Predicting the mechanical properties and composition optimization of a burn-resistant titanium alloy for aero-engines

-

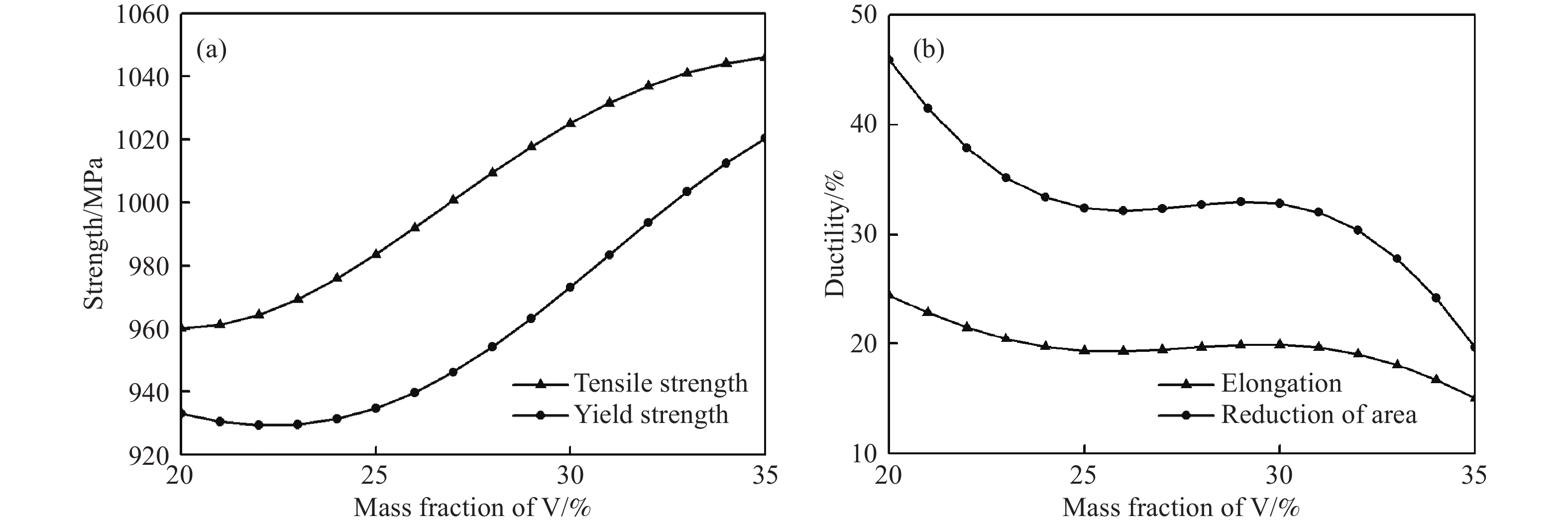

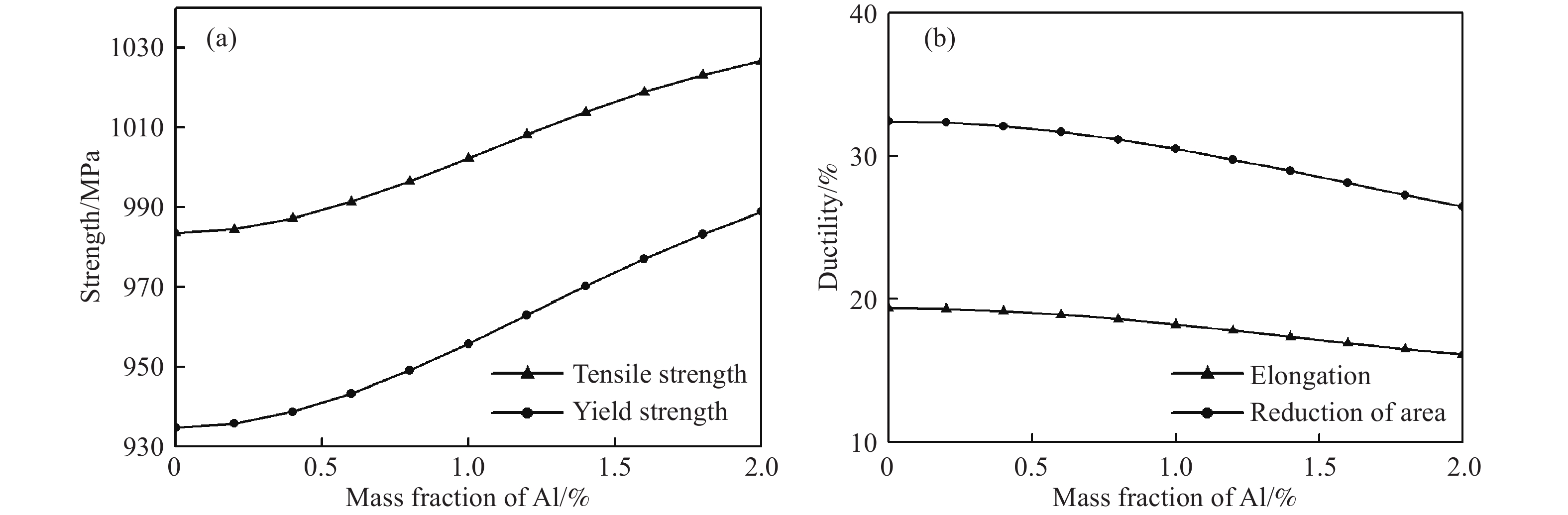

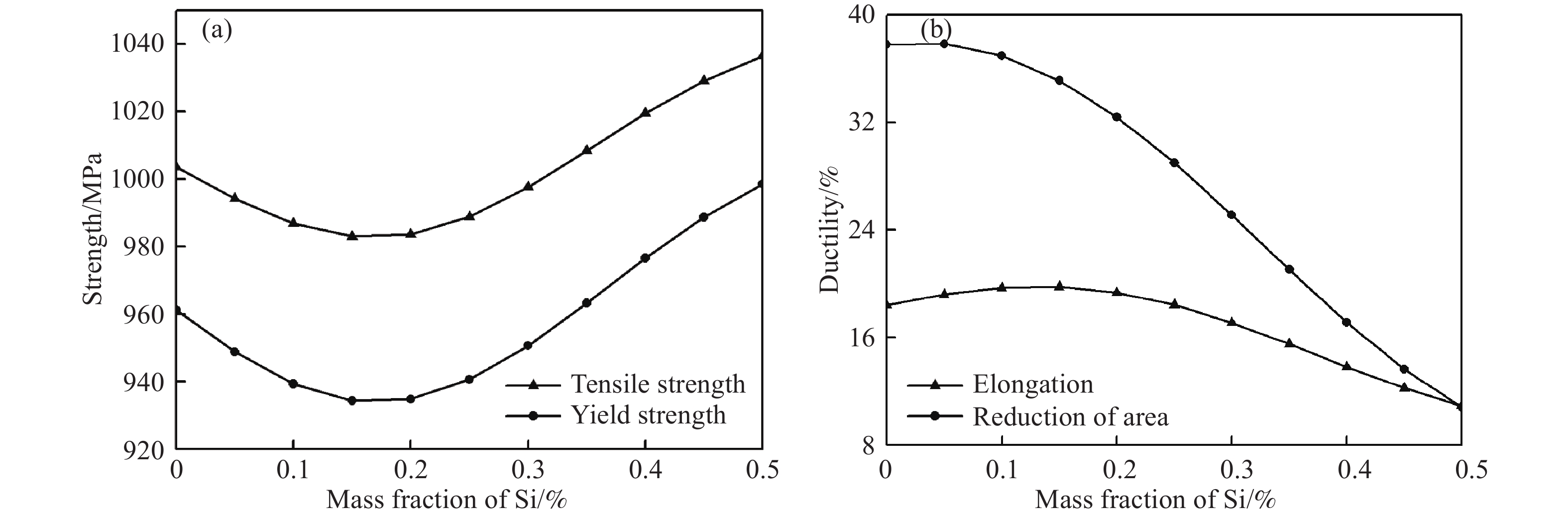

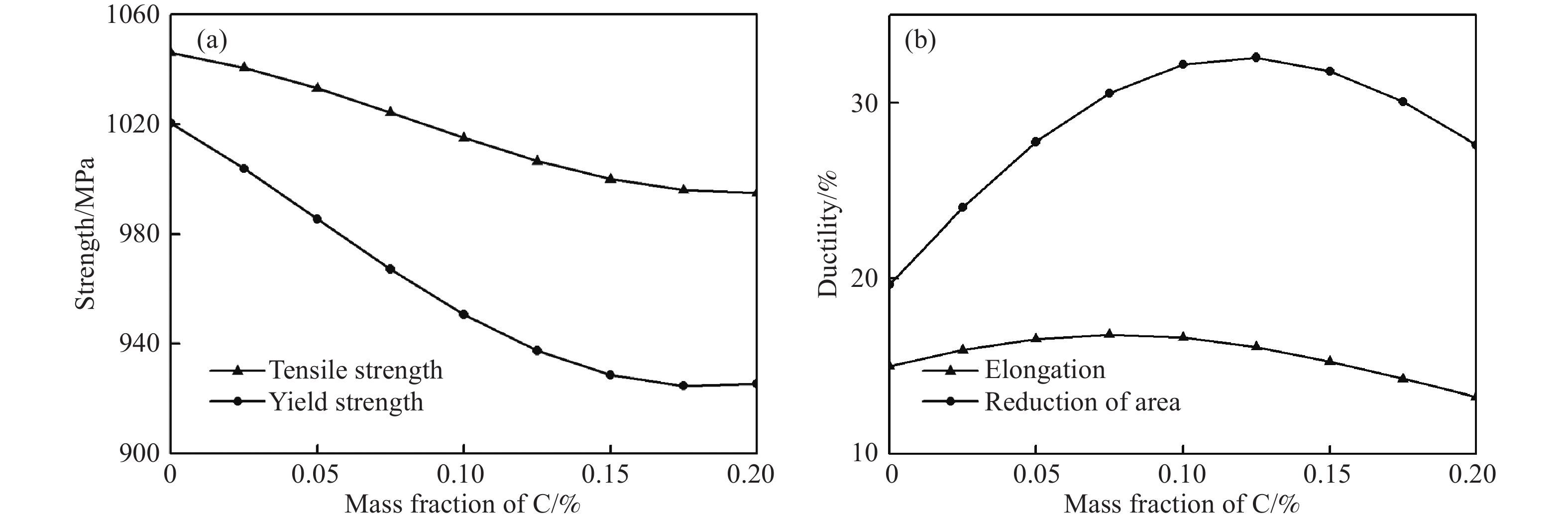

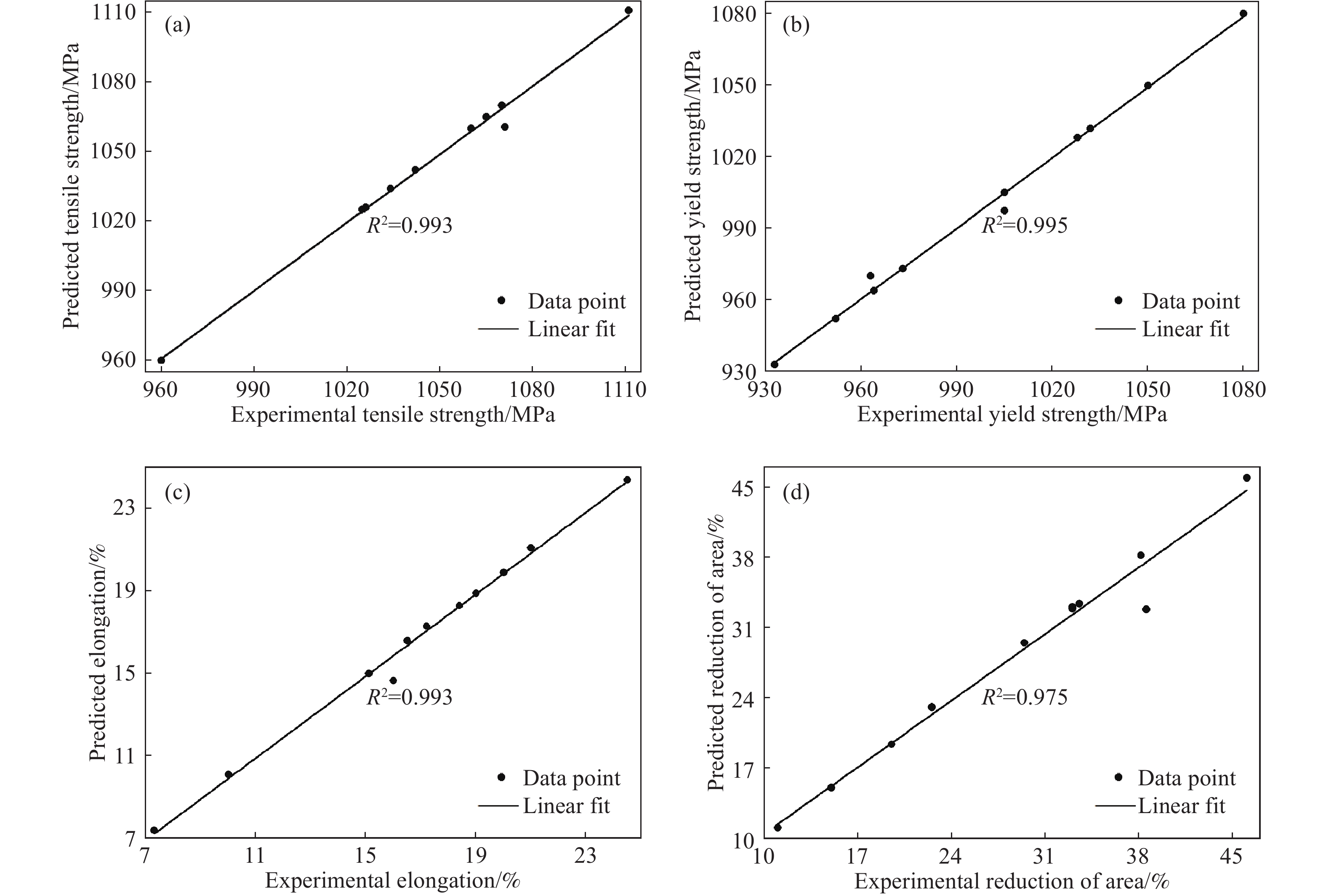

摘要: 采用支持向量機算法,在實驗數據的基礎上,建立航空發動機阻燃鈦合金的合金化元素與力學性能關系模型,分析合金化元素對力學性能的影響規律。模型的輸入參數為V、Al、Si和C元素,輸出參數為室溫拉伸性能(抗拉強度、屈服強度、延伸率和斷面收縮率)。結果表明:各個力學性能支持向量機模型的線性相關系數均在0.975以上,具有較高的預測能力;各個力學性能測試樣本實驗值與模型預測值的絕對百分誤差均在5%以內,具有良好的泛化能力,能夠有效地反映出阻燃鈦合金的合金化元素與力學性能之間的定量關系,進而實現對該合金的成分優化。對于Ti?35V?15Cr阻燃鈦合金,可以通過加入質量分數為0~0.1%的Si元素和質量分數為0.05%~0.125%的C元素,并減少質量分數為2%~5%的V元素,來提高力學性能;對于Ti?25V?15Cr阻燃鈦合金,可以通過加入質量分數為1.5%~1.8%的Al元素和質量分數為0.15%~0.2%的C元素,來提高力學性能。Abstract: Lightweight high-temperature titanium alloys are a key material for aero-engines. With the increasing use of new titanium alloys in aero-engines, titanium fire has become a typical catastrophic fault that plagues material design and selection. A burn-resistant titanium alloy is a special material developed to deal with the problem of titanium fire. Its application in aero-engines has become one of the key technologies for the prevention and control of titanium fire. Therefore, explaining the influence of the alloying elements of burn-resistant titanium alloys on mechanical properties is important to provide an important theoretical basis for the design and application of these alloys. Based on the experimental data, the relationship model between the alloying elements and mechanical properties of a burn-resistant titanium alloy was established using a support vector machine algorithm, and the effect of the alloying elements on the mechanical properties was analyzed. The input parameters of the model were V, Al, Si, and C elements, and the output parameters were the room temperature tensile properties (tensile strength, yield strength, elongation, and the reduction of area). Results show that the linear correlation coefficient of each mechanical property of the SVM model is above 0.975, which signifies good prediction ability. The absolute percentage error between the predicted and experimental values of each mechanical property test sample is within 5%, indicating good generalization ability and an effective reflection of the quantitative relationship between the alloying elements and mechanical properties of the burn-resistant titanium alloy for optimizing the composition of the alloy. The mechanical properties of the Ti–35V–15Cr alloy can be improved by adding 0–0.1% Si element and 0.05%–0.125% C element and reducing 2%–5% V element. Meanwhile, the mechanical properties of the Ti–25V–15Cr alloy can be improved by adding 1.5%–1.8% Al element and 0.15%–0.2% C element.

-

表 1 Ti?V?Cr系阻燃鈦合金實驗值與支持向量機模型預測值的誤差比較

Table 1. Error comparison of the mechanical properties of the experimental data with the predicted values using SVM

Sample Mass fraction/% Comparison Mechanical properties V Al Si C Tensile strength/MPa Yield strength/MPa Elongation/% Reduction of area/% 1 35.00 0 0 0 Experimental 1042 1028 10.0 15.0 Predicted 1042.10 1028.10 10.10 15.10 Absolute error/% 0.01 0.01 1.00 0.67 2 35.00 0 0.25 0 Experimental 1060 1032 15.1 19.5 Predicted 1059.90 1031.90 15.00 19.40 Absolute error/% 0.01 0.01 0.66 0.52 3 35.00 0 0.50 0 Experimental 1111 1080 7.3 11.0 Predicted 1110.90 1079.90 7.40 11.10 Absolute error/% 0.01 0.01 1.37 0.91 4 35.00 0 0 0.08 Experimental 1071 1005 18.4 33.0 Predicted 1060.60 997.32 18.30 32.90 Absolute error% 0.97 0.76 0.55 0.30 5 35.00 0 0.50 0.08 Experimental 1065 1005 19.0 33.5 Predicted 1065.10 1005.10 18.90 33.40 Absolute error/% 0.01 0.01 0.52 0.30 6 35.00 0 0 0.15 Experimental 1034 952 21.0 38.1 Predicted 1034.10 952.10 21.10 38.20 Absolute error/% 0.01 0.01 0.47 0.26 7* 25.50 2.60 0 0.27 Experimental 1070 1050 16.0 22.5 Predicted 1069.90 1049.90 14.66 23.11 Absolute error/% 0.01 0.01 8.39 2.70 8* 20.00 0 0.20 0 Experimental 960 933 24.5 46.0 Predicted 960.10 933.10 24.40 45.90 Absolute error/% 0.01 0.01 0.41 0.22 9* 30.00 0 0.20 0 Experimental 1025 973 20.0 38.5 Predicted 1024.90 973.10 19.90 32.84 Absolute error/% 0.01 0.01 0.50 14.70 10 35.00 0 0.30 0.10 Experimental 1025 964 17.2 33.0 Predicted 1024.90 963.90 17.30 33.10 Absolute error/% 0.01 0.01 0.58 0.30 11 35.20 0 0.17 0.07 Experimental 1026 963 16.5 29.4 Predicted 1026.10 970.16 16.60 29.50 Absolute error/% 0.01 0.74 0.61 0.34 12** 25.20 0 0.21 0 Experimental 969 942 18.5 30.4 Predicted 986.21 936.34 19.18 31.78 Absolute error/% 1.78 0.60 3.68 4.54 Note: **is test set and the rest are training sets;* are the data from references [12,16]. www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Liang X Y, Mi G B, Li P J, et al. Theoretical study on ignition of titanium alloy under high temperature friction condition. Acta Phys Sin, 2020, 69(21): 343 doi: 10.7498/aps.69.20200304梁賢燁, 弭光寶, 李培杰, 等. 鈦合金高溫摩擦著火理論研究. 物理學報, 2020, 69(21):343 doi: 10.7498/aps.69.20200304 [2] Mi G B, Huang X, Cao J X, et al. Microstructure characteristics of burning products of Ti?V?Cr fireproof titanium alloy by frictional ignition. Acta Phys Sin, 2016, 65(5): 056103 doi: 10.7498/aps.65.056103弭光寶, 黃旭, 曹京霞, 等. 摩擦點火Ti?V?Cr阻燃鈦合金燃燒產物的組織特征. 物理學報, 2016, 65(5):056103 doi: 10.7498/aps.65.056103 [3] Zhao Y Q, Zhu K Y, Qu H L, et al. Microstructures of a burn resistant highly stabilized β-titanium alloy. Mater Sci Eng:A, 2000, 282(1-2): 153 doi: 10.1016/S0921-5093(99)00761-3 [4] Ouyang P X, Mi G B, Cao J X, et al. Microstructure characteristics after combustion and fireproof mechanism of TiAl-based alloys. Mater Today Commun, 2018, 16: 364 doi: 10.1016/j.mtcomm.2018.07.012 [5] Xiong J S, Huang J F, Xie G L, et al. Effect of electroplating Cr coating on combustion characteristics of TC4 titanium alloy. Chin J Eng, 2020, 42(8): 1007熊家帥, 黃進峰, 解國良, 等. 電鍍Cr涂層對TC4鈦合金燃燒性能的影響. 工程科學學報, 2020, 42(8):1007 [6] Liang X Y, Mi G B Li P J, et al. Theoretical calculation of characteristics on titanium fire in aero-engine. J Aeronaut Mater, 2021, 41(6): 59梁賢燁, 弭光寶, 李培杰, 等. 航空發動機鈦火特性理論計算研究. 航空材料學報, 2021, 41(6):59 [7] Mi G B, Yao K, Min X H. Effect of temperature on wear behavior in a Ti-V-Cr base fireproof titanium alloy. Int J Precis Eng Manuf, 2017, 18: 1553 doi: 10.1007/s12541-017-0184-3 [8] Hood R, Johnson C M, Soo S L, et al. High-speed ball nose end milling of burn-resistant titanium (BuRTi) alloy. Int J Comput Integr Manuf, 2014, 27(2): 139 doi: 10.1080/0951192X.2013.801563 [9] Li Y G, Blenkinsop P A, Loretto M H, et al. Effect of carbon and oxygen on microstructure and mechanical properties of Ti?25V?15Cr?2Al (wt%) alloys. Acta Mater, 1999, 47(10): 2889 doi: 10.1016/S1359-6454(99)00173-1 [10] Li Y G, Blenkinsop P A, Loretto M H, et al. Effect of aluminium on deformation structure of highly stabilised β-Ti?V?Cr alloys. Mater Sci Technol, 1999, 15(2): 151 doi: 10.1179/026708399101505680 [11] Sun F S, Lavernia E J. Creep behavior of nonburning Ti?35V?15Cr?xC alloys. J Mater Eng Perform, 2005, 14(6): 784 doi: 10.1361/105994905X75619 [12] Xin S W, Zhao Y Q, Zeng W D, et al. Effect of V on the thermal stability and creep of Ti?V?Cr burn-resistant titanium alloy. Rare Met Mater Eng, 2007, 36(11): 2031 doi: 10.3321/j.issn:1002-185x.2007.11.036辛社偉, 趙永慶, 曾衛東, 等. V元素對Ti?V?Cr系阻燃鈦合金熱強性的影響. 稀有金屬材料與工程, 2007, 36(11):2031 doi: 10.3321/j.issn:1002-185x.2007.11.036 [13] Mi G B, Huang X, Cao J X, et al. Ignition resistance performance and its theoretical analysis of Ti?V?Cr type fireproof titanium alloys. Acta Metall Sin, 2014, 50(5): 575弭光寶, 黃旭, 曹京霞, 等. Ti?V?Cr系阻燃鈦合金的抗點燃性能及其理論分析. 金屬學報, 2014, 50(5):575 [14] Cao J X, Huang X, Mi G B, et al. Research progress on application technique of Ti?V?Cr burn resistant titanium alloys. J Aeronaut Mater, 2014, 34(4): 92 doi: 10.11868/j.issn.1005-5053.2014.4.009曹京霞, 黃旭, 弭光寶, 等. Ti?V?Cr系阻燃鈦合金應用研究進展. 航空材料學報, 2014, 34(4):92 doi: 10.11868/j.issn.1005-5053.2014.4.009 [15] Lai Y J, Zhang P X, Xin S W, et al. Research progress on engineered technology of burn-resistant titanium alloys in China. Rare Met Mater Eng, 2015, 44(8): 2067賴運金, 張平祥, 辛社偉, 等. 國內阻燃鈦合金工程化技術研究進展. 稀有金屬材料與工程, 2015, 44(8):2067 [16] Sun H Y, Zhao J, Liu Y A, et al. Effect of C addition on microstructure and mechanical properties of Ti?V?Cr burn resistant titanium alloys. Chin J Mater Res, 2019, 33(7): 537 doi: 10.11901/1005.3093.2019.090孫歡迎, 趙軍, 劉翊安, 等. C含量對Ti?V?Cr系阻燃鈦合金微觀組織和力學性能的影響. 材料研究學報, 2019, 33(7):537 doi: 10.11901/1005.3093.2019.090 [17] Zhou T, Song Z, Sundmacher K. Big data creates new opportunities for materials research: A review on methods and applications of machine learning for materials design. Engineering, 2019, 5(6): 1017 doi: 10.1016/j.eng.2019.02.011 [18] Wang H, Xiang X D, Zhang L T. Data+AI: The core of materials genomic engineering. Sci Technol Rev, 2018, 36(14): 15汪洪, 項曉東, 張瀾庭. 數據+人工智能是材料基因工程的核心. 科技導報, 2018, 36(14):15 [19] Wu W, Sun Q. Applying machine learning to accelerate new materials development. Sci Sin Phys Mech Astron, 2018, 48(10): 58吳煒, 孫強. 應用機器學習加速新材料的研發. 中國科學:物理學 力學 天文學, 2018, 48(10):58 [20] Malinov S, Sha W, McKeown J J. Modelling the correlation between processing parameters and properties in titanium alloys using artificial neural network. Comput Mater Sci, 2001, 21(3): 375 doi: 10.1016/S0927-0256(01)00160-4 [21] Noori Banu P S, Devaki Rani S. Knowledge-based artificial neural network model to predict the properties of alpha+ beta titanium alloys. J Mech Sci Technol, 2016, 30(8): 3625 doi: 10.1007/s12206-016-0723-3 [22] Sun L N. Heat treatment process optimization of directional solidification titanium alloys based on neural network. Ordnance Mater Sci Eng, 2017, 40(4): 30孫麗娜. 定向凝固鈦合金熱處理工藝的神經網絡優化. 兵器材料科學與工程, 2017, 40(4):30 [23] Noori Banu P S, Devaki Rani S. Artificial neural network based optimization of prerequisite properties for the design of biocompatible titanium alloys. Comput Mater Sci, 2018, 149: 259 doi: 10.1016/j.commatsci.2018.03.039 [24] Xu J J, Wang F. Tensile strength forecasting model foundation and checking of Ti?Al?V series Ti alloys. Hot Work Technol, 2018, 47(10): 72許佳佳, 王飛. Ti?Al?V系鈦合金抗拉強度預測模型的建立及驗證. 熱加工工藝, 2018, 47(10):72 [25] Zhang X M, Xi Y Q, Li M, et al. Prediction of superplastic deformation behavior of WSTi3515S burn-resistant titanium alloy based on BP artificial neural network. Special Cast Nonferrous Alloys, 2019, 39(6): 668張學敏, 惠玉強, 李咪, 等. 基于BP神經網絡的WSTi3515S阻燃鈦合金超塑性變形行為預測. 特種鑄造及有色合金, 2019, 39(6):668 [26] Zhou X H, Lou M Q, Zhang X M, et al. Prediction of effect of thermal exposure on tensile properties of TC4 titanium alloy based on neural network. Hot Work Technol, 2019, 48(14): 128周曉虎, 樓美琪, 張學敏, 等. 基于神經元網絡的熱暴露對TC4鈦合金拉伸性能影響預測. 熱加工工藝, 2019, 48(14):128 [27] Anand P, Rastogi R, Chandra S. A class of new support vector regression models. Appl Soft Comput, 2020, 94: 106446 doi: 10.1016/j.asoc.2020.106446 [28] Sun H Y, Zhao J, Liu Y A, et al. Microstructure and mechanical properties of a new type burn resistant titanium alloy with lower cost. Rare Met Mater Eng, 2019, 48(6): 1892孫歡迎, 趙軍, 劉翊安, 等. 一種新型低成本阻燃鈦合金的微觀組織與力學性能. 稀有金屬材料與工程, 2019, 48(6):1892 -

下載:

下載: