-

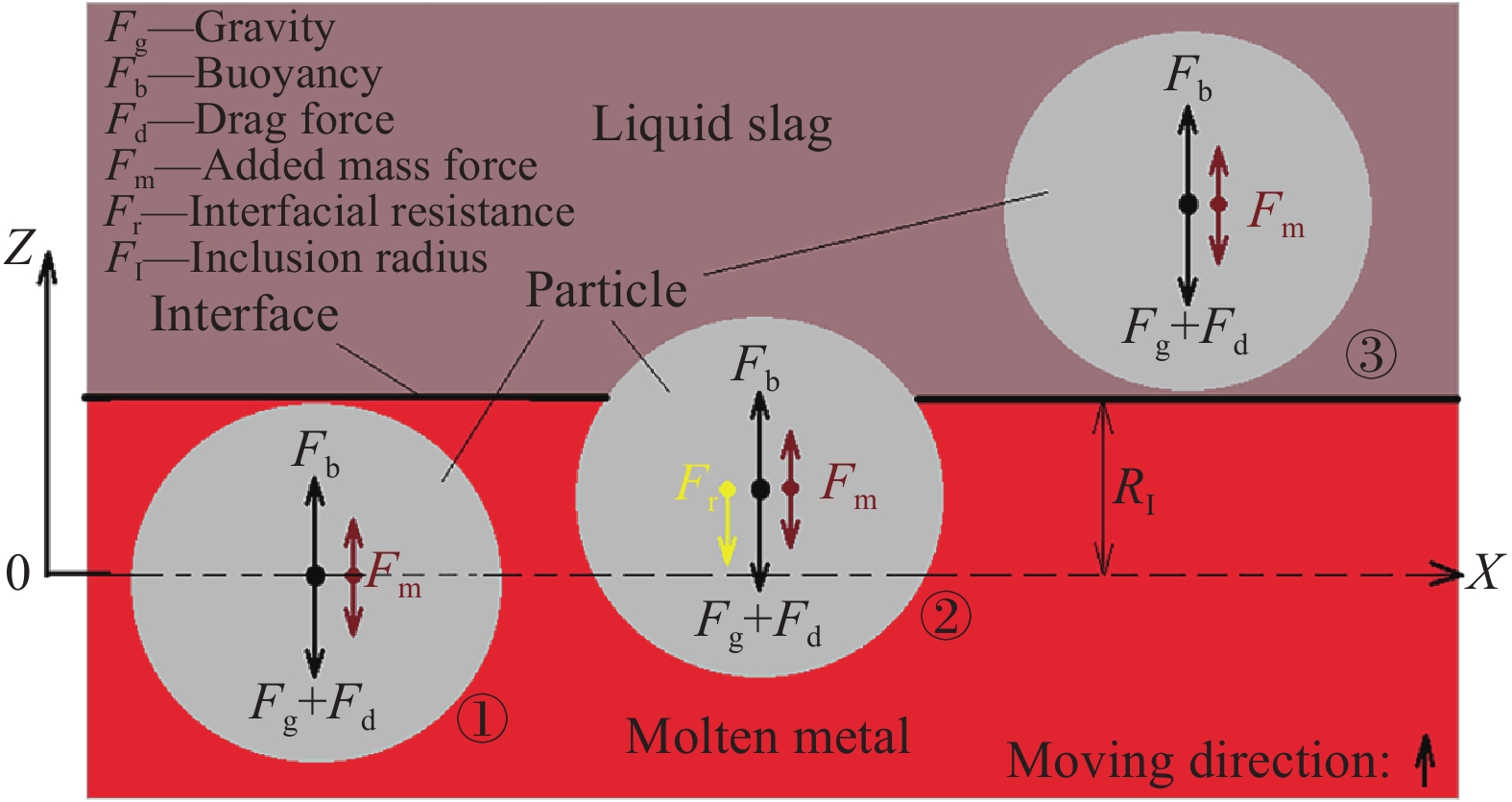

摘要: 鋼中夾雜物的去除一直是潔凈鋼研究的熱點,對于提高鋼材質量、保障產品性能具有重要意義。鋼液中夾雜物主要通過上浮至頂渣被吸收而去除,這個過程可細分為夾雜物在鋼液中長大上浮、在鋼?渣界面穿越分離、在熔渣中被吸附溶解3個步驟。鋼?渣兩相的物性差異及界面特性導致不符合條件的夾雜物無法穿過界面與鋼液分離,這使得該步驟成為夾雜物去除的決定性環節,且由于鋼?渣兩相周圍快速的物性過渡、并行的物理化學現象以及高溫、不透明等特性影響,使該步驟研究難度增大。近年來,隨著數值模擬技術和高溫實驗設備的進步,夾雜物穿越鋼?渣界面行為的研究取得了一些進展。經典的受力分析模型能夠對夾雜物界面行為進行半定量的預測,且對于渣系優化等具有一定的指導作用;計算流體動力學(CFD)模型在研究夾雜物界面現象方面具有優勢,但研究尚處于初期,未來有望適用于更大的尺度范圍、更多的行為場景和相態;水模型與數值模型相結合是一種有效的研究界面行為的方法,隨著實驗技術進步,可進一步對微觀尺度的界面行為進行研究;高溫共聚焦原位觀察是研究界面行為最為直接的方法,對于探究夾雜物界面行為極有幫助,有望通過設備改進,更加完整、深入地揭示夾雜物去除的關鍵機理。Abstract: The removal of inclusions in steel has always been a hot topic in the field of clean steel, and it is important for improving the quality of steel and guaranteeing product performance. Inclusions in steel are mainly removed by allowing them to float to the top slag and get absorbed in it. This removal process can be subdivided into three steps: growing up and floating in the molten steel, separation through the steel-slag interface, and dissolution in the liquid slag phase. Owing to the difference in physical properties of a steel-slag system and its interfacial characteristics, incompatible inclusions cannot be separated by crossing the interface, making this step a key factor for the inclusions’ removal. Moreover, this step occurs with the rapid physical transition of the steel and slag phases along with physical and chemical phenomena in parallel as well as the presence of high temperature, opaqueness, and other characteristics of the impact, making the study more challenging. In recent years, with the advancement of technologies such as numerical simulation and high-temperature equipment, the study of the behavior of inclusions crossing the interface has gradually increased. The classical force analysis model can predict the interfacial behavior of inclusions semiquantitatively and has a certain guidance role for slag system optimization. The computational fluid dynamics (CFD) model has advantages in the study of interfacial phenomena of inclusions, but it is still in the early stage of research. In the future, it is expected to expand to a larger scale, including more behavior scenarios and phase states. The combination of water and numerical models is an effective method to study interfacial behavior. The simulation results at a microscopic scale will be further extended with the advancement of experimental technology in the future. The high-temperature confocal in situ observation is the most direct research method, which is extremely helpful to understand and reveal the interfacial behavior of inclusions. Furthermore, it is expected to reveal the key mechanism of inclusions removal in a more complete and in-depth manner through equipment improvement in the future.

-

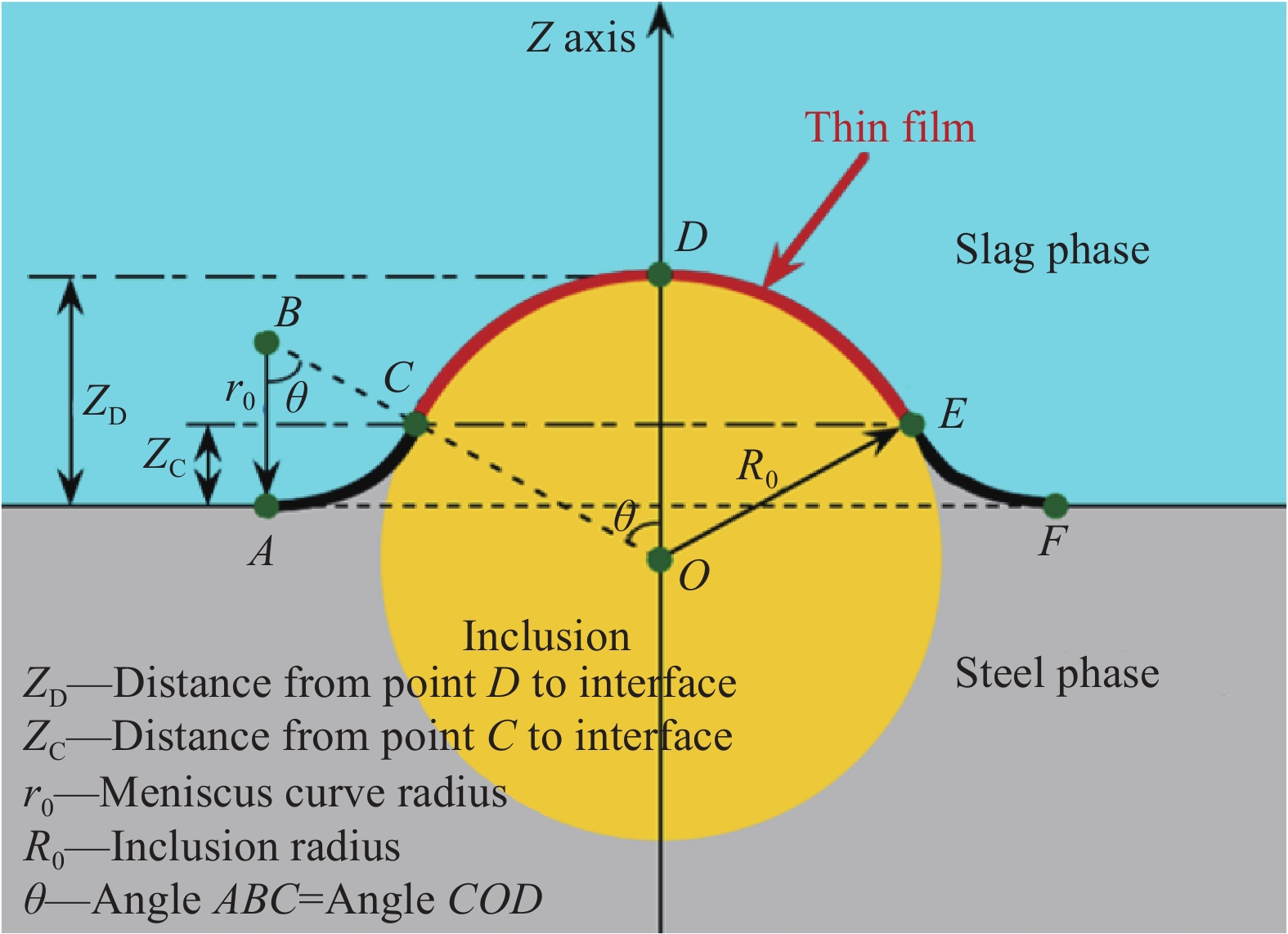

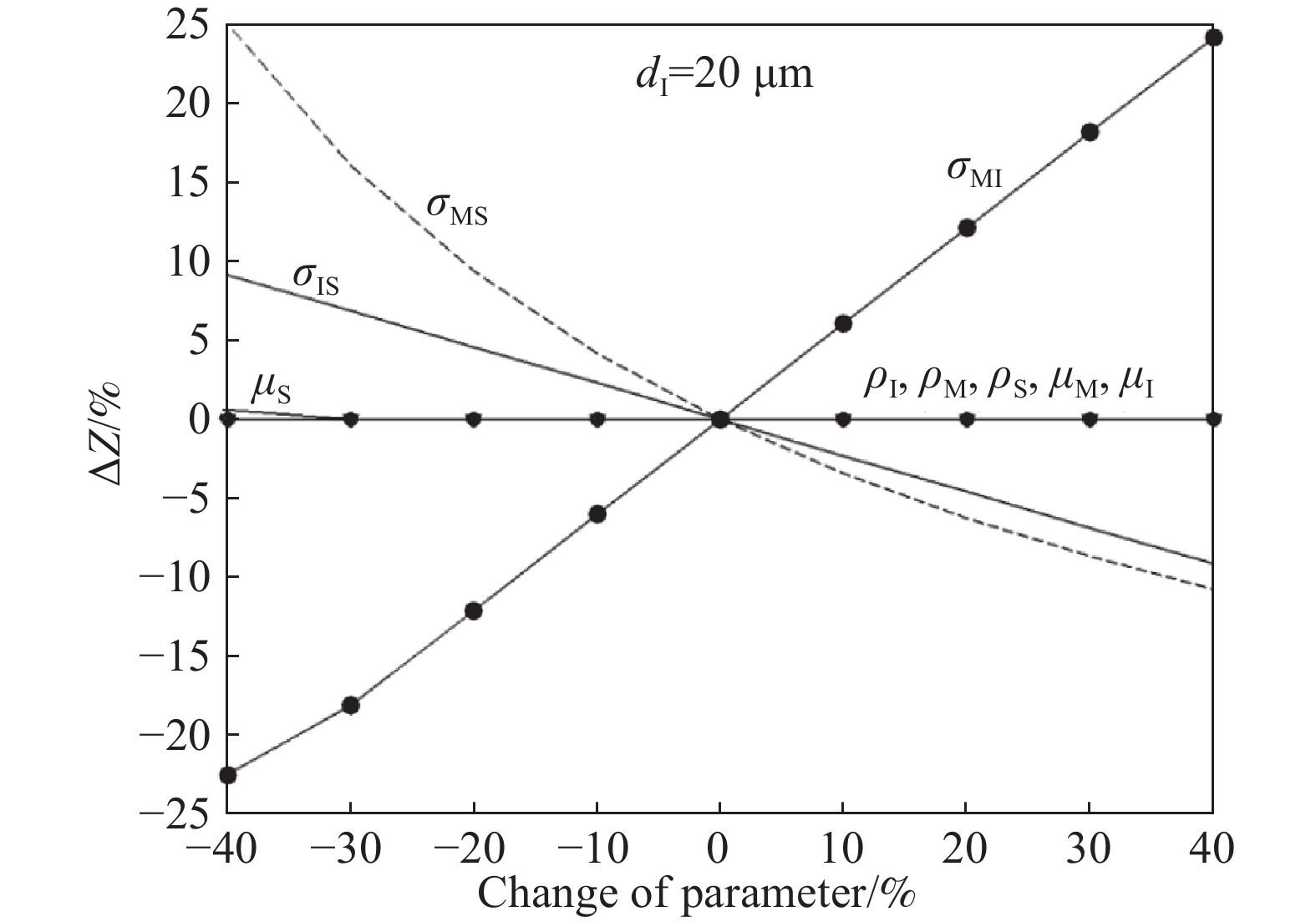

圖 8 物性參數改變對20 μm的液態50%Al2O3–50%CaO (質量百分數)夾雜物去除位移的影響[9]

Figure 8. Effects of physical properties on a 20 μm liquid 50%Al2O3–50%CaO (mass fraction) inclusion’s displacement during removal[9]

σMS—steel?slag interface tension;σIS—inclusion?slag interface tension;σMI—steel?inclusion interface tension;dI—inclusion diameter;ρI—inclusion density;ρM—molten steel density;ρS—slag density;μM—molten steel viscosity;μI—inclusion viscosity;μS—slag viscosity

表 1 夾雜物受力分析模型及其特征

Table 1. Inclusions’ dynamic force analysis model and their features

Year and Reference Model features Inclusion type Slag type Temperature/

K1992, Nakajima et al.[1] Basic model with consideration of steel film drainage Rigid sphere Al2O3, Al2O3?SiO2?TiO2 and Al2O3?SiO2?FeO?TiO2 SiO2?Al2O3?CaF2?MgO?CaO?

Na2O and so on three types1823 1998, Bouris and Bergeles [6] Considering the steel film drainage and re-entrainment of inclusion Rigid sphere Al2O3, Al2O3?SiO2?TiO2 and Al2O3?SiO2?FeO?TiO2 SiO2?Al2O3?CaF2?MgO?CaO?

Na2O and so on three types— 2005, Shannon and Sridhar [7] Study the separation of different inclusion shapes Sphere, octahedron and plate shape LF refining slag, tundish flux and mold flux — 2006, Valdez et al. [8] Considering the separation and dissolution of inclusion separately Rigid sphere Al2O3, MgO, ZrO2 and Mg Al2O4 LF refining slag, tundish flux and mold flux 1773 2005, Strandh et al. [9] First study focusing on the liquid inclusion separation Rigid liquid sphere LF refining slag 1773, 1873 2005, Strandh et al. [10] Application of the model to optimizing tundish flux content Rigid sphere Al2O3 Tundish flux 1823 2008, Shannon et al. [11] Study on the contact velocity of inclusion with the interface Rigid sphere Al2O3 Tundish flux — 2014, Yang et al. [12] Revise the drag force and terminal velocity equations according to Re number Rigid sphere Al2O3 LF refining slag 1873 2019, Liu et al. [4] Coupling the separation and dynamic dissolution model of inclusion Rigid sphere Al2O3 LF refining slag 1873 2019, Xuan et al.[3] Considering the interfacial deformation at the stage of thin-film drainage Rigid liquid sphere VD refining slag 1873 www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Nakajima K, Okamura K. Inclusion transfer behavior across molten steel–slag interface // The 4th International Conference on Molten Slags and Fluxes. Sendai, 1992: 505 [2] Liu C, Yang S F, Li J S, et al. Motion behavior of nonmetallic inclusions at the interface of steel and slag. part I: Model development, validation, and preliminary analysis. Metall Mater Trans B, 2016, 47(3): 1882 [3] Xuan C J, Persson E S, Sevastopolev R, et al. Motion and detachment behaviors of liquid inclusion at molten steel?slag interfaces. Metall Mater Trans B, 2019, 50(4): 1957 doi: 10.1007/s11663-019-01568-2 [4] Liu W, Yang S F, Li J S, et al. Numerical model of inclusion separation from liquid metal with consideration of dissolution in slag. J Iron Steel Res Int, 2019, 26(11): 1147 doi: 10.1007/s42243-018-0212-2 [5] Yang S F, Liu W, Li J S. Motion of solid particles at molten metal?liquid slag interface. JOM, 2015, 67(12): 2993 doi: 10.1007/s11837-015-1642-y [6] Bouris D, Bergeles G. Investigation of inclusion re-entrainment from the steel?slag interface. Metall Mater Trans B, 1998, 29(3): 641 doi: 10.1007/s11663-998-0099-6 [7] Shannon G N, Sridhar S. Modeling Al2O3 inclusion separation across steel?slag interfaces. Scand J Metall, 2005, 34(6): 353 doi: 10.1111/j.1600-0692.2005.00755.x [8] Valdez M, Shannon G S, Sridhar S. The ability of slags to absorb solid oxide inclusions. ISIJ Int, 2006, 46(3): 450 doi: 10.2355/isijinternational.46.450 [9] Strandh J, Nakajima K, Eriksson R, et al. A mathematical model to study liquid inclusion behavior at the steel?slag interface. ISIJ Int, 2005, 45(12): 1838 doi: 10.2355/isijinternational.45.1838 [10] Strandh J, Nakajima K, Eriksson R, et al. Solid inclusion transfer at a steel?slag interface with focus on tundish conditions. ISIJ Int, 2005, 45(11): 1597 doi: 10.2355/isijinternational.45.1597 [11] Shannon G, White L, Sridhar S. Modeling inclusion approach to the steel/slag interface. Mater Sci Eng A, 2008, 495(1-2): 310 doi: 10.1016/j.msea.2007.09.087 [12] Yang S F, Li J S, Liu C, et al. Motion behavior of nonmetal inclusions at the interface of steel and slag. part II:Model application and discussion. Metall Mater Trans B, 2014, 45(6): 2453 [13] Liu W, Yang S F, Li J S. Calculation of static suspension depth and meniscus shape of a solid spherical inclusion at the steel?slag interface. Metall Mater Trans B, 2020, 51(2): 422 doi: 10.1007/s11663-020-01770-7 [14] S?der M, J?nsson P, Jonsson L. Inclusion growth and removal in gas-stirred ladles. Steel Res Int, 2004, 75(2): 128 doi: 10.1002/srin.200405938 [15] Zhu M Y, Zheng S G, Huang Z Z, et al. Numerical simulation of nonmetallic inclusions behaviour in gas-stirred ladles. Steel Res Int, 2005, 76(10): 718 doi: 10.1002/srin.200506085 [16] Miki Y, Thomas B G, Denissov A, et al. Model of inclusion removal during RH degassing of steel. Iron Steelmaker, 1997, 24(8): 31 [17] Miki Y, Thomas B G. Modeling of inclusion removal in a tundish. Metall Mater Trans B, 1999, 30(4): 639 doi: 10.1007/s11663-999-0025-6 [18] Wang L T, Zhang Q Y, Deng C H, et al. Mathematical model for removal of inclusion in molten steel by injecting gas at ladle shroud. ISIJ Int, 2005, 45(8): 1138 doi: 10.2355/isijinternational.45.1138 [19] Thomas B G, Zhang L F. Mathematical modeling of iron and steel making processes. mathematical modeling of fluid flow in continuous casting. ISIJ Int, 2001, 41(10): 1181 [20] Cho S M, Thomas B G, Hwang J Y, et al. Modeling of inclusion capture in a steel slab caster with vertical section and bending. Metals, 2021, 11(4): 654 doi: 10.3390/met11040654 [21] Geng D Q, Zheng J X, Wang K, et al. Simulation on decarburization and inclusion removal process in the ruhrstahl-heraeus (RH) process with ladle bottom blowing. Metall Mater Trans B, 2015, 46(3): 1484 doi: 10.1007/s11663-015-0314-1 [22] Chattopadhyay K, Isac M, Guthrie R I L. Considerations in using the discrete phase model (DPM). Steel Res Int, 2011, 82(11): 1287 doi: 10.1002/srin.201000214 [23] Duan H J, Ren Y, Zhang L F. Inclusion capture probability prediction model for bubble floatation in turbulent steel flow. Metall Mater Trans B, 2019, 50(1): 16 doi: 10.1007/s11663-018-1462-x [24] Chen K L, Wang D Y, Qu T P, et al. Physical and numerical simulation of the coalescence of liquid inclusion particles in molten steel. Chin J Eng, 2019, 41(10): 1280陳開來, 王德永, 屈天鵬, 等. 鋼中液態夾雜物聚并行為的數學物理模擬. 工程科學學報, 2019, 41(10):1280 [25] Xu Y G, Ersson M, J?nsson P. Numerical simulation of single argon bubble rising in molten metal under a laminar flow. Steel Res Int, 2015, 86(11): 1289 doi: 10.1002/srin.201400355 [26] Xuan C J, Persson E S, Jensen J, et al. A novel evolution mechanism of Mg?Al?oxides in liquid steel: Integration of chemical reaction and coalescence-collision. J Alloys Compd, 2020, 812: 152149 doi: 10.1016/j.jallcom.2019.152149 [27] Liu W, Yang S F, Li J S, et al. Numerical simulation of the three-phase flow of a bubble interacting with the steel?slag interface during the secondary refining process. Metall Mater Trans B, 2019, 50(4): 1542 doi: 10.1007/s11663-019-01580-6 [28] Liu W, Liu J, Zhao H X, et al. CFD modeling of solid inclusion motion and separation from liquid steel to molten slag. Metall Mater Trans B, 2021, 52(4): 2430 doi: 10.1007/s11663-021-02203-9 [29] Huang A, Wang H Z, Gu H Z, et al. A study on water modeling of inclusion removal in tundish with gas curtain. Special Steel, 2009, 30(1): 7黃奧, 汪厚植, 顧華志, 等. 氣幕擋墻中間包夾雜物去除的水模型研究. 特殊鋼, 2009, 30(1):7 [30] Ni B, Luo Z G, Di Z X, et al. Experimental study on inclusion removal in slab continuous casting mold by water modeling. Continuous Cast, 2009, 34(1): 1倪冰, 羅志國, 狄瞻霞, 等. 板坯連鑄結晶器內夾雜物去除的水模實驗研究. 連鑄, 2009, 34(1):1 [31] Chen X Y, Cao L, Hu J D, et al. Study on water modeling for mixing trait and inclusion removing of LF. Iron Steel, 2009, 44(12): 27 doi: 10.3321/j.issn:0449-749X.2009.12.006陳向陽, 曹磊, 胡建東, 等. LF精煉爐混合特性及夾雜物去除的水模型研究. 鋼鐵, 2009, 44(12):27 doi: 10.3321/j.issn:0449-749X.2009.12.006 [32] Cho J S, Lee H G. Cold model study on inclusion removal from liquid steel using fine gas bubbles. ISIJ Int, 2001, 41(2): 151 doi: 10.2355/isijinternational.41.151 [33] Nakaoka T, Taniguchi S, Matsumoto K, et al. Particle-size-grouping method of lnclusion agglomeration and its application to water model experiments. ISIJ Int, 2001, 41(10): 1103 doi: 10.2355/isijinternational.41.1103 [34] Zhou Y L, Deng Z Y, Zhu M Y. Separation mechanism of solid/liquid inclusions transfer at steel-slag interface. Chin J Process Eng, 2018, 18(1): 96 doi: 10.12034/j.issn.1009-606X.217237周業連, 鄧志銀, 朱苗勇. 固/液態夾雜物穿過鋼渣界面的分離機理. 過程工程學報, 2018, 18(1):96 doi: 10.12034/j.issn.1009-606X.217237 [35] Yang H B. Study on Moving Behavior of Inclusion during Process of Passing Steel−Slag Interface [Dissertation]. Beijing: University of Science and Technology Beijing, 2015楊宏博. 夾雜物穿越鋼渣界面過程運動行為研究[學位論文]. 北京: 北京科技大學, 2015 [36] Liu C, Li J S, Sun L Y, et al. Influence of floatation velocity on removal of inclusions at steel?slag interface. Special Steel, 2014, 35(5): 5 doi: 10.3969/j.issn.1003-8620.2014.05.002劉超, 李京社, 孫麗媛, 等. 上浮速度對鋼渣界面夾雜物去除的影響. 特殊鋼, 2014, 35(5):5 doi: 10.3969/j.issn.1003-8620.2014.05.002 [37] Liu C. Theoretical Study on the Separation and Removal of Inclusions at the Steel Slag Interface [Dissertation]. Beijing: University of Science and Technology Beijing, 2014劉超. 鋼渣界面夾雜物分離去除的理論研究 [學位論文]. 北京: 北京科技大學, 2014 [38] Kimura S, Nakajima K, Mizoguchi S. Behavior of alumina-magnesia complex inclusions and magnesia inclusions on the surface of molten low-carbon steels. Metall Mater Trans B, 2001, 32(1): 79 doi: 10.1007/s11663-001-0010-1 [39] Vantilt S, Coletti B, Blanpain B, et al. Observation of inclusions in manganese-silicon killed steels at steel?gas and steel-slag interfaces. ISIJ Int, 2004, 44(1): 1 doi: 10.2355/isijinternational.44.1 [40] Liu J, Guo M, Jones P T, et al. In situ observation of the direct and indirect dissolution of MgO particles in CaO?Al2O3?SiO2-based slags. J Eur Ceram Soc, 2007, 27(4): 1961 doi: 10.1016/j.jeurceramsoc.2006.05.107 [41] Kimura S, Nabeshima Y, Nakajima K, et al. Behavior of nonmetallic inclusions in front of the solid?liquid interface in low-carbon steels. Metall Mater Trans B, 2000, 31(5): 1013 doi: 10.1007/s11663-000-0077-0 [42] Misra P, Chevrier V, Sridhar S, et al. In situ observations of inclusions at the (Mn, Si)-killed steel/CaO?Al2O3 interface. Metall Mater Trans B, 2000, 31(5): 1135 doi: 10.1007/s11663-000-0090-3 [43] Coletti B, Blanpain B, Vantilt S, et al. Observation of calcium aluminate inclusions at interfaces between Ca-treated, Al-killed steels and slags. Metall Mater Trans B, 2003, 34(5): 533 doi: 10.1007/s11663-003-0021-1 [44] Wikstr?m J, Nakajima K, Shibata H, et al. In situ studies of the agglomeration phenomena for calcium-alumina inclusions at liquid steel?liquid slag interface and in the slag. Mater Sci Eng:A, 2008, 495(1-2): 316 doi: 10.1016/j.msea.2007.09.084 [45] Wikstr?m J, Nakajima K, Shibata H, et al. In situ studies of agglomeration between Al2O3?CaO inclusions at metal/gas, metal/slag interfaces and in slag. Ironmak Steelmaker, 2008, 35(8): 589 doi: 10.1179/174328108X284589 [46] Liu J H, Verhaeghe F, Guo M X, et al. In situ observation of the dissolution of spherical alumina particles in CaO?Al2O3?SiO2 melts. J Am Ceram Soc, 2007, 90(12): 3818 [47] Yin H B, Shibata H, Emi T, et al. “in-situ” observation of collision, agglomeration and cluster formation of alumina inclusion particles on steel melts. ISIJ Int, 1997, 37(10): 936 doi: 10.2355/isijinternational.37.936 [48] Wikstr?m J, Nakajima K, Jonsson L, et al. Application of a model for liquid inclusion separation at a steel?slag interface for laboratory and industrial situations. Steel Res Int, 2008, 79(11): 826 doi: 10.1002/srin.200806206 [49] Rocha V C, Pereira J A M, Yoshioka A, et al. Evaluation of secondary steelmaking slags and their relation with steel cleanliness. Metall Mater Trans B, 2017, 48(3): 1423 doi: 10.1007/s11663-017-0935-7 [50] Wang H M, Li G R, Dai Q X, et al. Effect of additives on viscosity of LATS refining ladle slag. ISIJ Int, 2006, 46(5): 637 doi: 10.2355/isijinternational.46.637 [51] Hanao M, Tanaka T, Kawamoto M, et al. Evaluation of surface tension of molten slag in multi-component systems. ISIJ Int, 2007, 47(7): 935 doi: 10.2355/isijinternational.47.935 [52] Duchesne M A, Hughes R W. Slag density and surface tension measurements by the constrained sessile drop method. Fuel, 2017, 188: 173 doi: 10.1016/j.fuel.2016.10.023 -

下載:

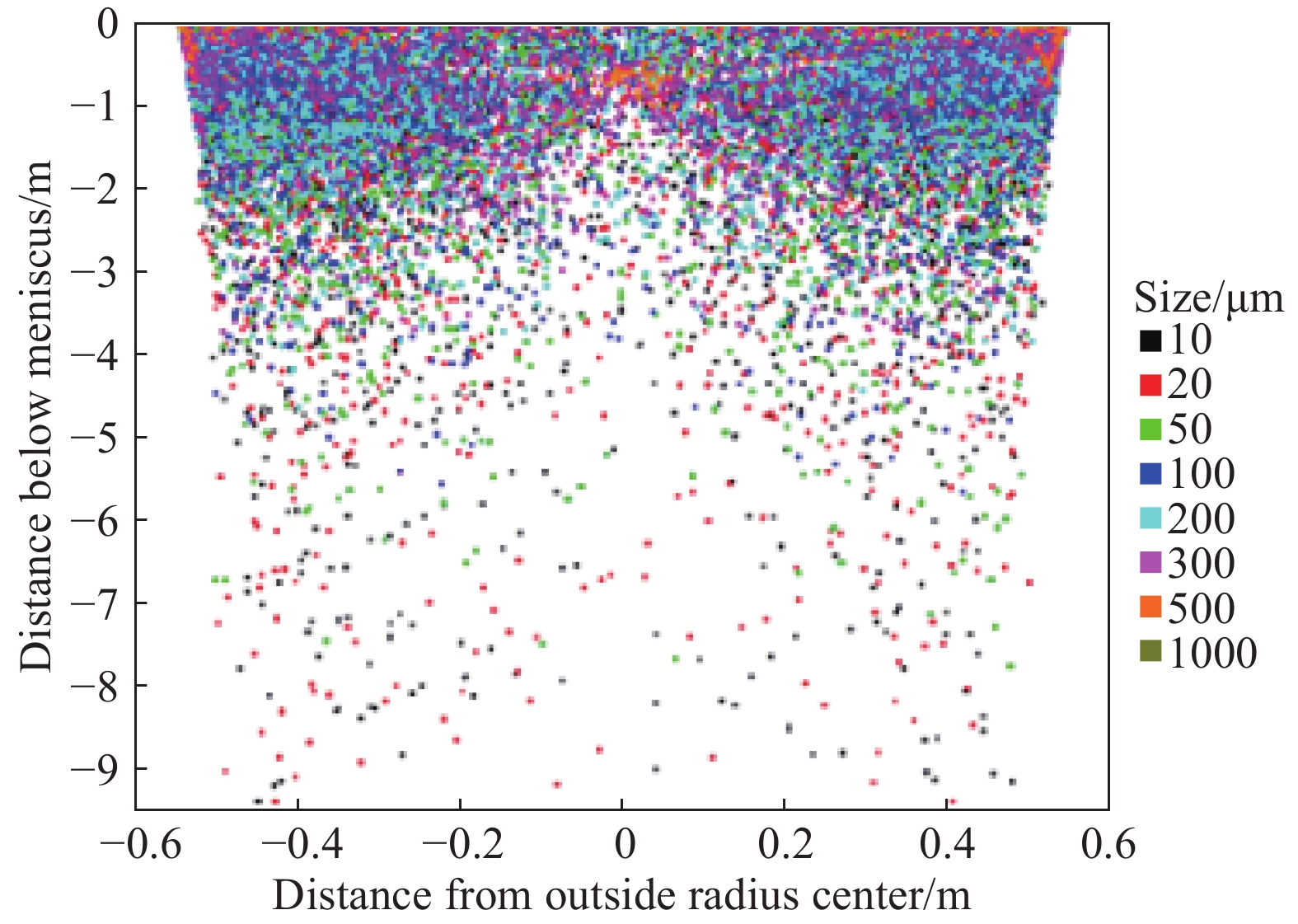

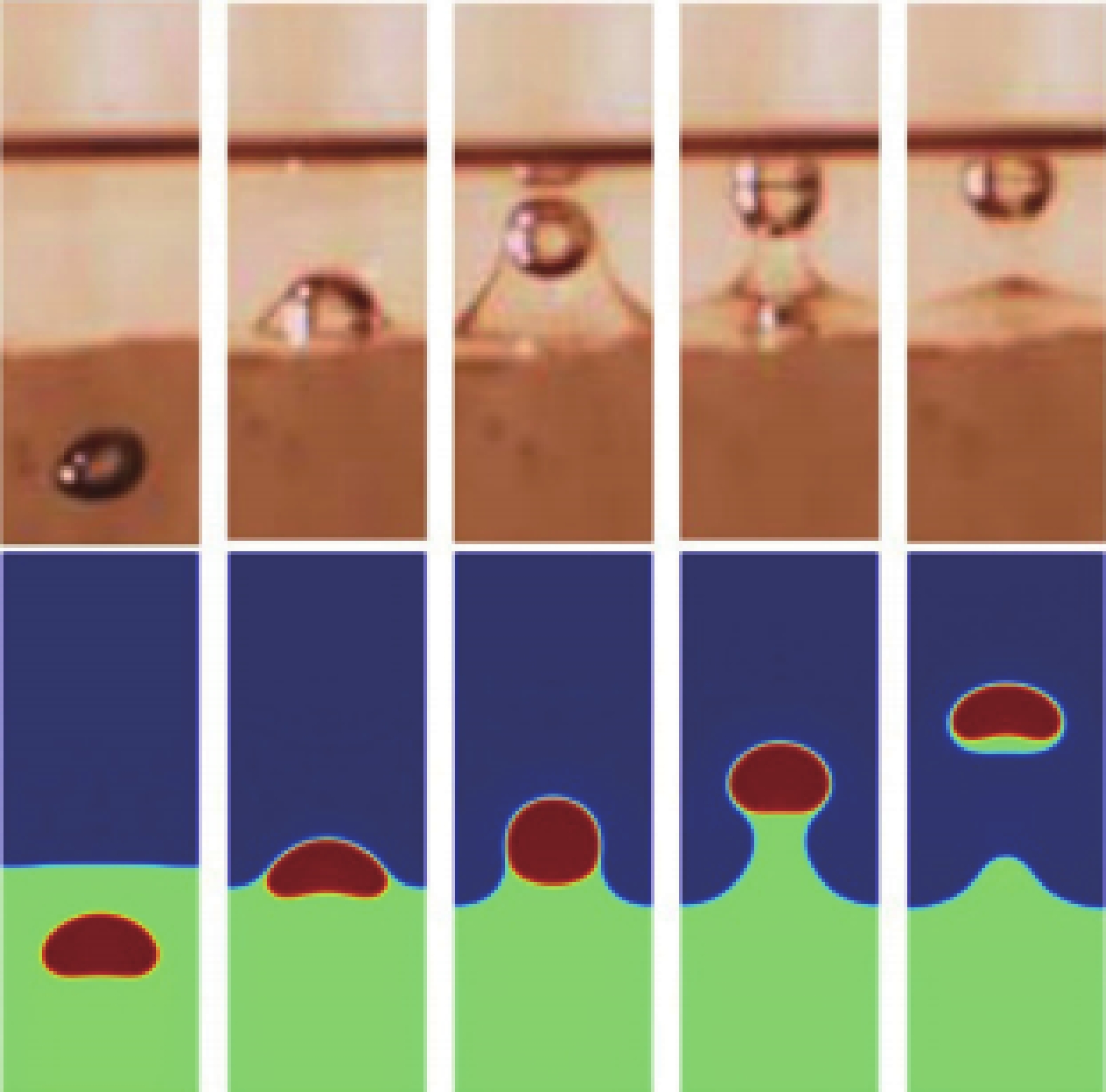

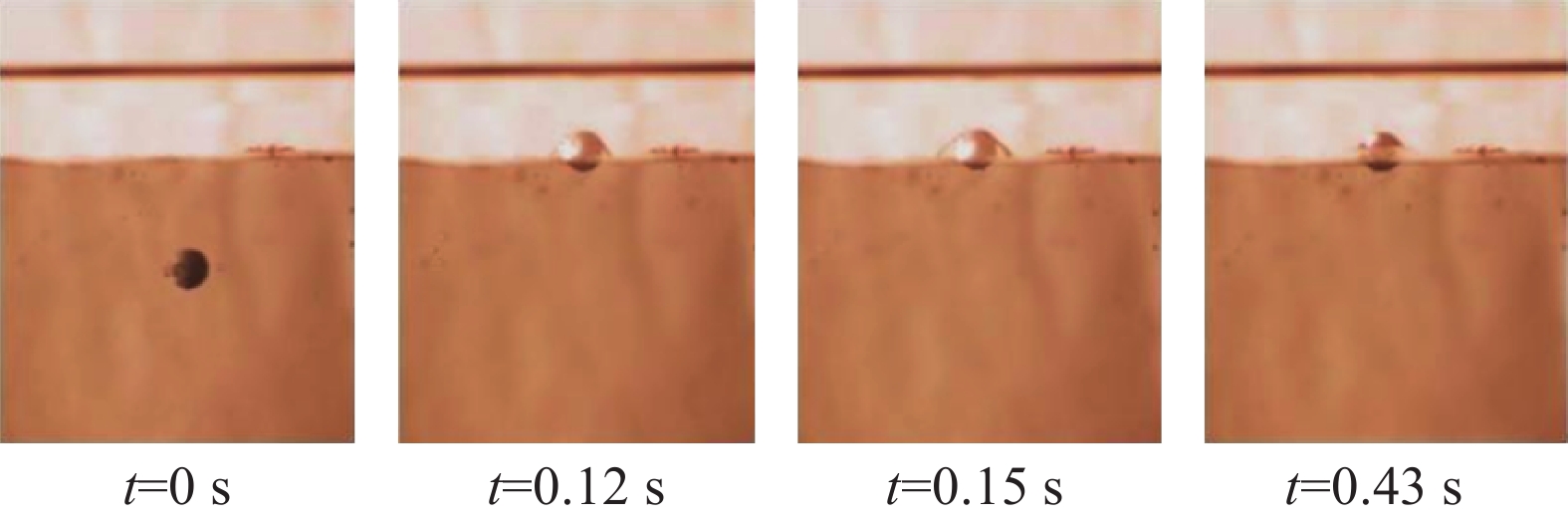

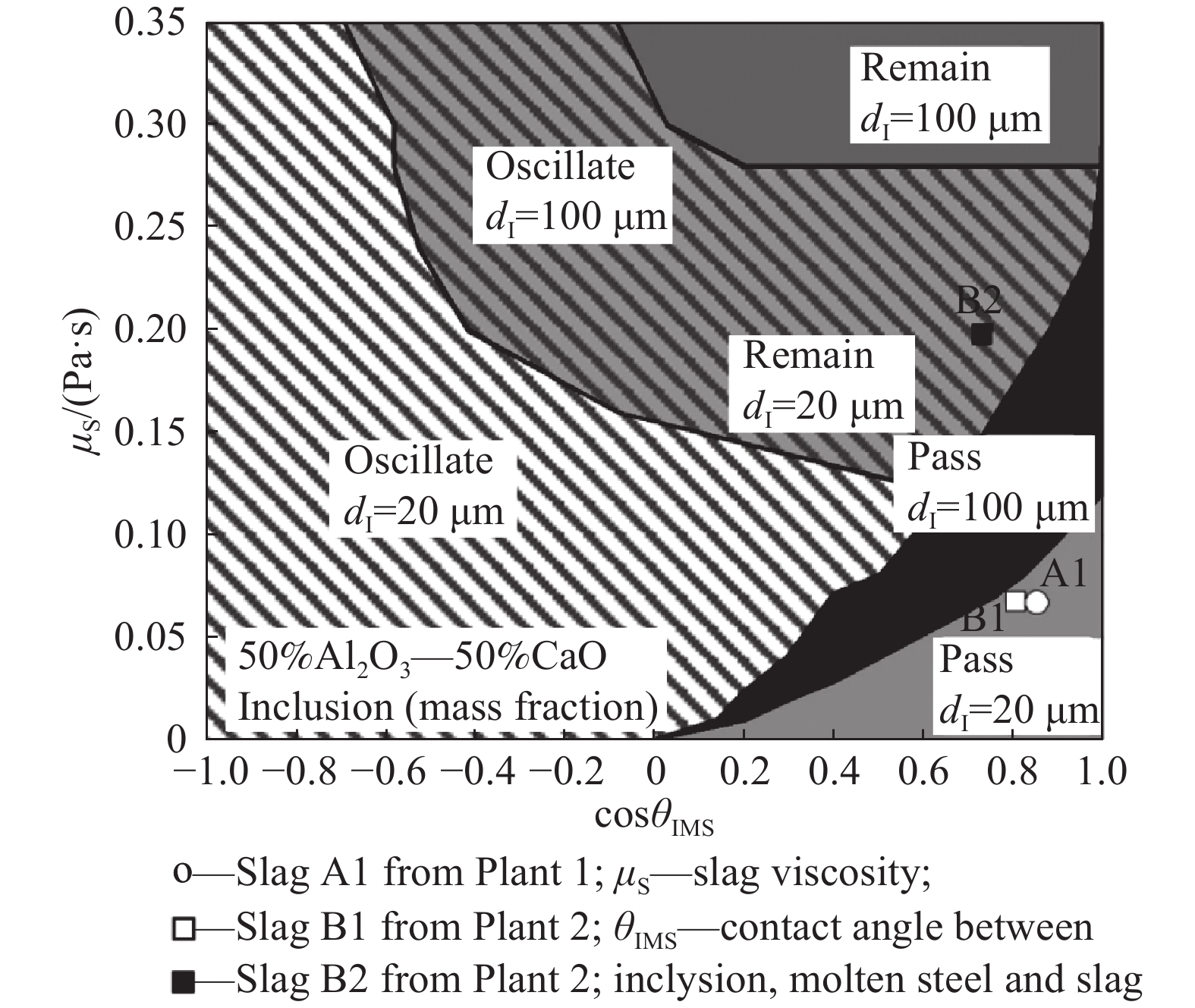

下載: