Application status and prospect of low carbon technology in iron and steel industry

-

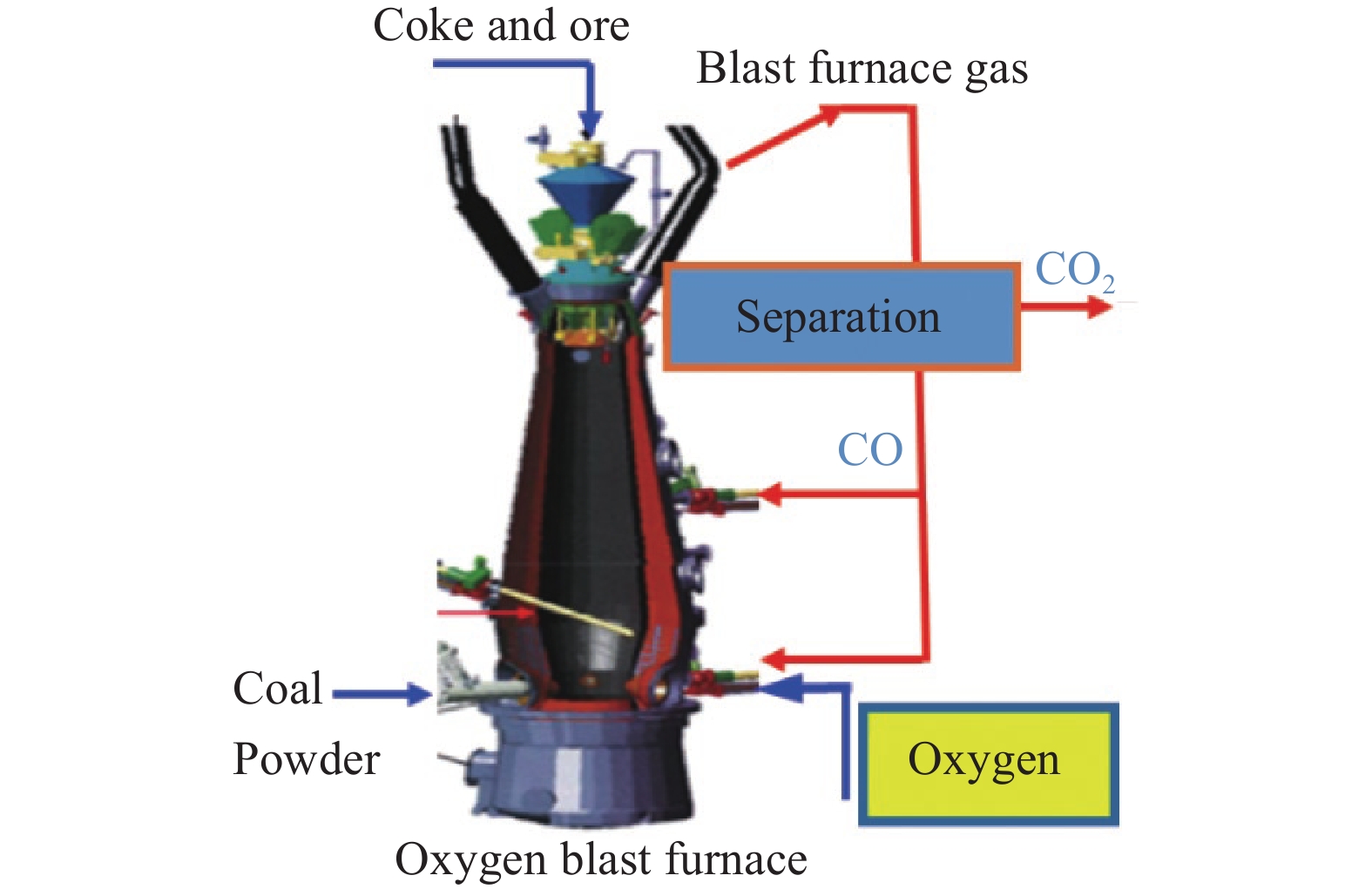

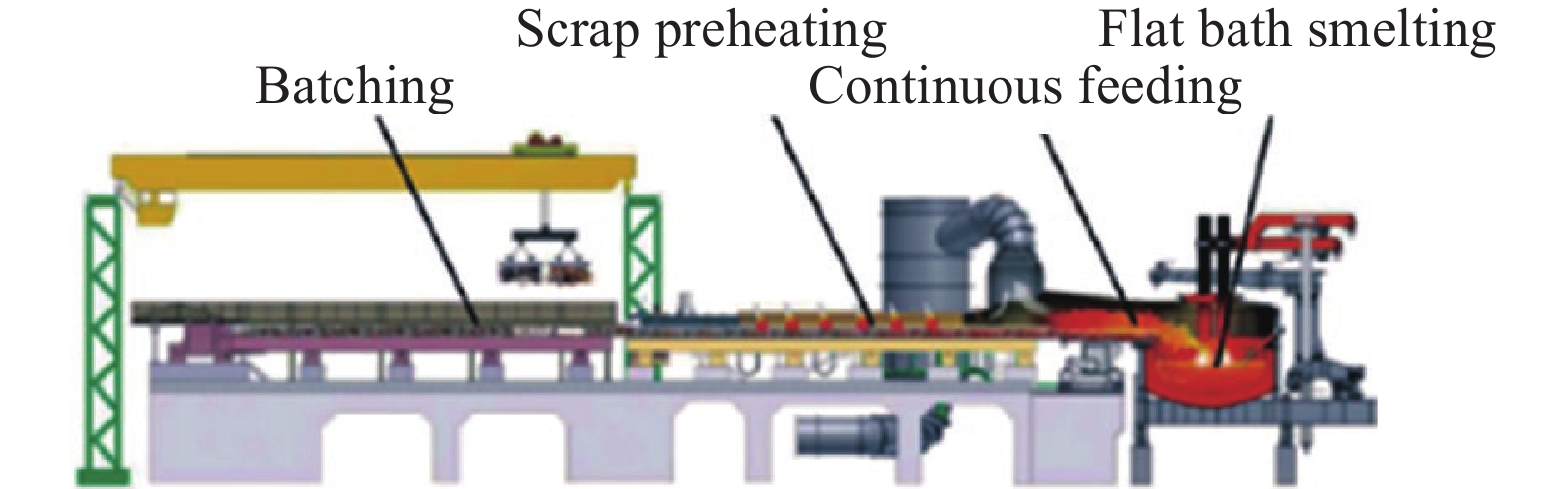

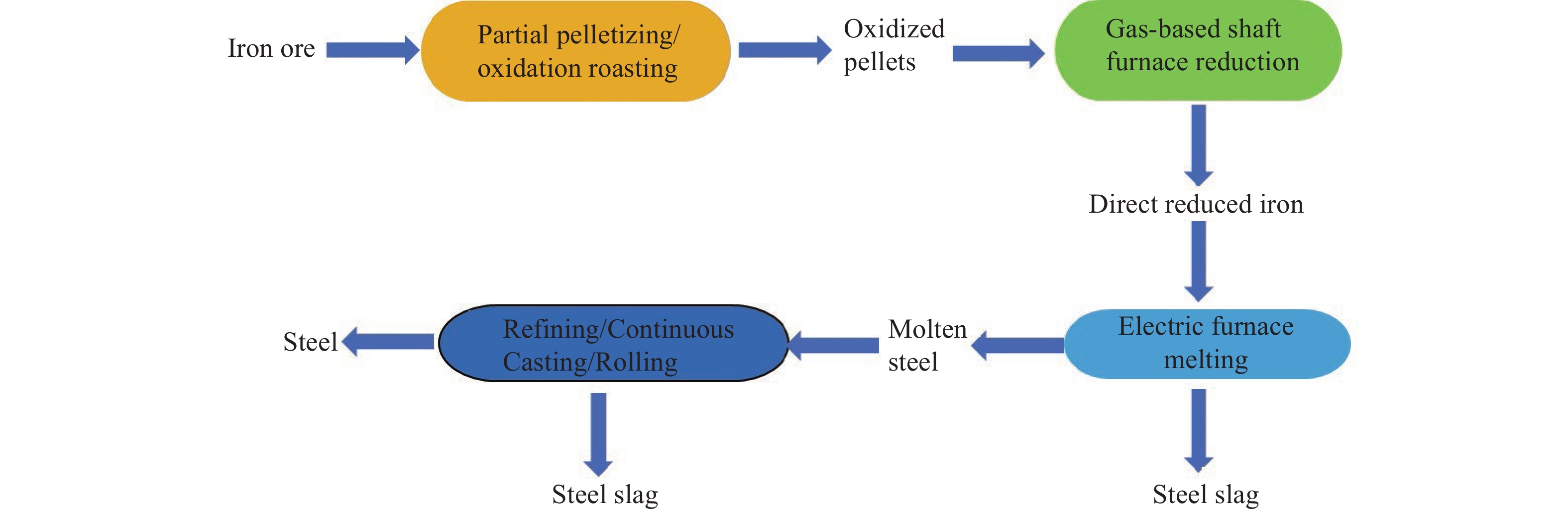

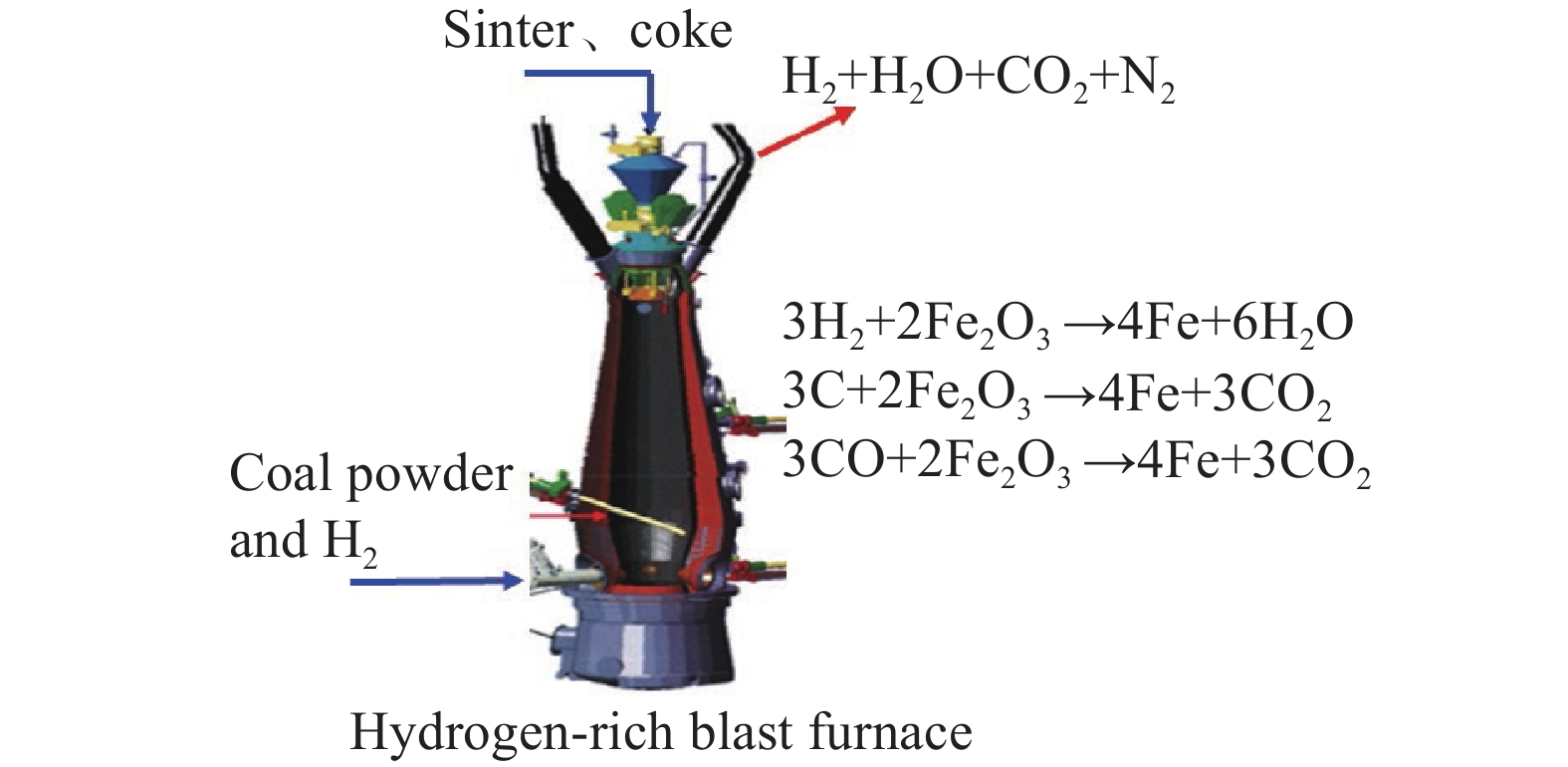

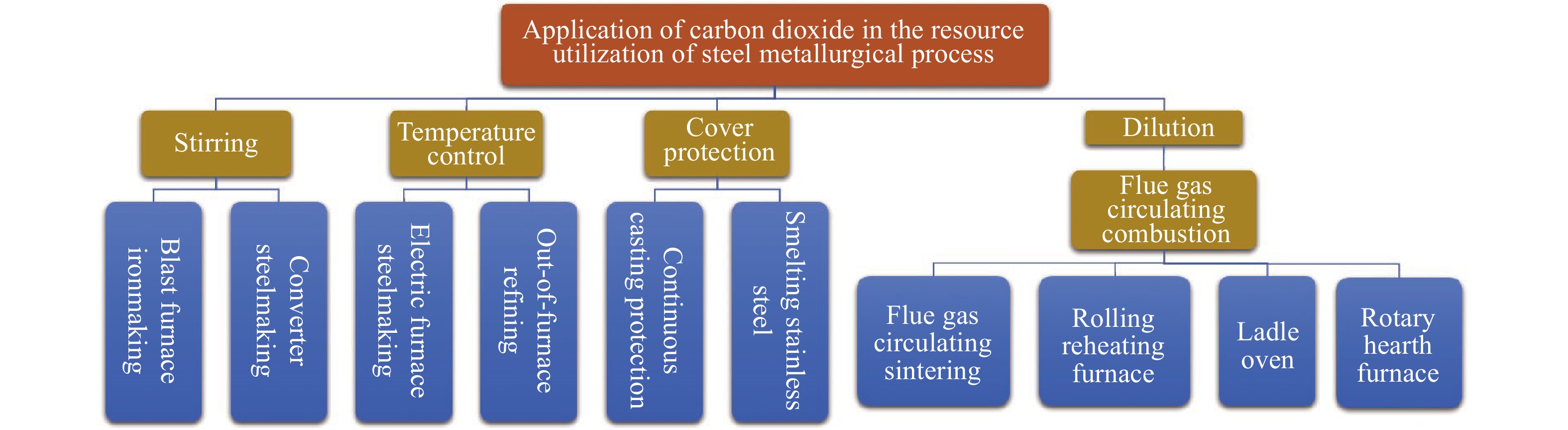

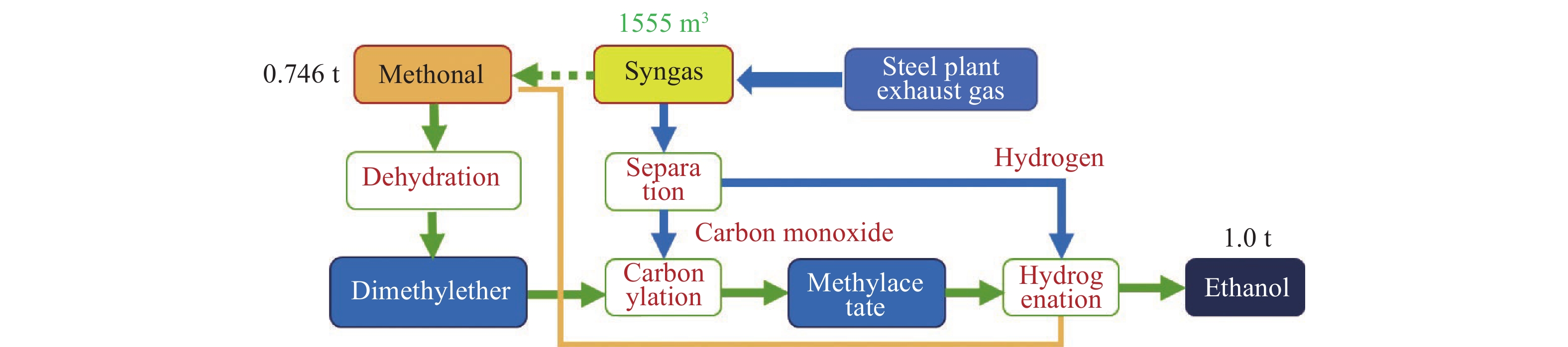

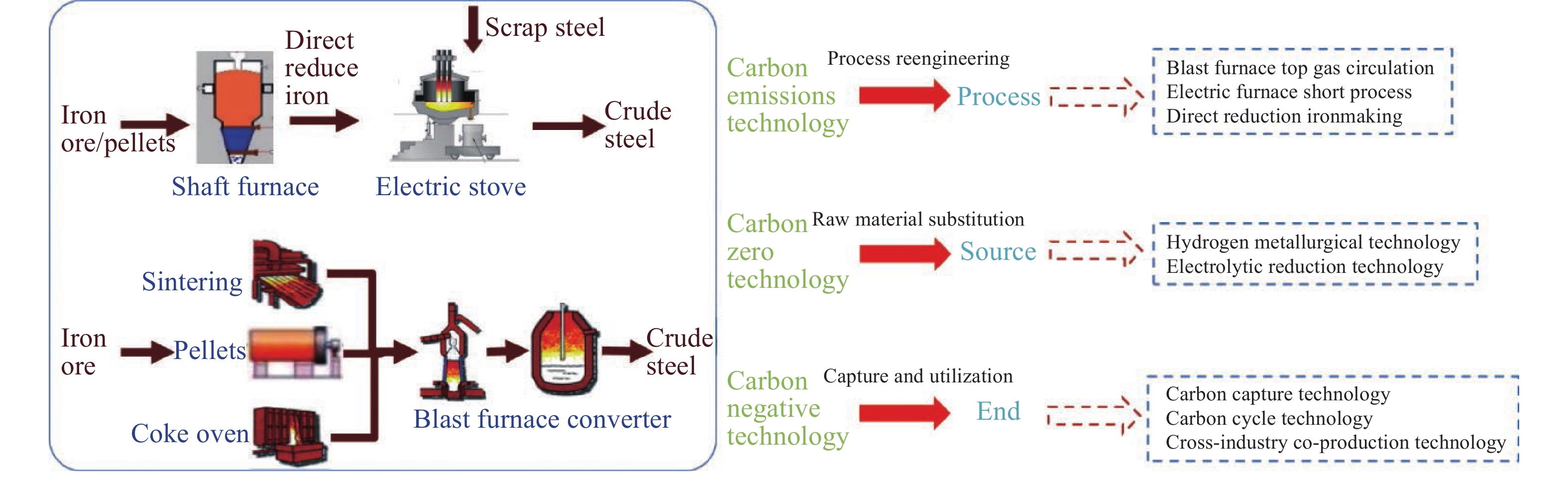

摘要: 在總結了國外低碳排放項目和國內各大鋼企的碳達峰與碳中和的技術節點和低碳技術手段的基礎之上,從碳減排、碳零排和碳負排三個層次劃分梳理當今鋼鐵行業的眾多低碳技術,并對各個低碳技術的碳排放削減量、成熟度和推廣時間進行歸納。在碳減排方面,通過優化工藝和流程再造減少鋼鐵行業生產過程中的二氧化碳排放,如高爐爐頂煤氣循環技術;在碳零排方面,利用氫氣或清潔電能減少或者替代高二氧化碳排放因子煤炭/焦炭的使用,從源頭上降低二氧化碳的排放,如氫冶金技術;在碳負排方面,主要從高碳排放強度高爐煉鐵工序進行二氧化碳捕集,分別在鋼廠內進行自身綠色循環利用和在廠外進行化工聯產制造高附加值化工產品(如甲醇乙醇等),對靠近油田的鋼材實施二氧化碳地質封存,在末端上降低二氧化碳的排放。Abstract: China proposes to achieve carbon peaking and carbon neutralization by 2030 and 2060, respectively. As a heavily carbon-based fuel industry, the carbon dioxide emission of the iron and steel industry is lower than that of the power and transportation industries. In 2020, the carbon dioxide emissions of China’s steel industry were approximately 1.98 billion tons, accounting for more than 18% of the national carbon dioxide emissions. To achieve the “carbon neutral” emission reduction target of the steel industry, the three parts of the entire process of steel production, i.e., “source–process–end,” need to be involved in the exploration of low-carbon technologies. This study summarized the low-carbon technology measures of foreign low-carbon dioxide emission projects and major domestic steel companies’ carbon peaking and carbon neutralization projects; divided and classified the low-carbon technologies in today’s steel industry from three levels, i.e., carbon dioxide emission reduction, zero carbon dioxide emission, and negative carbon dioxide emission; and summarized the carbon dioxide emission reduction, maturity, and promotion time of each low-carbon technology. In terms of carbon dioxide emission reduction, carbon dioxide emissions in the production process of the steel industry were reduced by optimizing processes and process reengineering, such as blast furnace top gas circulation technology. In terms of zero carbon dioxide emissions, hydrogen or clean electricity was used to reduce or replace coal or coke with high carbon dioxide emission factors to reduce carbon dioxide emissions from the source, such as hydrogen metallurgical technology. In terms of negative carbon dioxide emissions, carbon dioxide capture was mainly conducted in the high carbon dioxide emission intensity blast furnace ironmaking process, green recycling was performed in the steel plant, and chemical coproduction was implemented outside the plant to produce high value-added chemical products, such as methanol and ethanol. Finally, geological storage of carbon dioxide on steel near the oil field was implemented to reduce carbon dioxide emissions.

-

表 1 物理吸附與化學吸收方法捕集CO2比較

Table 1. Comparison of CO2 capture by the physical adsorption and chemical absorption methods

Capture technology Representative method Common materials Advantages Disadvantages Physical method Pressure swing adsorption 13X molecular sieve 1. Low energy consumption

2. Mature technology and flexible operation

3. No corrosive problem

4. Suitable for high concentration CO21. The flue gas needs to be cooled and dewatered before adsorption

2. The capture efficiency is low and there is a lack of high capture performance materialsChemical method Liquid amine absorption Alkane alcohol amine solution, amino acid salt solution 1. Suitable for low concentration and large flow flue gas

2. High absorption efficiency1. The absorbent is easy to evaporate and lose

2. The regeneration energy consumption is high

3. The absorption liquid easily corrodes the equipment

4. The solution circulation is large and the area occupied by the absorption tower and regeneration tower is largeOthers Carbonization reaction Calcium-based materials 1. Wide sources of calcium oxide

2. Low price

3. Carbonated products can be used as road materials1. Low capture efficiency

2. Poor sintering resistance and cannot be recycled many times

3. High regeneration energy consumptionwww.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] National Bureau of Statistics. Statistical communiqué of the People’s Republic of China on the 2020 national economic and social development. China Stat, 2021(3): 8國家統計局. 中華人民共和國2020年國民經濟和社會發展統計公報. 中國統計, 2021(3):8 [2] Bui M, Adjiman C S, Bardow A, et al. Carbon capture and storage (CCS): The way forward. Energy Environ Sci, 2018, 11(5): 1062 doi: 10.1039/C7EE02342A [3] Zhang X Y, Jiao K X, Zhang J L, et al. A review on low carbon emissions projects of steel industry in the World. J Clean Prod, 2021, 306: 127259 doi: 10.1016/j.jclepro.2021.127259 [4] Quader M A, Ahmed S, Ghazilla R A R, et al. A comprehensive review on energy efficient CO2 breakthrough technologies for sustainable green iron and steel manufacturing. Renewable Sustainable Energy Rev, 2015, 50: 594 doi: 10.1016/j.rser.2015.05.026 [5] Yan J J. Progress and future of ultra-low CO2 steel making program. China Metall, 2017, 27(2): 6嚴珺潔. 超低二氧化碳排放煉鋼項目的進展與未來. 中國冶金, 2017, 27(2):6 [6] Wang G, Wang J S, Zuo H B, et al. Effect of blast furnace gas recycling with hydrogen injection on low carbon development of Chinese ironmaking. China Metall, 2019, 29(10): 1王廣, 王靜松, 左海濱, 等. 高爐煤氣循環耦合富氫對中國煉鐵低碳發展的意義. 中國冶金, 2019, 29(10):1 [7] Xue Q G, Yang F, Zhang X X, et al. Development of oxygen blast furnace and its research progress in Beijing University of science and technology. Chin J Eng, 2021, 43(12): 1577薛慶國, 楊帆, 張欣欣, 等. 氧氣高爐的發展歷程及其在北京科技大學的研究進展. 工程科學學報, 2021, 43(12):1577 [8] Yao C L, Zhu H C, Jiang Z H, et al. CO2 emissions calculation and analysis of electric arc furnace with continuous feeding of only scrap. J Mater Metall, 2020, 19(4): 259姚聰林, 朱紅春, 姜周華, 等. 全廢鋼連續加料電弧爐短流程碳排放計算及分析. 材料與冶金學報, 2020, 19(4):259 [9] Cheng W. The EAF market and the continuous casting and rolling of long products. Metall Econ Manage, 2020(1): 22程威. 中國電爐市場與長材連鑄連軋. 冶金經濟與管理, 2020(1):22 [10] Ruan Q H, Bai M M. Comparison of my country’s long-process steelmaking and short-process steelmaking costs. China Steel, 2019(10): 58 doi: 10.3969/j.issn.1672-5115.2019.10.018阮清華, 白苗苗. 我國長流程煉鋼與短流程煉鋼成本比較. 中國鋼鐵業, 2019(10):58 doi: 10.3969/j.issn.1672-5115.2019.10.018 [11] Wang X J. Technological progress of EAF steelmaking in China. Iron Steel, 2019, 54(8): 1王新江. 中國電爐煉鋼的技術進步. 鋼鐵, 2019, 54(8):1 [12] Jiang Z H, Yao C L, Zhu H C, et al. Technology development trend in electric arc furnace steelmaking. Iron Steel, 2020, 55(7): 1姜周華, 姚聰林, 朱紅春, 等. 電弧爐煉鋼技術的發展趨勢. 鋼鐵, 2020, 55(7):1 [13] Li B. Fundamental Study on the Smelting High-Purity Iron and High-Purity Bearing Steel Using Direct Reduced Iron Prepared by Hydrogen [Dissertation]. Beijing: University of Science and Technology Beijing, 2020李彬. 基于氫氣直接還原鐵冶煉高純鐵和高純軸承鋼的基礎研究[學位論文]. 北京: 北京科技大學, 2020 [14] Zhou X. Overview and development analysis of direct reduction process. Metall Econ Manage, 2017(4): 53 doi: 10.3969/j.issn.1002-1779.2017.04.016周翔. 直接還原工藝綜述及發展分析. 冶金經濟與管理, 2017(4):53 doi: 10.3969/j.issn.1002-1779.2017.04.016 [15] Song Z, Li X S, Zha C H. Development status and trend of direct reduction iron technology in my country. China Steel Focus, 2020(16): 22宋贊, 李相帥, 查春和. 我國直接還原鐵工藝的發展現狀及趨勢. 冶金管理, 2020(16):22 [16] Shi Y. The world's direct reduced iron production exceeded 100 million tons for the first time. China Steel Focus, 2020(18): 30石禹. 世界直接還原鐵產量首次超過億噸. 冶金管理, 2020(18):30 [17] Ying Z W, Chu M S, Tang J, et al. Current situation and future adaptability analysis of non-blast furnace ironmaking process. Hebei Metall, 2019(6): 1應自偉, 儲滿生, 唐玨, 等. 非高爐煉鐵工藝現狀及未來適應性分析. 河北冶金, 2019(6):1 [18] Ren L, Zhou S, Peng T D, et al. A review of CO2 emissions reduction technologies and low-carbon development in the iron and steel industry focusing on China. Renewable Sustainable Energy Rev, 2021, 143: 110846 doi: 10.1016/j.rser.2021.110846 [19] Tang J, Chu M S, Li F, et al. Development status and future trend of hydrogen metallurgy in China. Hebei Metall, 2020(8): 1唐玨, 儲滿生, 李峰, 等. 我國氫冶金發展現狀及未來趨勢. 河北冶金, 2020(8):1 [20] Yilmaz C, Wendelstorf J, Turek T. Modeling and simulation of hydrogen injection into a blast furnace to reduce carbon dioxide emissions. J Clean Prod, 2017, 154: 488 doi: 10.1016/j.jclepro.2017.03.162 [21] Zhao Y, Wang Y B, Wang T H. Research progress on the absorption of carbon dioxide by organic amine method. Recycl Resour Circ Econ, 2020, 13(7): 26 doi: 10.3969/j.issn.1674-0912.2020.07.009趙毅, 王永斌, 王添顥. 有機胺法吸收二氧化碳的研究進展. 再生資源與循環經濟, 2020, 13(7):26 doi: 10.3969/j.issn.1674-0912.2020.07.009 [22] Li J G, Li J Z, Qin B H. Simulation of carbon dioxide capture and desorption in steel industry flue gas. Energy Environ Prot, 2019, 33(5): 23 doi: 10.3969/j.issn.1006-8759.2019.05.005李建光, 李進中, 欽柏豪. 模擬鋼鐵行業煙氣中CO2捕獲與解析實驗研究. 能源環境保護, 2019, 33(5):23 doi: 10.3969/j.issn.1006-8759.2019.05.005 [23] Zhang P K, Zhang Z W, Wang L. Numerical analysis of novel lime calcination process for CO2 capture. Chin J Eng, https://doi.org/10.13374/j.issn2095-9389.2021.03.22.002張培昆, 張震威, 王立. 用于CO2捕集的新型石灰煅燒過程的數值分析. 工程科學學報,https://doi.org/10.13374/j.issn2095-9389.2021.03.22.002 [24] Zhu R, Wang X L, Liu R Z. Recent progress and prospective of application of carbon dioxide in ferrous metallurgy process. China Metall, 2017, 27(4): 1朱榮, 王雪亮, 劉潤藻. 二氧化碳在鋼鐵冶金流程應用研究現狀與展望. 中國冶金, 2017, 27(4):1 [25] Wu Z L, Wang H, Yang P Z, et al. Commercial progress in the production of absolute ethanol from tail gas in the iron and steel industry. New Technol New Prod China, 2019(13): 133 doi: 10.3969/j.issn.1673-9957.2019.13.077吳志連, 王輝, 楊培志, 等. 鋼鐵工業尾氣制無水乙醇商業進展. 中國新技術新產品, 2019(13):133 doi: 10.3969/j.issn.1673-9957.2019.13.077 [26] Budinis S, Krevor S, Mac Dowell N, et al. An assessment of CCS costs, barriers and potential. Energy Strategy Rev, 2018, 22: 61 [27] Sang S X. Research review on technical effectiveness of CO2 geological storage and enhanced coalbed methane recovery. Coal Geol Explor, 2018, 46(5): 1 doi: 10.3969/j.issn.1001-1986.2018.05.001桑樹勛. 二氧化碳地質存儲與煤層氣強化開發有效性研究述評. 煤田地質與勘探, 2018, 46(5):1 doi: 10.3969/j.issn.1001-1986.2018.05.001 [28] Wang B D, Zhao X L, Cui Q, et al. Environmental monitoring analysis of injected CO2 in saline layer for Shenhua CO2 storage project. Environ Eng, 2018, 36(2): 33王保登, 趙興雷, 崔倩, 等. 中國神華煤制油深部咸水層CO2地質封存示范項目監測技術分析. 環境工程, 2018, 36(2):33 -

下載:

下載: