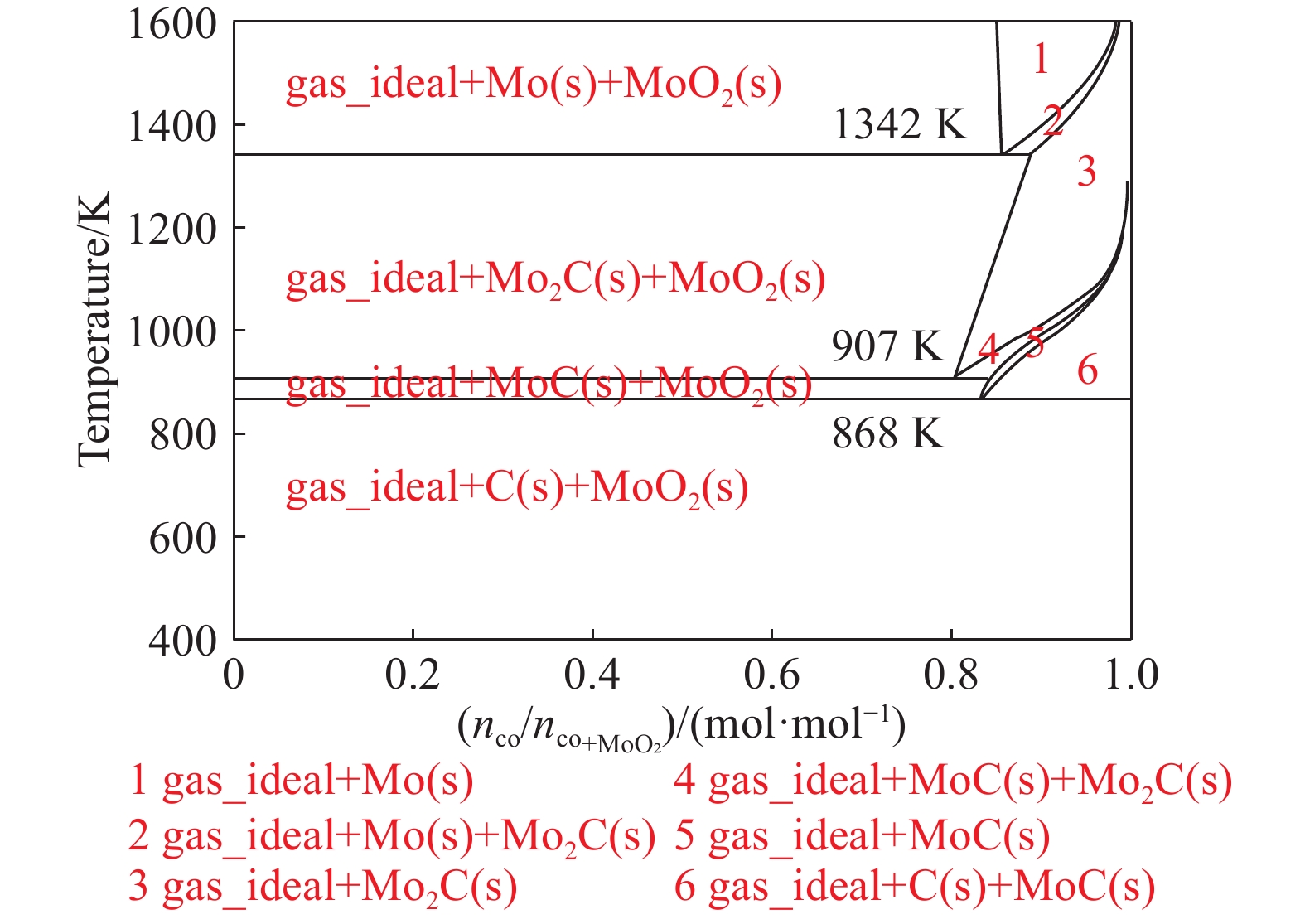

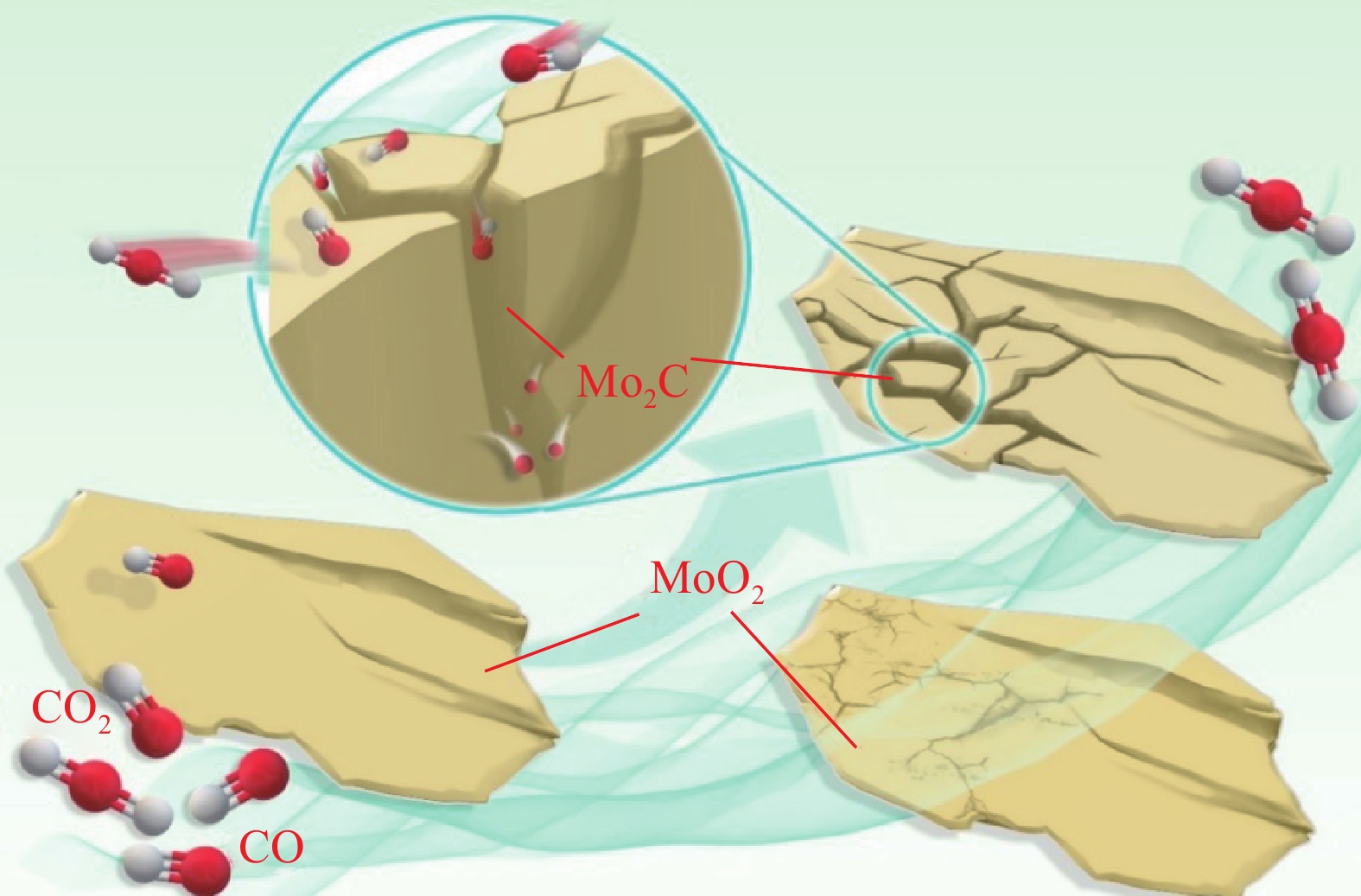

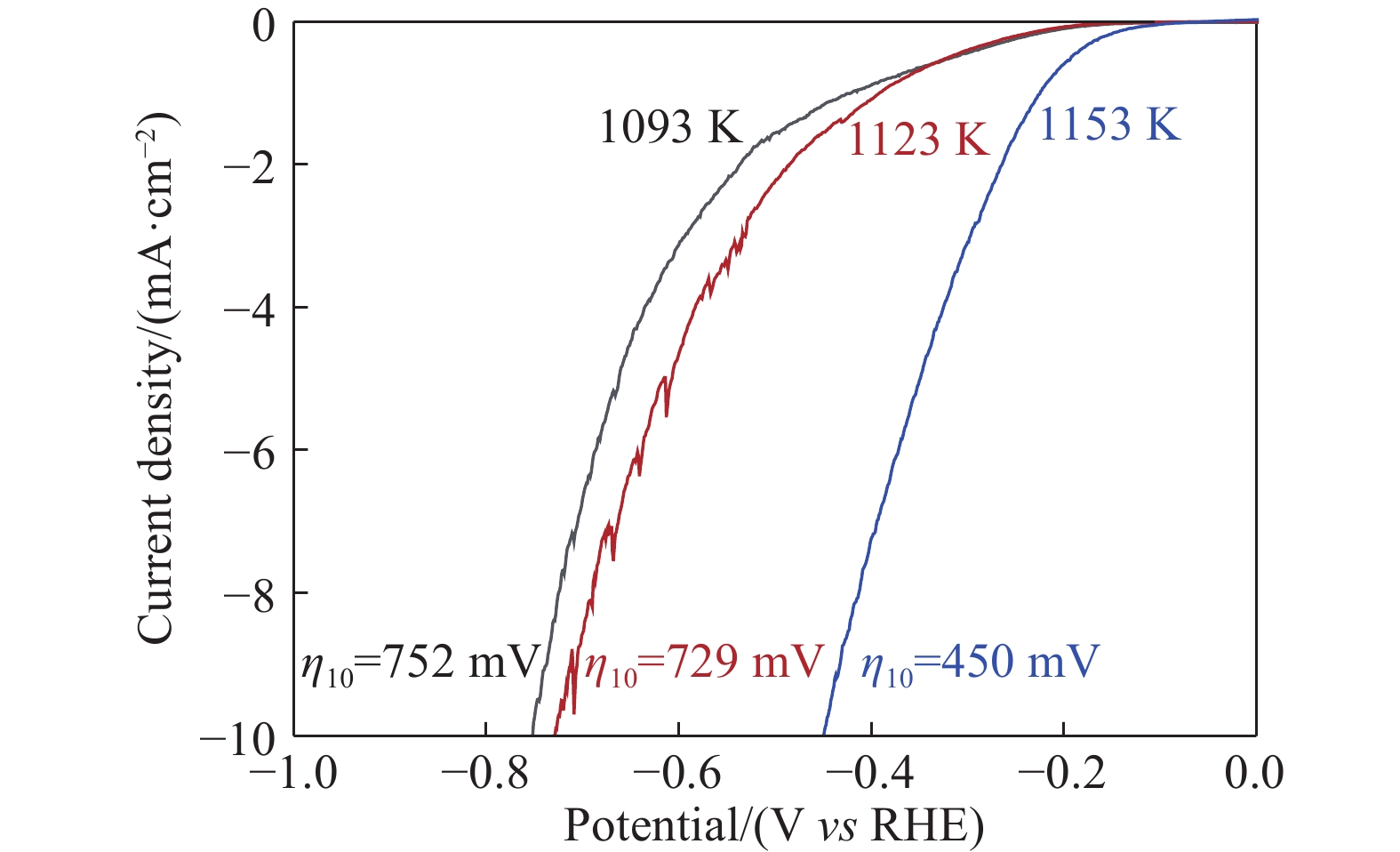

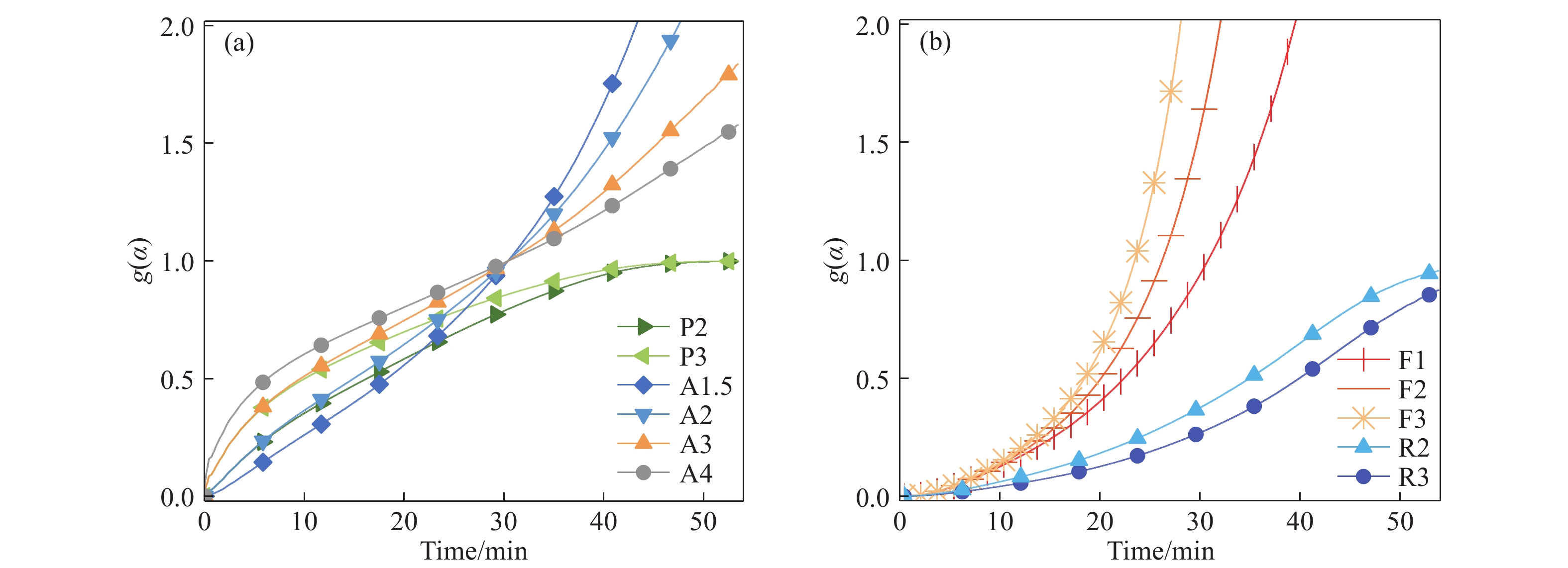

Abstract: Molybdenum carbide (Mo2C), as an alternative to platinum group metals, has been widely used in the hydrocarbon and hydrogen evolution reactions due to its excellent catalytic performance. The exploitation of its preparation method with high efficiency and low cost, therefore, received increasing attention in recent decades. In the current work, the preparation method of Mo2C by reducing MoO2 with CO–15%CO2 mixed gases was proposed, in which the main focus was laid in the reaction kinetics and reduction mechanism studies of the reduction-carburization processes. To determine the isothermal reaction temperature, the nonisothermal reactions of MoO2 in CO–15%CO2 mixed gases under different heating rates (2, 5, 10, and 15 K·min–1) were conducted first. After that, the isothermal reactions in the temperature range from 993 to 1153 K were carried out. Different analytical technologies, such as the thermodynamic calculation, Field emission scanning electron microscopy (FE-SEM), X-ray diffraction (XRD), Thermogravimetric (TG), Brunauer-Emmett-Teller (BET), and model fitting methods were adopted to analyze the experimental data. The results revealed that both the beginning (953 to 997, 1015, and 1031 K) and ending reaction temperatures (1100 to 1201, 1318, and 1383 K) were gradually increased with the increase of the heating rate (2 to 5, 10, and 15 K·min–1); besides, the reaction rate increased with increasing the temperature was also obtained. Phase transformation process of MoO2 to Mo2C was found to proceed by a one-step reaction (MoO2→Mo2C) without the formation of intermediate product Mo. The study also discovered that both Mo2C and MoO2 maintained the similar platelet-shaped morphology during the reaction process, but partial micro-pores and cracks were formed on the product surface because of the entry of reaction gases and escape of the product gases as well as the shrinking of the molar volume, increasing the specific surface area of the as-obtained Mo2C by nearly 20 times when compared to that of the raw material. Kinetics analysis revealed that the reduction-carburization process of MoO2 to Mo2C were not controlled by a one-step reaction mechanism but by the co-action of nucleation growth and interfacial chemical reactions. It was also discovered that the nucleation growth accounted for 68.9% and the chemical reaction accounted for 31.1%, with the extracted activation energies of 80.651 and 121.002 kJ·mol–1, respectively. The work would make a better understanding of the reaction processes of MoO2 to Mo2C in CO–15%CO2 mixed gases.-

Key words:

- CO–15%CO2 mixed gases /

- MoO2 /

- Mo2C /

- reaction mechanism /

- kinetics

-

圖 7 CO–15%CO2混合氣體在不同升溫速率下還原MoO2所得產物形貌. (a) 2 K·min–1; (b) 5 K·min–1; (c) 10 K·min–1; (d) 15 K·min–1

Figure 7. Morphologies of the samples obtained by the temperature-programmed reduction of MoO2 by CO–15%CO2 mixed gases at different heating rates: (a) 2 K·min–1; (b) 5 K·min–1; (c) 10 K·min–1; (d) 15 K·min–1

圖 8 不同溫度下CO–15%CO2混合氣體恒溫還原MoO2所得Mo2C形貌圖. (a) 993 K; (b) 1025 K; (c) 1058 K; (d) 1093 K; (e) 1123 K; (f) 1153 K

Figure 8. Morphologies of the samples obtained by the isothermal reduction of MoO2 to Mo2C by CO–15%CO2 mixed gases at different temperatures: (a) 993 K; (b) 1025 K; (c) 1058 K; (d) 1093 K; (e) 1123 K; (f) 1153 K

圖 9 993 K下CO–15%CO2混合氣體恒溫還原MoO2不同反應進度所得產物形貌. (a1~a3) α = 0.263; (b1~b3) α = 0.503; (c1~c3) α = 0.744; (d1~d3) α = 1

Figure 9. Morphologies of the samples obtained by reducing MoO2 with CO–15%CO2 mixed gases at 993 K for different reaction extents: (a1–a3) α = 0.263; (b1–b3) α = 0.503; (c1–c3) α = 0.744; (d1–d3) α = 1

No. Model Integral form g(α) = kt Explicit form 1 Power law (P2) α1/2 α= (kt)2 2 Power law (P3) α1/3 α = (kt)3 3 Avarami-Erofeev (A1.5) [?ln(1 ? α)]2/3 α = 1 ? exp[? (kt)3/2] 4 Avarami-Erofeev (A2) [?ln(1 ? α)]1/2 α = 1 ? exp[? (kt)2] 5 Avarami-Erofeev (A3) [?ln(1 ? α)]1/3 α = 1 ? exp[? (kt)3] 6 Avarami-Erofeev (A4) [?ln(1 ? α)]1/4 α = 1 ? exp[? (kt)4] 7 First-order (F1) ?ln(1 ? α) α = 1 ? exp(? kt) 8 Second-order (F2) (1 ? α)–1 ? 1 α = 1 ? (kt +1)–1 9 Third-order (F3) 1/2[(1 ? α)–2 ? 1] α = 1 ? (2kt + 1)–1/2 10 Contracting area (R2) 1 ? (1 ? α)1/2 α = 1 ? (1 ? kt)2 11 Contracting volume (R3) 1 ? (1 ? α)1/3 α = 1 ? (1 ? kt)3 www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Liu L, Liu R, Du Q Q, et al. Research on preparation of 2D nano MoC and its electrocatalytic hydrogen evolution property. New Chem Mater, 2021, 49(2): 60 doi: 10.19817/j.cnki.issn1006-3536.2021.02.014劉璐, 劉蕊, 杜倩倩, 等. 二維碳化鉬納米材料的制備及其析氫催化性能研究. 化工新型材料, 2021, 49(2):60 doi: 10.19817/j.cnki.issn1006-3536.2021.02.014 [2] Ouyang T, Ye Y Q, Wu C Y, et al. Heterostructures composed of N-doped carbon nanotubes encapsulating cobalt and β-Mo2C nanoparticles as bifunctional electrodes for water splitting. Angew Chem Int Ed, 2019, 58(15): 4923 doi: 10.1002/anie.201814262 [3] Yan H, Xie Y, Jiao Y, et al. Holey reduced graphene oxide coupled with an Mo2N–Mo2C heterojunction for efficient hydrogen evolution. Adv Mater, 2018, 30(2): 1704156 doi: 10.1002/adma.201704156 [4] Liang T, Suo Y H, Ma S T, et al. Research progress in preparation and application of molybdenum carbide catalyst. Chem Adhesion, 2017, 39(4): 286 doi: 10.3969/j.issn.1001-0017.2017.04.014梁婷, 所艷華, 馬守濤, 等. 碳化鉬催化劑的制備及應用研究進展. 化學與粘合, 2017, 39(4):286 doi: 10.3969/j.issn.1001-0017.2017.04.014 [5] Zhang K M, Wang D D, Yan X L. Preparation of molybdenum carbide/carbon nanosheets composites for hydrogen evolution reaction. Appl Chem Ind, 2020, 49(2): 291 doi: 10.3969/j.issn.1671-3206.2020.02.007張凱敏, 王冬冬, 閆曉麗. 碳化鉬/碳納米片復合材料的制備及析氫性能研究. 應用化工, 2020, 49(2):291 doi: 10.3969/j.issn.1671-3206.2020.02.007 [6] Yang P, Shi S, Dai B, et al. Preparation and electro-catalytic hydrogen-evolution properties of nano-carbon molybdenum. J Shihezi Univ (Nat Sci) , 2018, 36(3): 370 doi: 10.13880/j.cnki.65-1174/n.2018.03.018楊盼, 石松, 代斌, 等. 碳化鉬納米材料的制備及電催化析氫性能. 石河子大學學報(自然科學版), 2018, 36(3):370 doi: 10.13880/j.cnki.65-1174/n.2018.03.018 [7] Kwak W J, Lau C, Shin C D, et al. A Mo2C/carbon nanotube composite cathode for lithium-oxygen batteries with high energy efficiency and long cycle life. ACS Nano, 2015, 9(4): 4129 doi: 10.1021/acsnano.5b00267 [8] Sun G D, Zhang G H, Yan B J, et al. Study on the reduction of commercial MoO3 with carbon black to prepare MoO2 and Mo2C nanoparticles. Int J Appl Ceram Technol, 2020, 17(11): 917 [9] Volpe L, Boudart M. Compounds of molybdenum and tungsten with high specific surface area. J Solid State Chem, 1985, 59(3): 348 doi: 10.1016/0022-4596(85)90302-0 [10] Xu C, Wang L B, Liu Z B, et al. Large-area high-quality 2D ultrathin Mo2C superconducting crystals. Nat Mater, 2015, 14(11): 1135 doi: 10.1038/nmat4374 [11] Pang M, Wang X K, Xia W, et al. Mo(VI)-melamine hybrid As single-source precursor to pure-phase β-Mo2C for the selective hydrogenation of naphthalene to tetralin. Ind Eng Chem Res, 2013, 52(12): 4564 doi: 10.1021/ie400119d [12] Hyeon T, And M F, Suslick K S. Nanostructured molybdenum carbide: Sonochemical synthesis and catalytic properties. J Am Chem Soc, 1996, 118(23): 5492 doi: 10.1021/ja9538187 [13] Lin Z X, Wan W M, Yao S Y, et al. Cobalt-modified molybdenum carbide as a selective catalyst for hydrodeoxygenation of furfural. Appl Catal B Environ, 2018, 233: 160 doi: 10.1016/j.apcatb.2018.03.113 [14] Xiao T C, York A, Coleman K, et al. Effect of carburising agent on the structure of molybdenum carbides. J Mater Chem, 2001, 11(12): 3094 doi: 10.1039/b104011c [15] Qiu Z G, Li Q, Ma S B, et al. Effect of final carbonization temperature on catalytic performance of β-Mo2C in quinoline hydrodenitrogenation. J Fuel Chem Technol, 2020, 48(3): 357 doi: 10.3969/j.issn.0253-2409.2020.03.012邱澤剛, 李僑, 馬少博, 等. 碳化終溫對β-Mo2C催化喹啉加氫脫氮性能影響. 燃料化學學報, 2020, 48(3):357 doi: 10.3969/j.issn.0253-2409.2020.03.012 [16] Wang L, Xue Z L, Huang A, et al. Mechanism and kinetic study of reducing MoO3 to MoO2 with CO-15 vol % CO2 mixed gases. ACS Omega, 2019, 4(22): 20036 doi: 10.1021/acsomega.9b03171 [17] Wang L, Bu C Y, Zhang G H, et al. Study of the reduction of industrial grade MoO3 powders with CO or CO–CO2 gases to prepare MoO2. Metall Mater Trans B, 2017, 48(4): 2047 doi: 10.1007/s11663-017-0979-8 [18] Song C M, Zhang G H, Zhou G Z. Preparation of MoC by reducing MoO3 with CO gas. Chin J Nonferrous Met, 2020, 30(4): 906 doi: 10.11817/j.ysxb.1004.0609.2020-35731宋成民, 張國華, 周國治. CO氣基還原MoO3制備MoC. 中國有色金屬學報, 2020, 30(4):906 doi: 10.11817/j.ysxb.1004.0609.2020-35731 [19] Wu Y D, Zhang G H, Xu R, et al. Fabrication of pure V2O3 powders by reducing V2O5 powders with CO-CO2 mixed gases. Ceram Int, 2019, 45(2): 2117 doi: 10.1016/j.ceramint.2018.10.117 [20] Valendar H M, Yu D W, Barati M, et al. Isothermal kinetics of reduction and carburization of WO3–NiO nanocomposite powder by CO/CO2. J Therm Anal Calorim, 2017, 128(1): 553 doi: 10.1007/s10973-016-5883-y [21] Pan W, Ma Z J, Zhao Z X, et al. Effect of Na2O on the reduction of Fe2O3 compacts with CO/CO2. Metall Mater Trans B, 2012, 43(6): 1326 doi: 10.1007/s11663-012-9738-z [22] Li M C, Wang L, Yang F, et al. Reaction behavior of reduction of WO3 to WO2.72 under CO–CO2 mixed gases. Chin J Nonferrous Met, 2022, 32(3): 866李夢超, 王璐, 楊帆, 等. CO–CO2混合氣體還原WO3至WO2.72的反應行為. 中國有色金屬學報, 2022, 32(3):866 [23] Wang L, Zhang G H, Chou K C. Preparation of Mo2C by reducing ultrafine spherical β-MoO3 powders with CO or CO-CO2 gases. J Aust Ceram Soc, 2018, 54(1): 97 doi: 10.1007/s41779-017-0131-x [24] Wang L, Zhang G H, Chou K C. Study on oxidation mechanism and kinetics of MoO2 to MoO3 in air atmosphere. Int J Refract Met Hard Mater, 2016, 57: 115 doi: 10.1016/j.ijrmhm.2016.03.001 [25] Holzwarth U, Gibson N. The Scherrer equation versus the ‘Debye-Scherrer equation’. Nat Nanotechnol, 2011, 6(9): 534 doi: 10.1038/nnano.2011.145 [26] Dang J, Zhang G H, Wang L, et al. Study on reduction of MoO2 powders with CO to produce Mo2C. J Am Ceram Soc, 2016, 99: 819 doi: 10.1111/jace.14042 [27] Bale C W, Bélisle E, Chartrand P, et al. FactSage thermochemical software and databases–—recent developments. Calphad, 2009, 33(2): 295 doi: 10.1016/j.calphad.2008.09.009 [28] Yang Z H, Cai P J, Shi L, et al. A facile preparation of nanocrystalline Mo2C from graphite or carbon nanotubes. J Solid State Chem, 2006, 179(1): 29 doi: 10.1016/j.jssc.2005.09.037 [29] Ma L, Ting L R L, Molinari V, et al. Efficient hydrogen evolution reaction catalyzed by molybdenum carbide and molybdenum nitride nanocatalysts synthesized via the urea glass route. J Mater Chem A, 2015, 3(16): 8361 doi: 10.1039/C5TA00139K [30] Dang J, Zhang G H, Chou K C. Study on kinetics of hydrogen reduction of MoO2. Int J Refract Met Hard Mater, 2013, 41: 356 doi: 10.1016/j.ijrmhm.2013.05.009 [31] Wang L, Zhang G H, Wang J S, et al. Study on hydrogen reduction of ultrafine MoO2 to produce ultrafine Mo. J Phys Chem C, 2016, 120(7): 4097 doi: 10.1021/acs.jpcc.5b11394 [32] Tang W D, Xue X X, Yang S T, et al. Mineralogical characteristics and isothermal oxidation kinetics of Hongge chromium containing vanadium and titanium magnetite pellets. Chin J Eng, 2018, 40(5): 548湯衛東, 薛向欣, 楊松陶, 等. 紅格含鉻釩鈦磁鐵礦球團礦物學和等溫氧化動力學. 工程科學學報, 2018, 40(5):548 [33] Almazrouei M, Janajreh I. Model-fitting approach to kinetic analysis of non-isothermal pyrolysis of pure and crude glycerol. Renew Energy, 2020, 145: 1693 doi: 10.1016/j.renene.2019.07.095 [34] Wang L, Zhang G H, Chou K C. Mechanism and kinetic study of hydrogen reduction of ultra-fine spherical MoO3 to MoO2. Int J Refract Met Hard Mater, 2016, 54: 342 doi: 10.1016/j.ijrmhm.2015.09.003 [35] Dang J, Zhang G H, Chou K C, et al. Kinetics and mechanism of hydrogen reduction of MoO3 to MoO2. Int J Refract Met Hard Mater, 2013, 41: 216 doi: 10.1016/j.ijrmhm.2013.04.002 -

下載:

下載: