-

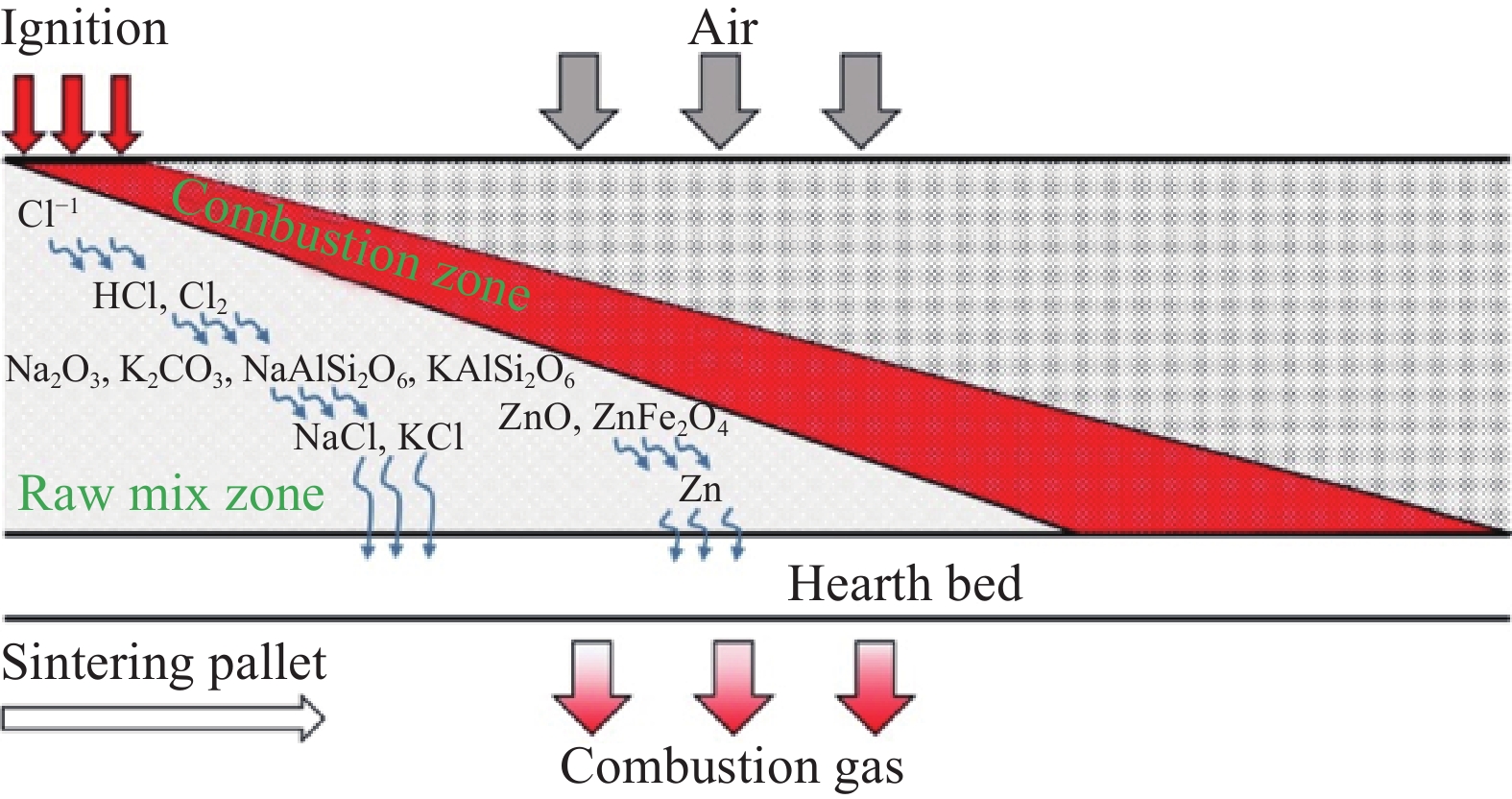

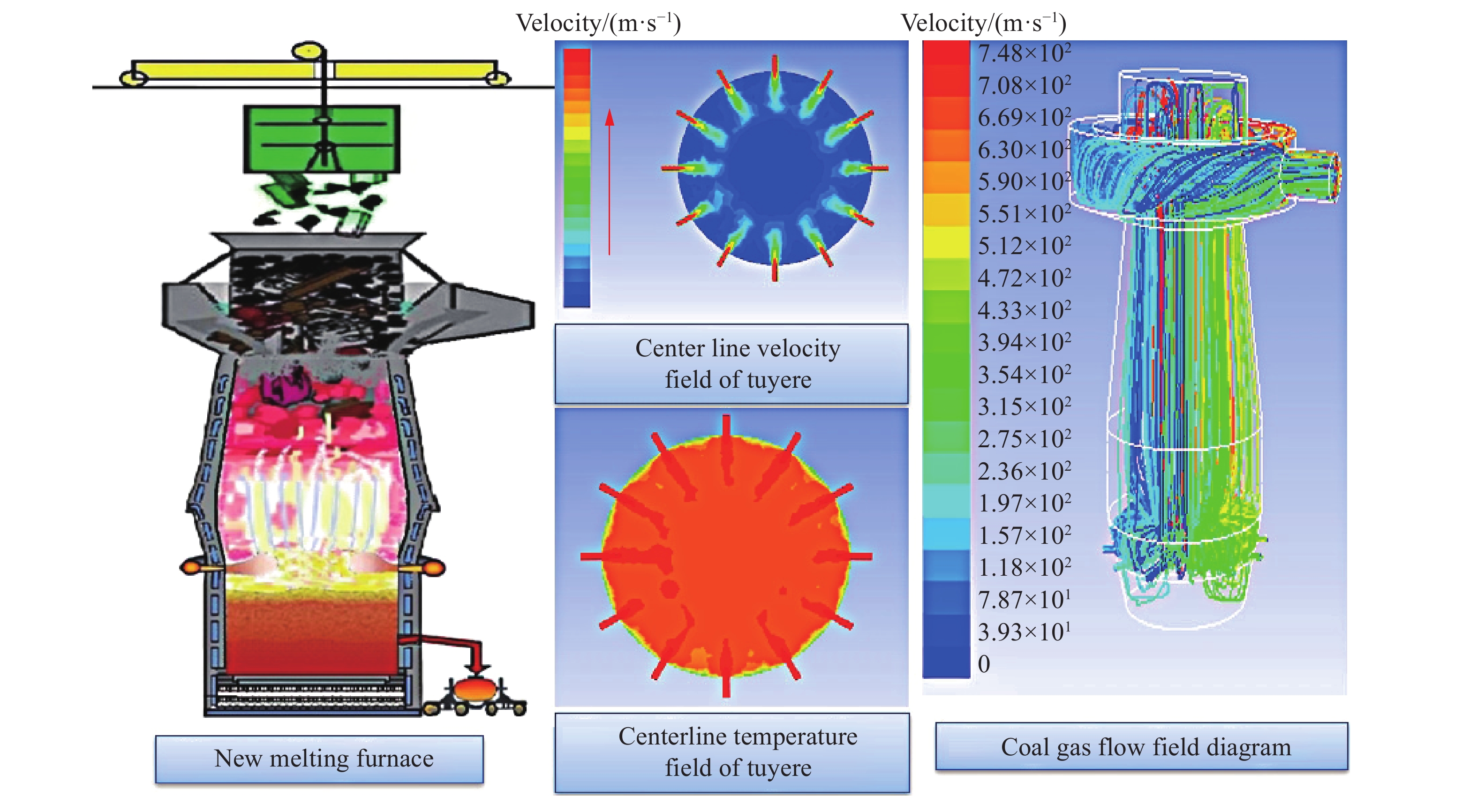

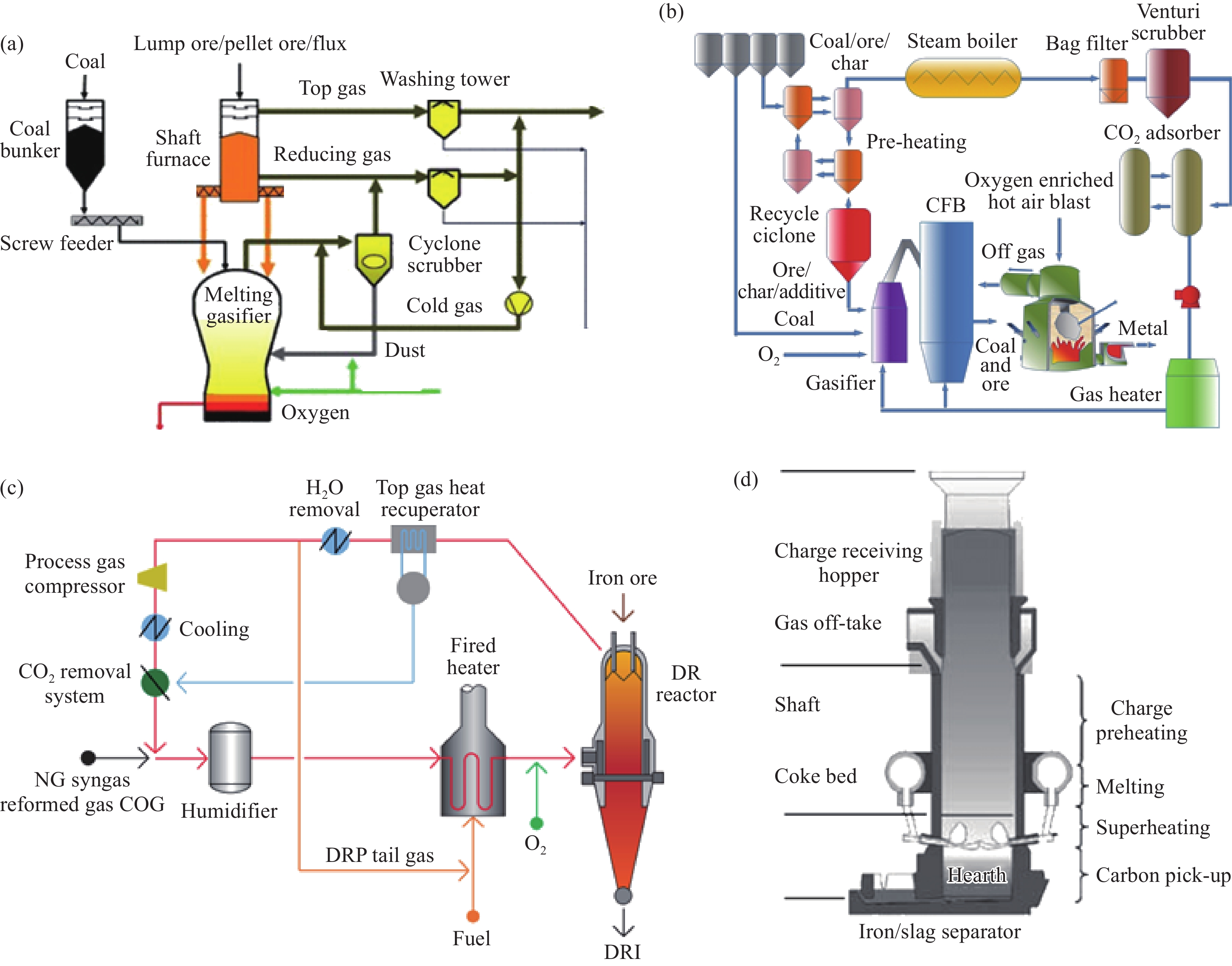

摘要: 從煉鐵新技術及基礎理論研究方面介紹了燒結球團提質降耗新技術、焦炭在高爐內行為解析研究、高爐噴吹清潔燃料技術、高爐長壽技術、高爐煉鐵數據建模技術以及冶金塵泥再處理技術。從基礎研究出發,提出了目前最具有潛力的煉鐵新技術;然后在國家碳中和戰略的大背景下,綜述了目前國際上的非高爐煉鐵技術研究進展,為我國低碳煉鐵發展提供依據;最后從最新微觀研究手段出發,介紹了目前煉鐵研究領域在微觀尺度的研究進展,多尺度綜合調控研究高爐煉鐵過程機理,為未來低碳煉鐵發展方向提供思路。Abstract: The Chinese government made a statement at the 75th United Nations General Assembly in 2020 to increase the country’s nationally determined contributions, adopt more effective policies and measures, strive to reach the peak of carbon dioxide emissions by 2030 and achieve carbon neutrality by 2060. In recent years, with the rapid development of the iron and steel industry, the iron and steel industry has been promoted by various measures such as large-scale equipment, high-efficiency energy utilization, and reduction of pollutant emissions. Moreover, this industry has gradually made efforts to achieve low-carbon emissions. However, due to the particularity of the steel industry’s process system, the steel industry is still the main battlefield in China’s carbon emission reduction. The ironmaking process accounts for the largest proportion of energy consumption and emissions in the entire process of iron and steel smelting. Annual CO2 emissions of the iron and steel industry account for 6.7% of total global emissions, of which the energy consumption and emissions of the ironmaking system account for the total energy consumption of the entire iron and steel process, facing the important challenge of saving energy and emission reduction. To adapt to the trend and realize the transformation and upgrading of the ironmaking industry, various processes of the ironmaking industry have made great efforts in reform and innovation in recent years. This article introduces the new technology of sintering pellet quality improvement and consumption reduction from the aspects of new ironmaking technology and basic theoretical research, analysis of coke behavior in the blast furnace, blast furnace clean fuel injection technology, blast furnace longevity technology, blast furnace ironmaking data modeling technology, and metallurgical dust and mud reprocessing technology. Starting from basic research, the new ironmaking technology with the most potential is proposed. Then, under the general background of the current national carbon neutral strategy, the current international non-blast furnace ironmaking technology research progress is reviewed to provide a basis for the development of low-carbon ironmaking in China. Finally, starting from the latest micro-research methods, it introduces the current research progress in the field of ironmaking in the micro-scale, multi-scale comprehensive regulation and control of the mechanism of the blast furnace ironmaking process, and provides ideas for the future development of low-carbon ironmaking.

-

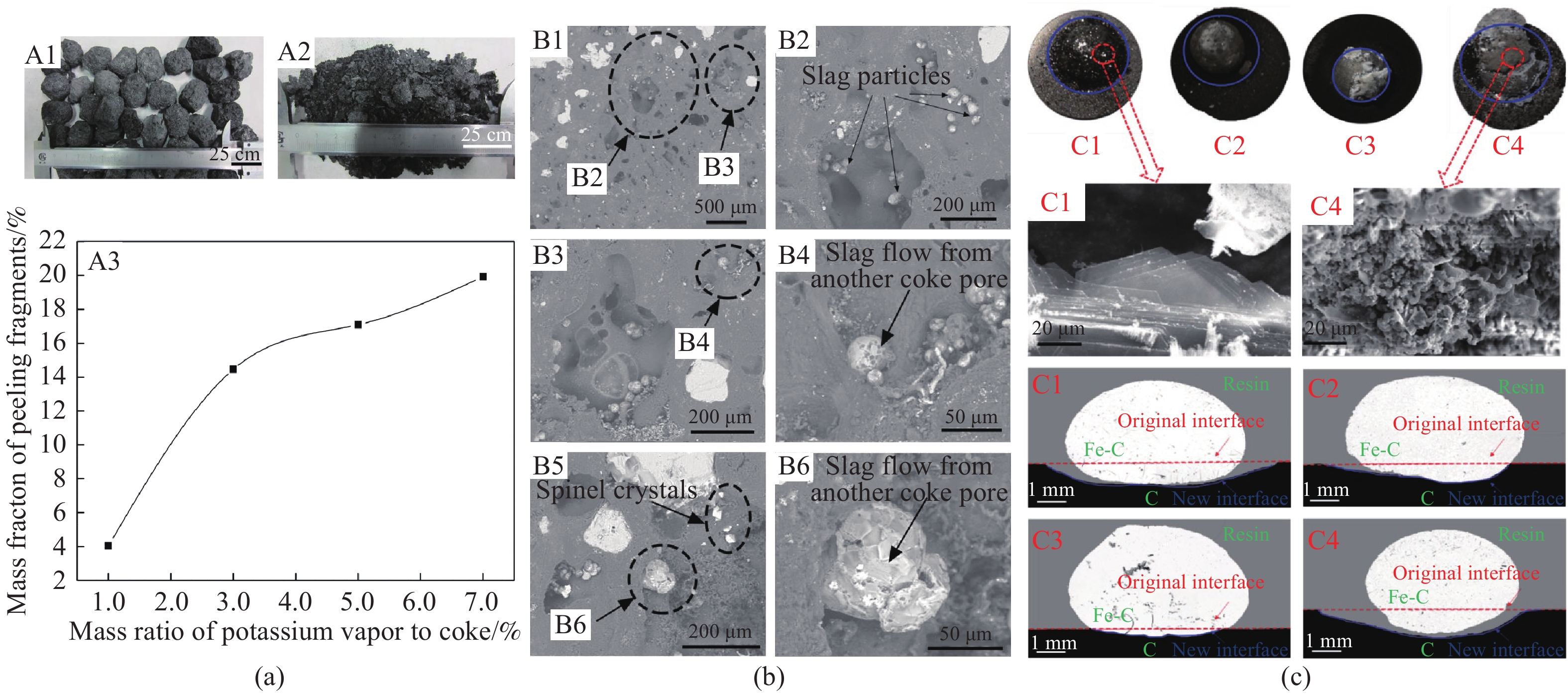

圖 2 (a)堿化前(A1)后(A2)的焦炭樣品及剝落的焦炭碎屑質量隨著K含量的變化;(b)表征爐渣流過爐缸的焦炭內部氣孔管道的SEM圖;(c)不同碳質基質溶解后的形貌

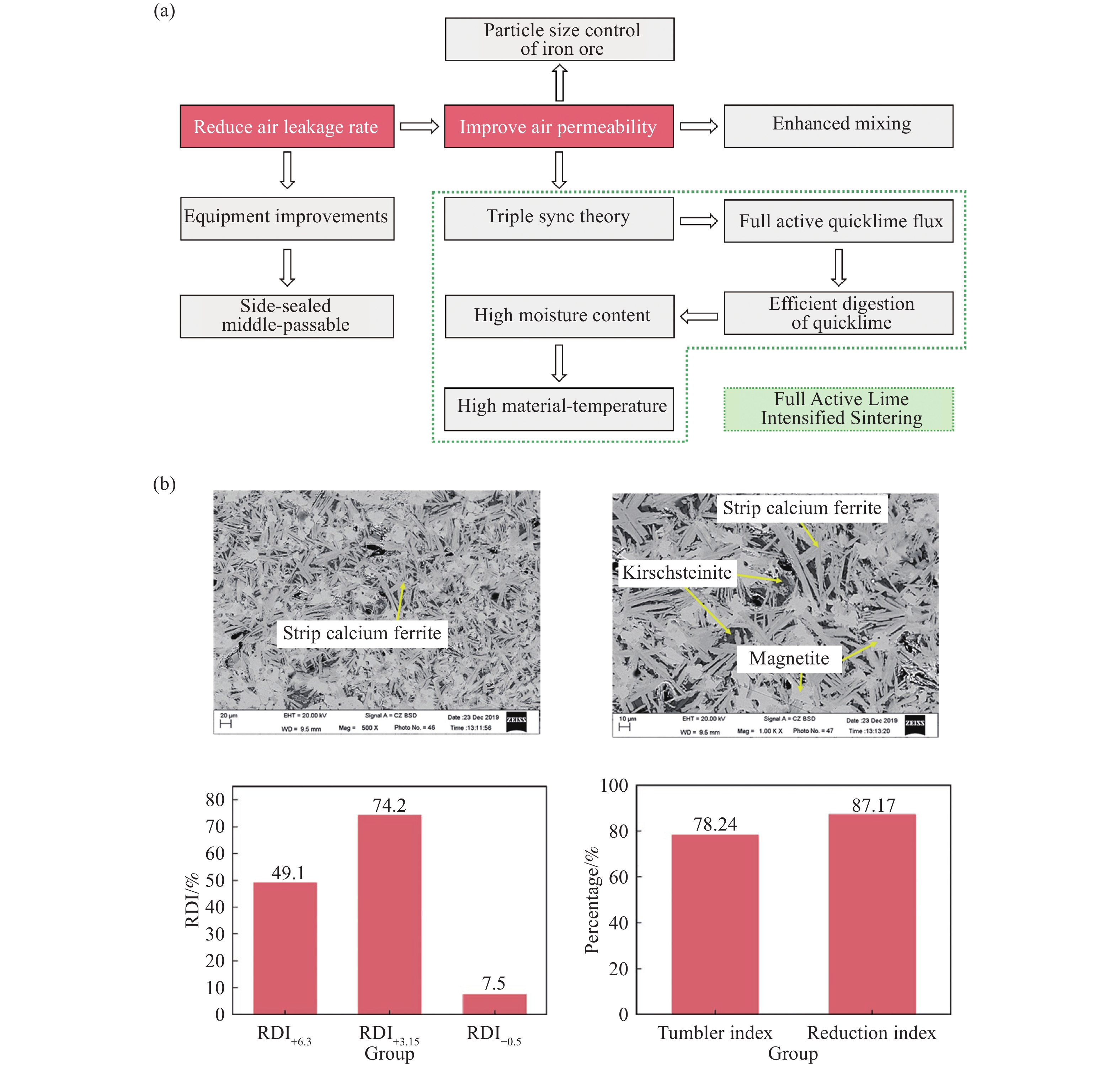

Figure 2. (a) Expansion behavior of minerals in the coke before (A1) and after (A2) being potash alkalization; (b) SEM image of the pore pipe inside the coke that characterizes the flow of slag through the hearth; (c) morphology of different carbonaceous substrates after dissolution

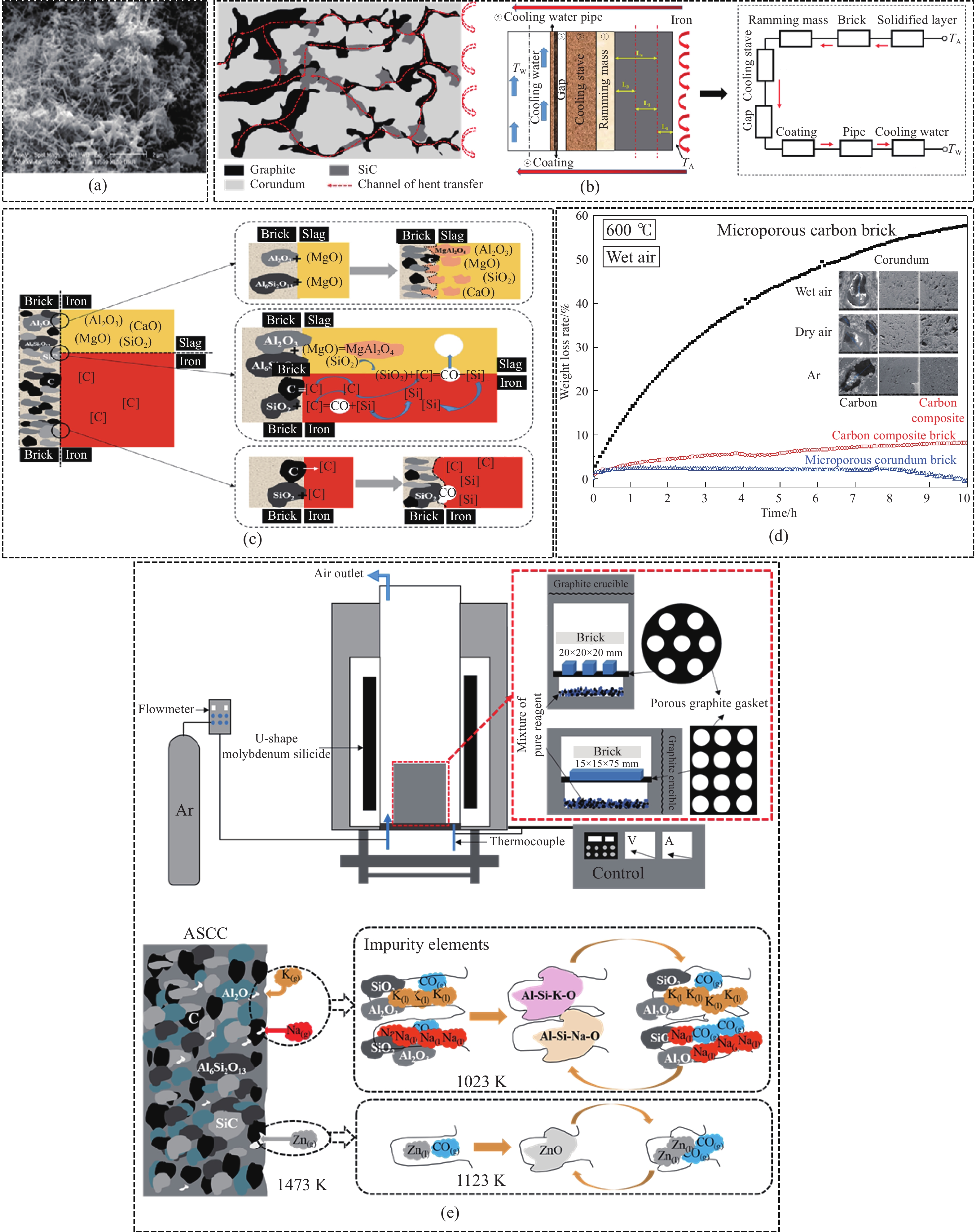

圖 3 碳復合材料綜合性能。(a)SiC晶須;(b)碳復合材料導熱機制;(c)碳復合材料渣鐵侵蝕機理;(d)不同材料氧化侵蝕對比;(e)碳復合材料有害元素侵蝕裝置及機理

Figure 3. Comprehensive properties of the carbon composite material: (a) SiC whiskers; (b) thermal conduction mechanism of carbon composites materials; (c) slag-iron erosion mechanism of alumina-carbon composite brick; (d) oxidation erosion of different materials; (e) erosion device and mechanism of harmful elements in carbon composite materials.

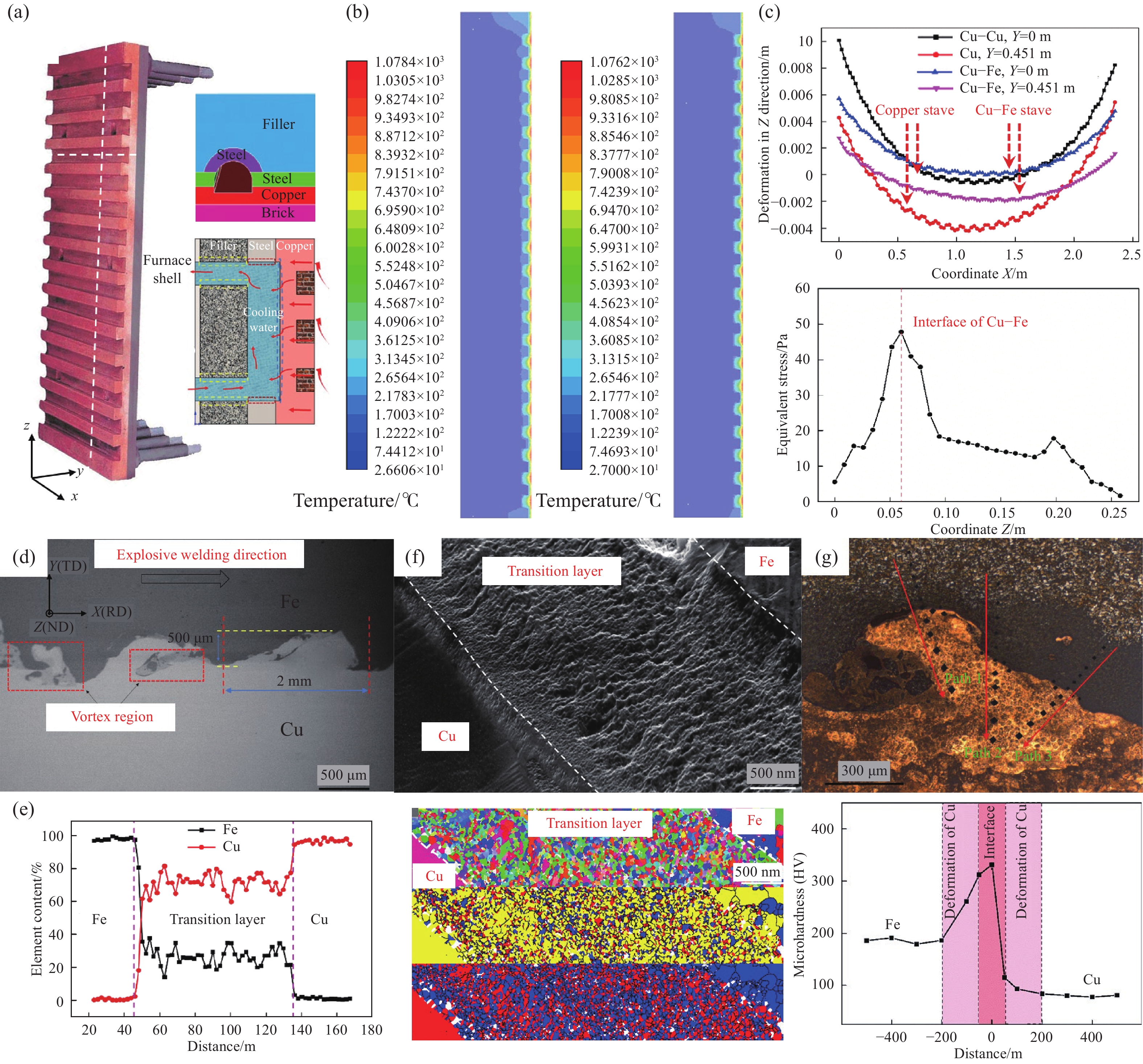

圖 4 銅鋼復合冷卻壁制造與表征[47-49]。(a)銅鋼復合冷卻壁本體及水道焊接形式示意圖;(b)銅冷卻壁與銅鋼復合冷卻壁溫度場分布對比;(c)銅冷卻壁與銅鋼復合冷卻壁相同厚度位置變形量;(d)Cu-Fe界面微觀結構;(e)Cu-Fe界面元素分布;(f)Cu-Fe界面晶粒大小;(g)Cu-Fe界面顯微硬度

Figure 4. Manufacture and characterization of the copper and steel composite cooling stave[47-49]: (a) schematic diagram of copper and steel composite cooling stave body and channel welding form; (b) comparison of temperature field distribution between copper cooling stave and copper-steel composite cooling stave; (c) deformation of copper cooling stave and copper-steel composite cooling stave with the same thickness; (d) Cu-Fe interface microstructure; (e) Cu-Fe interface element distribution; (f) Cu-Fe interface grain size; (g) Cu-Fe interface microhardness

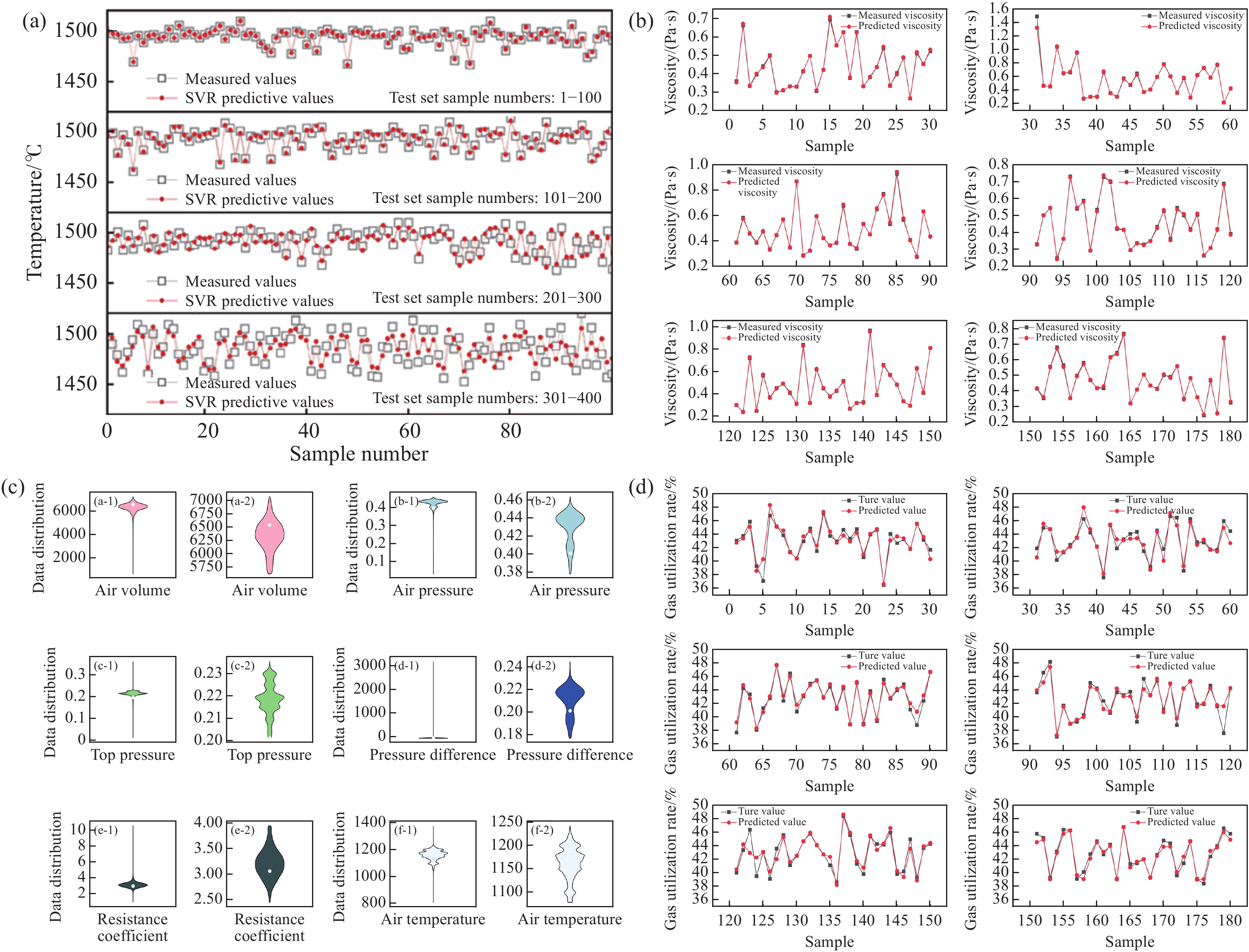

圖 5 (a)基于支持向量回歸(SVR)的鐵水溫度預測模型在測試集上的預測結果[54];(b)爐渣黏度預測模型在測試集上的預測結果[52];(c)對煤氣利用率進行預測建模時對原始數據進行數據預處理前后的數據分布對比圖[53];(d)高爐煤氣利用率預測模型在測試集上的預測結果[53]

Figure 5. (a) Prediction results of the support vector regression (SVR)-based iron temperature prediction model on the test set [54]; (b) prediction results of the slag viscosity prediction model using the test set[52]; (c) comparison of the data distribution before and after the original data preprocess during the gas utilization rate modeling[53]; (d) prediction results of the blast furnace gas utilization prediction model on the test set[53]

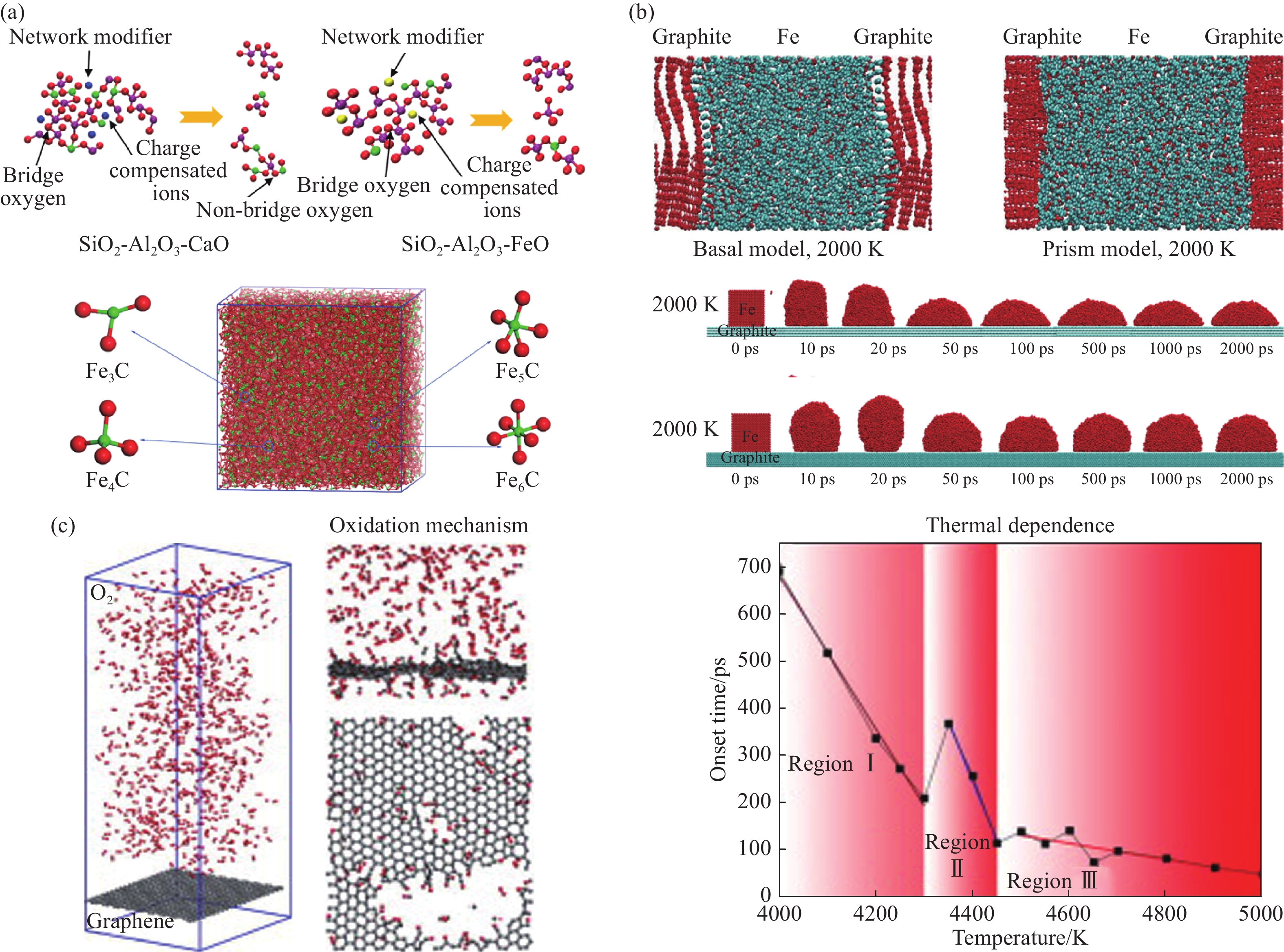

圖 9 (a)高溫爐渣微觀結構單元模型圖和鐵液熔體微觀結構圖[88];(b)鐵碳交互作用模型圖和鐵碳界面潤濕行為模型圖[95];(c)碳的微觀氧化反應過程機理圖[97]

Figure 9. (a) Microstructure of the blast furnace slag and liquid iron[88]; (b) interaction model between iron and carbon and the wetting behavior between liquid iron and graphene[95]; (c) mechanism diagram of the carbon microscopic oxidation process[97]

www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Wang Z Y, Zhang J L, Liu Z J, et al. Status, technological progress, and development directions of the ironmaking industry in China. Ironmak Steelmak, 2019, 46(10): 937 doi: 10.1080/03019233.2019.1697111 [2] Cui L, Ba K M, Li F Q, et al. Life cycle assessment of ultra-low treatment for steel industry sintering flue gas emissions. Sci Total Environ, 2020, 725: 138292 doi: 10.1016/j.scitotenv.2020.138292 [3] Wang Y Z, Liu Z J, Zhang J L, et al. Study of stand-support sintering to achieve high oxygen potential in iron ore sintering to enhance productivity and reduce CO content in exhaust gas. J Clean Prod, 2020, 252: 119855 doi: 10.1016/j.jclepro.2019.119855 [4] Zhang J L, Kan Y H, Zhang S J, et al. Application of full active lime intensified sintering technology in ultra-thick layer. Iron Steel, 2020, 55(8): 56張建良, 闞永海, 張士軍, 等. 全活性石灰強化燒結技術在超厚料層中的應用. 鋼鐵, 2020, 55(8):56 [5] Liu Z J, Niu L L, Zhang S J, et al. Comprehensive technologies for iron ore sintering with a bed height of 1000 mm to improve sinter quality, enhance productivity and reduce fuel consumption. ISIJ Int, 2020, 60(11): 2400 doi: 10.2355/isijinternational.ISIJINT-2020-219 [6] Wang R R, Zhang J L, Liu Z J, et al. Interaction between iron ore and magnesium additives during induration process of pellets. Powder Technol, 2020, 361: 894 doi: 10.1016/j.powtec.2019.11.006 [7] Chen J W, Jiao Y, Wang X D. Thermodynamic studies on gas-based reduction of vanadium titano-magnetite pellets. Int J Miner Metall Mater, 2019, 26(7): 822 doi: 10.1007/s12613-019-1795-8 [8] Wang Z C, Chu M S, Tang J, et al. Effects of reducing atmosphere and gangue composition on reduction swelling of oxidized pellets. J Northeast Univ (Nat Sci) , 2012, 33(1): 94 doi: 10.12068/j.issn.1005-3026.2012.01.023王兆才, 儲滿生, 唐玨, 等. 還原氣氛和脈石成分對氧化球團還原膨脹的影響. 東北大學學報(自然科學版), 2012, 33(1):94 doi: 10.12068/j.issn.1005-3026.2012.01.023 [9] Liu Z G, Chu M S, Wang H T, et al. Effect of MgO content in sinter on the softening-melting behavior of mixed burden made from chromium-bearing vanadium-titanium magnetite. Int J Miner Metall Mater, 2016, 23(1): 25 doi: 10.1007/s12613-016-1207-2 [10] Liu Z J, Cheng Q, Li K J, et al. The interaction of nanoparticulate Fe2O3 in the sintering process: A molecular dynamics simulation. Powder Technol, 2020, 367: 97 doi: 10.1016/j.powtec.2020.03.043 [11] Wang Y Z, Schenk J, Zhang J L, et al. Novel sintering indexes to evaluate and correlate the crystal characteristics and compressive strength in magnetite pellets. Powder Technol, 2020, 362: 517 doi: 10.1016/j.powtec.2019.12.022 [12] Wang R R, Zhang J L, Liu Z J, et al. Effect of lime addition on the mineral structure and compressive strength of magnesium containing pellets. Powder Technol, 2020, 376: 222 doi: 10.1016/j.powtec.2020.08.038 [13] Yan B J, Xing Y, Lu P, et al. A critical review on the research progress of multi-pollutant collaborative control technologies of sintering flue gas in the iron and steel industry. Chin J Eng, 2018, 40(7): 767閆伯駿, 邢奕, 路培, 等. 鋼鐵行業燒結煙氣多污染物協同凈化技術研究進展. 工程科學學報, 2018, 40(7):767 [14] Iwami Y, Iwase K, Hirosawa T, et al. Development of gas fuel injection technology in iron ore sintering process // 2015-Sustainable Industrial Processing Summit. Antalya, 2015, 3: 183 [15] Zhou W T, Hu J G, Guo Y L. New sintering technologies and analysis on prospect of popularization in China. World Iron Steel, 2011, 11(6): 47 doi: 10.3969/j.issn.1672-9587.2011.06.007周文濤, 胡俊鴿, 郭艷玲. 燒結新技術及其在國內的推廣前景分析. 世界鋼鐵, 2011, 11(6):47 doi: 10.3969/j.issn.1672-9587.2011.06.007 [16] Li K J, Zhang J L, Barati M, et al. Influence of alkaline (Na, K) vapors on carbon and mineral behavior in blast furnace cokes. Fuel, 2015, 145: 202 doi: 10.1016/j.fuel.2014.12.086 [17] Li K J, Khanna R, Bouhadja M, et al. A molecular dynamic simulation on the factors influencing the fluidity of molten coke ash during alkalization with K2O and Na2O. Chem Eng J, 2017, 313: 1184 doi: 10.1016/j.cej.2016.11.011 [18] Li K J, Khanna R, Zhang J L, et al. Molecular dynamics investigation on coke ash behavior in the high-temperature zones of a blast furnace: Influence of alkalis. Energy Fuels, 2017, 31(12): 13466 doi: 10.1021/acs.energyfuels.7b02795 [19] Li K J, Zhang J L, Liu Y X, et al. Graphitization of coke and its interaction with slag in the hearth of a blast furnace. Metall Mater Trans B, 2016, 47(2): 811 doi: 10.1007/s11663-015-0574-9 [20] Li K J, Zhang J L, Sun M M, et al. Existence state and structures of extracted coke and accompanied samples from tuyere zone of a large-scale blast furnace. Fuel, 2018, 225: 299 doi: 10.1016/j.fuel.2018.03.155 [21] Sun M M, Zhang J L, Li K J, et al. Dissolution behaviors of various carbonaceous materials in liquid iron: Interaction between graphite and iron. JOM, 2019, 71(12): 4305 doi: 10.1007/s11837-019-03664-9 [22] Sun M M, Zhang J L, Li K J, et al. The interfacial behavior between coke and liquid iron: A comparative study on the influence of coke pore, carbon structure and ash. JOM, 2020, 72(6): 2174 doi: 10.1007/s11837-020-04048-0 [23] Sun M M, Zhang J L, Zhang L, et al. Investigation of the microstructure interaction mechanism of coke-slag-metal in deadman of blast furnace. Ironmak Steelmak, 2021: 1 [24] Sun M M, Pang K L, Zhang J L, et al. In situ monitoring and dissolution limit of carbon dissolution in hot metal. Steel Res Int, 2021, 92(10): 2100111 doi: 10.1002/srin.202100111 [25] Ning X J, Dang H, Zhang J L, et al. Research progress of low-order coal pyrolysis process and semi-coke production process. Iron Steel, 2021, 56(1): 1寧曉鈞, 黨晗, 張建良, 等. 低階煤熱解與蘭炭生產工藝研究進展. 鋼鐵, 2021, 56(1):1 [26] Bai F Q, Wang X D. Commercial test of injecting semi-coke in No.3 BF of Xinxing ductile. Ironmaking, 2019, 38(3): 16白鳳強, 王小東. 新興鑄管3號高爐噴吹蘭炭工業試驗. 煉鐵, 2019, 38(3):16 [27] Gong L W. Semi-coke coal injection practice in Taiyuan steel's BF. Ironmaking, 2018, 37(5): 16鞏黎偉. 太鋼高爐噴吹蘭炭煤生產實踐. 煉鐵, 2018, 37(5):16 [28] Wang H Y, Zhang J L, Wang G W, et al. Industrial test of BF injected with upgraded pulverized coal. Ironmaking, 2018, 37(1): 24王海洋, 張建良, 王廣偉, 等. 高爐噴吹提質煤粉的工業試驗. 煉鐵, 2018, 37(1):24 [29] Wang G W, Zhang J L, Shao J G, et al. Thermal behavior and kinetic analysis of co-combustion of waste biomass/low rank coal blends. Energy Convers Manag, 2016, 124: 414 doi: 10.1016/j.enconman.2016.07.045 [30] Wang G W, Zeng Y, Zhang J L, et al. Study on blending optimization of pulverized coal injection into blast furnace of ansteel. Angang Technol, 2021(1): 1王廣偉, 曾宇, 張建良, 等. 鞍鋼高爐噴煤優化搭配研究. 鞍鋼技術, 2021(1):1 [31] Wang H F, Zhang C X, Hu C Q, et al. Important development trends of coke oven gas utilization in steel plant. J Iron Steel Res, 2008, 20(3): 1王海風, 張春霞, 胡長慶, 等. 鋼鐵企業焦爐煤氣利用的一個重要發展方向. 鋼鐵研究學報, 2008, 20(3):1 [32] Chen Y X, Wang G W, Zhang J L, et al. Theoretical analysis of injecting coke oven gas with oxygen enriched into blast furnace. Iron Steel, 2012, 47(2): 12陳永星, 王廣偉, 張建良, 等. 高爐富氧噴吹焦爐煤氣理論研究. 鋼鐵, 2012, 47(2):12 [33] Kidnay A J, Parrish W R, McCartney D G. Fundamentals of Natural Gas Processing. Boca Raton: CRC Press, 2019 [34] Ma Y K, Nie B S, He X Q, et al. Mechanism investigation on coal and gas outburst: An overview. Int J Miner Metall Mater, 2020, 27(7): 872 doi: 10.1007/s12613-019-1956-9 [35] Roy S K, Nayak D, Dash N, et al. Microwave-assisted reduction roasting—magnetic separation studies of two mineralogically different low-grade iron ores. Int J Miner Metall Mater, 2020, 27(11): 1449 doi: 10.1007/s12613-020-1992-5 [36] Wang P, Zhang J L, Wang G W, et al. Analysis of basic characteristics of Arundo donax char prepared by pyrolysis. China Metall, 2019, 29(2): 12王朋, 張建良, 王廣偉, 等. 熱解制備蘆竹半焦基礎性能分析. 中國冶金, 2019, 29(2):12 [37] McKendry P. Energy production from biomass (part 1): Overview of biomass. Bioresour Technol, 2002, 83(1): 37 doi: 10.1016/S0960-8524(01)00118-3 [38] Wang G W, Zhang J L, Chang W W, et al. Structural features and gasification reactivity of biomass chars pyrolyzed in different atmospheres at high temperature. Energy, 2018, 147: 25 doi: 10.1016/j.energy.2018.01.025 [39] Zhang J L, Lin X H, Kong D W, et al. Combustion characteristics and kinetic analysis of biomass char and coal blends. J Univ Sci Technol Beijing, 2012, 34(3): 348張建良, 林祥海, 孔德文, 等. 生物質焦與煤混合燃燒特性及動力學分析. 北京科技大學學報, 2012, 34(3):348 [40] Zuo H B, Wang C, Zhang J L, et al. Application status and important technical indexes of BF hearth refractory. Iron Steel, 2015, 50(2): 1左海濱, 王聰, 張建良, 等. 高爐爐缸耐火材料應用現狀及重要技術指標. 鋼鐵, 2015, 50(2):1 [41] Jiao K X, Zhang J L, Zuo H B, et al. Composition and formation mechanism of viscous layers in blast furnace hearth. J Northeast Univ (Nat Sci) , 2014, 35(7): 987 doi: 10.3969/j.issn.1005-3026.2014.07.017焦克新, 張建良, 左海濱, 等. 高爐爐缸黏滯層物相及形成機理. 東北大學學報(自然科學版), 2014, 35(7):987 doi: 10.3969/j.issn.1005-3026.2014.07.017 [42] Zuo H B, Wang C, Zhang J L, et al. Oxidation behavior and kinetics of Al2O3–SiC–SiO2–C composite in air. Ceram Int, 2015, 41(7): 9093 doi: 10.1016/j.ceramint.2015.03.307 [43] Liu Y X, Liu F J, Zhang J L, et al. Oxidation behavior of carbon composite bricks used in blast furnace hearth in steam. Bull Chin Ceram Soc, 2017, 36(2): 519劉彥祥, 劉福軍, 張建良, 等. 高爐爐缸用碳復合磚在水蒸氣條件下的氧化行為研究. 硅酸鹽通報, 2017, 36(2):519 [44] Jiao K X, Fan X Y, Zhang J L, et al. Corrosion behavior of alumina-carbon composite brick in typical blast furnace slag and iron. Ceram Int, 2018, 44(16): 19981 doi: 10.1016/j.ceramint.2018.07.265 [45] Liu Q, Cheng S S, Zhao H B, et al. Thermal deformation analysis of copper- steel composite staves. Chin J Eng, 2016, 38(1): 108劉奇, 程樹森, 趙宏博, 等. 銅鋼復合冷卻壁熱變形分析. 工程科學學報, 2016, 38(1):108 [46] Deng Y, Jiao K X, Wu Q C, et al. Damage mechanism of copper stave used in blast furnace. Ironmak Steelmak, 2018, 45(10): 886 doi: 10.1080/03019233.2017.1361625 [47] Zhang H, Jiao K X, Zhang J L, et al. A new method for evaluating cooling capacity of blast furnace cooling stave. Ironmak Steelmak, 2019, 46(7): 671 doi: 10.1080/03019233.2018.1454388 [48] Zhang H, Zhang J L, Jiao K X, et al. Analysis on cooling capacity and thermal deformation of copper-steel composite cooling stave. Ironmaking, 2018, 37(1): 10張恒, 張建良, 焦克新, 等. 銅鋼復合冷卻壁傳熱能力及熱變形分析. 煉鐵, 2018, 37(1):10 [49] Zhang H, Jiao K X, Zhang J L, et al. Experimental and numerical investigations of interface characteristics of copper/steel composite prepared by explosive welding. Mater Des, 2018, 154: 140 doi: 10.1016/j.matdes.2018.05.027 [50] Jiang D W, Wang Z Y, Zhang J L, et al. Predictive modelling for contact angle of liquid metals and oxide ceramics by comparing Gaussian process regression with other machine learning methods. Ceram Int, https://doi.org/10.1016/j.ceramint.2021.09.146 [51] Wang Z Y, Dai J H, Jiang D W, et al. Optimization of blast furnace charging system combining data traceability and numerical simulation. China Metall, 2020, 30(11): 11王振陽, 戴建華, 江德文, 等. 結合數據追溯與數值模擬的高爐布料制度優化. 中國冶金, 2020, 30(11):11 [52] Jiang D W, Zhang J L, Wang Z Y, et al. A prediction model of blast furnace slag viscosity based on principal component analysis and K-nearest neighbor regression. JOM, 2020, 72(11): 3908 doi: 10.1007/s11837-020-04360-9 [53] Wang Z Y, Jiang D W, Wang X D, et al. Prediction of blast furnace hot metal temperature based on support vector regression and extreme learning machine. Chin J Eng, 2021, 43(4): 569王振陽, 江德文, 王新東, 等. 基于支持向量回歸與極限學習機的高爐鐵水溫度預測. 工程科學學報, 2021, 43(4):569 [54] Liu X Y, Liu X G, Wang W H. Application of Bayesian network to predicting silicon content in hot metal. Iron Steel, 2005, 40(3): 17 doi: 10.3321/j.issn:0449-749X.2005.03.004劉學藝, 劉祥官, 王文慧. 貝葉斯網絡在高爐鐵水硅含量預測中的應用. 鋼鐵, 2005, 40(3):17 doi: 10.3321/j.issn:0449-749X.2005.03.004 [55] Jezierski J, Janerka K. Selected aspects of metallurgical and foundry furnace dust utilization. Pol J Environ Stud, 2011, 20(1): 101 [56] Liu Z J, Wang G W, Zhang J L, et al. Study on CO2 gasification reactivity and structure characteristics of carbonaceous materials from the corex furnace. Energy Fuels, 2018, 32(5): 6155 doi: 10.1021/acs.energyfuels.8b00072 [57] Li Y, Zhang J L, Liu Z J, et al. Reduction mechanism of iron oxide briquettes by carbonaceous materials extracted from blast furnace dust. Metall Mater Trans B, 2019, 50(5): 2296 doi: 10.1007/s11663-019-01628-7 [58] Wang Y Z, Liu Z J, Zhang J L, et al. Advanced converter sludge utilization technologies for the recovery of valuable elements: A review. J Hazard Mater, 2020, 381: 120902 doi: 10.1016/j.jhazmat.2019.120902 [59] Júnior J H N, Contrucci M A, D'Abreu J C. Tecnored process - high potential in using different kinds of solid fuels. Mat Res, 2005, 8(4): 447 doi: 10.1590/S1516-14392005000400016 [60] Fisch T, Kesseler K. OxyCup shaft furnace of Thyssen Krupp Steel Strategy for economic recycling of fine grained ferrous and carbonaceous residues // Proceedings of Environmental Seminar. Beijing, 2006: 90 [61] McClelland J M, Metius G E. Recycling ferrous and nonferrous waste streams with FASTMET. JOM, 2003, 55(8): 30 doi: 10.1007/s11837-003-0101-3 [62] Kikuchi S, Ito S, Kobayashi I, et al. ITmk3 process. Kobelco Technology Review, 2010, 29: 77 [63] Wang F, Zhang J L, Mao R, et al. Bonding mechanism and strength deterioration of self-reducing briquettes made from iron-bearing dust and sludge. J Central South Univ (Sci Technol) , 2016, 47(2): 367 doi: 10.11817/j.issn.1672-7207.2016.02.002王飛, 張建良, 毛瑞, 等. 含鐵塵泥自還原團塊固結機理及強度劣化. 中南大學學報(自然科學版), 2016, 47(2):367 doi: 10.11817/j.issn.1672-7207.2016.02.002 [64] Wang Y Z, Zhang J L, Liu Z J, et al. Co-utilization of converter sludge-containing dedust wastewater in iron ore sintering to save fresh water, enhance quality and reduce pollution. J Clean Prod, 2019, 234: 157 doi: 10.1016/j.jclepro.2019.06.186 [65] Liu Z J, Zhang J L, Du C B, et al. Treatment Technic for Sintering added Steelmaking Sludge: China Patent, 201910019375.5. 2020-3-31劉征建, 張建良, 杜誠波, 等. 一種燒結配加煉鋼污泥的處理工藝方法: 中國專利, 201910019375.5. 2020-3-31 [66] Mao R, Zhang J L, Liu Z J, et al. Experimental studies on self-reduction for the pellets made of iron-contained dust and sludge from a steel enterprise. J Northeast Univ (Nat Sci) , 2015, 36(6): 790 doi: 10.3969/j.issn.1005-3026.2015.06.008毛瑞, 張建良, 劉征建, 等. 鋼鐵廠含鐵塵泥球團自還原實驗研究. 東北大學學報(自然科學版), 2015, 36(6):790 doi: 10.3969/j.issn.1005-3026.2015.06.008 [67] Zhang J L, Wang J Y, Liu Z J, et al. A Smelting Furnace Steel Mill Solid Waste Treatment Process for: China Patent, 201310659226.8. 2014-3-5張建良, 王俊英, 劉征建, 等. 一種熔融爐處理鋼鐵廠固體廢料工藝方法: 中國專利, 201310659226.8. 2014-3-5 [68] Zhang X Y, Jiao K X, Zhang J L, et al. A review on low carbon emissions projects of steel industry in the World. J Clean Prod, 2021, 306: 127259 doi: 10.1016/j.jclepro.2021.127259 [69] Xu R S, Zhang J L, Wang W, et al. Dissolution kinetics of solid fuels used in COREX gasifier and its influence factors. J Iron Steel Res Int, 2018, 25(3): 298 doi: 10.1007/s42243-018-0030-6 [70] Xu R S, Zhang J L, Wang G W, et al. Isothermal kinetic analysis on fast pyrolysis of lump coal used in COREX process. J Therm Anal Calorim, 2016, 123(1): 773 doi: 10.1007/s10973-015-4972-7 [71] Xu R S, Zhang J L, Wang G W, et al. Devolatilization characteristics and kinetic analysis of lump coal from China COREX3000 under high temperature. Metall Mater Trans B, 2016, 47(4): 2535 doi: 10.1007/s11663-016-0708-8 [72] Wang H Y, Zhang J L, Wang G W, et al. Feasibility research of injection of BF dust into melter gasifier of COREX. Iron Steel, 2017, 52(8): 29王海洋, 張建良, 王廣偉, 等. 高爐除塵灰用于COREX氣化爐噴吹的可行性研究. 鋼鐵, 2017, 52(8):29 [73] Zhou H, Wu S L, Kou M Y, et al. Physical simulation of the position and evolution process of dust accumulation in the bustle pipe of a COREX shaft furnace. Chin J Eng, 2018, 40(3): 349周恒, 吳勝利, 寇明銀, 等. COREX豎爐圍管堵塞位置及其演變過程的物理模擬. 工程科學學報, 2018, 40(3):349 [74] Wang H Y, Zhang J L, Wang G W, et al. Balance analysis of alkali metals and Zinc in European metallurgical furnace of Bayi Steel. Ironmaking, 2018, 37(4): 61王海洋, 張建良, 王廣偉, 等. 八鋼歐冶爐堿金屬及鋅平衡分析. 煉鐵, 2018, 37(4):61 [75] Du B B, Wu S L, Zhou H, et al. Effect of scaffolding on solid flow in COREX shaft furnace by discrete element simulation method. Iron Steel, 2020, 55(1): 12杜斌斌, 吳勝利, 周恒, 等. COREX豎爐結瘤對物料運動行為影響的DEM模擬. 鋼鐵, 2020, 55(1):12 [76] Zhang J L, Zhang G Q, Liu Z J, et al. Production overview and main characteristics of HIsmelt process in Shandong Molong. China Metall, 2018, 28(5): 37張建良, 張冠琪, 劉征建, 等. 山東墨龍HIsmelt工藝生產運行概況及主要特點. 中國冶金, 2018, 28(5):37 [77] Zhang J L, Li K J, Zhang G Q, et al. Technological innovation of HIsmelt process in SD molong and latest production index. Ironmaking, 2018, 37(2): 56張建良, 李克江, 張冠琪, 等. 山東墨龍HIsmelt工藝的技術創新及最新生產指標. 煉鐵, 2018, 37(2):56 [78] Wu L F, Yang G Q, Ma B L. Development history and improvement direction of HIsmelt smelting reduction process. Hebei Metall, 2021(9): 8武龍飛, 楊廣慶, 馬保良. HIsmelt熔融還原工藝的發展歷程及改進方向. 河北冶金, 2021(9):8 [79] Cao C Z, Meng Y J, Yan F X, et al. Analysis on energy efficiency and optimization of HIsmelt process // Energy Technology 2019. San Antonio, 2019: 3 [80] Ma H B, Jiao K X, Zhang J L. The influence of basicity and TiO2 on the crystallization behavior of high Ti-bearing slags. CrystEngComm, 2020, 22(2): 361 doi: 10.1039/C9CE01695C [81] Zhang B, Zhang J L, Liu X L, et al. Effect of reduction conditions on metallization rate of pellets in gas-based reduction. China Metall, 2014, 24(Suppl 1): 166張波, 張建良, 劉興樂, 等. 還原條件對氣基還原中球團金屬化率的影響. 中國冶金, 2014, 24(增刊 1): 166 [82] Yi L Y, Huang Z C, Peng H, et al. Action rules of H2 and CO in gas-based direct reduction of iron ore pellets. J Central South Univ, 2012, 19(8): 2291 doi: 10.1007/s11771-012-1274-0 [83] Li W, Wang N, Fu G Q, et al. Influence of roasting characteristics on gas-based direct reduction behavior of Hongge vanadium titanomagnetite pellet with simulated shaft furnace gases. Powder Technol, 2017, 310: 343 doi: 10.1016/j.powtec.2017.01.062 [84] Li K J, Zhang J L, Liu Z J, et al. Comprehensive evaluation of OxyCup process for steelmaking dust treatment based on calculation of mass balance and heat balance. J Iron Steel Res Int, 2014, 21(6): 575 doi: 10.1016/S1006-706X(14)60089-3 [85] Wang G L, Liu Z J, Zhang J L, et al. Soft-melting property of dust briquettes based on OxyCup shaft furnace. China Metall, 2018, 28(11): 61王桂林, 劉征建, 張建良, 等. 基于OxyCup豎爐處理工藝的塵泥團塊軟熔性能. 中國冶金, 2018, 28(11):61 [86] Jiang C H, Xiong Z X, Bu Y S, et al. Study on the structure and properties of high-calcium coal ash in the high-temperature zone of a blast furnace: A molecular dynamics simulation investigation. JOM, 2020, 72(7): 2713 doi: 10.1007/s11837-020-04154-z [87] Jiang C H, Li K J, Zhang J L, et al. Effect of MgO/Al2O3 ratio on the structure and properties of blast furnace slags: A molecular dynamics simulation. J Non Cryst Solids, 2018, 502: 76 doi: 10.1016/j.jnoncrysol.2018.06.043 [88] Jiang C H, Li K J, Zhang J L, et al. Molecular dynamics simulation on the effect of MgO/Al2O3 ratio on structure and properties of blast furnace slag under different basicity conditions. Metall Mater Trans B, 2019, 50(1): 367 doi: 10.1007/s11663-018-1450-1 [89] Jiang C H, Li K J, Zhang J L, et al. The effect of CaO(MgO) on the structure and properties of aluminosilicate system by molecular dynamics simulation. J Mol Liq, 2018, 268: 762 doi: 10.1016/j.molliq.2018.07.123 [90] Jiang C H, Li K J, Zhang J L, et al. The effect of CaO and MgO on the structure and properties of coal ash in the blast furnace: A molecular dynamics simulation and thermodynamic calculation. Chem Eng Sci, 2019, 210: 115226 doi: 10.1016/j.ces.2019.115226 [91] Bi Z S, Li K J, Jiang C H, et al. Performance and transition mechanism from acidity to basicity of amphoteric oxides (Al2O3 and B2O3) in SiO2?CaO?Al2O3?B2O3 system: A molecular dynamics study. Ceram Int, 2021, 47(9): 12252 doi: 10.1016/j.ceramint.2021.01.074 [92] Bi Z S, Li K J, Jiang C H, et al. Effects of B2O3 on the structure and properties of blast furnace slag by molecular dynamics simulation. J Non Cryst Solids, 2021, 551: 120412 doi: 10.1016/j.jnoncrysol.2020.120412 [93] Bi Z S, Li K J, Jiang C H, et al. Effects of amphoteric oxide (Al2O3 and B2O3) on the structure and properties of SiO2?CaO melts by molecular dynamics simulation. J Non Cryst Solids, 2021, 559: 120687 doi: 10.1016/j.jnoncrysol.2021.120687 [94] Jiang C H, Li K J, Zhang J L, et al. Structural characteristics of liquid iron with various carbon contents based on atomic simulation. J Mol Liq, 2021, 342: 116957 doi: 10.1016/j.molliq.2021.116957 [95] Jiang C H, Zhang J L, Li K J, et al. Influence of graphite crystalline orientation on the carbon dissolution reaction in liquid iron: A ReaxFF molecular dynamics simulation study. J Mol Liq, 2021, 335: 115688 doi: 10.1016/j.molliq.2021.115688 [96] Jiang C H, Xiong Z X, Li K J, et al. Molecular dynamics simulation study on the wetting behavior of liquid iron and graphite. J Mol Liq, 2020, 311: 113350 doi: 10.1016/j.molliq.2020.113350 [97] Li K J, Khanna R, Zhang H, et al. Thermal behaviour during initial stages of graphene oxidation: Implications for reaction kinetics and mechanisms. Chem Eng J, 2021, 421: 129742 doi: 10.1016/j.cej.2021.129742 [98] Li K J, Khanna R, Zhang H, et al. Thermal behaviour, kinetics and mechanisms of CO2 interactions with graphene: An atomic scale reactive molecular dynamic study. Chem Eng J, 2021, 425: 131529 doi: 10.1016/j.cej.2021.131529 [99] Tonomura S. Outline of course 50. Energy Procedia, 2013, 37: 7160 doi: 10.1016/j.egypro.2013.06.653 -

下載:

下載: