-

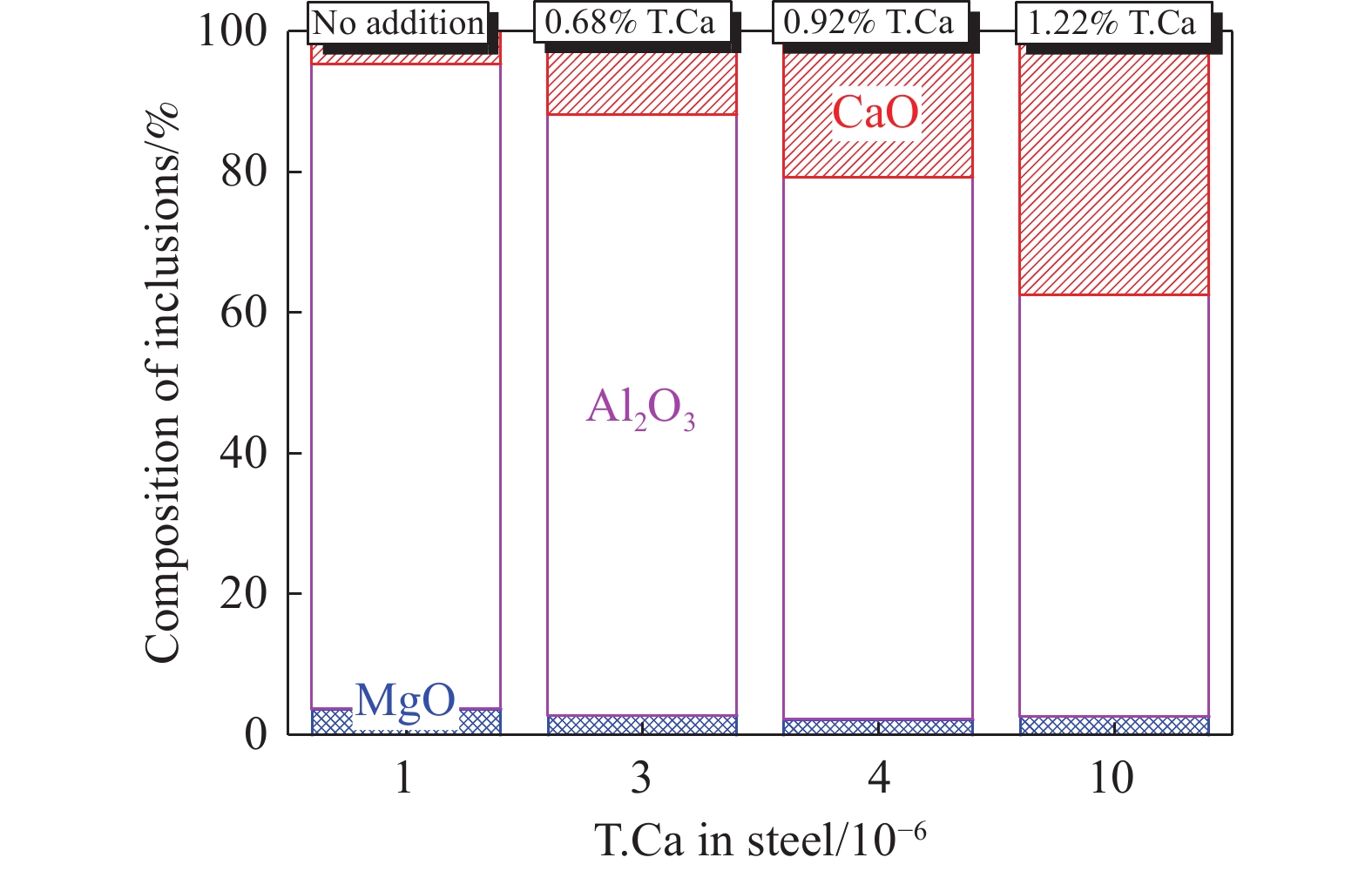

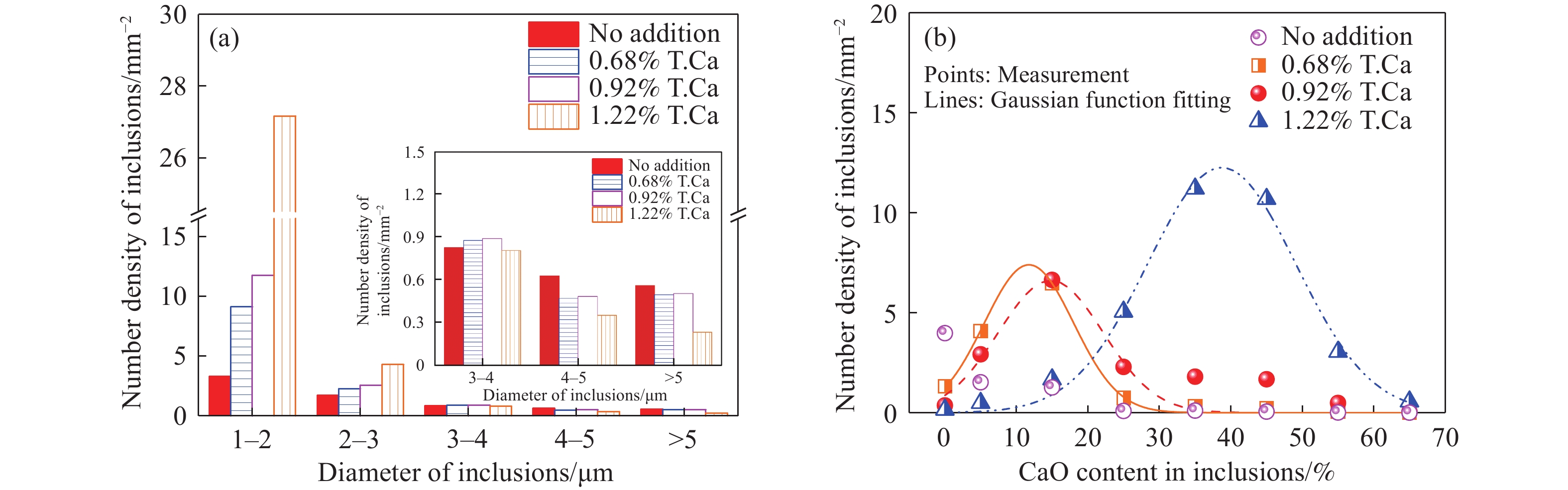

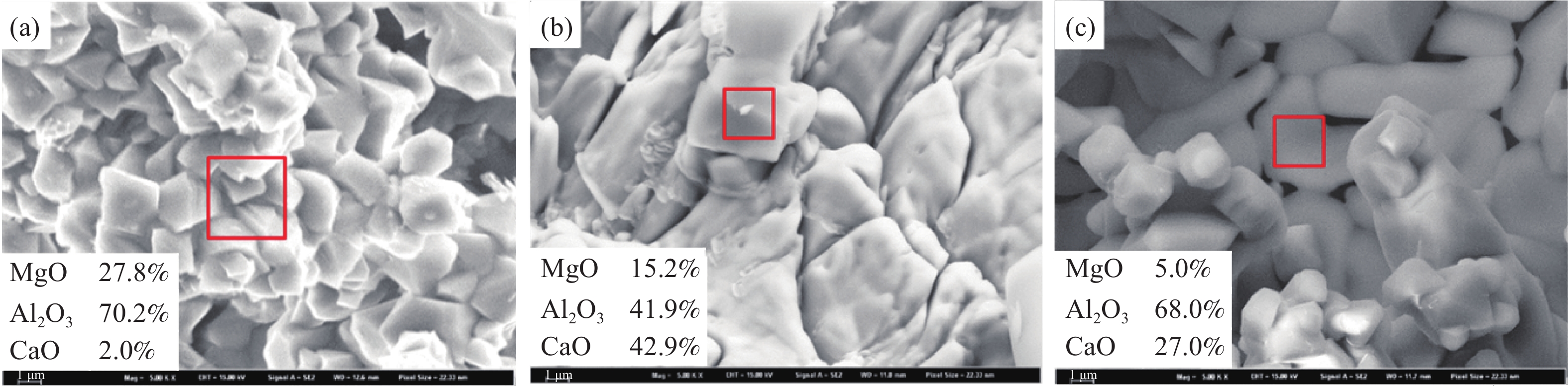

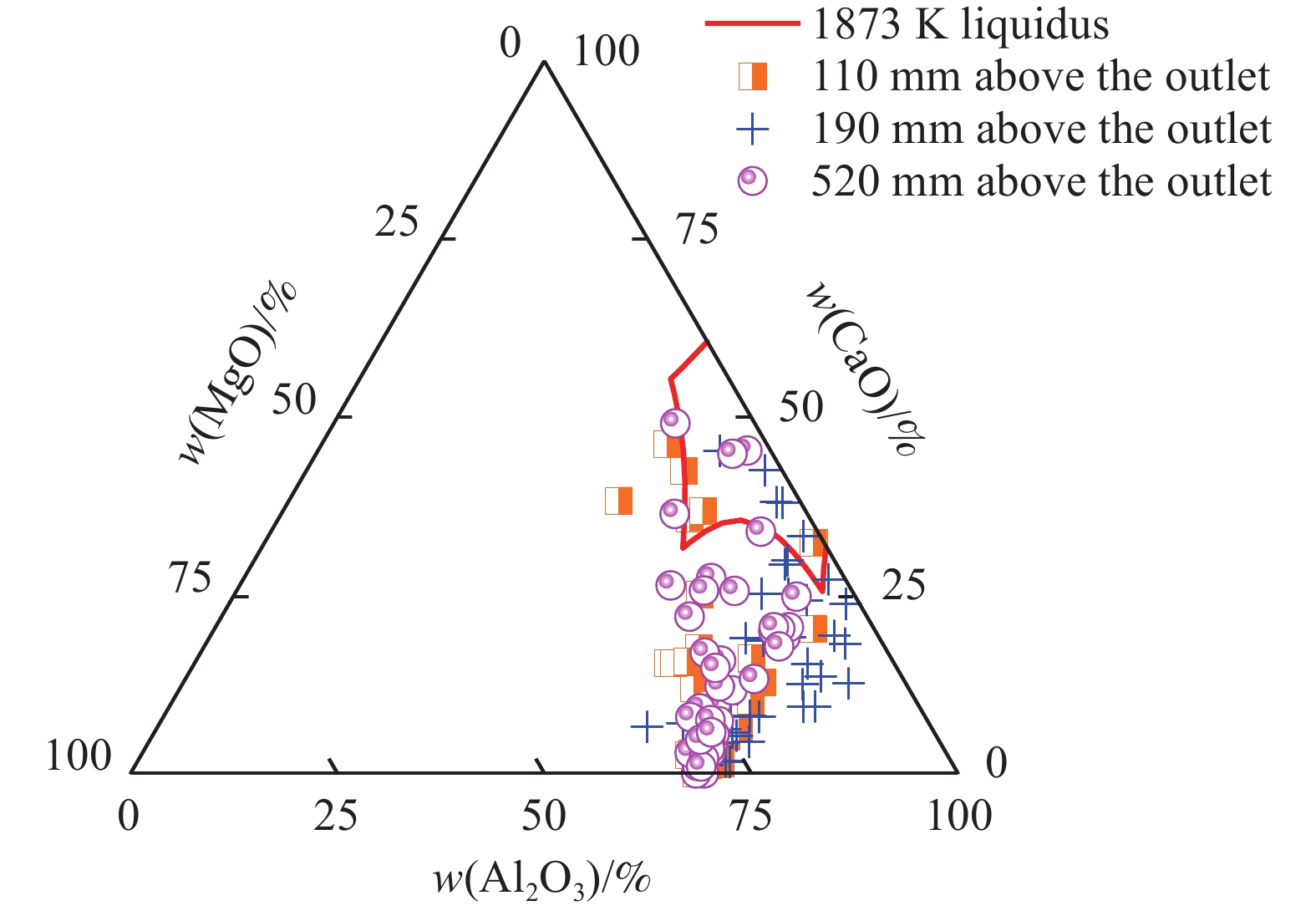

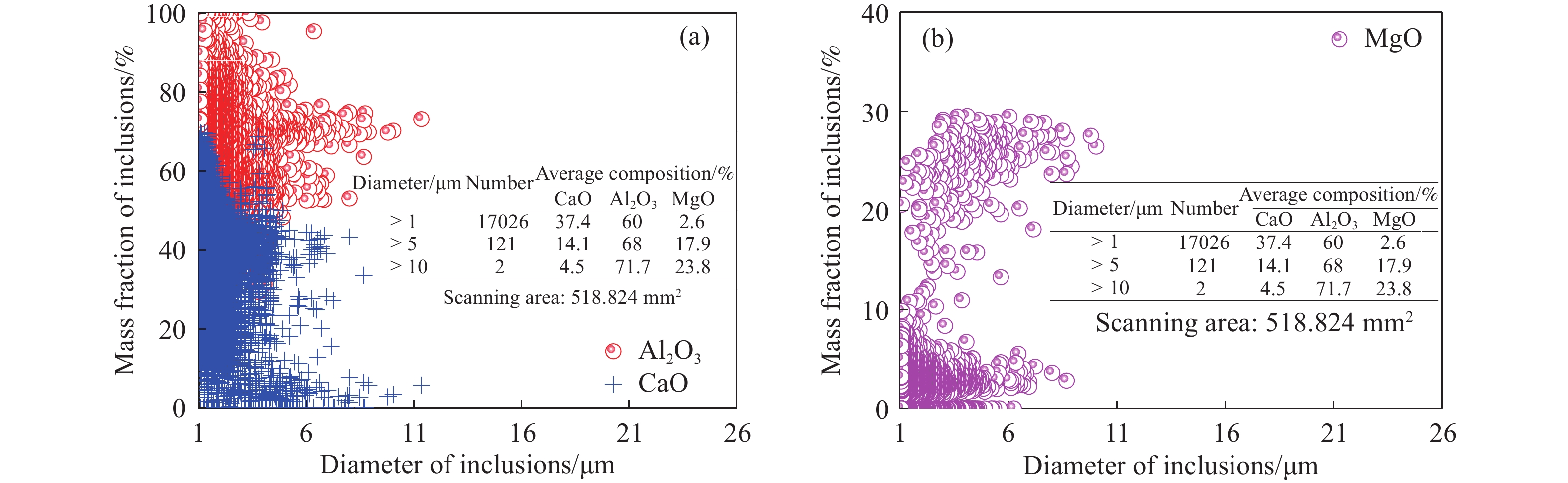

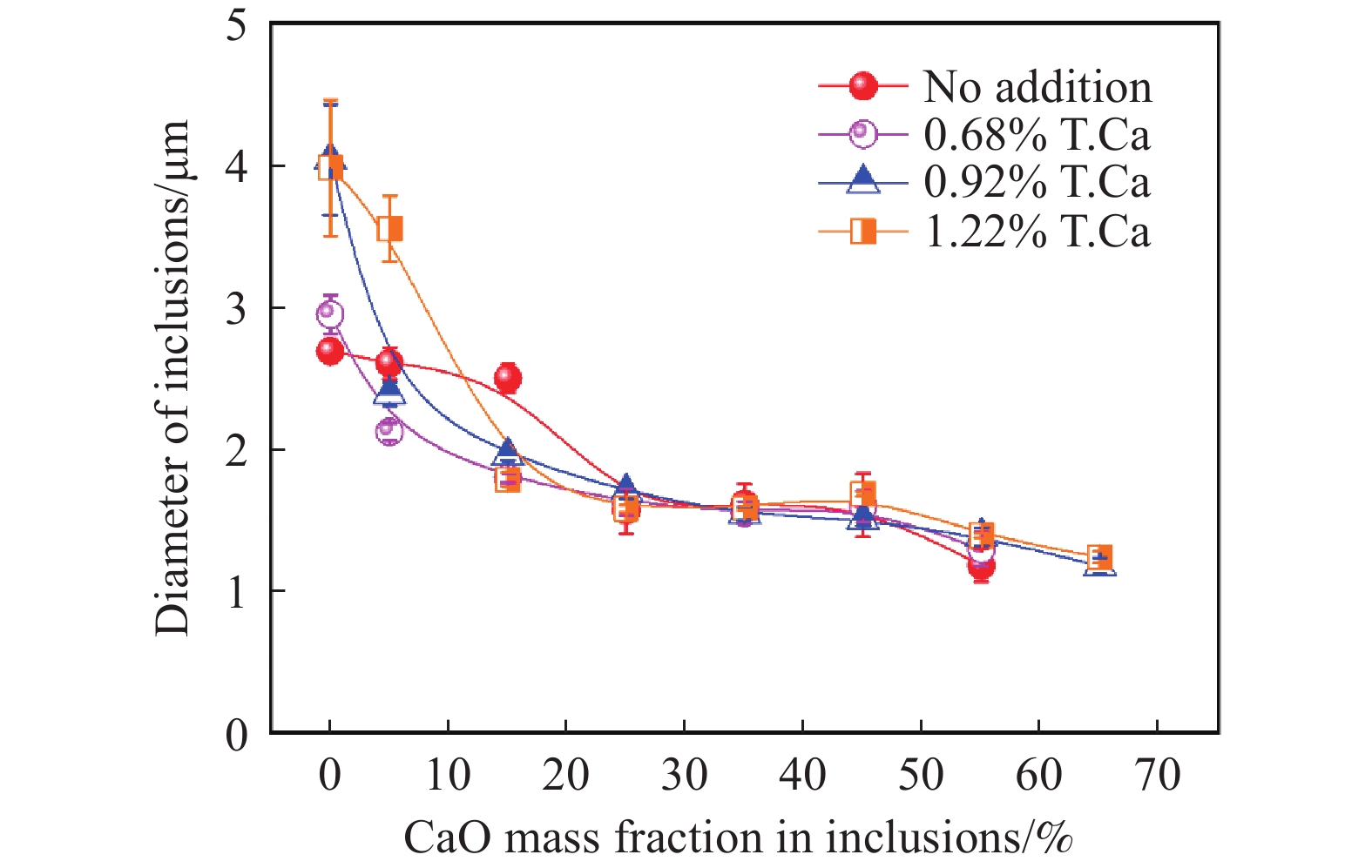

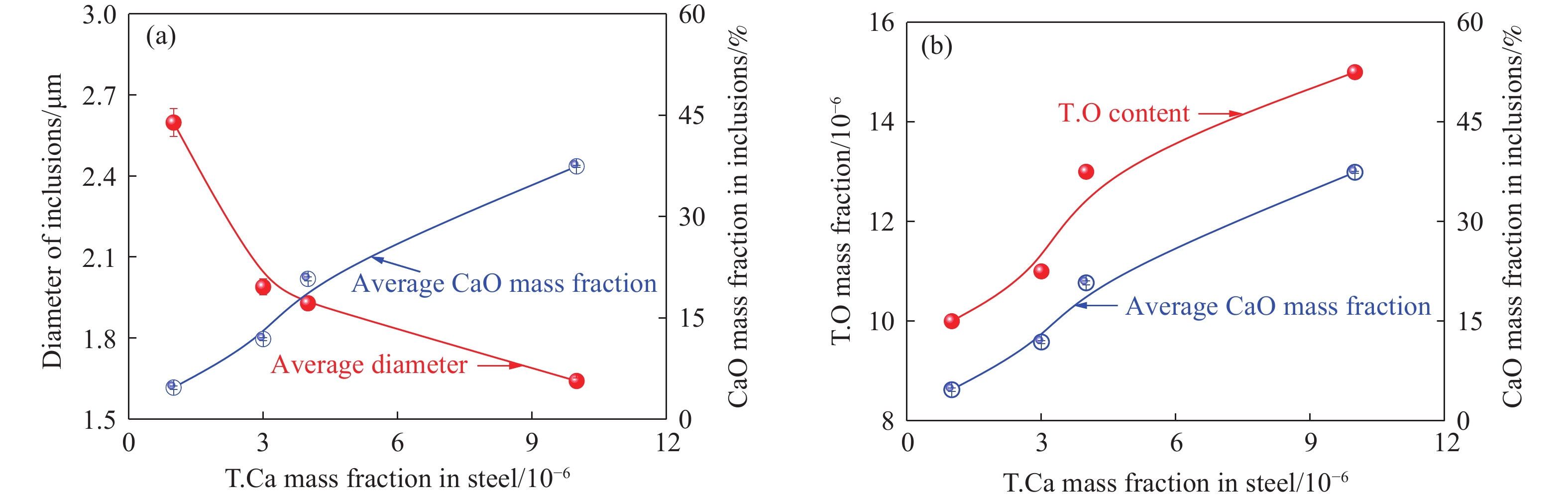

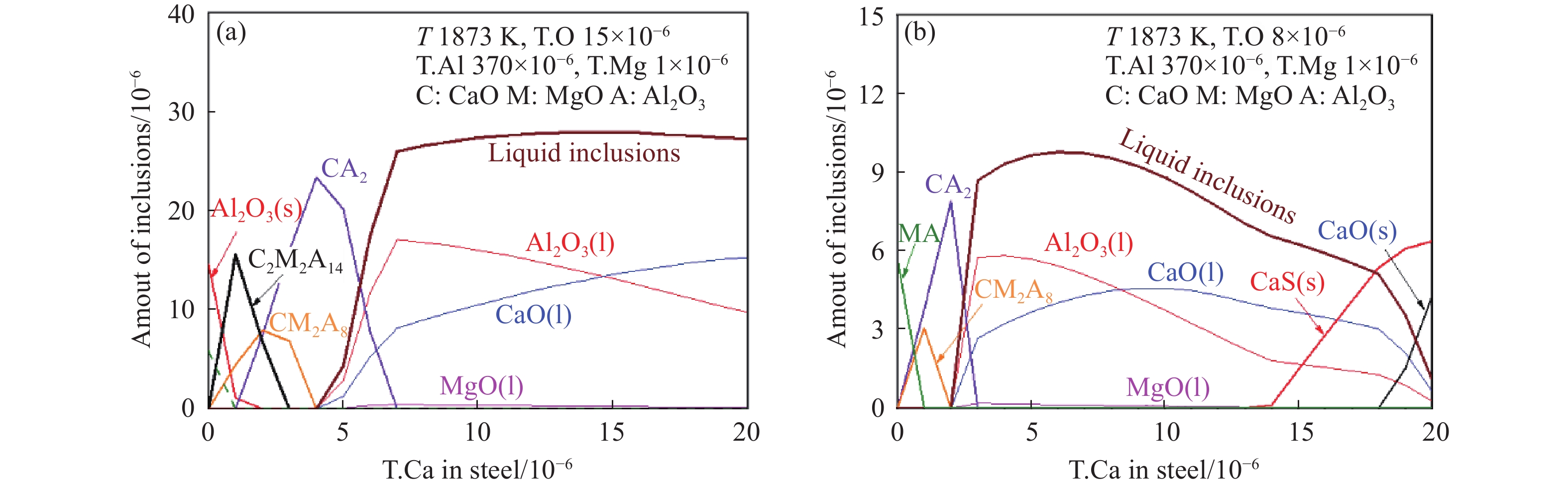

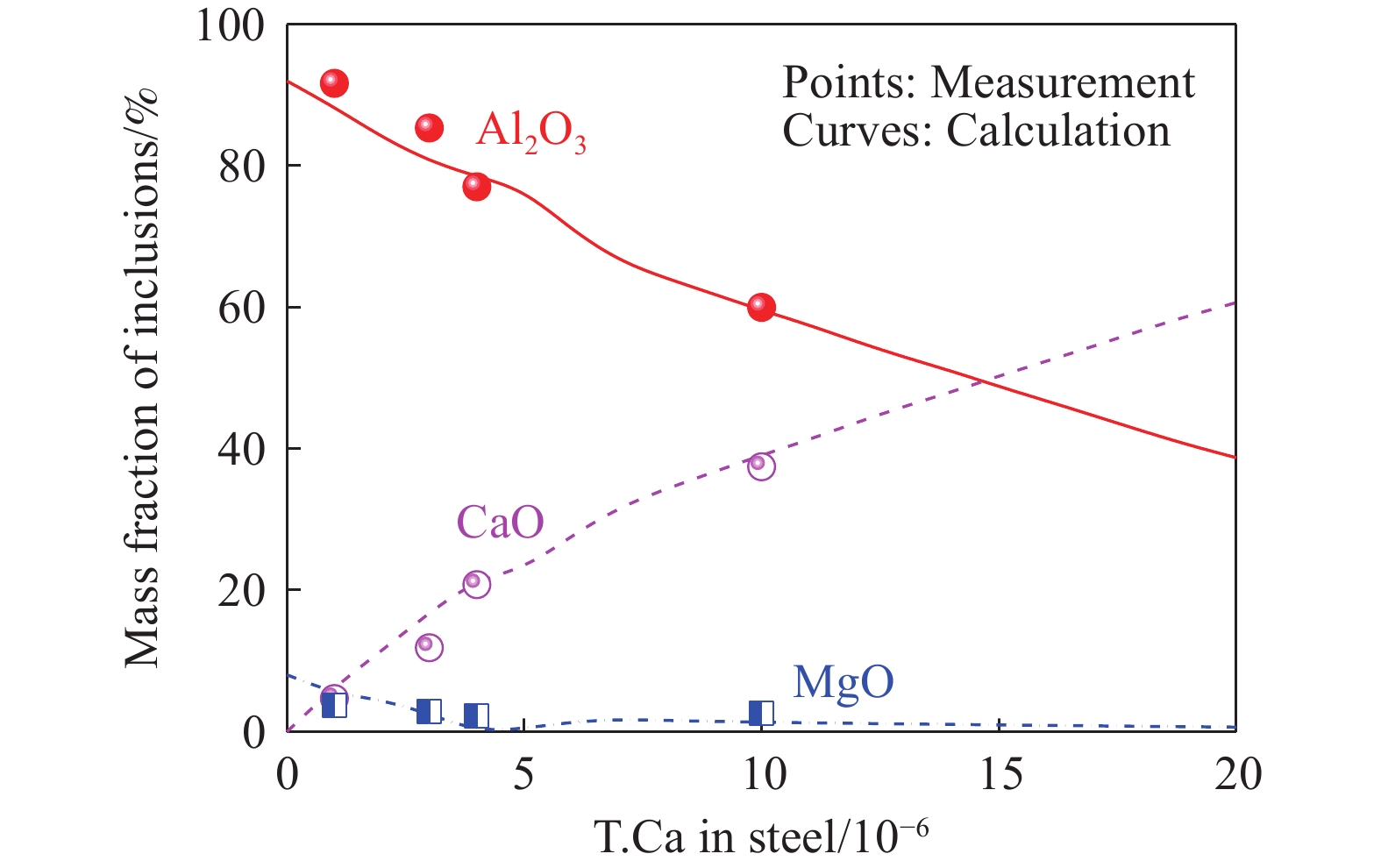

摘要: 大尺寸CaO?Al2O3類夾雜物容易引起軸承鋼疲勞失效,大尺寸CaO?Al2O3類夾雜物的控制是生產高端GCr15軸承鋼的關鍵因素之一。精煉過程中合金引入雜質元素、渣精煉和精煉過程中卷渣是鋁脫氧軸承鋼中大尺寸CaO?Al2O3類夾雜物的主要潛在來源。硅鐵合金通常用來提高軸承鋼的淬火和抗回火軟化性。本文通過實驗室實驗、樣品分析和熱力學計算,研究了硅鐵合金中金屬鈣元素對鋁脫氧鋼中夾雜物的影響。硅鐵合金主要由深色的硅相和淺色的硅鐵相組成,鈣元素在硅相和硅鐵相的界面處以金屬化合物形式存在。研究發現,加入硅鐵合金后,鋼中總鈣(T.Ca)含量增加,鋼中的Al2O3和MgO·Al2O3夾雜物被改性為CaO?Al2O3類夾雜物,夾雜物尺寸隨著夾雜物中CaO含量增加而減小,鋼中并未生成大尺寸CaO?Al2O3類夾雜物。隨著鋼中T.Ca含量增加,夾雜物平均尺寸降低,鋼中T.O含量增加,表明硅鐵合金中金屬鈣元素不會直接引起鋼中大尺寸CaO?Al2O3類夾雜物的生成。但是生成的小尺寸固相CaO?Al2O3類夾雜物在水口處粘附結瘤,結瘤物脫落后會成為鋼中大尺寸CaO?Al2O3類夾雜物的來源之一。

-

關鍵詞:

- 鋁脫氧鋼 /

- 硅鐵合金 /

- 金屬鈣元素 /

- CaOAl2O3類夾雜物 /

- 潔凈度

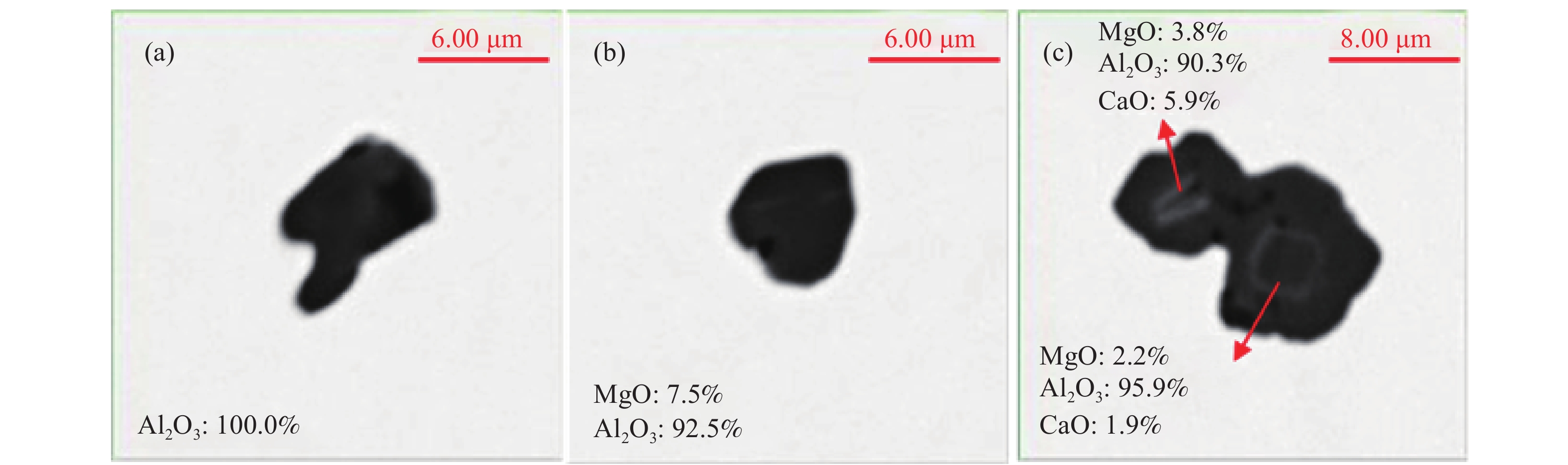

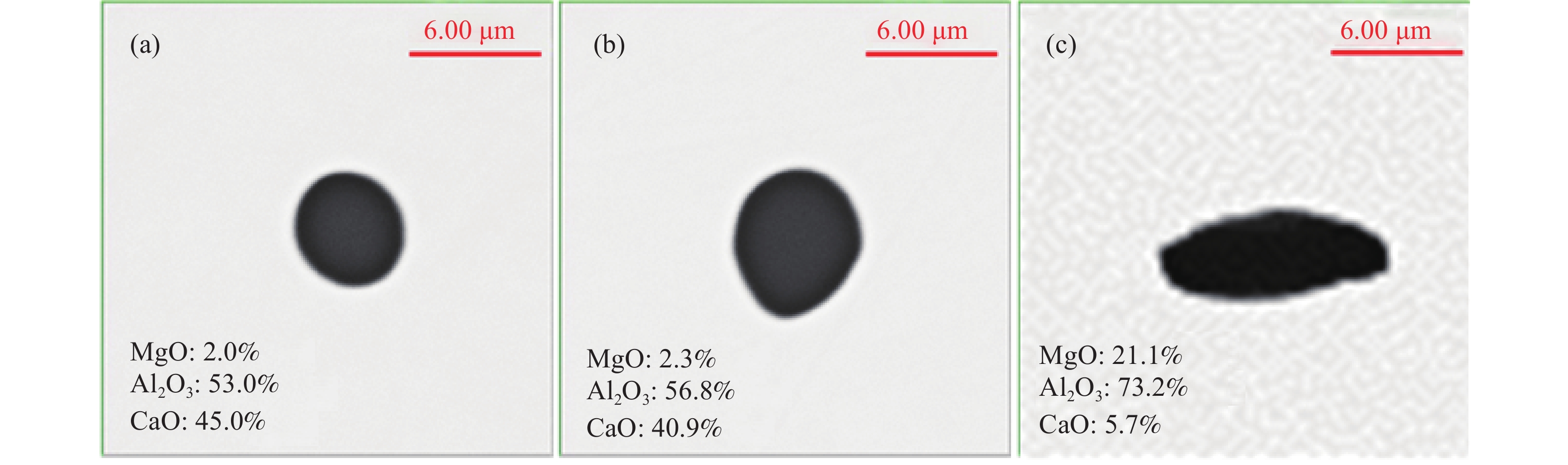

Abstract: Large CaO?Al2O3-type inclusions easily induce fatigue failure of bearing steels, so controlling large CaO?Al2O3-type inclusions is the key to producing high-quality GCr15-bearing steel. Impurity elements in alloys added during refining, slag refining, and slag entrainment during the refining process are the main potential sources for forming large CaO?Al2O3-type inclusions in Al-killed bearing steels. The ferrosilicon alloy is applied to improve the quenching and tempering softening resistance of Al-killed bearing steels. In this work, the effect of the calcium element in ferrosilicon alloys on inclusions in Al-killed bearing steel was studied through laboratory experiments, observations, and thermodynamic calculations. The ferrosilicon alloy mainly consists of the dark silicon and light ferrosilicon phases. The calcium element in ferrosilicon alloys exists as a metal compound at the interface between the silicon phase and the ferrosilicon phase. The total calcium (T.Ca) content in molten steel increases after adding the ferrosilicon alloy and modifying the Al2O3 and MgO·Al2O3 inclusions into CaO?Al2O3-type ones. The size of inclusions in the molten steel decreases with an increase in the CaO content in the inclusions. Large CaO?Al2O3-type inclusions are rarely generated. With the increase of the T.Ca in the molten steel, the T.O in the steel increases, whereas the average size of the inclusions decreases. It was observed that the calcium element in ferrosilicon alloys is not the direct cause for the formation of large size CaO?Al2O3 inclusions in the steel. However, the generated small, solid CaO?Al2O3-type inclusions clog the wall of the submerged entry nozzle, leading to dislodging of the big clogging lump into the molten steel. This lump is one of the reasons for large and irregularly shaped CaO?Al2O3 type inclusions in the steel product.-

Key words:

- Al-killed steel /

- ferrosilicon alloys /

- calcium element /

- CaO?Al2O3 type inclusions /

- cleanliness

-

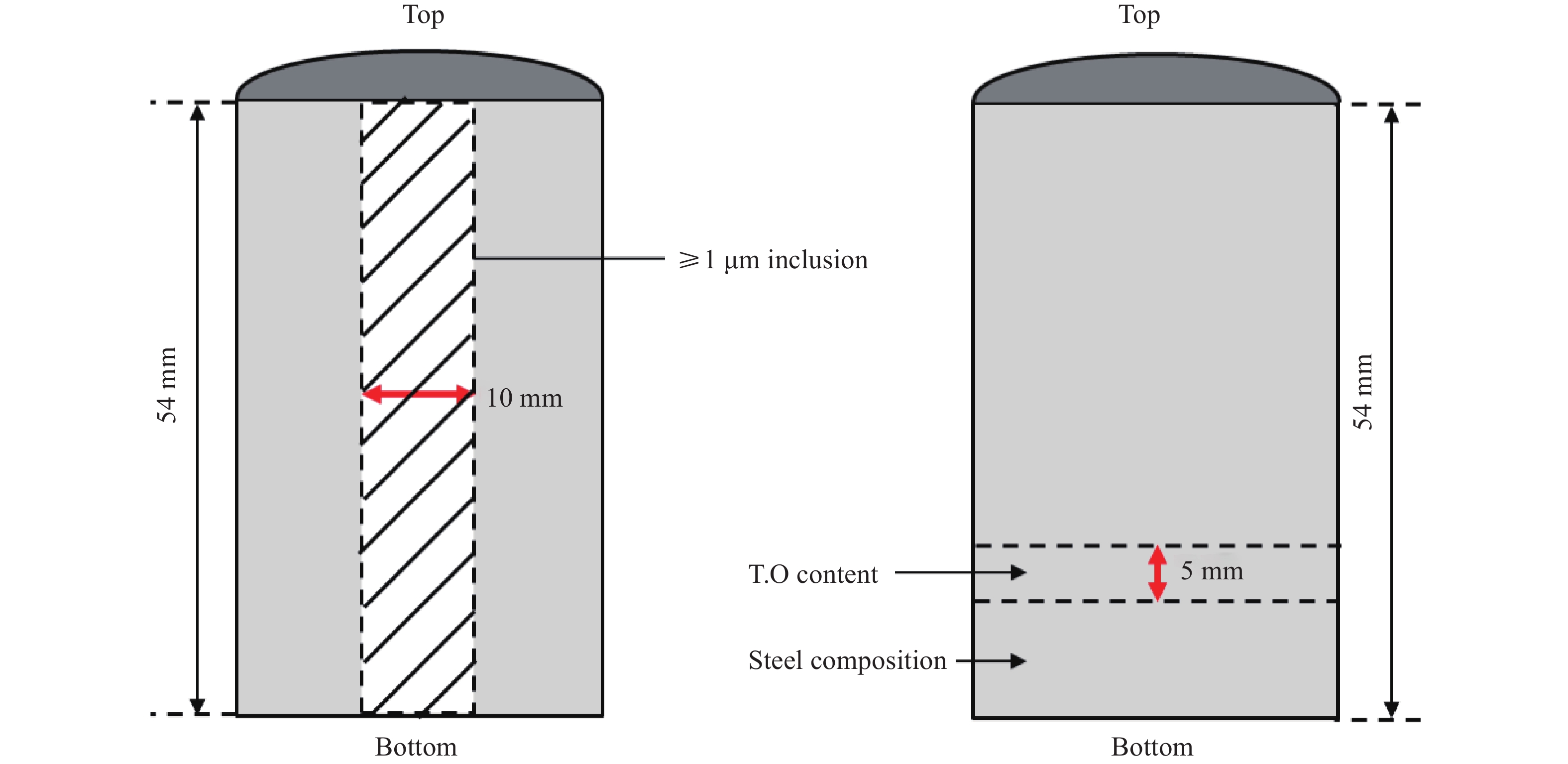

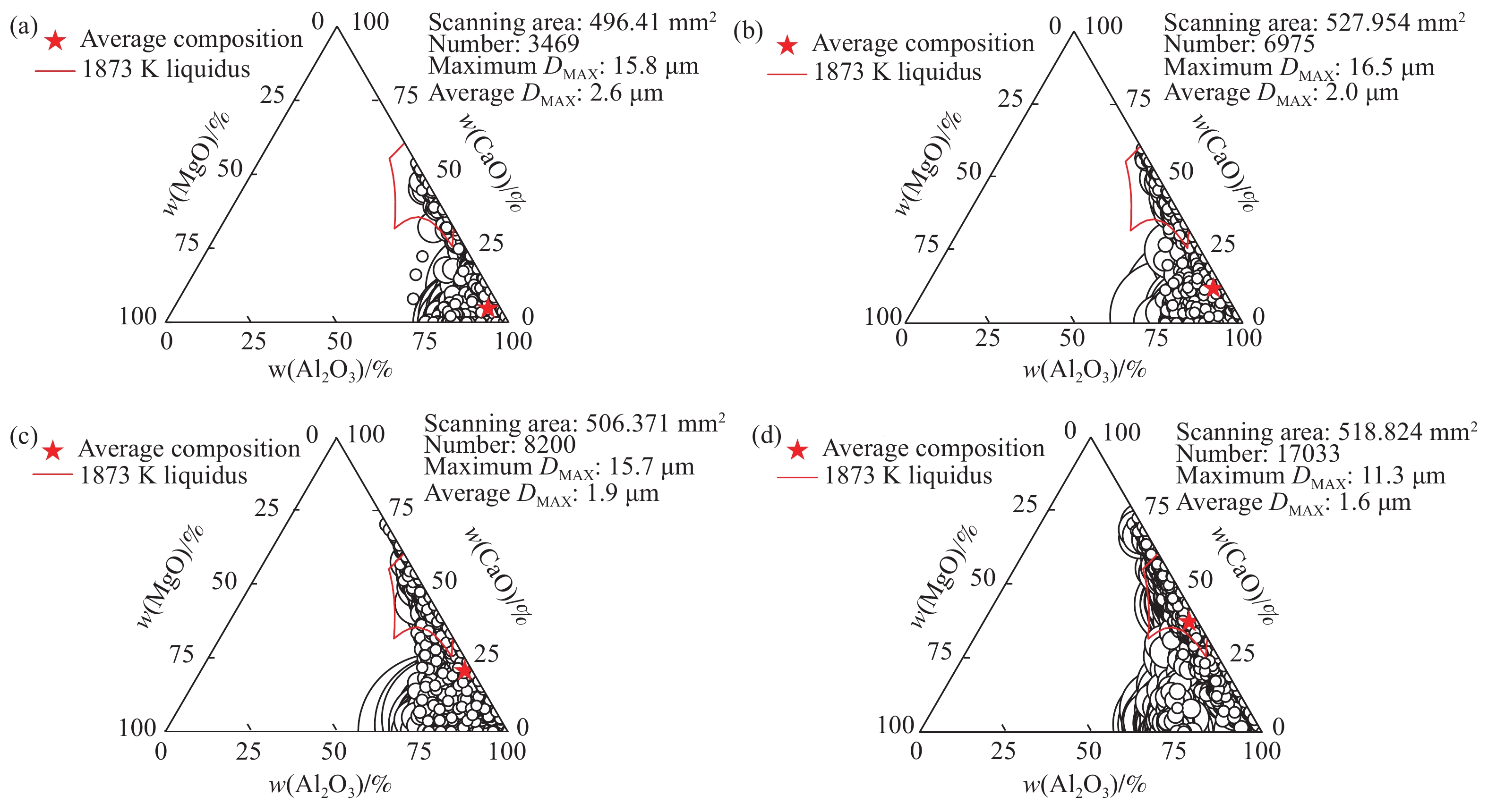

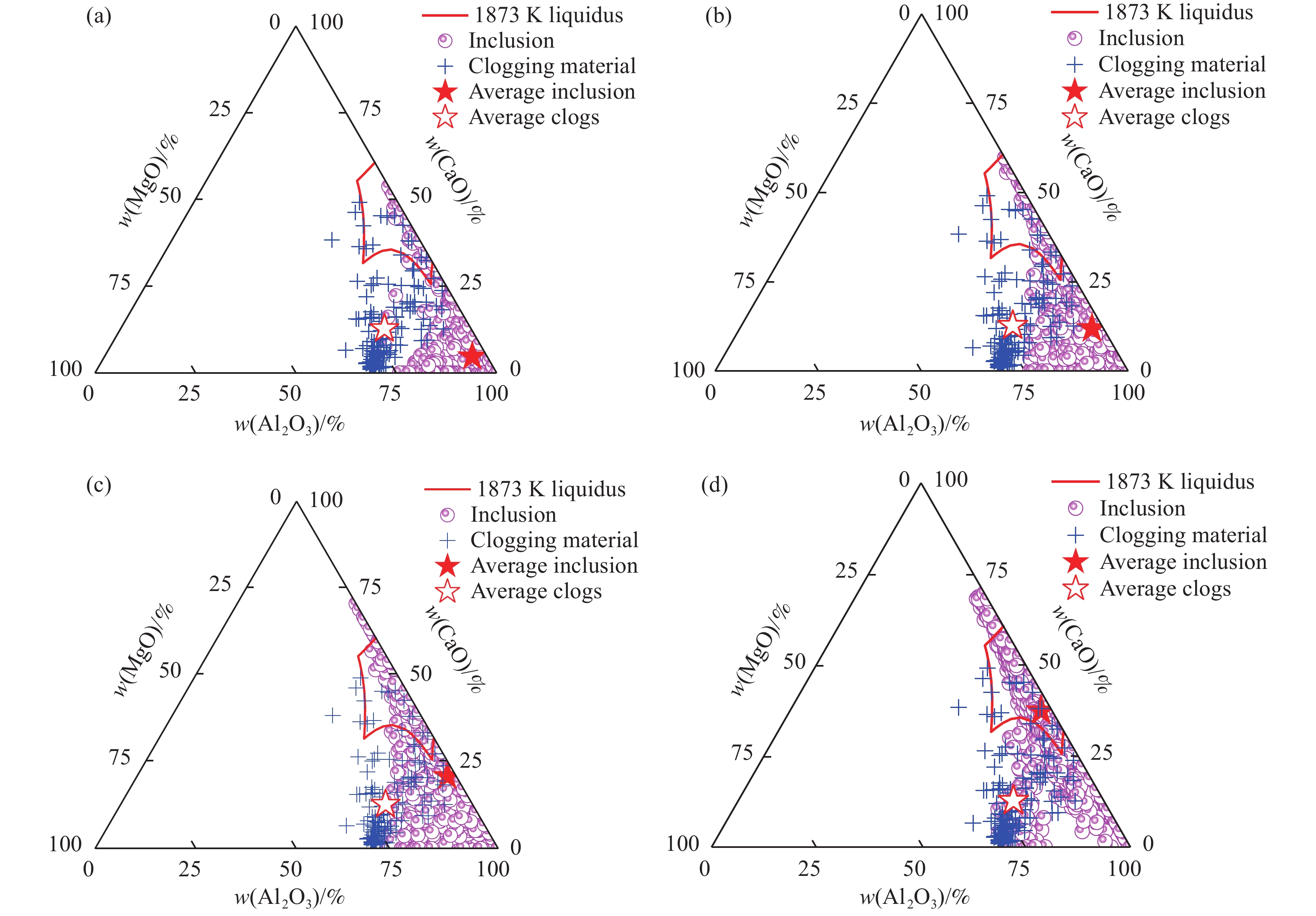

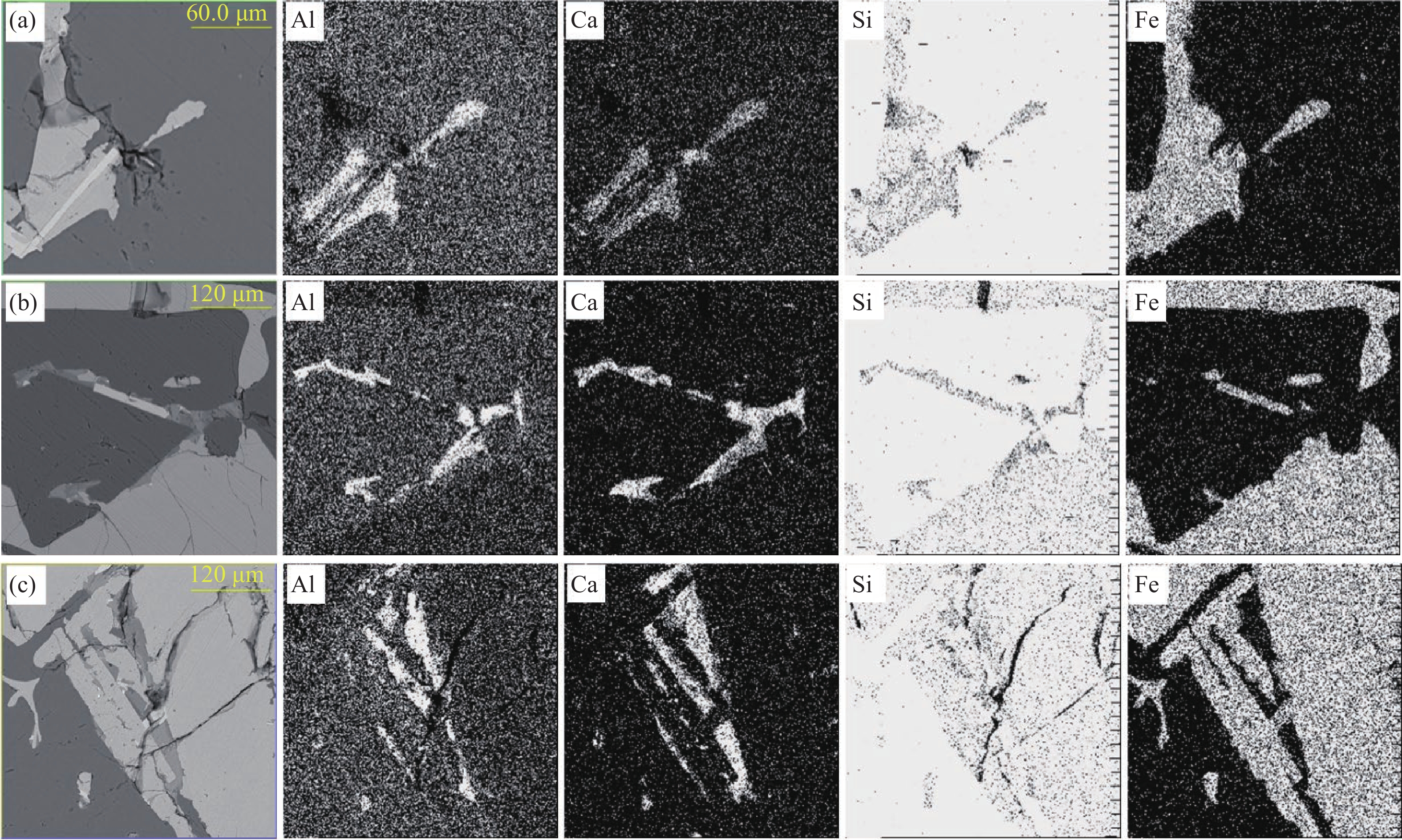

圖 10 加入不同含鈣量的硅鐵條件下鋼中夾雜物和水口結瘤物的成分對比. (a) 未加硅鐵; (b) 0.68% T.Ca; (c) 0.92% T.Ca; (d) 1.22% T.Ca

Figure 10. Composition comparison of clogging materials on the submerged entry nozzle and inclusions in the steel by adding ferrosilicon alloy containing different T.Ca contents: (a) not adding ferrosilicon alloy; (b) 0.68% T.Ca; (c) 0.92% T.Ca; (d) 1.22% T.Ca

表 1 硅鐵合金中鈣和鋁的質量分數

Table 1. Mass fraction of T.Ca and T.Al in ferrosilicon alloys

% Ferrosilicon T.Ca T.Al Type A 0.68 1.11 Type B 0.92 1.28 Type C 1.22 1.84 表 2 實驗后鋼成分(質量分數)

Table 2. Steel compositions after experiments

% Ferrosilicon C Cr Si Mn T.S T.Al T.Ca T.O Fe No addition 0.99 1.57 0.31 0.38 0.001 0.030 0.0001 0.0010 Balanced Type A 0.97 1.57 0.63 0.38 0.001 0.033 0.0003 0.0011 Balanced Type B 0.96 1.57 0.62 0.38 0.001 0.036 0.0004 0.0013 Balanced Type C 1.00 1.57 0.65 0.38 0.001 0.037 0.0010 0.0015 Balanced 表 3 文獻報道的 1873 K下γIG,θ,α和計算的對應c,Wad

Table 3. Reported γIG, θ, α from literatures, and calculated c, Wad

Mass fraction of inclusions/% $\gamma_{\text{IG} }$/(J·m?2) $ \theta $/(°) $ \alpha $/(°) $\gamma_{\text{MI} }$/(J·m?2) $ c $ $W_{\text{ad} }$/(J·m?2) CaO Al2O3 MgO 58.0 42.0 0 0.688[37] 54.3[37] 35.7[37] 1.206 0.577 1.178 49.4 50.6 0 0.669[37] 58.1[37] 38.6[37] 1.245 0.581 1.120 36.4 63.4 0 0.684[37] 65.9[37] 44.8[37] 1.303 0.587 1.077 20.0 80.0 0 0.619[41] 112.7[42] — 1.273 0.584 1.041 15.0 85.0 0 0.638[41] 112.7[42] — 1.292 0.586 1.041 10.0 90.0 0 0.659[41] 115.2[42] — 1.381 0.596 0.974 5.0 95.0 0 0.692[41] 123.4[42] — 1.626 0.620 0.762 0 71.7 28.3 0.512[43] 140.2[44] — 1.815 0.637 0.393 0 100.0 0 0.750[36] 144.0[45] — 2.122 0.661 0.324 www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Zhang L F. Non-metallic Inclusions in Steel: Fundamentals. Beijing: Metallurgical Industry Press, 2019張立峰. 鋼中非金屬夾雜物. 北京: 冶金工業出版社, 2019 [2] Zhang L F. Nonmetallic Inclusions in Steels: Industrial Practice. Beijing: Metallurgical Industry Press, 2019張立峰. 鋼中非金屬夾雜物: 工業實踐. 北京: 冶金工業出版社, 2019 [3] Li M, Wang X C, Duan J H, et al. Formation and controlling of Type-D inclusions in bearing steel. Chin J Eng, 2018, 40(Suppl 1): 31李明, 王新成, 段加恒, 等. 軸承鋼中D類夾雜物的形成與控制. 工程科學學報, 2018, 40(增刊1): 31 [4] Sugimoto S, Oi S. Development of high productivity process of ultra-high-cleanliness bearing steel. Sanyo Technical Report, 2018, 25(1): 50杉本晉一郎, 大井茂博. 超高清浄度軸受鋼の高生産性プロセスの開発. 山陽特殊製鋼技報, 2018, 25(1):50 [5] Long H, Cheng G G, Qiu W S, et al. Characteristics, sources analysis of large size inclusions and technical improvement during bearing steel production. China Metall, 2020, 30(9): 53 doi: 10.13228/j.boyuan.issn1006-9356.20200329龍鵠, 成國光, 丘文生, 等. 軸承鋼中大尺寸夾雜物的特征、來源及改進工藝. 中國冶金, 2020, 30(9):53 doi: 10.13228/j.boyuan.issn1006-9356.20200329 [6] Yang C Y, Luan Y K, Li D Z, et al. Very high cycle fatigue behavior of bearing steel with rare earth addition. Int J Fatigue, 2020, 131: 105263 doi: 10.1016/j.ijfatigue.2019.105263 [7] Yang C Y, Liu P, Luan Y K, et al. Study on transverse-longitudinal fatigue properties and their effective-inclusion-size mechanism of hot rolled bearing steel with rare earth addition. Int J Fatigue, 2019, 128: 105193 doi: 10.1016/j.ijfatigue.2019.105193 [8] Gu C, Bao Y P, Gan P, et al. An experimental study on the impact of deoxidation methods on the fatigue properties of bearing steels. Steel Res Int, 2018, 89(9): 1800129 doi: 10.1002/srin.201800129 [9] Kawakami K. Generation mechanisms of non-metallic inclusions in high-cleanliness steel. Sanyo Technical Report, 2007, 14(1): 22川上潔. 高清浄度鋼における介在物の生成起源. 山陽特殊製鋼技報, 2007, 14(1):22 [10] Ohta H, Kimura S, Mimura T, et al. Behavior of CaO containing inclusions during ladle refining of ultraclean bearing steel. Kobe Steel Eng Rep, 2011, 61(1): 98太田裕己, 木村世意, 三村毅, 等. 超清浄軸受鋼の取鍋精錬時におけるCaO含有介在物の挙動. 神戸製鋼技報, 2011, 61(1):98 [11] Chi Y G, Deng Z Y, Zhu M Y. Effect of ladle usage on cleanliness of bearing steel. Metall Mater Trans B, 2018, 49(1): 440 doi: 10.1007/s11663-017-1150-2 [12] Ma W J, Bao Y P, Wang M, et al. Effect of Mg and Ca treatment on behavior and particle size of inclusions in bearing steels. ISIJ Int, 2014, 54(3): 536 doi: 10.2355/isijinternational.54.536 [13] Zhu S X, Yu Z, Yin H, et al. Investigation on relationship between nozzle clogging and large inclusions in bearing steel bars. Steelmaking, 2017, 33(1): 73朱守欣, 于湛, 殷皓, 等. 軸承鋼水口結瘤與棒材中大型夾雜物關系研究. 煉鋼, 2017, 33(1):73 [14] Riyahimalayeri K, ?lund P, Selleby M. Effect of vacuum degassing on non-metallic inclusions in an ASEA-SKF ladle furnace. Ironmak Steelmak, 2013, 40(6): 470 doi: 10.1179/174328113X13711140547880 [15] Gong W, Jiang Z H, Zhan D P, et al. Thermodynamic analysis of magnesium behavior in bearing steel. Chin J Process Eng, 2009, 9(Suppl 1): 117龔偉, 姜周華, 戰東平, 等. 軸承鋼中鎂的行為熱力學分析. 過程工程學報, 2009, 9(增刊1): 117 [16] Chen X Y, Jiang Z H, Zhu M Y, et al. Modification behavior of magnesium on alumina inclusion in bearing steel GCr15. Special Steel, 2009, 30(4): 11 doi: 10.3969/j.issn.1003-8620.2009.04.004陳向陽, 姜周華, 朱苗勇, 等. 鎂對GCr15軸承鋼中氧化鋁夾雜的變質行為. 特殊鋼, 2009, 30(4):11 doi: 10.3969/j.issn.1003-8620.2009.04.004 [17] Wang B, Jiang Z H, Jiang M F. Inclusion modification in GCr15 bearing steel with Al-Mg alloy treatment. Chin J Nonferrous Met, 2006, 16(10): 1736 doi: 10.3321/j.issn:1004-0609.2006.10.014王博, 姜周華, 姜茂發. 鎂鋁合金處理GCr15軸承鋼夾雜物的變質. 中國有色金屬學報, 2006, 16(10):1736 doi: 10.3321/j.issn:1004-0609.2006.10.014 [18] Yang C Y, Zhuang Q, Liu H, et al. Analysis on modification behavior of rare earth to inclusions in highly clean bearing steel. China Metall, 2020, 30(9): 45楊超云, 莊權, 劉航, 等. 稀土變質高潔凈軸承鋼中夾雜物的行為分析. 中國冶金, 2020, 30(9):45 [19] Dong D X, Yang C Y, Hu Y S, et al. Analysis on modification behavior of rare earth to inclusions in high clean bearing steel. China Metall, 2020, 30(6): 30董大西, 楊超云, 胡云生, 等. 高潔凈軸承鋼中稀土變質夾雜物行為分析. 中國冶金, 2020, 30(6):30 [20] Yang C Y, Luan Y K, Li D Z, et al. Effect of RE on inclusions in highly clean bearing steel. Steelmaking, 2016, 32(4): 54楊超云, 欒義坤, 李殿中, 等. 稀土元素對高潔凈度軸承鋼中夾雜物的影響研究. 煉鋼, 2016, 32(4):54 [21] Li J X, Tang P, Pan Y H, et al. Thermodynamic analysis of the relationship between refining slag composition and inclusion type in bearing steel. Chin J Eng, 2016, 38(Suppl 1): 195李敬想, 唐萍, 潘銀虎, 等. 精煉渣成分與軸承鋼夾雜物類型關系熱力學分析. 工程科學學報, 2016, 38(增刊1): 195 [22] Ruan X J, Jiang Z H, Gong W, et al. Influence of refining slag on oxygen content and inclusions in bearing steel. Special Steel, 2008, 29(5): 1 doi: 10.3969/j.issn.1003-8620.2008.05.001阮小江, 姜周華, 龔偉, 等. 精煉渣對軸承鋼中氧含量和夾雜物的影響. 特殊鋼, 2008, 29(5):1 doi: 10.3969/j.issn.1003-8620.2008.05.001 [23] Cheng G, Zhang L F, Ren Y. Characterization and evolution of non-metallic inclusions in GCr15 bearing steels during cooling and solidification. Ironmak Steelmak, 2020, 47(10): 1217 doi: 10.1080/03019233.2020.1719315 [24] Zhang Y X, Zhang L F, Chu Y P, et al. Transformation of inclusions in a complicated-deoxidized heavy rail steels during heating. Steel Res Int, 2020, 91(9): 2000120 doi: 10.1002/srin.202000120 [25] Wang Y, Yang W, Zhang L F. Effect of cooling rate on oxide inclusions during solidification of 304 stainless steel. Steel Res Int, 2019, 90(7): 1900027 doi: 10.1002/srin.201900027 [26] Chen W B, Ren Y, Xu H K, et al. Evolution of inclusions in solid stainless steels during heat treatment process. Iron Steel, 2018, 53(10): 38陳為本, 任英, 徐海坤, 等. 熱處理過程固態不銹鋼中夾雜物的轉變. 鋼鐵, 2018, 53(10):38 [27] Yang W, Guo C B, Li C, et al. Transformation of inclusions in pipeline steels during solidification and cooling. Metall Mater Trans B, 2017, 48(5): 2267 doi: 10.1007/s11663-017-1012-y [28] Ren Y, Zhang L F, Pistorius P C. Transformation of oxide inclusions in type 304 stainless steels during heat treatment. Metall Mater Trans B, 2017, 48(5): 2281 doi: 10.1007/s11663-017-1007-8 [29] Taniguchi S, Kikuchi A. Mechanisms of collision and coagulation between fine particles in fluid. Tetsu-to-Hagane, 1992, 78(4): 527 doi: 10.2355/tetsutohagane1955.78.4_527 [30] Saffman P G, Turner J S. On the collision of drops in turbulent clouds. J Fluid Mech, 1956, 1(1): 16 doi: 10.1017/S0022112056000020 [31] Frenkel J. Kinetic Theory of Liquids, Chapter VI. New York: Dover Publications, 1955 [32] Cramb A W, Jimbo I. Calculation of the interfacial properties of liquid steel - slag systems. Steel Res, 1989, 60(3-4): 157 doi: 10.1002/srin.198900893 [33] Bretonnet J, Lucas L, Olette M. Experimental determination of the interfacial tensions between Fe-C alloys and molten slags. C R Hebd Seances Acad Sci, 1977, 285(2): 45 [34] Cheng L M, Zhang L F, Shen P. Interfacial phenomena in ironmaking and steelmaking. Chin J Eng, 2018, 40(10): 1139程禮梅, 張立峰, 沈平. 鋼鐵冶金過程中的界面現象. 工程科學學報, 2018, 40(10):1139 [35] Cheng L M, Zhang L F, Shen P. Fundamentals of interfacial wettability in ironmaking and steelmaking. Chin J Eng, 2018, 40(12): 1434程禮梅, 張立峰, 沈平. 鋼鐵冶金過程中的界面潤濕性的基礎. 工程科學學報, 2018, 40(12):1434 [36] Nogi K, Ogino K. Role of interfacial phenomena in deoxidation process of molten iron. Can Metall Q, 1983, 22(1): 19 doi: 10.1179/cmq.1983.22.1.19 [37] Bretonnet J, Lucas L, Olette M. Experimental method for the study of the interfacial properties between liquid metals and liquid slags. C R Hebd Seances Acad Sci, 1975, 280(19): 1169 [38] Tian Q R, Wang G C, Shang D L, et al. In situ observation of the precipitation, aggregation, and dissolution behaviors of TiN inclusion on the surface of liquid GCr15 bearing steel. Metall Mater Trans B, 2018, 49(6): 3137 doi: 10.1007/s11663-018-1411-8 [39] Nakajima K, Mu W Z, J?nsson P G. Assessment of a simplified correlation between wettability measurement and dispersion/coagulation potency of oxide particles in ferrous alloy melt. Metall Mater Trans B, 2019, 50(5): 2229 doi: 10.1007/s11663-019-01624-x [40] Mu W Z, J?nsson P G, Nakajima K. Prediction of intragranular ferrite nucleation from TiO, TiN, and VN inclusions. J Mater Sci, 2016, 51(4): 2168 doi: 10.1007/s10853-015-9527-6 [41] Choi J Y, Lee H G. Thermodynamic evaluation of the surface tension of molten CaO?SiO2?Al2O3 ternary slag. ISIJ Int, 2002, 42(3): 221 doi: 10.2355/isijinternational.42.221 [42] Shinozaki N, Echida N, Mukai K, et al. Wettability of Al2O3?MgO, ZrO2?CaO, Al2O3?CaO substrates with molten iron. Tetsu-to-Hagane, 1994, 80(10): 748 doi: 10.2355/tetsutohagane1955.80.10_748 [43] Yang G W, Wang X H, Huang F X, et al. Transient inclusion evolution during RH degassing. Steel Res Int, 2014, 85(1): 26 doi: 10.1002/srin.201300030 [44] Shen P. Study on Interfacial Phenomenon among Steel‒Slag‒Lining Refractory System [Dissertation]. Beijing: University of Science and Technology Beijing, 2017沈平. 冶金過程鋼液‒渣‒耐火材料間界面現象研究[學位論文]. 北京: 北京科技大學, 2017 [45] Sun L Y. Removal Behavior of Non-metallic Inclusions at the Interface of Slag and Steel [Dissertation]. Beijing: University of Science and Technology Beijing, 2013孫麗媛. 非金屬夾雜物在鋼渣界面的去除行為研究[學位論文]. 北京: 北京科技大學, 2013 -

下載:

下載: