Preparation of a tuff polymer and the mechanism of alkaline solution influences on compressive strengths

-

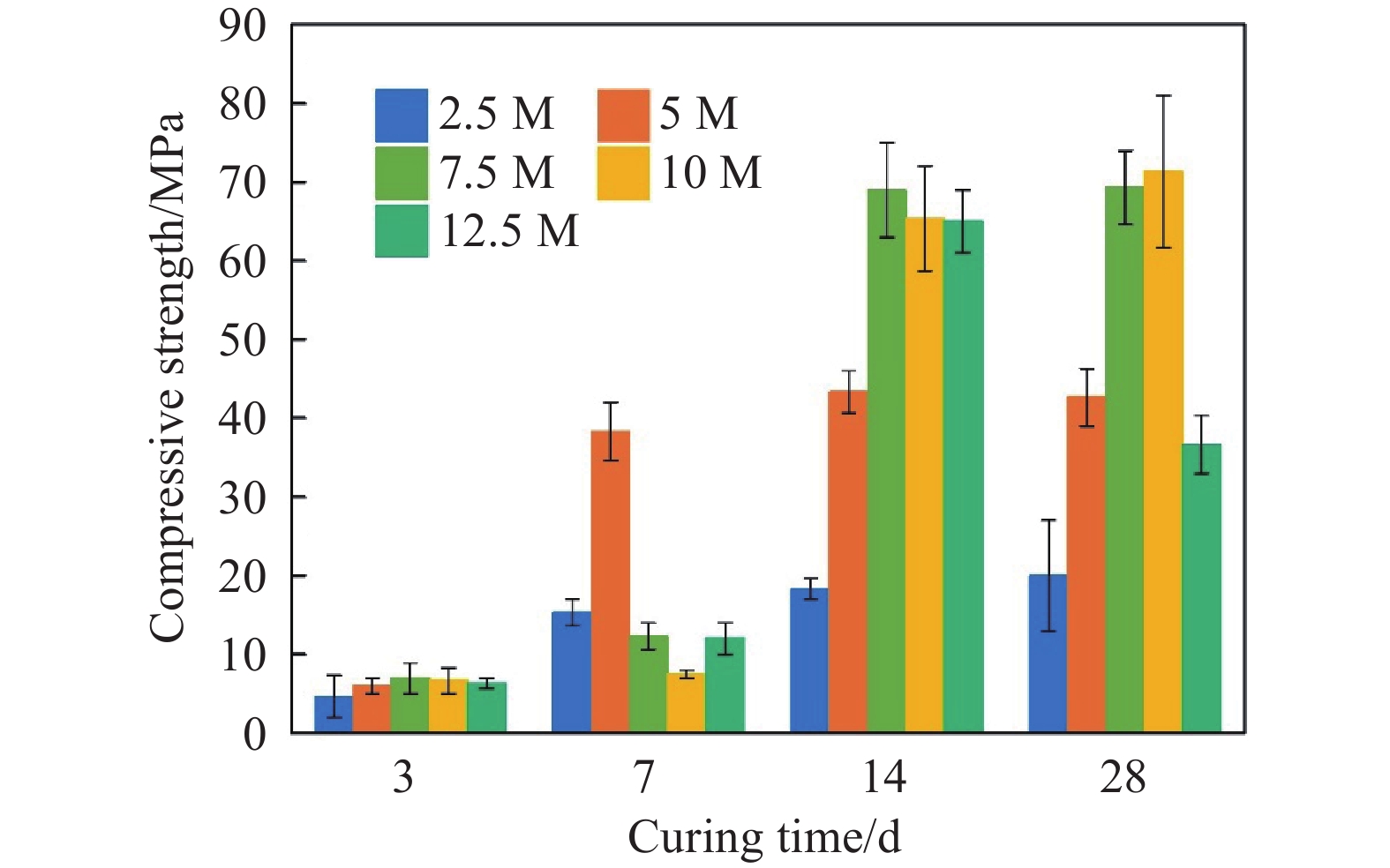

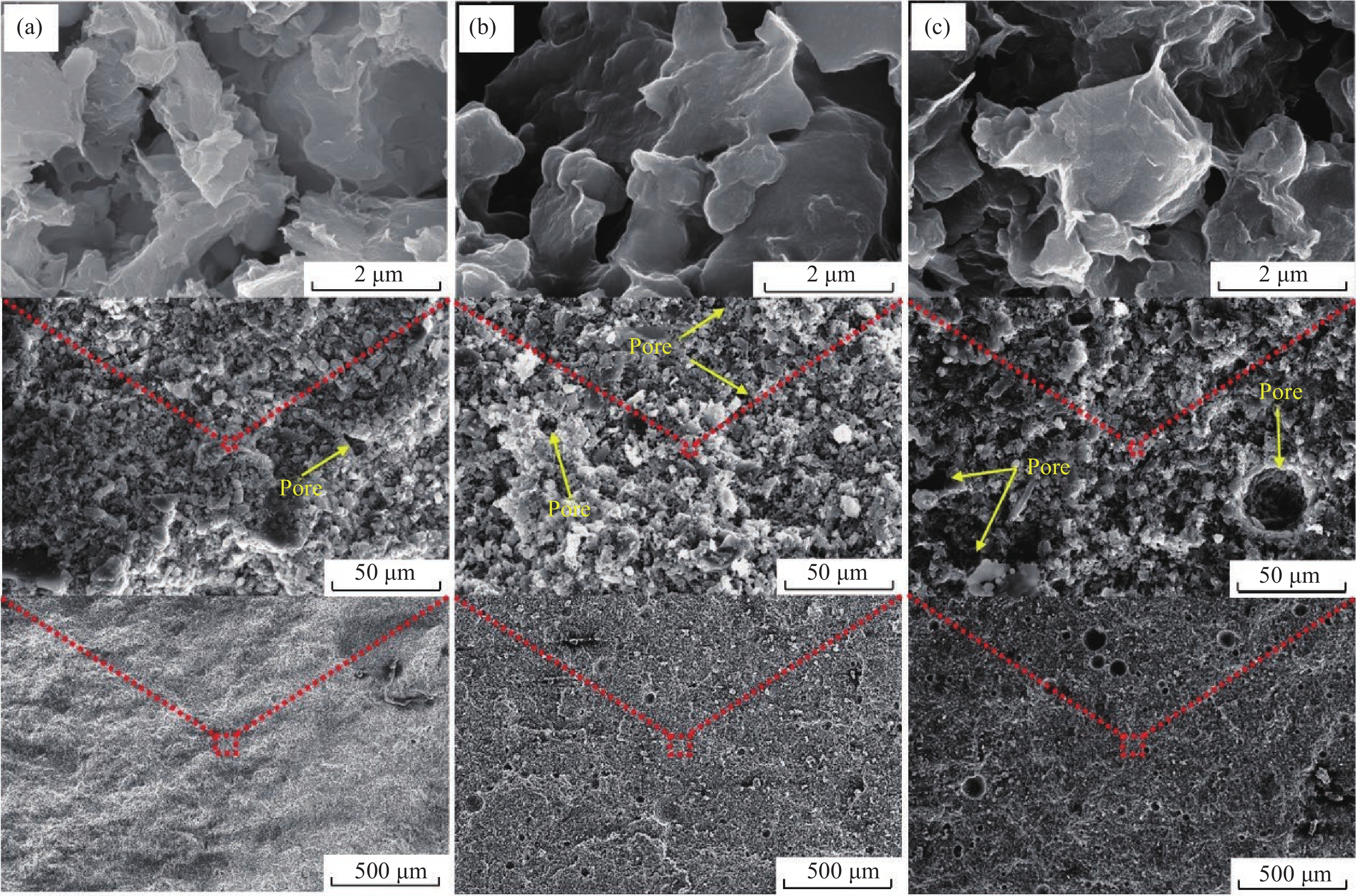

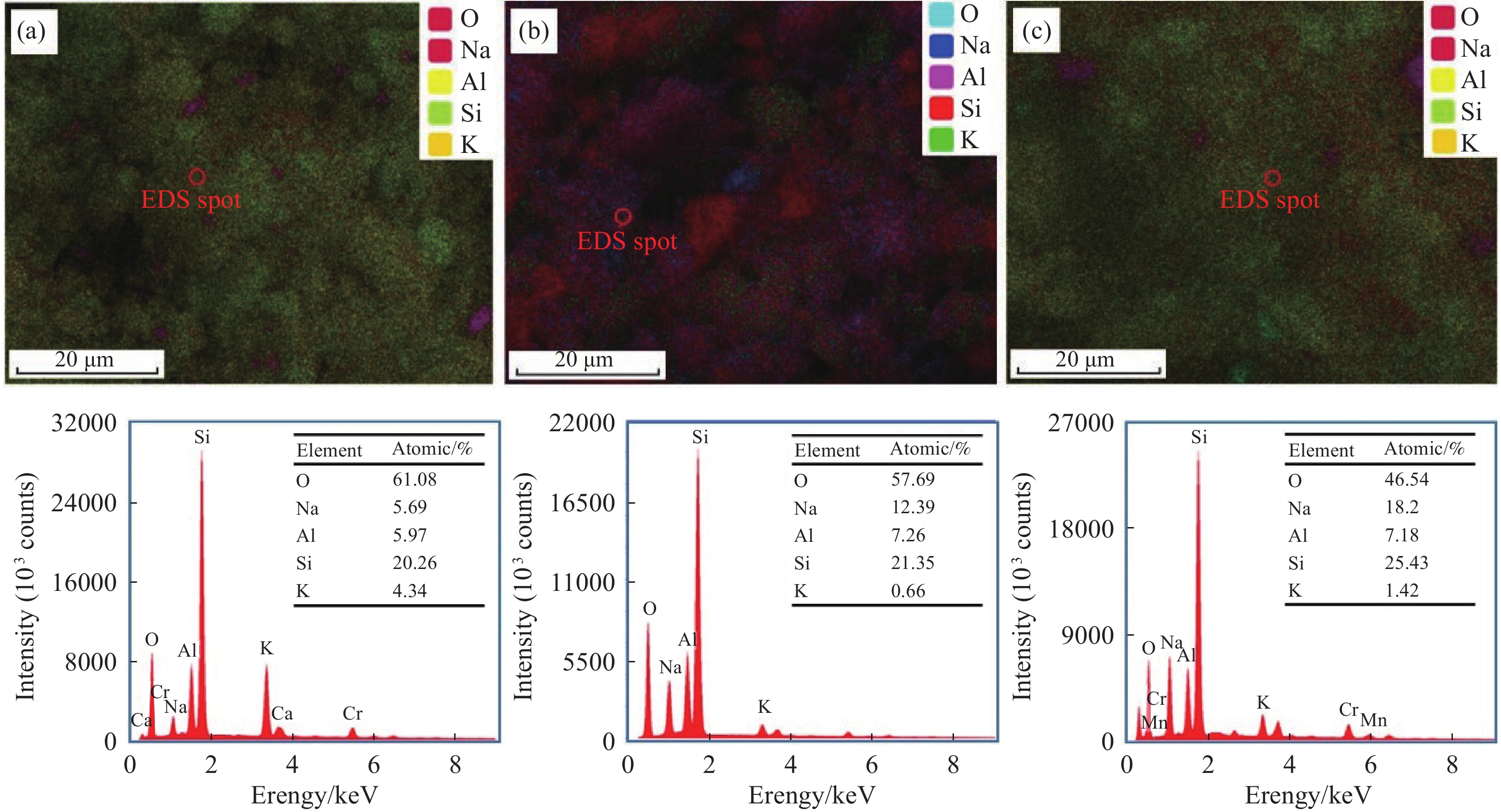

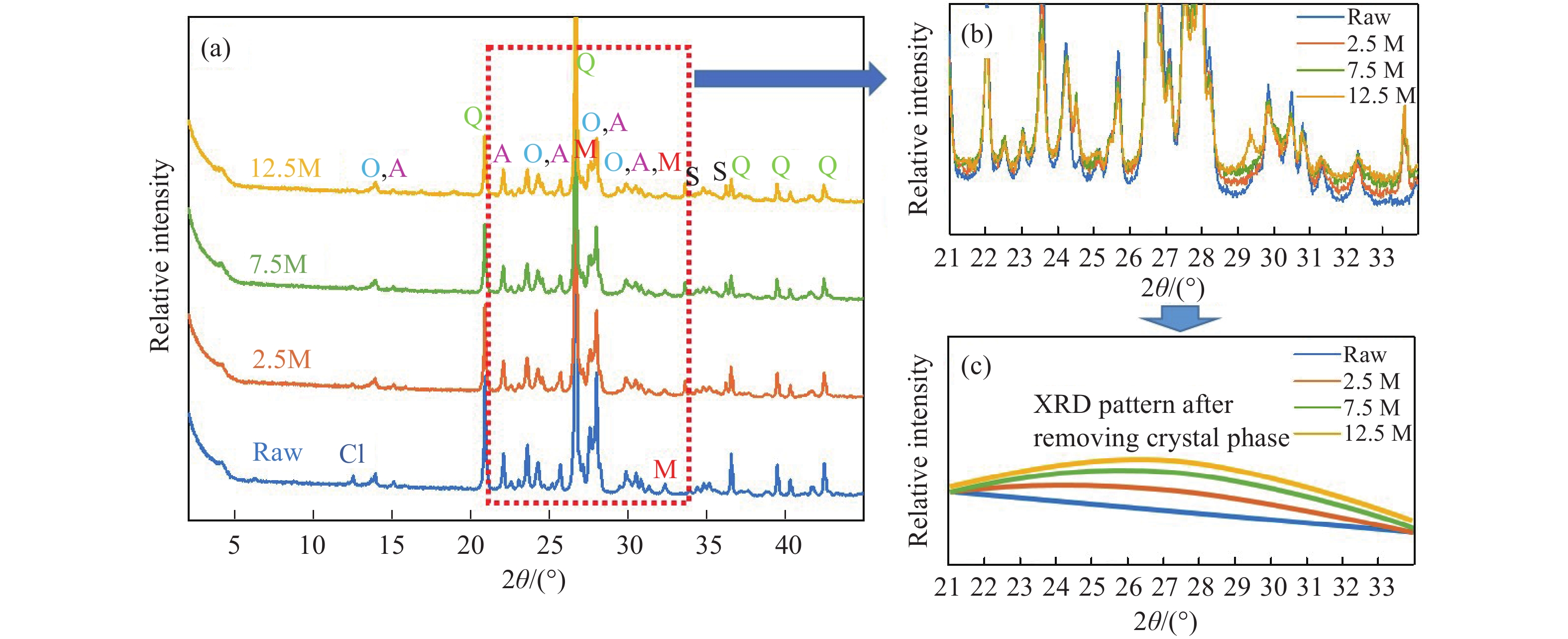

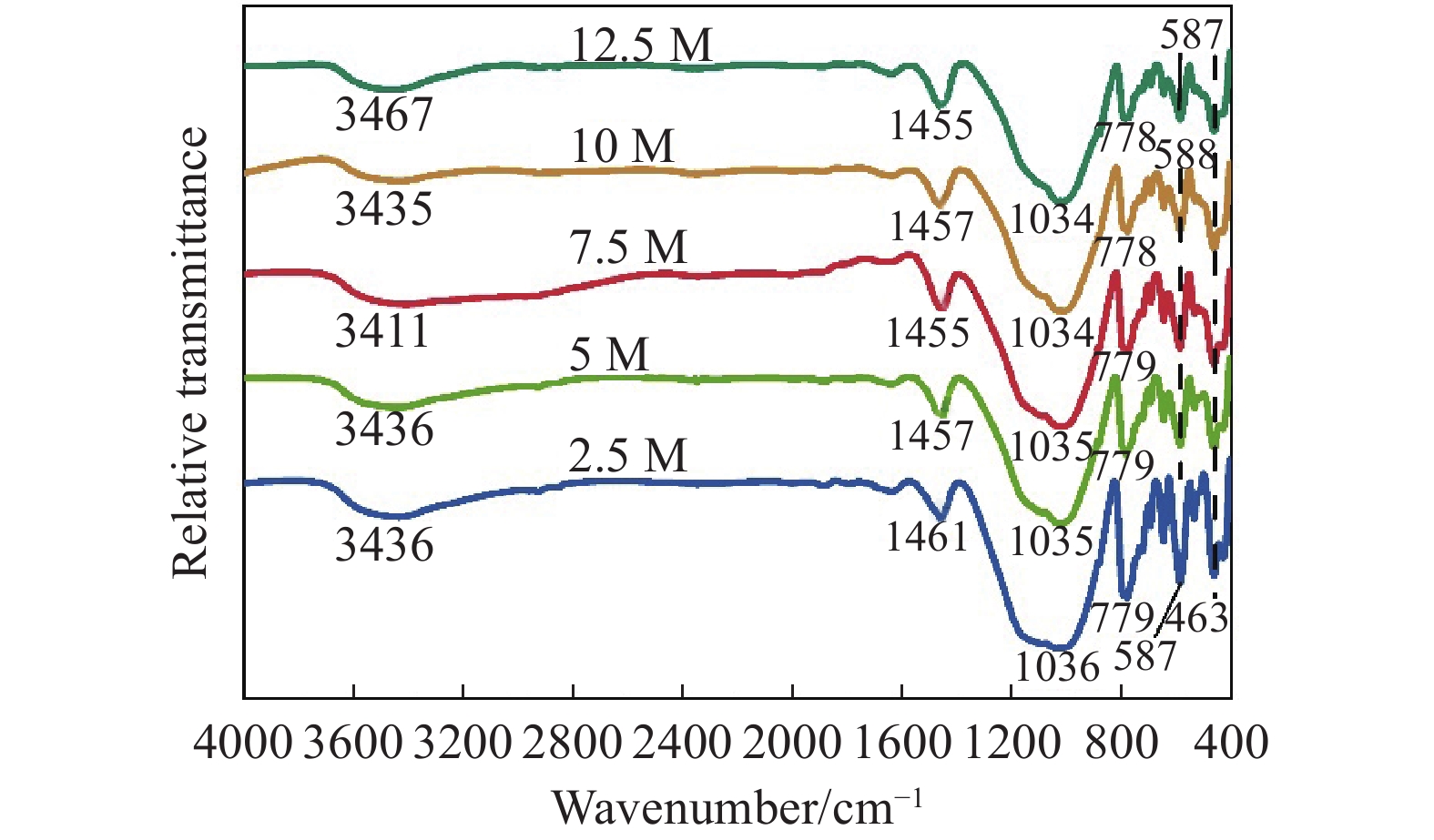

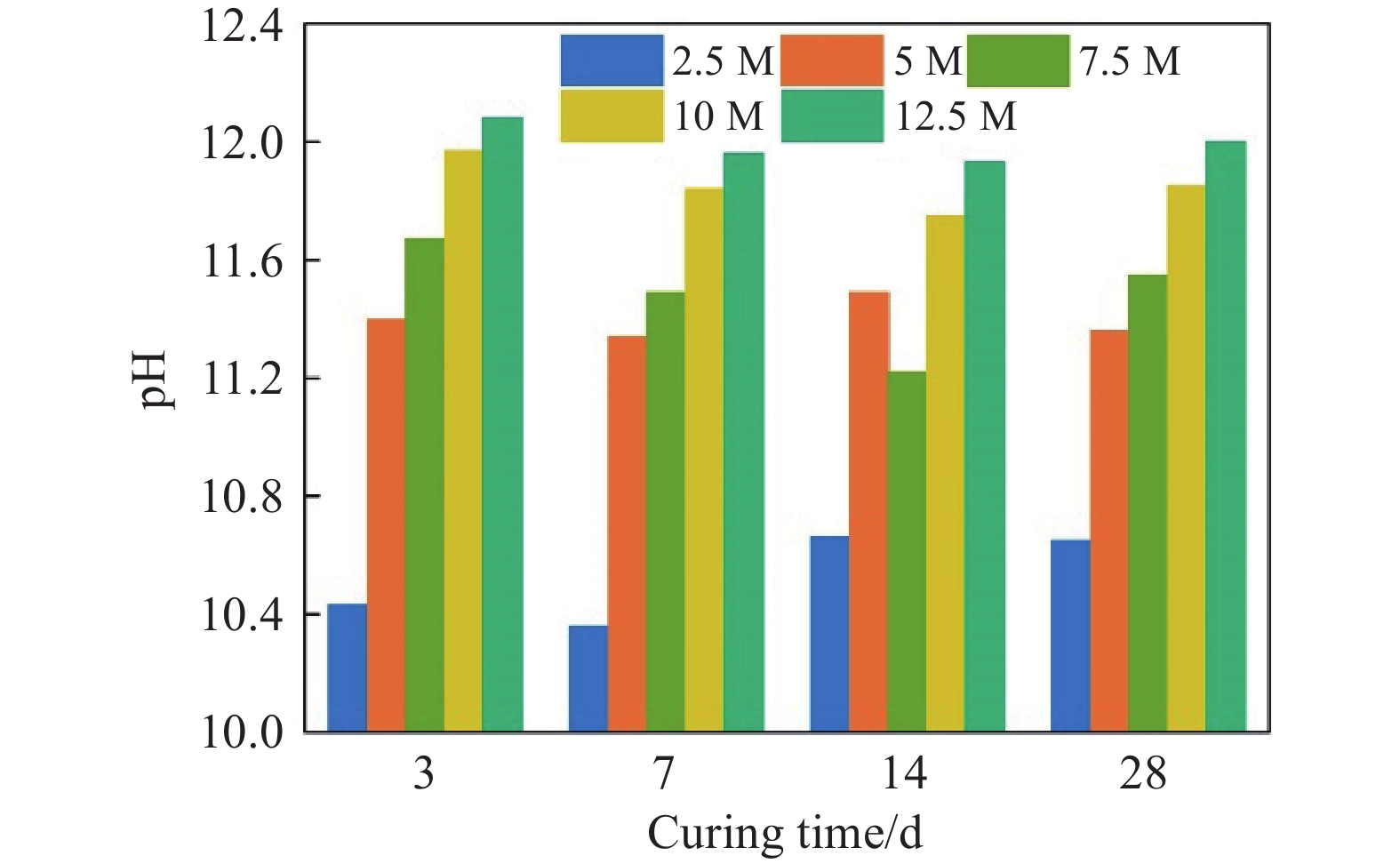

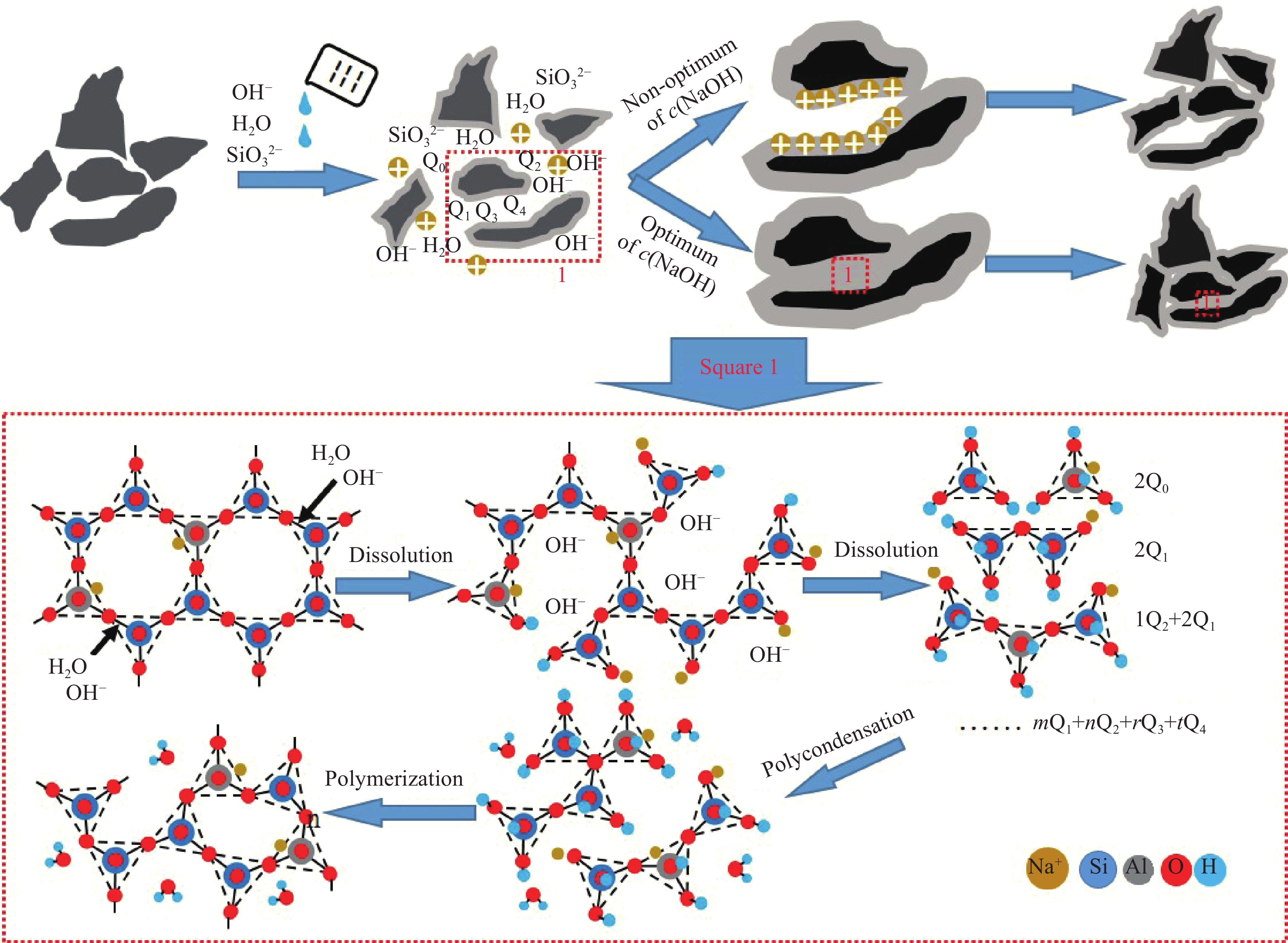

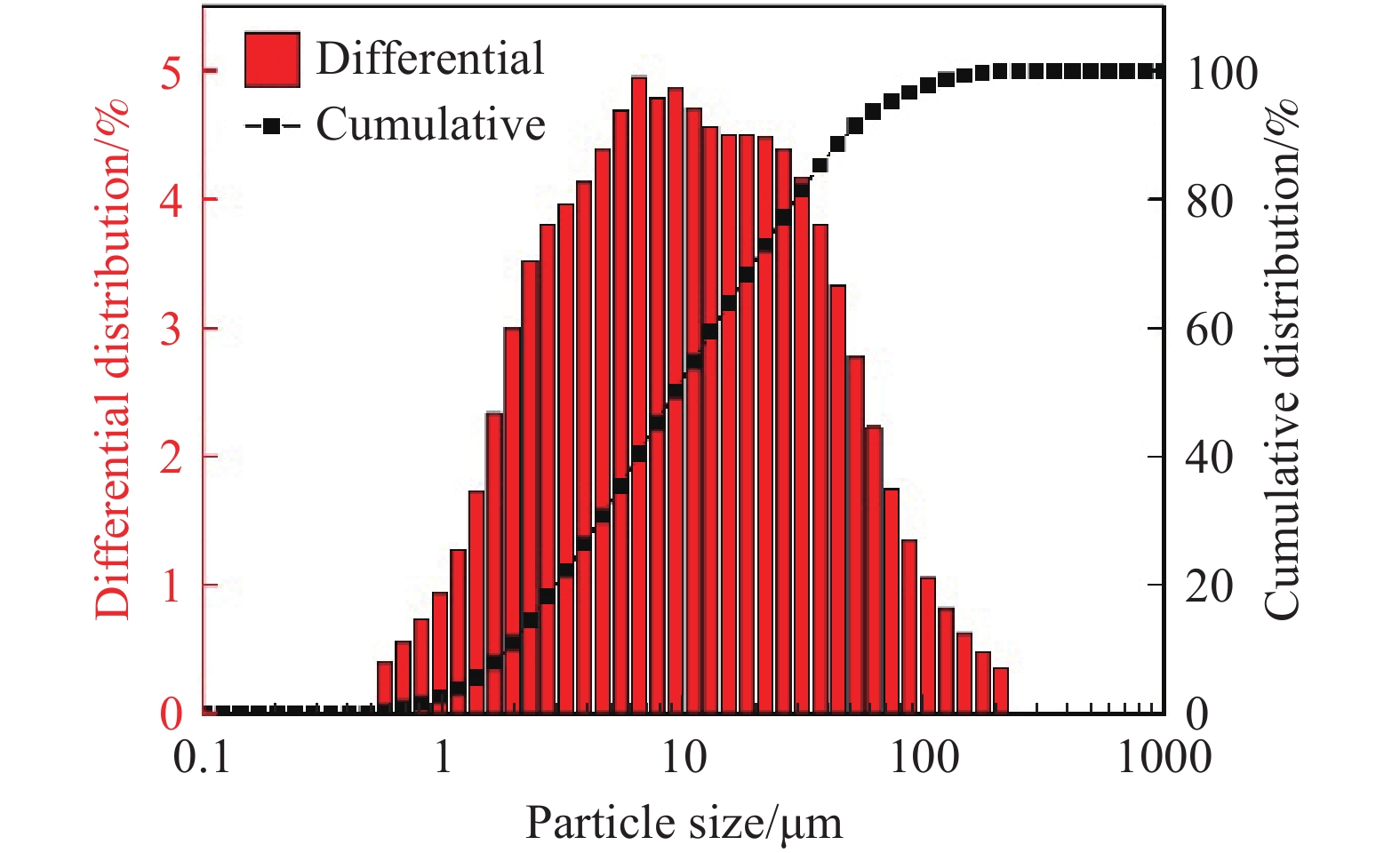

摘要: 為促進凝灰巖固體廢棄物的有效利用,提出一種凝灰巖石粉膠凝材料的制備方法,并通過抗壓強度測試、pH值測定、掃描電鏡、X射線能譜儀、X射線衍射分析和傅里葉變換紅外光譜等表征,探討了激發劑模數(n(SiO2)/ n(Na2O))對抗壓強度的影響規律及相關機理。結果表明,激發劑模數為0.042~0.055時,試樣的28 d最大抗壓強度達到71.33 MPa。隨著激發劑模數的降低,顆粒表面的溶解程度提高;生成的硅鋁酸鹽增加,使抗壓強度提高,但當模數低于最優值后,孔隙直徑增大,石粉顆粒表面的黏結面積減小,造成強度降低。當激發劑模數為0.080~0.150和0.034~0.055時,抗壓強度發展分別主要在3~7 d之間和7~14 d之間,與試樣浸出液的pH值變化有較好的對應關系。因為堿激發反應過程大量消耗OH?,強度上升;而過高的OH?濃度可能使產物重新解聚,以及片層顆粒間一端靜電斥力的增大使顆粒趨向點?面接觸,引起強度的下降。Abstract: To promote the effective utilization of the tuff powder waste, this paper proposes a preparation method for a tuff polymer. The raw material is the by-product in the machine-made tuff-based aggregate production process. NaOH and Na2SiO3 were added to the raw material successively and cured in an airtight condition at 60 ℃. Compared to the production of Portland cement, higher temperature excitation was not necessary, and lower carbon dioxide emissions during the chemical reaction were achieved. Based on the compressive strength, pH value, scanning electron microscopy, X-ray energy dispersive spectrometer, X-ray diffraction spectrogram, and Fourier transform infrared spectroscopy tests on samples with a variety modulus (n(SiO2)/n(Na2O)) of the activator, the mechanism of the modulus of activator influences on the compressive strengths of this tuff polymer was investigated. This work highlights the following: (1) A superior mechanical performance was observed. Results revealed that the optimum modulus was 0.042–0.055 at a range of 0.034–0.150, and the corresponding maximum strength of the tuff powder was 71.33 MPa. (2) The comprehensive microscopic characterization proved the mechanism of strength development. Microscopic characterization results revealed that the alkali activator mainly acted with the surface of tuff powder particles. With the decrease of the modulus of the activator, the dissolution extent of particles increased, and more aluminosilicate was produced, resulting in strength development. When the modulus was below the optimum value, defects such as pore diameter increased, and the contacting area of the polymer on the surface of the tuff particles decreased, resulting in strength deterioration. When the modulus of the activator was 0.150 and 0.080, the strength development occurred between three and seven days. When the modulus of the activator was 0.050, 0.042, and 0.034, the strength development mainly occurred between 7 and 14 days. The pH value variety of the leaching solution generally corresponded to strength development. The increased strengths are attributed to the consumption of OH? in the polymerization and polycondensation stages. Meanwhile, a pH value that is too high may result in depolymerization of the production in the polymerization and polycondensation stages. In addition, the electrostatic repulsion increased, and therefore the strengths of the tuff polymer decreased.

-

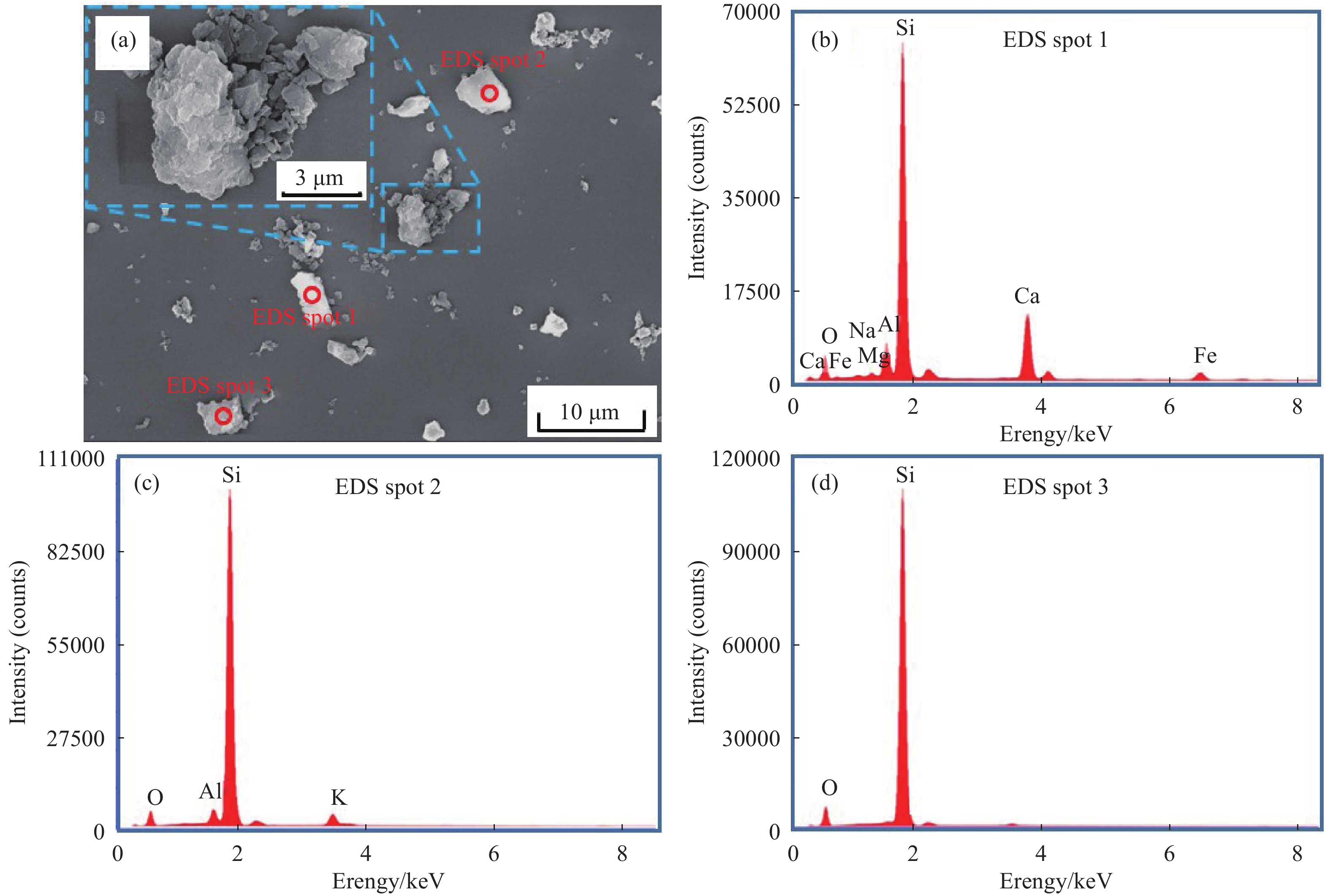

圖 7 養護28 d后凝灰巖基地聚合物的EDS Mapping照片和點分析. (a) n(SiO2)/n(Na2O) = 0.150;(b) n(SiO2)/ n(Na2O) = 0.055;(c) n(SiO2)/n(Na2O) = 0.034

Figure 7. EDS mapping patterns and point analysis of the tuff-based geopolymer after 28 days curing: (a) n(SiO2)/ n(Na2O) = 0.150; (b) n(SiO2)/n(Na2O) = 0.055; (c) n(SiO2)/n(Na2O) = 0.034

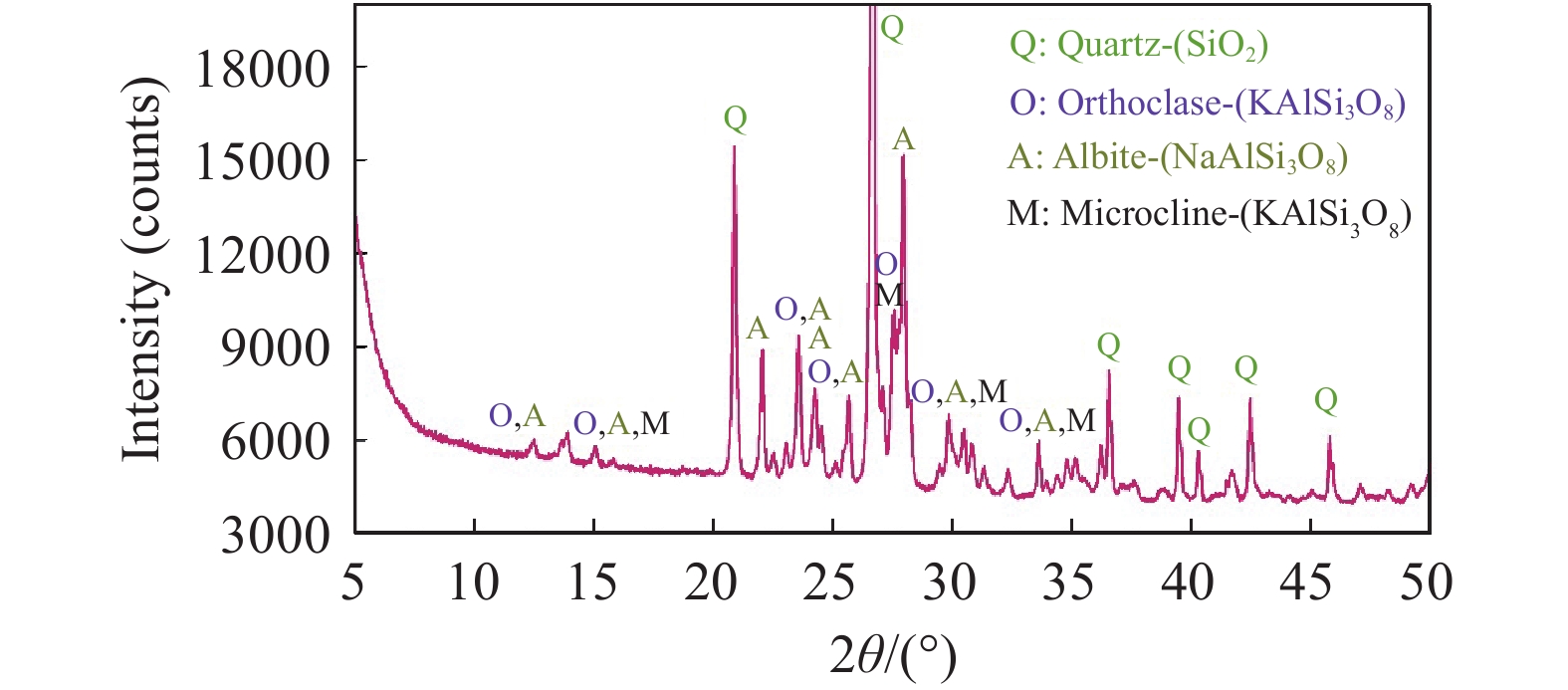

圖 8 養護28 d后凝灰巖基地聚合物的XRD譜圖.(a)2θ=2°~50°;(b)2θ=21°~34°;(c)2θ=21°~34°(去除晶相后)

Figure 8. XRD patterns of the tuff-based geopolymer after 28 days curing: (a) 2θ=2°–50°; (b) 2θ=21°–34°; (c) 2θ=21°–34°(after removing crystal phase)

Note: The intensity of quartz: raw materials (31582), 2.5M (26296), 7.5M (19673), 12.5M (19110). Q: Quartz, syn-SiO2; O: Orthoclase-K[AlSi3O8]; A: Albite, calcian, ordered-Na[AlSi3O8]; M: Microcline, intermediate-K[AlSi3O8]; Cl: Clinoptilolite; S: Sodium silicate -Na2SiO3

表 1 凝灰巖石粉的氧化物成分

Table 1. Oxide composition of the tuff powder

Chemical

compositionFe2O3 SiO2 Al2O3 MgO CaO Na2O K2O Others Mass fraction / % 1.58 69.92 11.51 0.35 1.00 3.89 4.81 6.94 表 2 不同試樣的堿激發劑組成

Table 2. Concentrations and dosages of activators in samples

Mix ID NaOH solution Na2SiO3 solution Modulus

[n(SiO2)/ n(Na2O)]Concentration /(mol?L?1) Dosage/mL Concentration /(mol?L?1) Dosage/mL 2.5 M 2.50 150.00 1.64 20.00 0.150 5 M 5.00 150.00 1.64 20.00 0.080 7.5 M 7.50 150.00 1.64 20.00 0.055 10 M 10.00 150.00 1.64 20.00 0.042 12.5 M 12.50 150.00 1.64 20.00 0.034 Wave number /

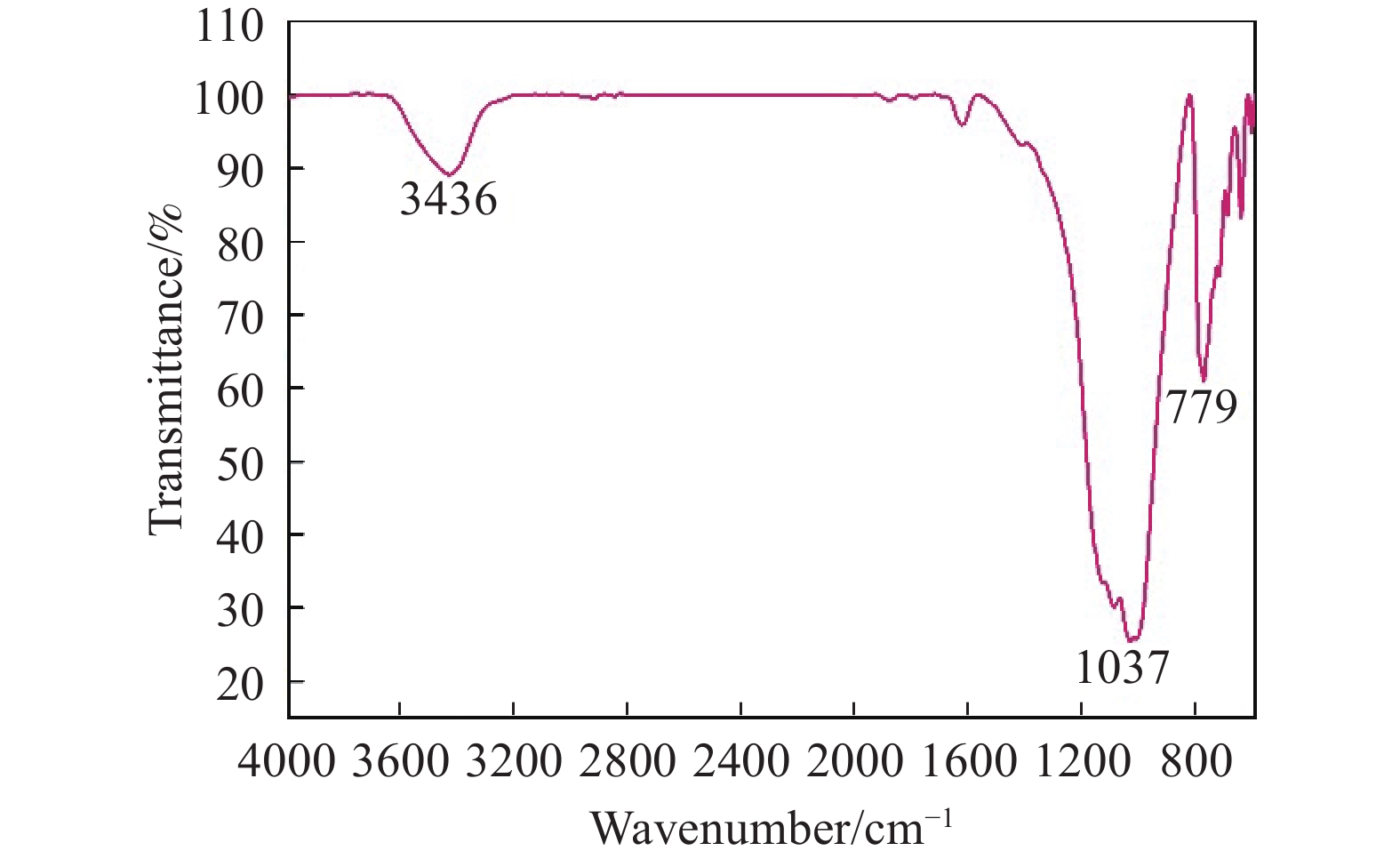

cm?1Assignments Comments 3410?3455, 3467 O—H stretching Strong band of the surface adsorbed and chemical bound water 1455, 1457, 1461 O—C—O stretching Strong band due to the carbonation of free Na+ into Na2CO3 1034, 1035, 1036 Si—O—T asymmetric stretching Strong band. Bridging oxygen atom (BO) of the original aluminosilicate framework. After the reaction, the band shift to a lower value indicating that the non-bridging oxygen atoms have replaced the bridging oxygen atoms on the surface of aluminosilicate and are charged compensated by alkalis 881 Si—O of non-polymerized SiO4 Strong band appears in the lesser polymerized product 778, 779 Symmetric stretching Si—O—Si Strong band appears in the lesser polymerized product 587, 588, 589 Si—O—Si, Al—O—Si symmetric stretching Should appear only in the polymerized product 463 T—O bending Should appear only in the polymerized product www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] He H, Wang Y L, Wang J J. Compactness and hardened properties of machine-made sand mortar with aggregate micro fines. Constr Build Mater, 2020, 250: 118828 doi: 10.1016/j.conbuildmat.2020.118828 [2] Mu S C. Physical and chemical features of tuff and its development and application. China Min Mag, 2000, 9(3): 17 doi: 10.3969/j.issn.1004-4051.2000.03.005木士春. 凝灰巖的物理化學性質及其開發利用. 中國礦業, 2000, 9(3):17 doi: 10.3969/j.issn.1004-4051.2000.03.005 [3] Mu S C. Preliminary study on development and utilization of tuff. Non Met Mines, 2000, 23(2): 18木士春. 凝灰巖開發利用初步研究. 非金屬礦, 2000, 23(2):18 [4] Chong L L, Shi C J, Yang J M, et al. Effect of limestone powder on the water stability of magnesium phosphate cement-based materials. Constr Build Mater, 2017, 148: 590 doi: 10.1016/j.conbuildmat.2017.04.207 [5] Turk K, Demirhan S. Effect of limestone powder on the rheological, mechanical and durability properties of ECC. Eur J Environ Civ Eng, 2017, 21(9): 1151 doi: 10.1080/19648189.2016.1150902 [6] Shi C J, Day R L. Comparison of different methods for enhancing reactivity of pozzolans. Cem Concr Res, 2001, 31(5): 813 doi: 10.1016/S0008-8846(01)00481-1 [7] Zhang Y S, Sun W, Li Z J. Composition design and microstructural characterization of geopolymeric binder. J Chin Ceram Soc, 2008, 36(Suppl 1): 153張云升, 孫偉, 李宗津. 地聚合物膠凝材料的組成設計和結構特征. 硅酸鹽學報, 2008, 36(增刊1): 153 [8] Oh J E, Monteiro P J M, Jun S S, et al. The evolution of strength and crystalline phases for alkali-activated ground blast furnace slag and fly ash-based geopolymers. Cem Concr Res, 2010, 40(2): 189 doi: 10.1016/j.cemconres.2009.10.010 [9] Bondar D, Lynsdale C J, Milestone N B, et al. Effect of type, form, and dosage of activators on strength of alkali-activated natural pozzolans. Cem Concr Compos, 2011, 33(2): 251 doi: 10.1016/j.cemconcomp.2010.10.021 [10] Shi H S, Xia M, Guo X L. Research development on mechanism of fly ash-based geopolymer and effect of each component. J Chin Ceram Soc, 2013, 41(7): 972 doi: 10.7521/j.issn.0454-5648.2013.07.15施惠生, 夏明, 郭曉潞. 粉煤灰基地聚合物反應機理及各組分作用的研究進展. 硅酸鹽學報, 2013, 41(7):972 doi: 10.7521/j.issn.0454-5648.2013.07.15 [11] Cheng H, Lin K L, Cui R, et al. The effects of SiO2/Na2O molar ratio on the characteristics of alkali-activated waste catalyst-metakaolin based geopolymers. Constr Build Mater, 2015, 95: 710 doi: 10.1016/j.conbuildmat.2015.07.028 [12] Aziz I H, Abdullah M M A B, Salleh M A A M, et al. Microstructure and porosity evolution of alkali activated slag at various heating temperatures. J Mater Res Technol, 2020, 9(6): 15894 doi: 10.1016/j.jmrt.2020.11.041 [13] Gijbels K, Pontikes Y, Samyn P, et al. Effect of NaOH content on hydration, mineralogy, porosity and strength in alkali/sulfate-activated binders from ground granulated blast furnace slag and phosphogypsum. Cem Concr Res, 2020, 132: 106054 doi: 10.1016/j.cemconres.2020.106054 [14] Nikolov A, Nugteren H, Rostovsky I. Optimization of geopolymers based on natural zeolite clinoptilolite by calcination and use of aluminate activators. Constr Build Mater, 2020, 243: 118257 doi: 10.1016/j.conbuildmat.2020.118257 [15] Guo X L, Yang J Y, Xiong G Y. Effect of magnesium aluminum silicate and rest time on the rheological properties of geopolymer. J Build Mater,http://kns.cnki.net/kcms/detail/31.1764.TU.20201130.0946.002.html郭曉潞, 楊君奕, 熊歸硯. 硅酸鎂鋁及靜置時間對地聚合物流變性能影響. 建筑材料學報,http://kns.cnki.net/kcms/detail/31.1764.TU.20201130.0946.002.html [16] Li S, Liu H X, Yang Y, et al. Mechanisms of drying shrinkage for alkali-activated slag/metakaolin composite materials. Mater Rep, 2021, 35(4): 4088 doi: 10.11896/cldb.19070067李爽, 劉和鑫, 楊永, 等. 堿激發礦渣/偏高嶺土復合膠凝材料干燥收縮機理研究. 材料導報, 2021, 35(4):4088 doi: 10.11896/cldb.19070067 [17] American Society for Testing and Materials, USA. ASTM C109 Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). Philadelphia: ASTM International, 2016 [18] Belie N D, Kratky J, Vlierberghe S V. Influence of pozzolans and slag on the microstructure of partially carbonated cement paste by means of water vapour and nitrogen sorption experiments and BET calculations. Cem Concr Res, 2010, 40(12): 1723 doi: 10.1016/j.cemconres.2010.08.014 [19] Davidovits J, Wang K J. Geopolymer Chemistry & Applications. Beijing: National Defense Industry Press, 2011約瑟夫∙戴維德維斯, 王克儉. 地聚合物化學及應用. 北京: 國防工業出版社, 2011 [20] Shi C J. An overview on the activation of reactivity of natural pozzolans. Can J Civ Eng, 2001, 28(5): 778 doi: 10.1139/l01-041 [21] Huang Z Y, Ou Y Y, Li C W. Mechanical property and microstructure of geopolymers with quartz powder by autoclaving curing. Bull Chin Ceram Soc, 2015, 34(10): 2925黃政宇, 區楊蔭, 李操旺. 蒸壓養護下摻石英粉地聚合物的力學性能及微觀結構. 硅酸鹽通報, 2015, 34(10):2925 [22] Qin L F, Qu B, Shi C J, et al. Effect of Ca/Si ratio on the formation and characteristics of synthetic aluminosilicate hydrate gels. Mater Rep, 2020, 34(12): 12057 doi: 10.11896/cldb.19070122覃麗芳, 曲波, 史才軍, 等. 鈣硅比對鋁硅酸鹽凝膠形成與特性的影響. 材料導報, 2020, 34(12):12057 doi: 10.11896/cldb.19070122 [23] Firdous R, Stephan D, Djobo J N Y. Natural pozzolan based geopolymers: A review on mechanical, microstructural and durability characteristics. Constr Build Mater, 2018, 190: 1251 doi: 10.1016/j.conbuildmat.2018.09.191 [24] Lynch J L V, Baykara H, Cornejo M, et al. Preparation, characterization, and determination of mechanical and thermal stability of natural zeolite-based foamed geopolymers. Constr Build Mater, 2018, 172: 448 doi: 10.1016/j.conbuildmat.2018.03.253 [25] Zhang M, Deskins N A, Zhang G P, et al. Modeling the polymerization process for geopolymer synthesis through reactive molecular dynamics simulations. J Phys Chem C, 2018, 122(12): 6760 doi: 10.1021/acs.jpcc.8b00697 [26] Li Y, Liu Y M. Progress and trend of bulk utilization technology of metallurgical solid wastes in China. Chin J Eng, 2021, 43(12): 1713李宇, 劉月明. 我國冶金固廢大宗利用技術的研究進展及趨勢. 工程科學學報, 2021, 43(12):1713 [27] Jiang G Z, Wu A X, Wang Y M. Curing performance of alkali-activated cement–phosphorous slag and its compatibility with sulfur tailings. Chin J Eng, 2020, 42(8): 963姜關照, 吳愛祥, 王貽明. 堿激發水泥?磷渣固化性能及與含硫尾砂的相容性. 工程科學學報, 2020, 42(8):963 -

下載:

下載: