-

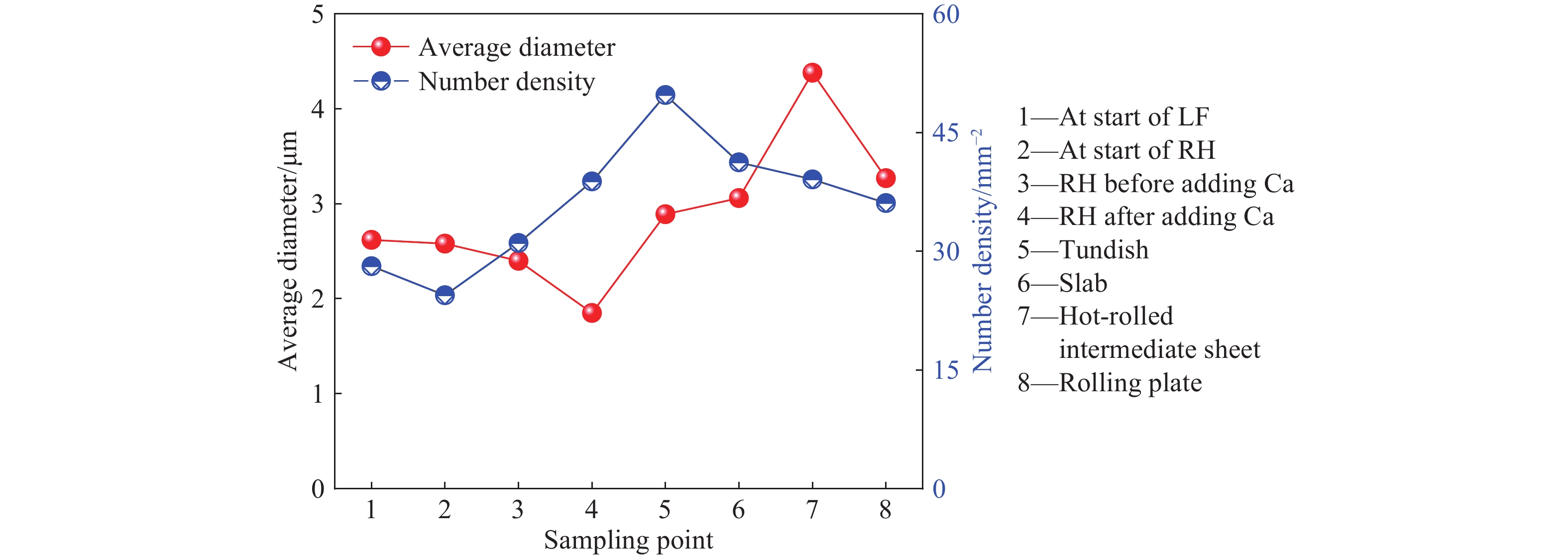

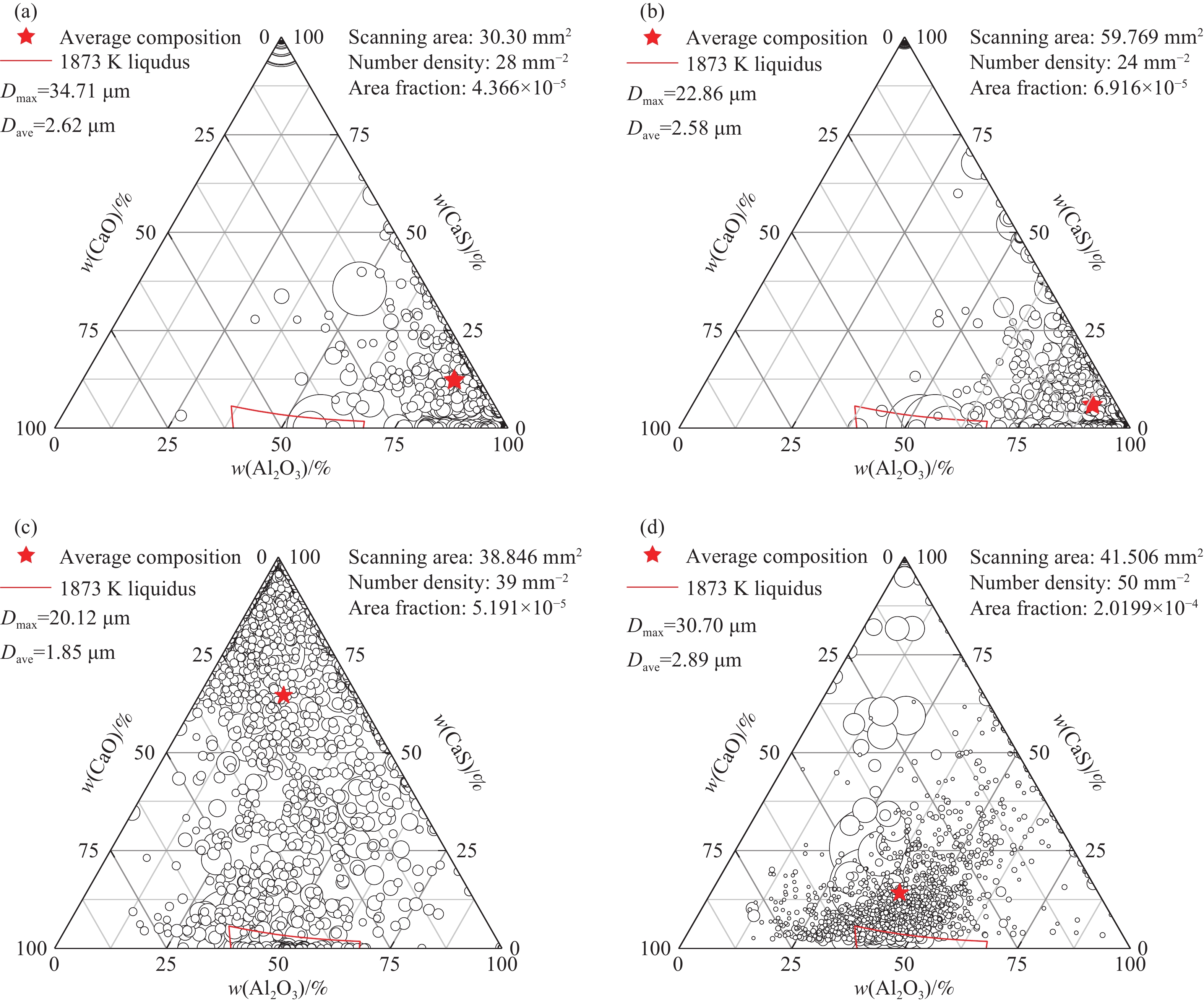

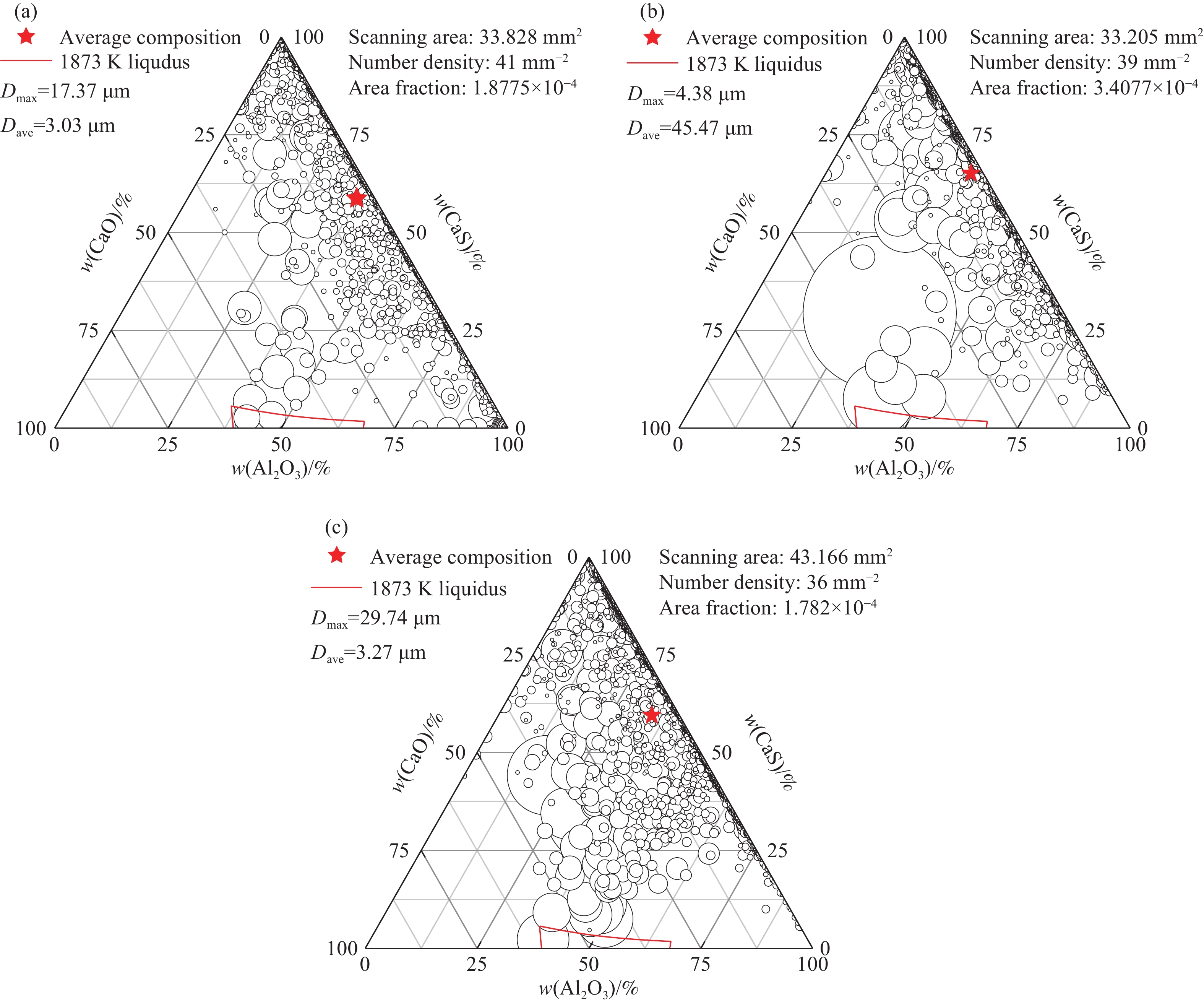

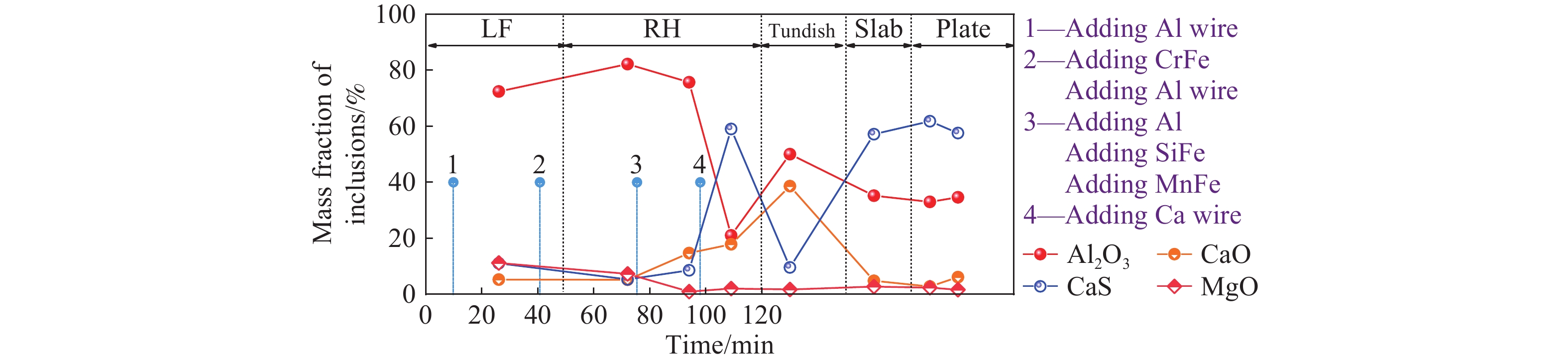

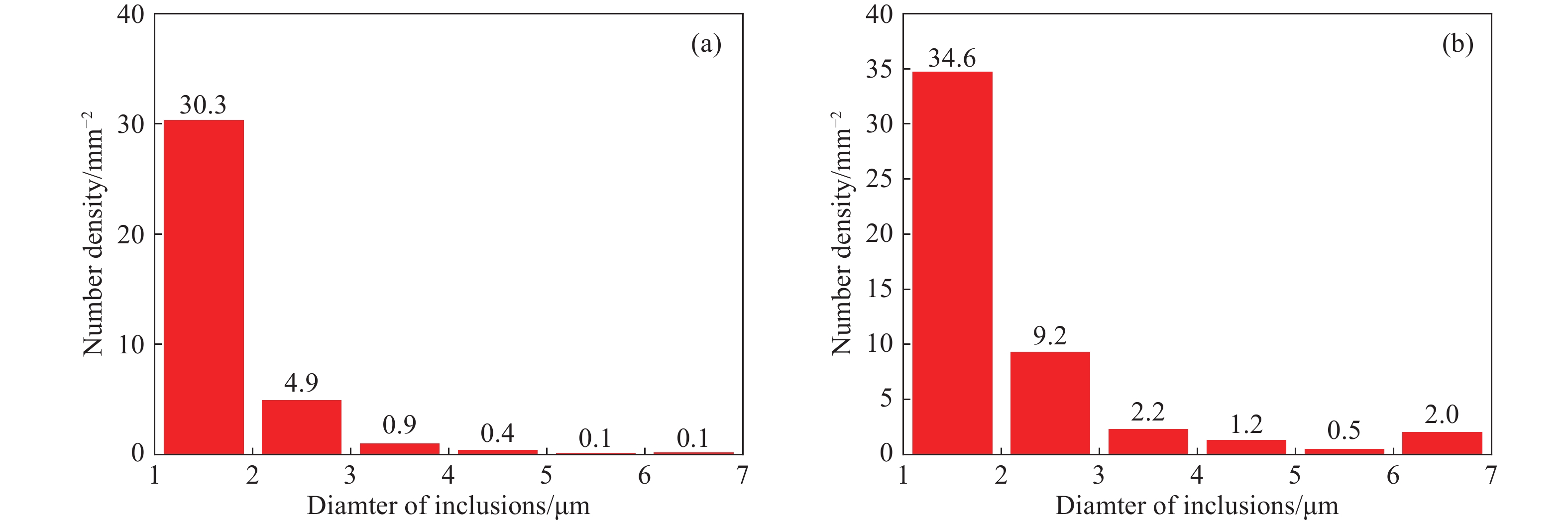

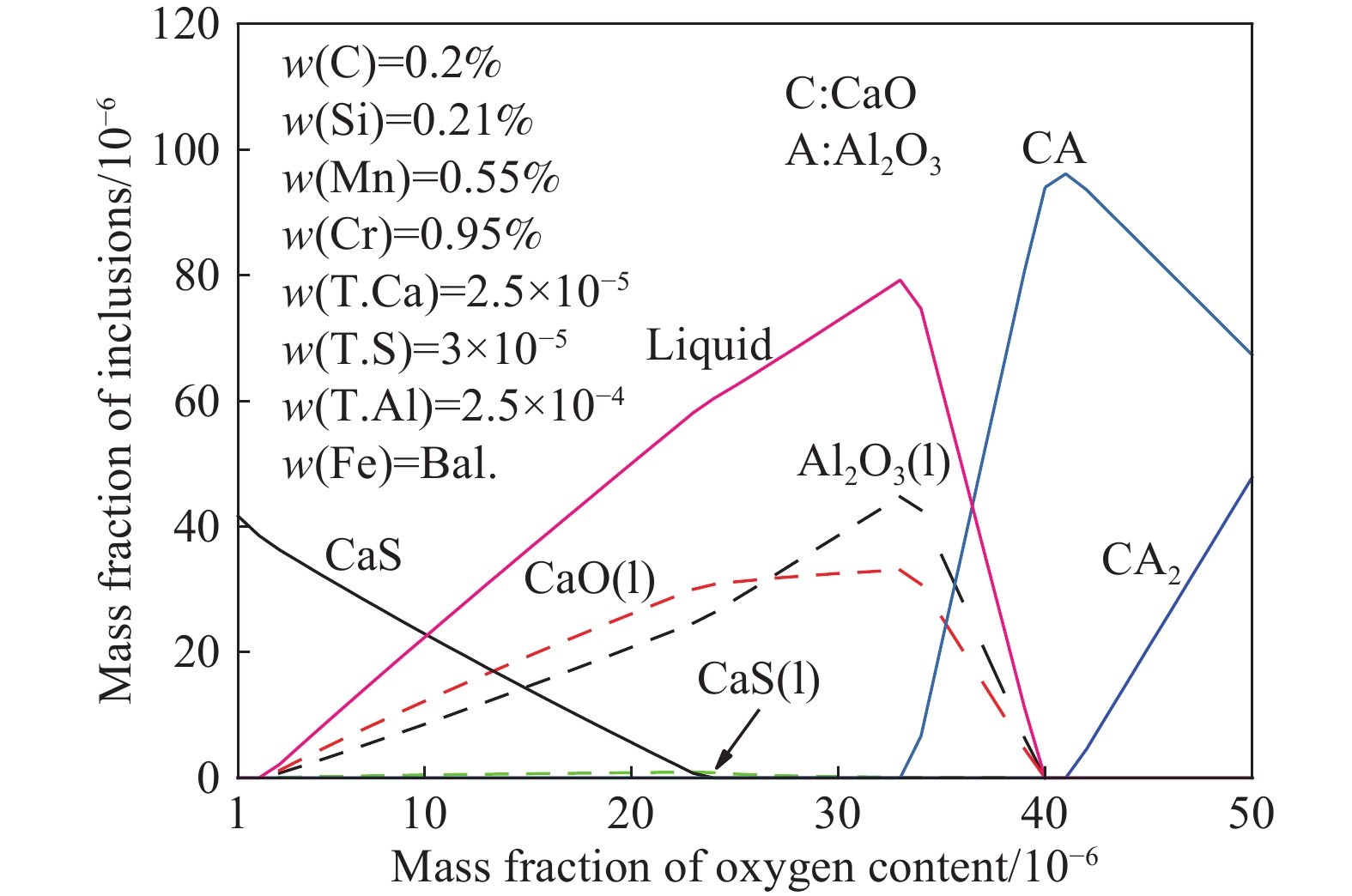

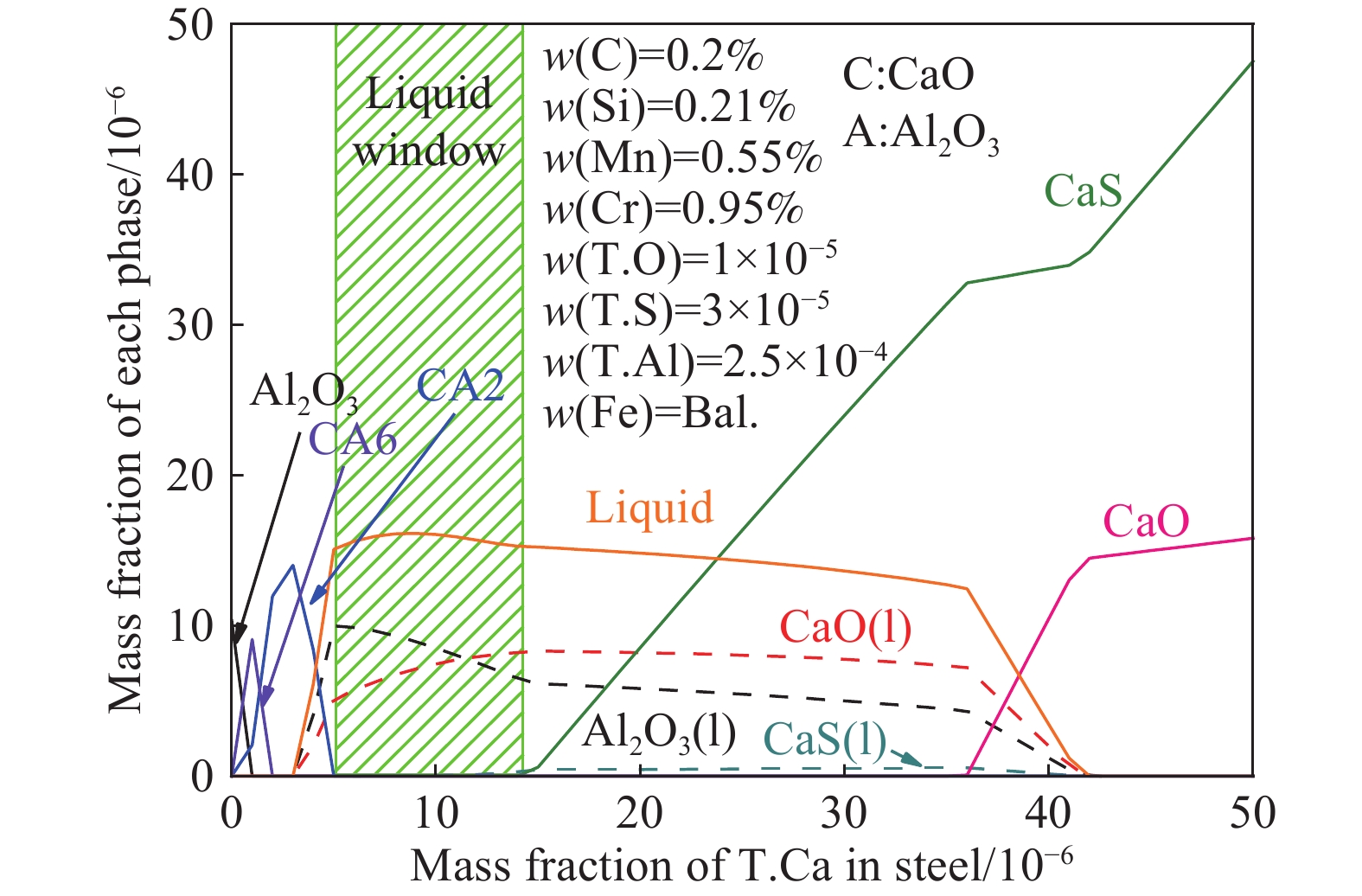

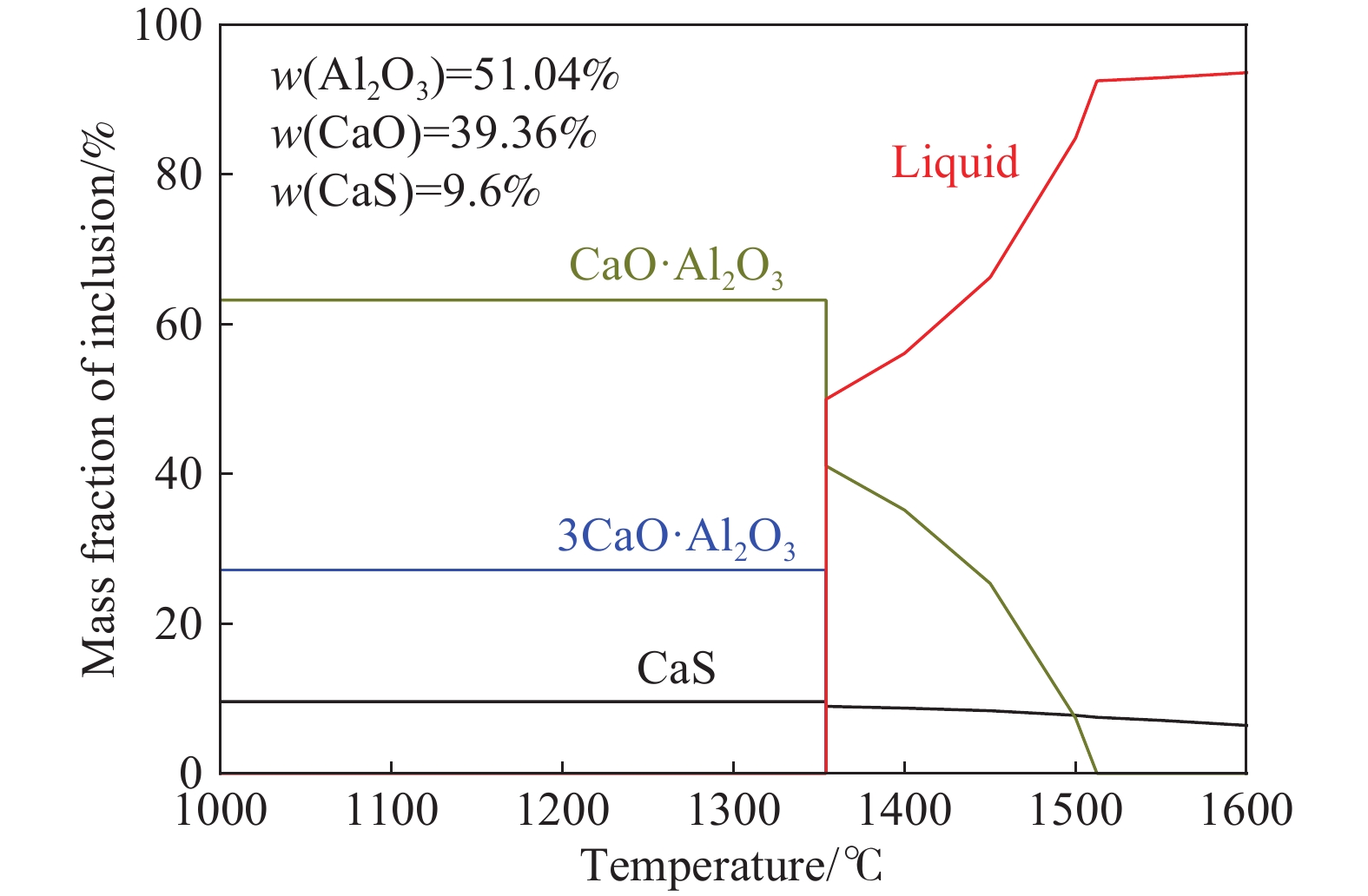

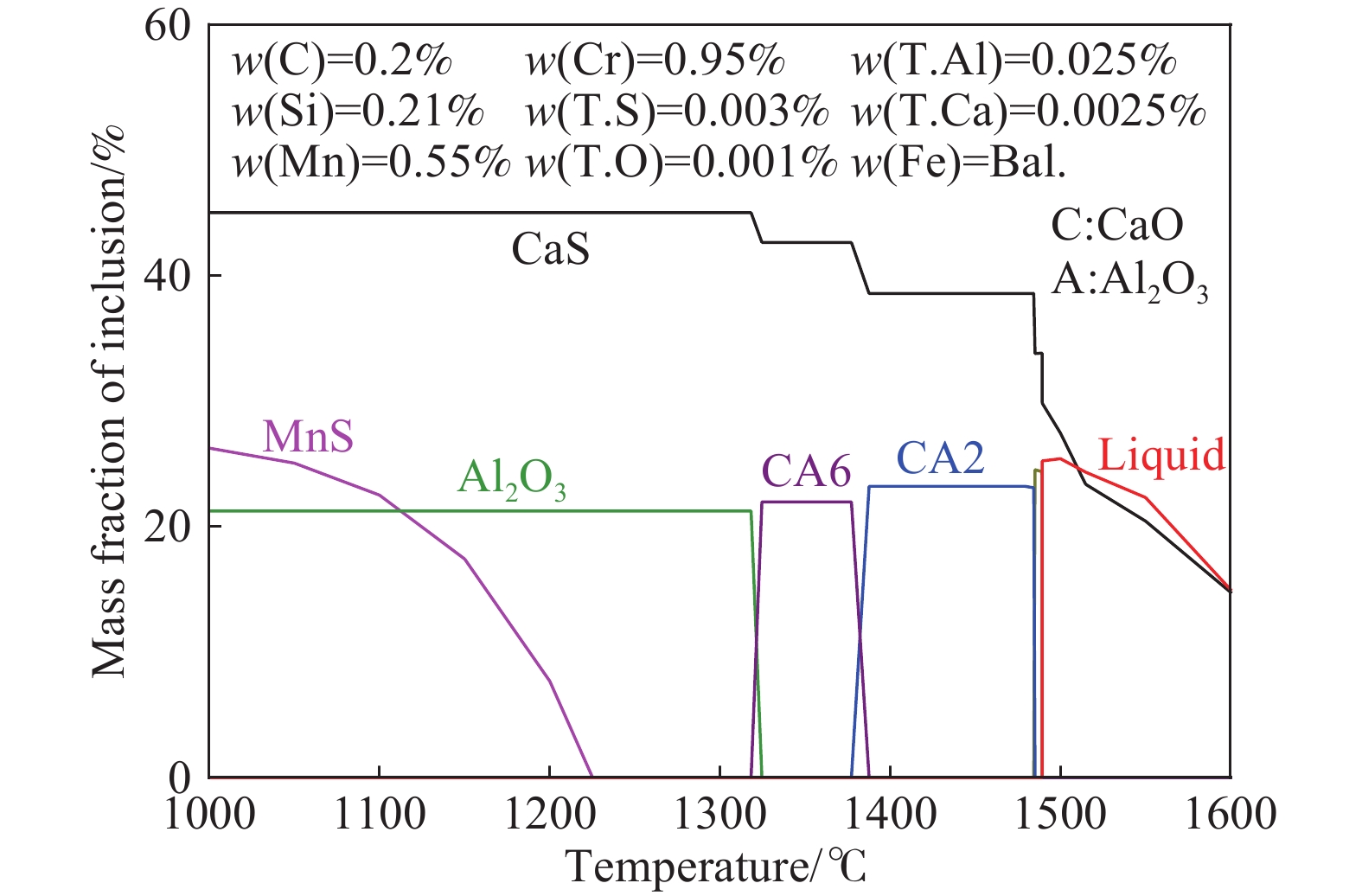

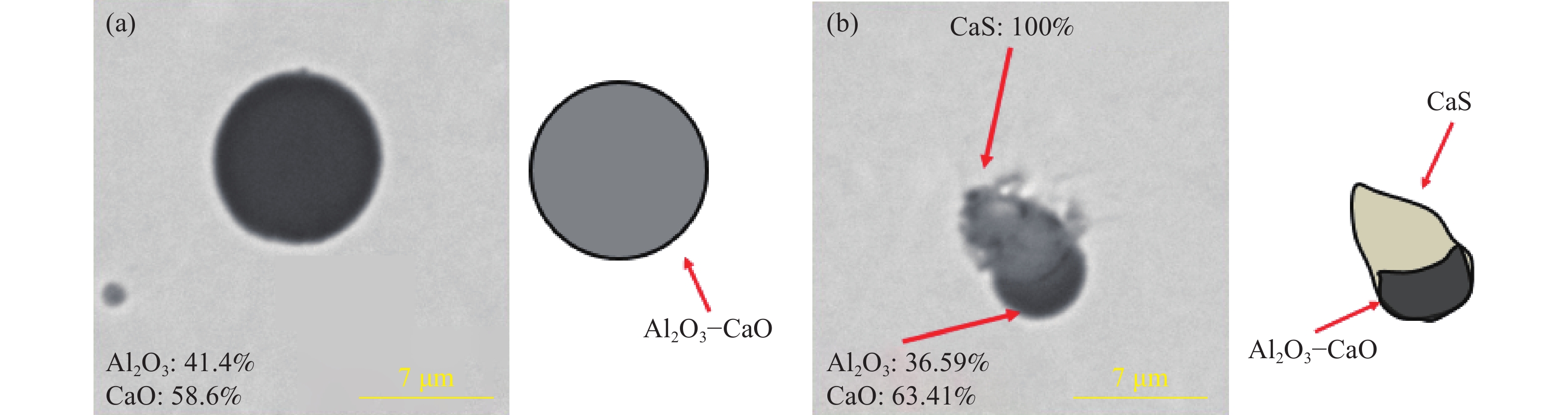

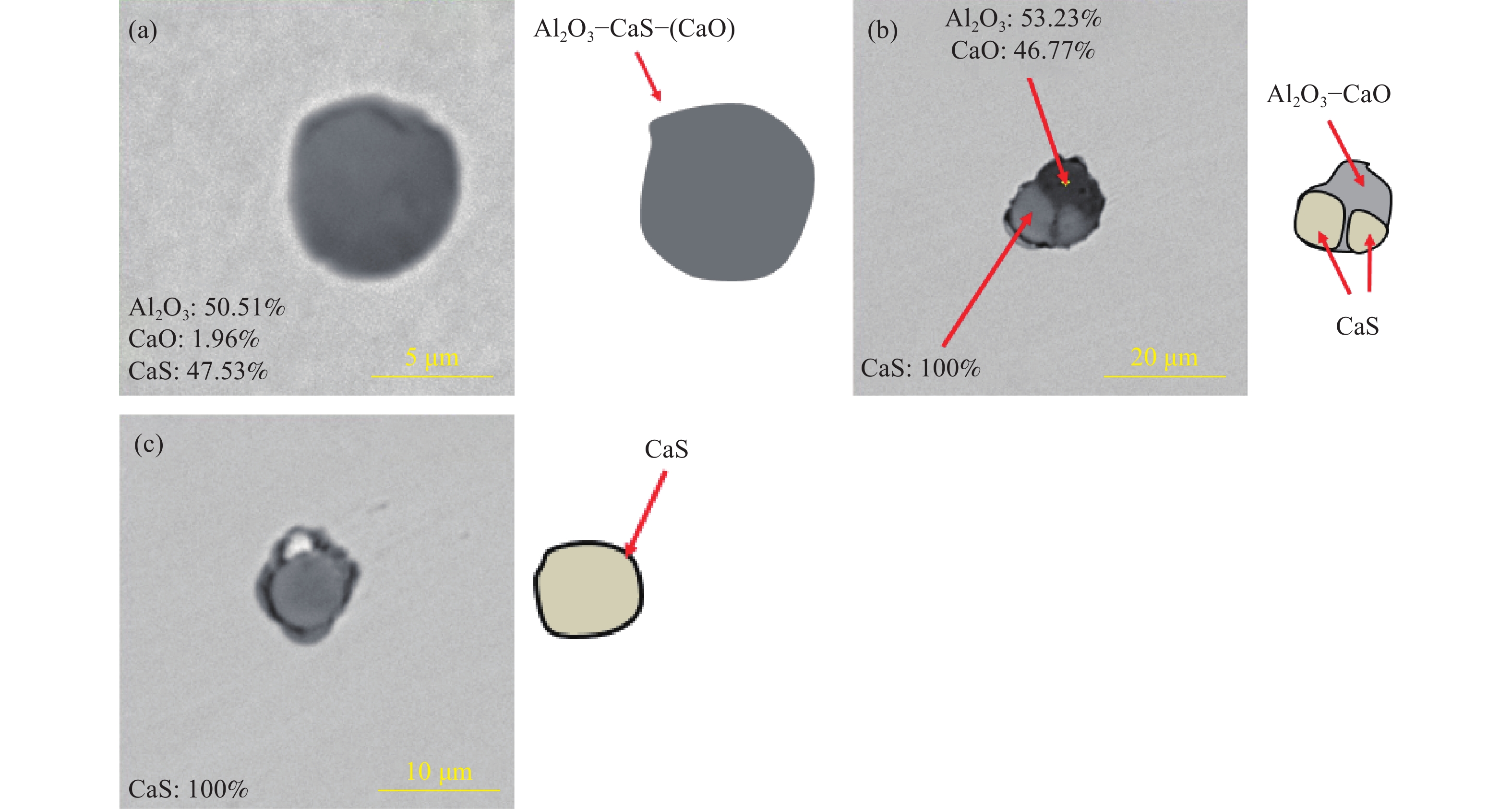

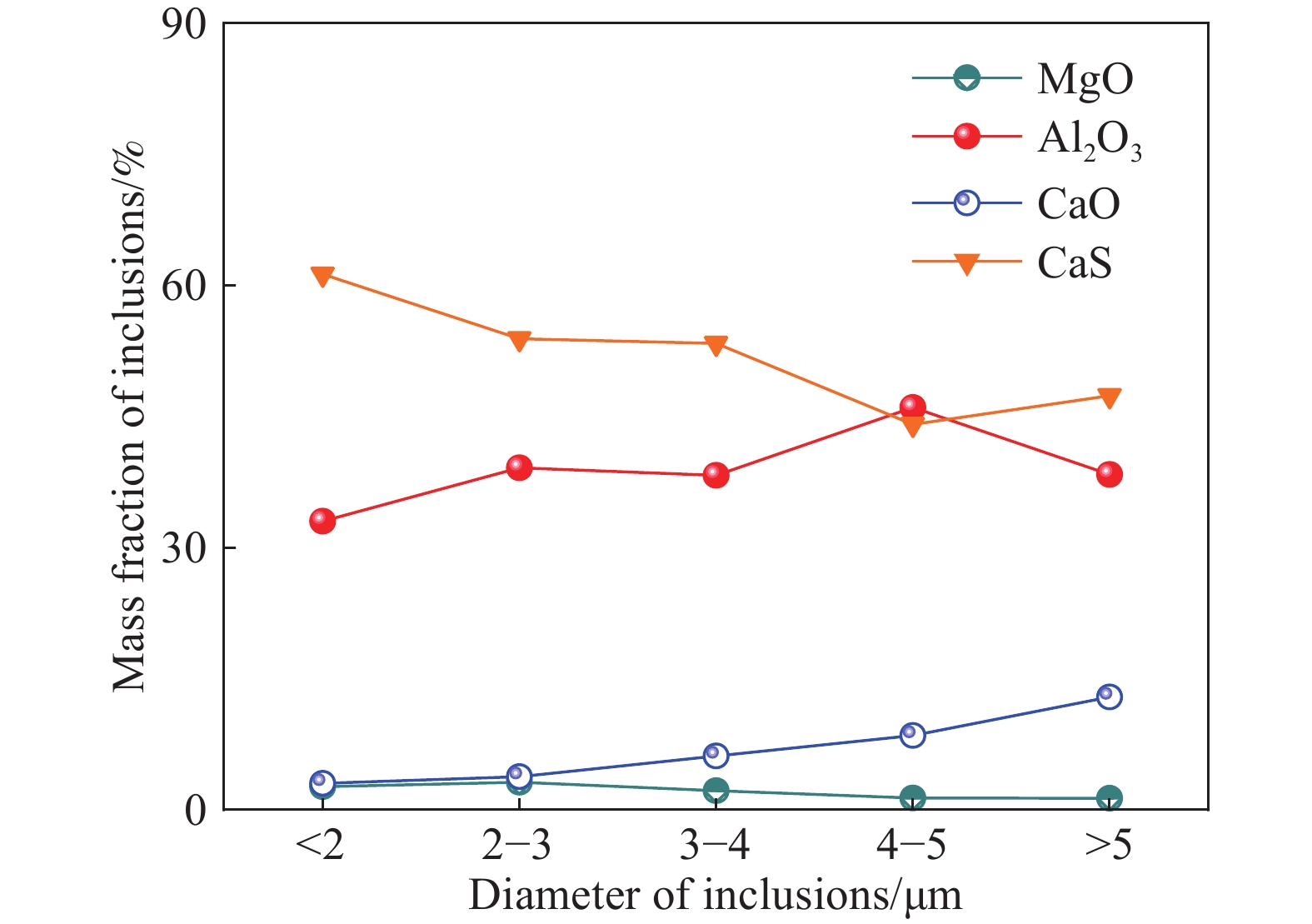

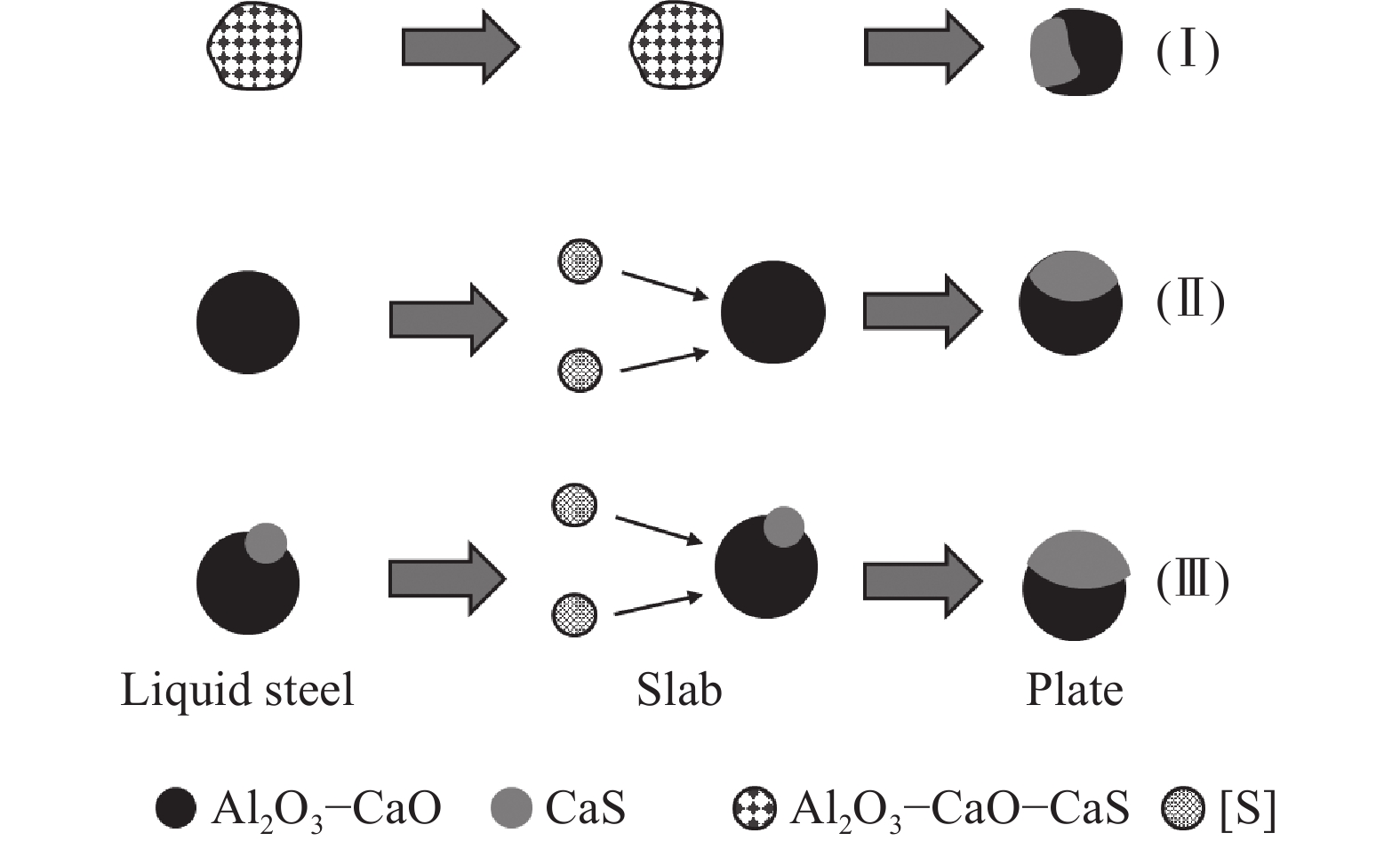

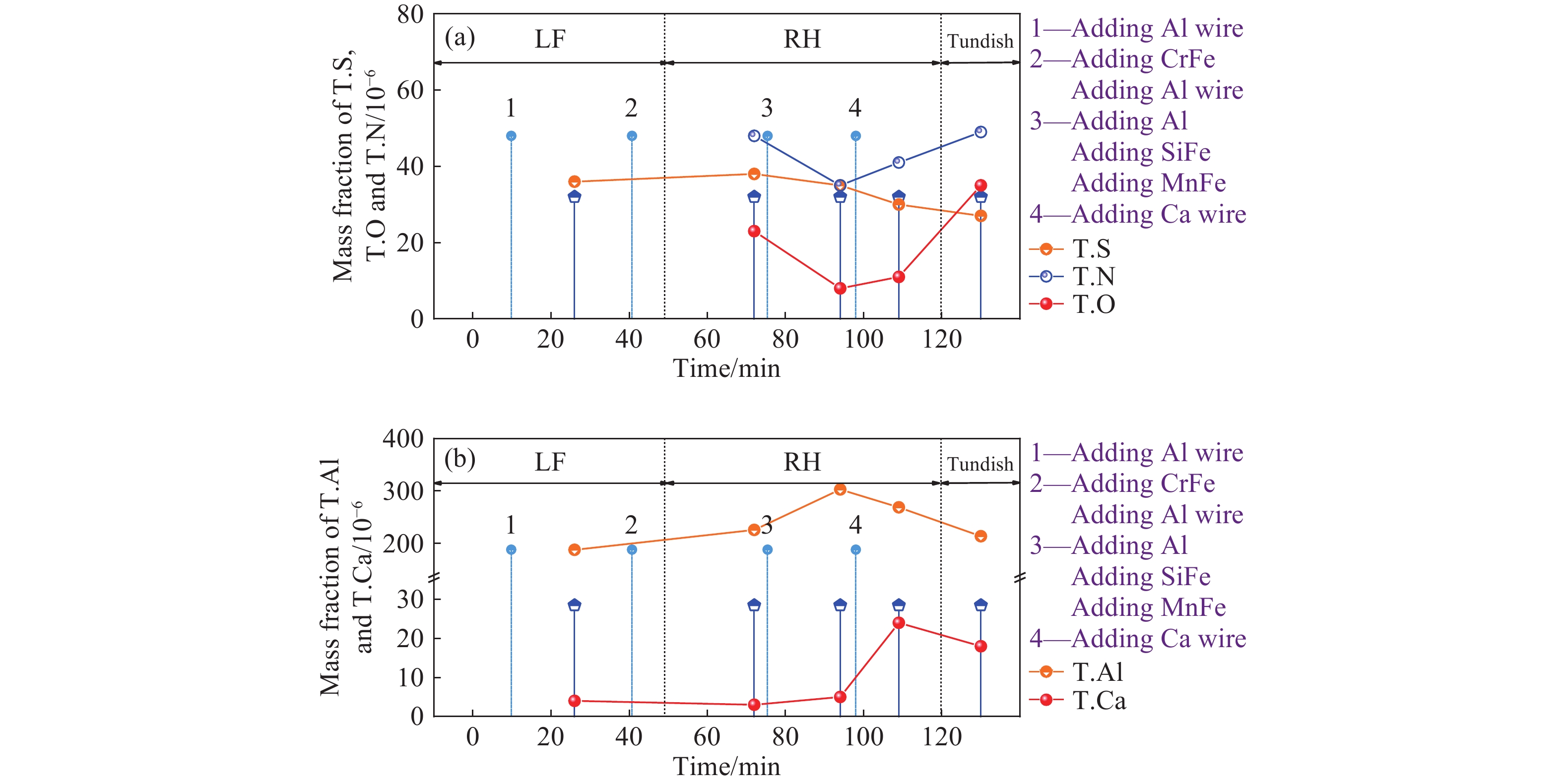

摘要: 為了進一步研究20CrMo合金鋼在生產過程中夾雜物的演變機理,實現對鋼中非金屬夾雜物的合理控制,保證生產順行,提高產品力學性能,針對“BOF→LF→RH→鈣處理→連鑄→熱軋”工序生產20CrMo合金鋼全流程中非金屬夾雜物的演變規律進行了研究。在LF精煉及RH精煉加鈣前鋼中非金屬夾雜物含有70%以上的Al2O3。鈣處理后,由于過量的鈣加入到鋼液中,夾雜物中CaS質量分數迅速增加至59%,Al2O3質量分數降低至21%。在連鑄過程中由于二次氧化的發生,夾雜物轉變為CaO?Al2O3,其中含有50%的Al2O3、39%的CaO和10%的CaS,并且夾雜物平均尺寸增加。在鋼的冷卻和凝固過程中,CaO質量分數降低至5%,CaS質量分數增加至57%,鋼中夾雜物轉變為Al2O3?CaO?CaS的復合夾雜物,同時含有少量大尺寸的CaO?Al2O3夾雜物。在鋼的軋制過程中,夾雜物中CaO含量進一步降低,CaS含量增加,夾雜物平均尺寸增加,形成了CaO?Al2O3與CaS黏結型的復合夾雜物與Al2O3?CaS復合夾雜物。對CaO-Al2O3與CaS黏結型的復合夾雜物的形成原因進行了討論。Abstract: 20CrMo alloy steel is commonly used to produce high-pressure pipes, gears, automobile parts, etc., and there are stringent requirements for its yield strength, tensile strength, and impact energy. In the actual production process, the existence of nonmetallic inclusions has an important impact on the properties of 20CrMo steel; therefore, studying the evolution of inclusions in the process is necessary. To further examine the evolutionary mechanism of inclusions in the overall production process, the evolution of nonmetallic inclusions in a 20CrMo alloy steel produced via the route of “Basic oxygen furnace (BOF)→Ladle furnace refining (LF)→ Vacuum cycle degassing process (RH)→ calcium treatment→ Continuous casting (CC)→ hot rolling” was studied. This process ensured a smooth production process and improved the mechanical properties of the products. Al2O3 was the main inclusions in the steel during LF and RH refining, which was up to 70%. After calcium treatment, CaS in inclusions increased to 59% and Al2O3 decreased to 21% due to the excessive mixing of calcium into the molten steel. Due to reoxidation during continuous casting, inclusions were transformed to CaO–Al2O3, with 50% Al2O3, 39% CaO, and 10% CaS. And the average diameter of inclusions also increased, which was detrimental to the mechanical properties of the steel. After cooling and solidification of the steel, CaO decreased to 5% and CaS increased to 57%. Inclusions in the steel were transformed into Al2O3–CaO–CaS, and a small amount of large-sized CaO–Al2O3 was also observed. During the rolling process of steel, the CaO content in inclusions further decreased while the CaS content and the diameter of inclusions increased. Moreover, two types of inclusions were observed in the hot-rolled plate, one being Al2O3–CaS compound inclusions, whose size was relatively small, and the other being CaO–Al2O3–CaS compound inclusions. Reasons for the formation of compound inclusions consisting of CaO–Al2O3 and CaS were also discussed.

-

Key words:

- alloy steel /

- calcium treatment /

- inclusions /

- reoxidation /

- solidification

-

表 1 20CrMo合金鋼化學成分(質量分數)

Table 1. Chemical composition of 20CrMo steel

% C Si Mn Cr Mo T.Al T.S T.Ca 0.2 0.21 0.55 0.95 0.2 0.025 <0.003 0.0025 www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Fan T, Yang Q K, Xie J B, et al. Effect of Mg on the inclusions in 20CrMo gear steel. Iron Steel Vanadium Titanium, 2019, 40(6): 149樊田, 楊乾坤, 謝劍波, 等. 鎂對20CrMo齒輪鋼中夾雜物的影響. 鋼鐵釩鈦, 2019, 40(6):149 [2] Guo D Y, Wu X D, Chen R L, et al. Research on precipitation of inclusions in calcium- treated sulfur- containing 20CrMo gear steel. Iron Steel Vanadium Titanium, 2012, 33(6): 69 doi: 10.7513/j.issn.1004-7638.2012.06.015郭登仰, 吳曉東, 陳瑞瀧, 等. 鈣處理含硫20CrMo齒輪鋼夾雜物析出研究. 鋼鐵釩鈦, 2012, 33(6):69 doi: 10.7513/j.issn.1004-7638.2012.06.015 [3] Luo H X, Zhang J, Qi L N. Study on heat treatment process and force analysis for oil drill pipes of 20CrMo. Hot Work Technol, 2017, 46(20): 211羅懷曉, 張劍, 齊麗娜. 20CrMo鋼石油鉆桿受力分析與熱處理工藝研究. 熱加工工藝, 2017, 46(20):211 [4] Li C. Carburizing and hardening of compressor main shaft of 20CrMo steel. Heat Treat, 2020, 35(2): 55 doi: 10.3969/j.issn.1008-1690.2020.02.015李春. 20CrMo鋼壓縮機主軸的滲碳淬火. 熱處理, 2020, 35(2):55 doi: 10.3969/j.issn.1008-1690.2020.02.015 [5] Zhang L F, Thomas B. G. Alumina Inclusion Behavior During Steel Deoxidation // 7th European Electric Steelmaking Conference. Venice, 2002: 2.77 [6] Zhang L F, Thomas B G. State of the art in the control of inclusions during steel ingot casting. Metall Mater Trans B, 2006, 37(5): 733 doi: 10.1007/s11663-006-0057-0 [7] Zhang L F. State of the art in the control of inclusions in tire cord steels - a review. Steel Res Int, 2006, 77(3): 158 doi: 10.1002/srin.200606370 [8] Zhang L F. Non-metallic Inclusions in Steels. Beijing: Metallurgical Industry Press, 2019張立峰. 鋼中非金屬夾雜物. 北京: 冶金工業出版社, 2019 [9] Hu Y, Chen W Q, Han H B, et al. Influence of calcium treatment on cleanness and fatigue life of 60Si2MnA spring steel. Ironmaking Steelmaking, 2017, 44(1): 28 doi: 10.1080/03019233.2016.1153026 [10] Zhang A M. Effect of non-metallic inclusion on property of steel. Phys Exam Test, 2006, 24(4): 42張愛梅. 非金屬夾雜物對鋼性能的影響. 物理測試, 2006, 24(4):42 [11] Zhang L F. Discussion on the index of steel cleanliness. Steelmaking, 2019, 35(3): 1張立峰. 關于鋼潔凈度指數的討論. 煉鋼, 2019, 35(3):1 [12] Sun D L, Li T, Zhao C L, et al. Study on large particle inclusion origin in the 20CrMo steel by tracer method. Ind Heat, 2018, 47(1): 27 doi: 10.3969/j.issn.1002-1639.2018.01.008孫大利, 李濤, 趙昌玲, 等. 20CrMo鋼中大顆粒夾雜物來源的示蹤研究. 工業加熱, 2018, 47(1):27 doi: 10.3969/j.issn.1002-1639.2018.01.008 [13] Li W, Zhu X, Yao J J, et al. Hydrogen traps and hydrogen induced cracking in 20CrMo steel. ISIJ Int, 2017, 57(1): 170 doi: 10.2355/isijinternational.ISIJINT-2016-281 [14] Ding C, Wang J Y, Liu J L. Analysis on fracture failure of 20CrMo automotive bearing. Hot Work Technol, 2011, 40(14): 197 doi: 10.3969/j.issn.1001-3814.2011.14.064丁晨, 王軍藝, 劉俊亮. 20CrMo汽車軸承斷裂失效分析. 熱加工工藝, 2011, 40(14):197 doi: 10.3969/j.issn.1001-3814.2011.14.064 [15] Wu X D, Zhang D X, Chen R L. Application of calcium treatment to sulfur gear steel 20CrMo. Adv Mater Res, 2014, 936: 1323 doi: 10.4028/www.scientific.net/AMR.936.1323 [16] Zhang L F. Several important scientific research points of non-metallic inclusions in steel. Steelmaking, 2016, 32(4): 1張立峰. 鋼中非金屬夾雜物幾個需要深入研究的課題. 煉鋼, 2016, 32(4):1 [17] Yang W, Zhang L F, Wang X H, et al. Characteristics of inclusions in low carbon Al-killed steel during ladle furnace refining and calcium treatment. ISIJ Int, 2013, 53(8): 1401 doi: 10.2355/isijinternational.53.1401 [18] Ren Y, Zhang L F, Li S S. Transient evolution of inclusions during calcium modification in linepipe steels. ISIJ Int, 2014, 54(12): 2772 doi: 10.2355/isijinternational.54.2772 [19] Zhang L F, Liu Y, Zhang Y, et al. Transient evolution of nonmetallic inclusions during calcium treatment of molten steel. Metall Mater Trans B, 2018, 49(4): 1841 doi: 10.1007/s11663-018-1289-5 [20] Ito Y I, Suda M, Kato Y, et al. Kinetics of shape control of alumina inclusions with calcium treatment in line pipe steel for sour service. ISIJ Int, 1996, 36(Supp l): S148 [21] Yang J, Chen B T, Tang W, et al. Experimental study to improve the castability of aluminum killed cold heading steel. Steel Res Int, 2013, 84(8): 703 doi: 10.1002/srin.201200246 [22] Zhang L F. Nonmetallic Inclusions in Steels: Industrial Practice. Beijing: Metallurgical Industry Press, 2019張立峰. 鋼中非金屬夾雜物: 工業實踐. 北京: 冶金工業出版社, 2019 [23] Wang H, Li J, Shi C B, et al. Evolution of inclusions in calcium-treated H13 die steel. Chin J Eng, 2018, 40(Suppl 1): 11王昊, 李晶, 史成斌, 等. 鈣處理H13鋼中夾雜物的轉變. 工程科學學報, 2018, 40(增刊 1):11 [24] Cai X F, Bao Y P, Lin L. Evolution of inclusions during calcium treatment in liquid steel and its thermodynamic analysis. Chin J Eng, 2016, 38(Suppl 1): 32蔡小鋒, 包燕平, 林路. 鈣處理過程夾雜物演變及熱力學分析. 工程科學學報, 2016, 38(增刊 1):32 [25] Sasai K, Mizukami Y. Reoxidation behavior of molten steel in tundish. ISIJ Int, 2000, 40(1): 40 doi: 10.2355/isijinternational.40.40 [26] Li M, Liu Y, Zhang L F. Effect of reoxidation on inclusions in steel during calcium treatment. Metall Res Technol, 2019, 116(2): 206 doi: 10.1051/metal/2018091 [27] Yang G W, Wang X H, Huang F X, et al. Influence of reoxidation in tundish on inclusion for Ca-treated Al-killed steel. Steel Res Int, 2014, 85(5): 784 doi: 10.1002/srin.201300243 [28] Ren Y, Zhang L F, Pistorius P C. Transformation of oxide inclusions in type 304 stainless steels during heat treatment. Metall Mater Trans B, 2017, 48(5): 2281 doi: 10.1007/s11663-017-1007-8 [29] Yang W, Guo C B, Li C, et al. Transformation of inclusions in pipeline steels during solidification and cooling. Metall Mater Trans B, 2017, 48(5): 2267 doi: 10.1007/s11663-017-1012-y [30] Cheng G, Li W F, Zhang X G, et al. Transformation of inclusions in solid GCr15 bearing steels during heat treatment. Metals, 2019, 9(6): 642 doi: 10.3390/met9060642 [31] Sun X H, Wang W J, Luo Y, et al. Evolution of inclusions in high-sulfur and low-oxygen steels after calcium treatment // AISTech 2019 — Proceedings of the Iron & Steel Technology Conference. Pittsburgh, 2019: 1233 [32] Zhang L F, Li F, Fang W. Thermodynamic investigation for the accurate calcium addition during calcium treatment of molten steels. Steelmaking, 2016, 32(2): 1張立峰, 李菲, 方文. 鋼液鈣處理過程中鈣加入量精準計算的熱力學研究. 煉鋼, 2016, 32(2):1 -

下載:

下載: