Kinetic model of the composition transformation of slag inclusions in molten steel in continuous casting mold

-

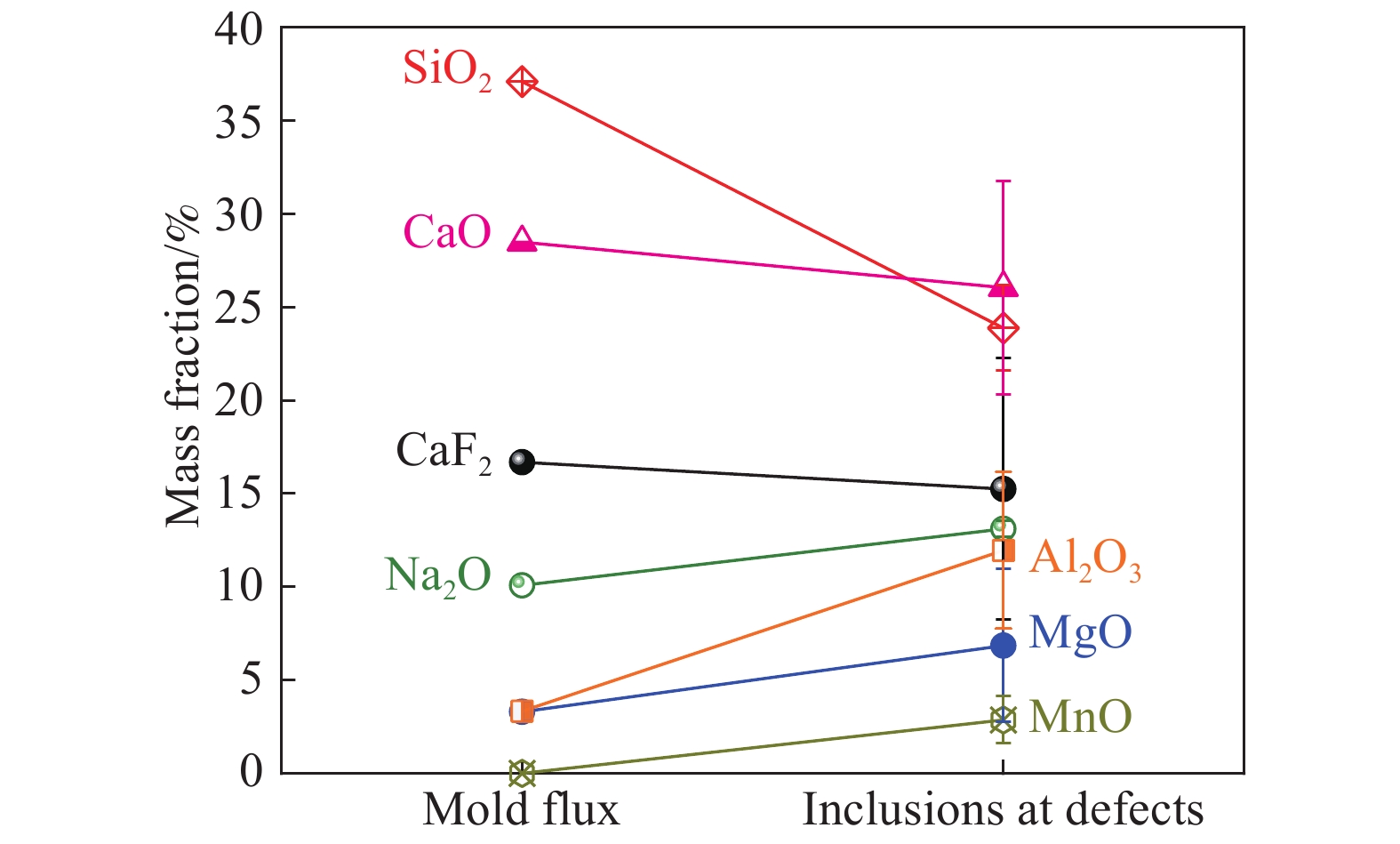

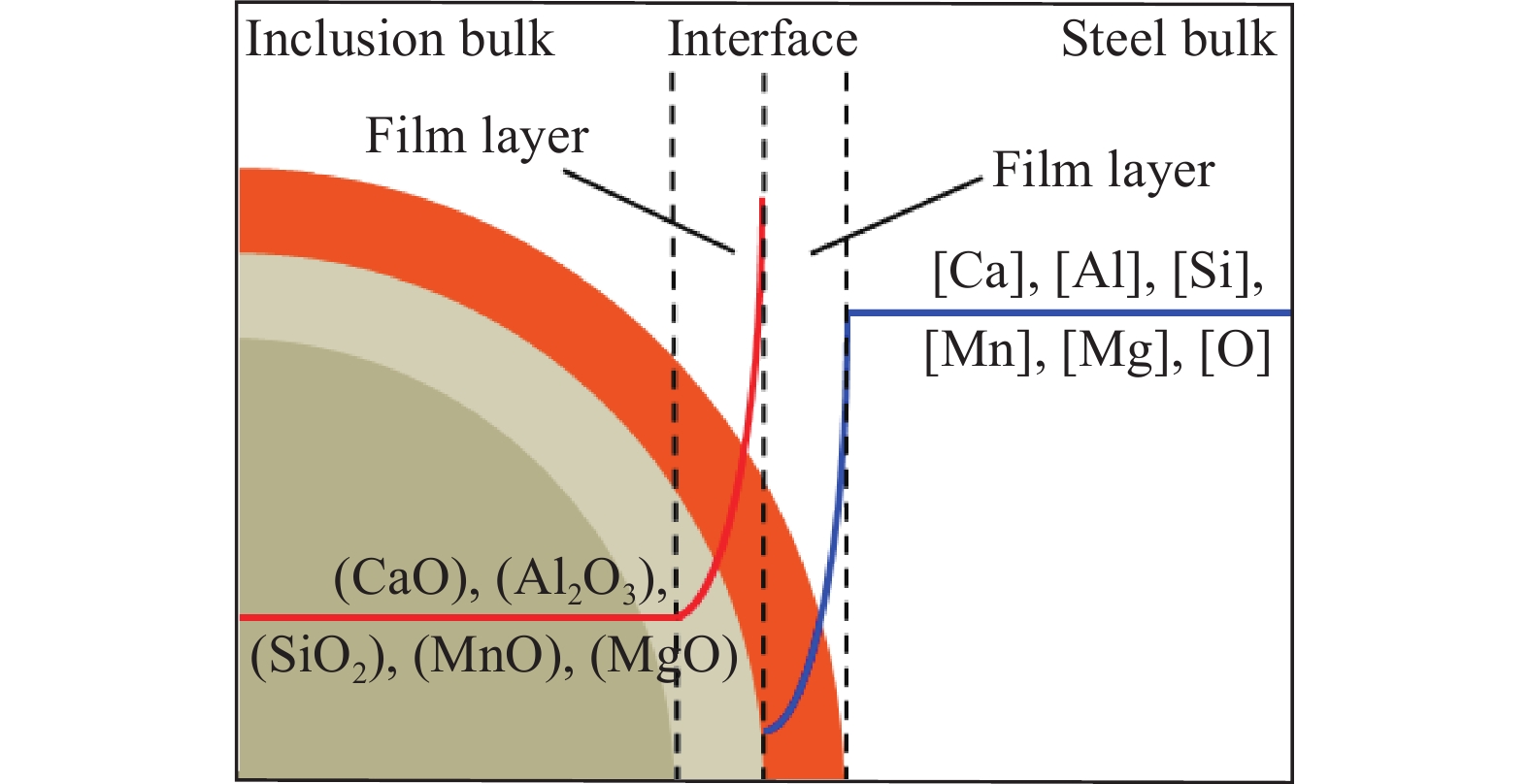

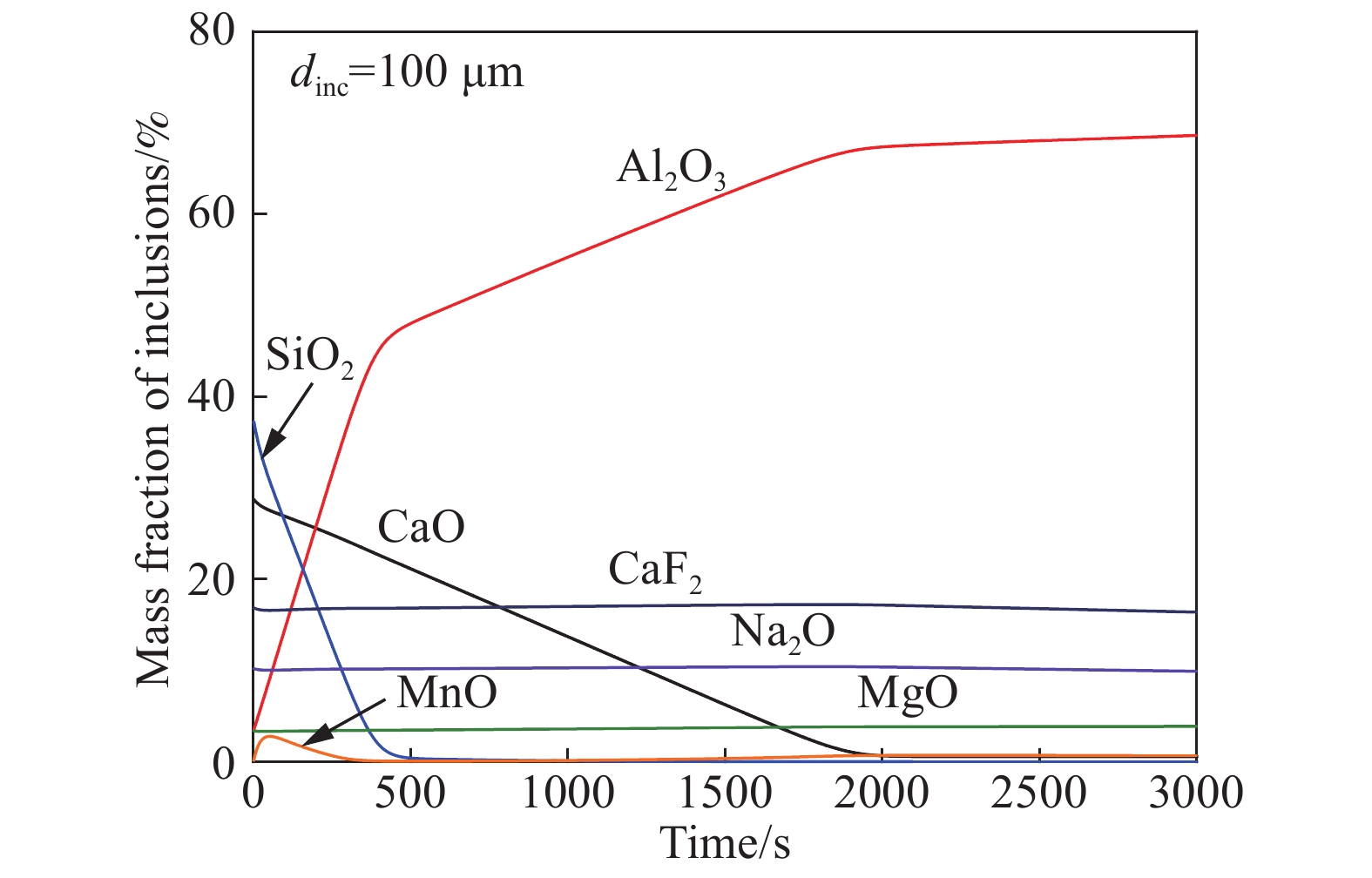

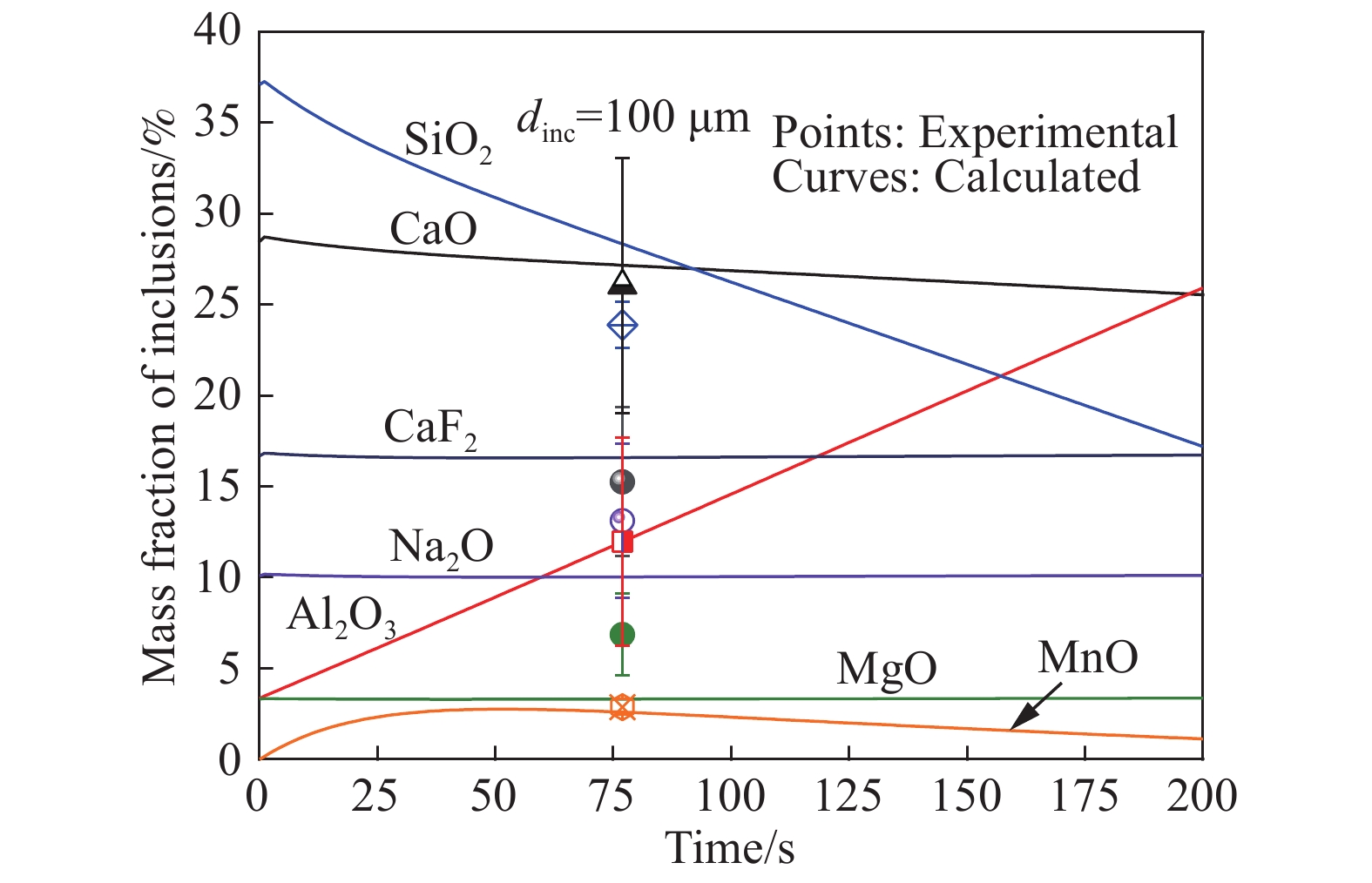

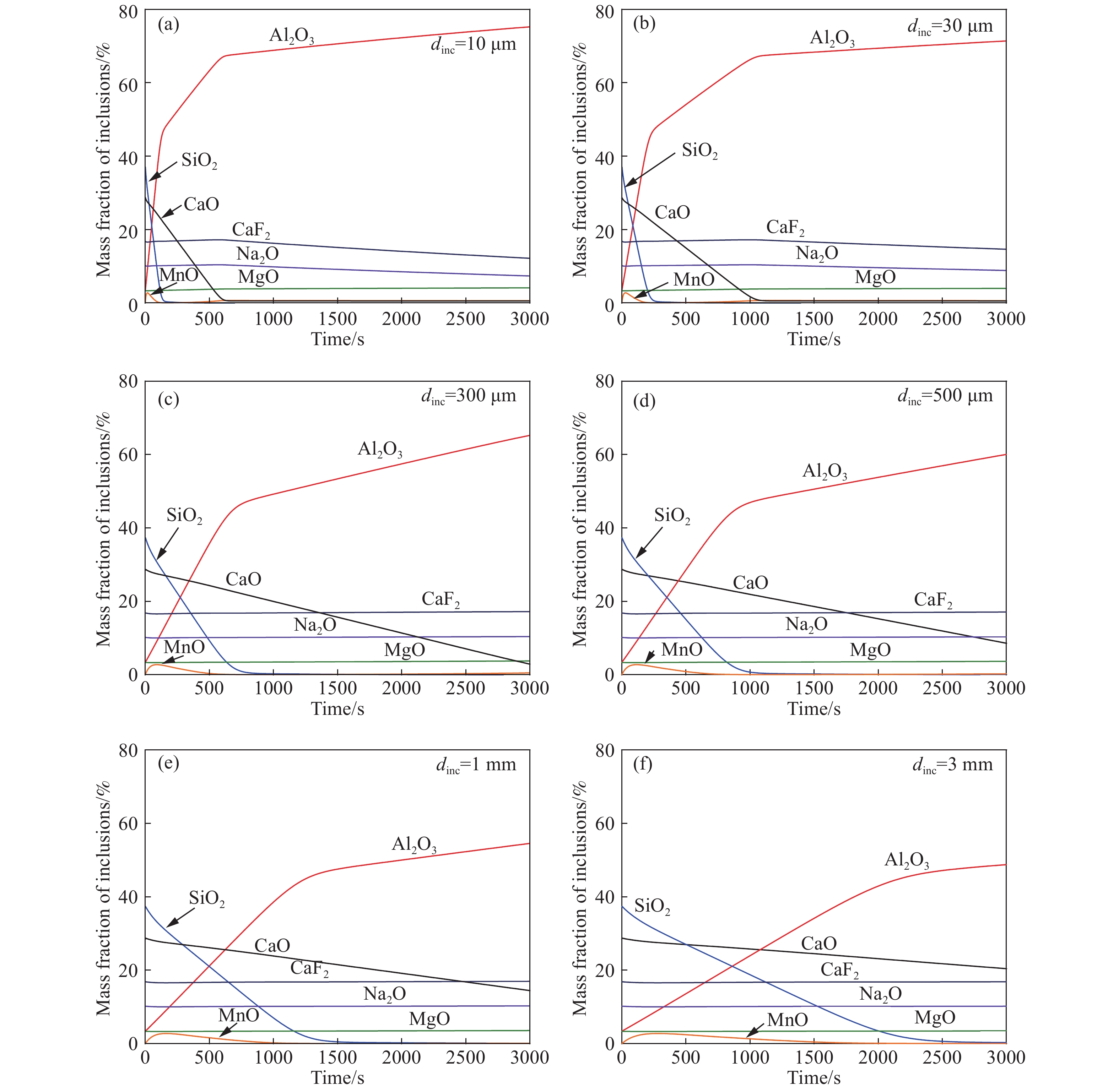

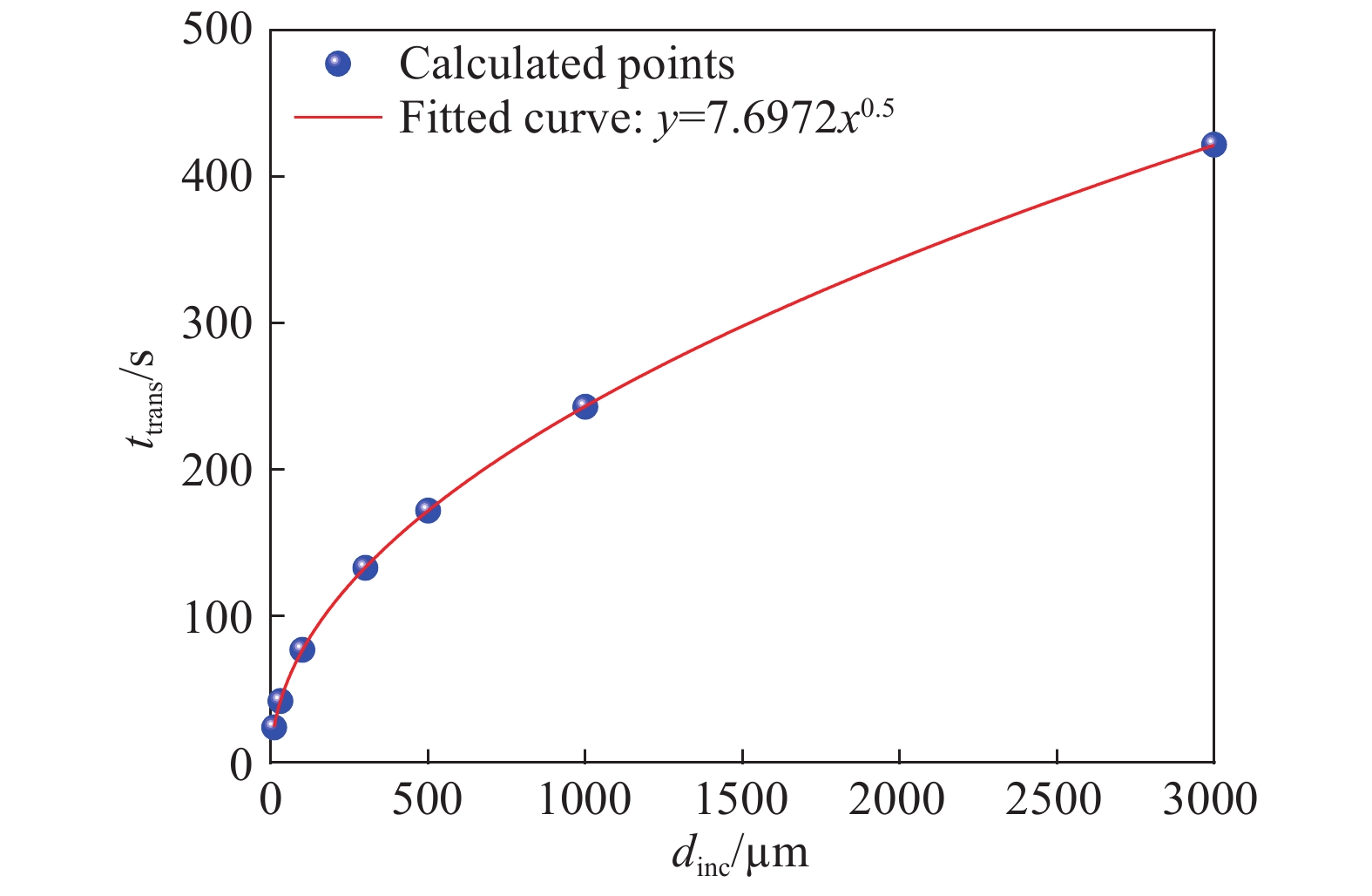

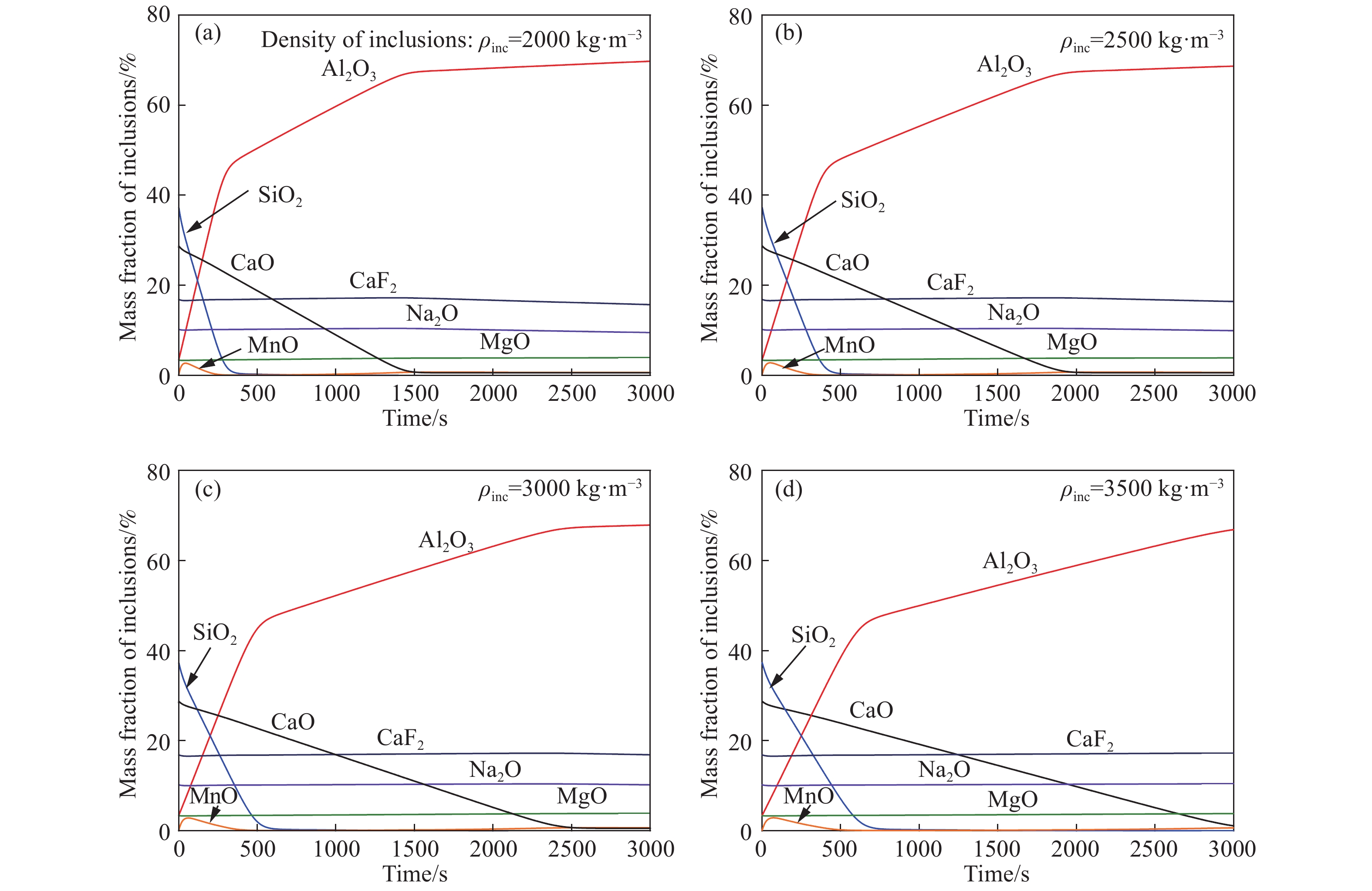

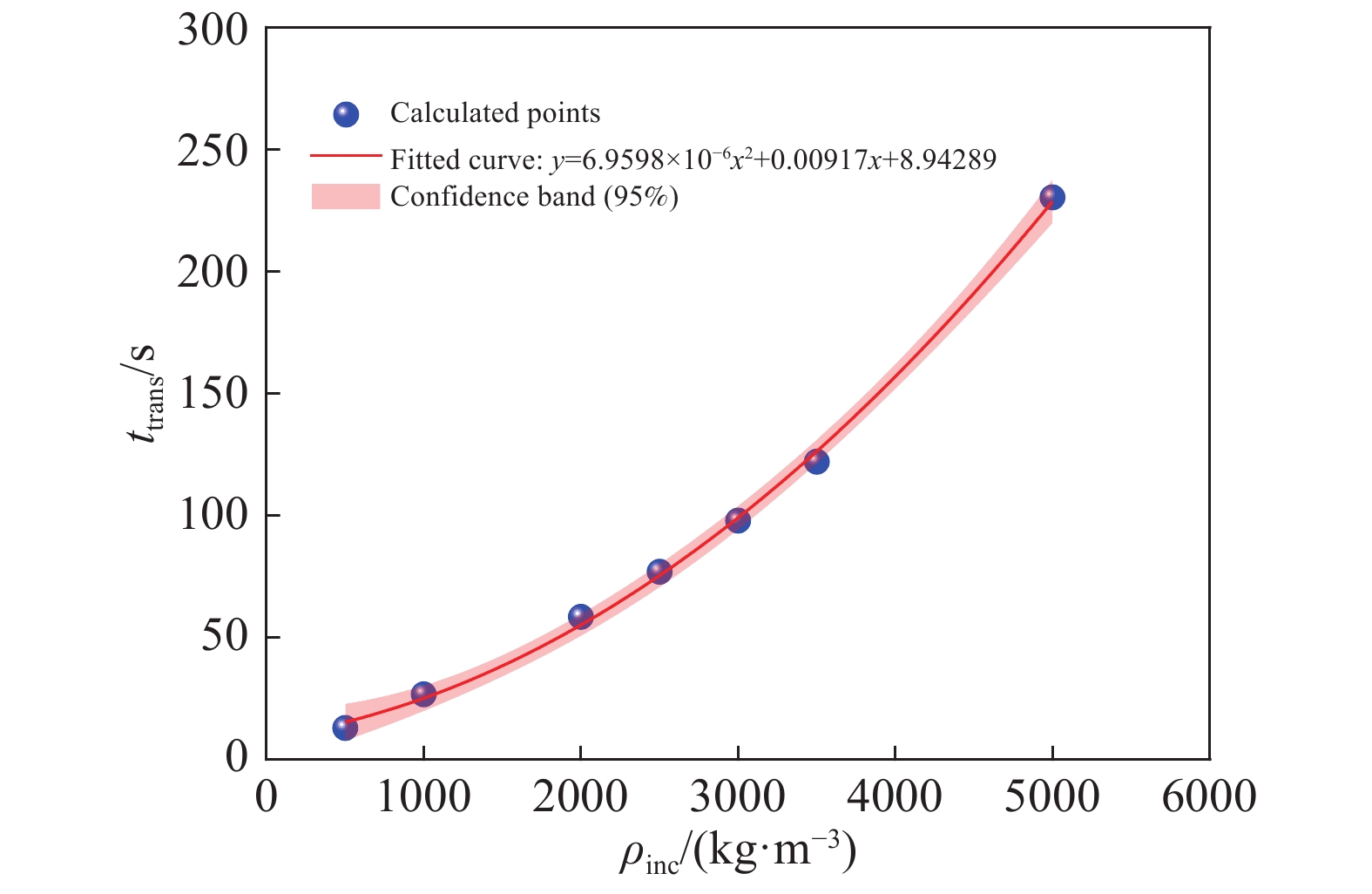

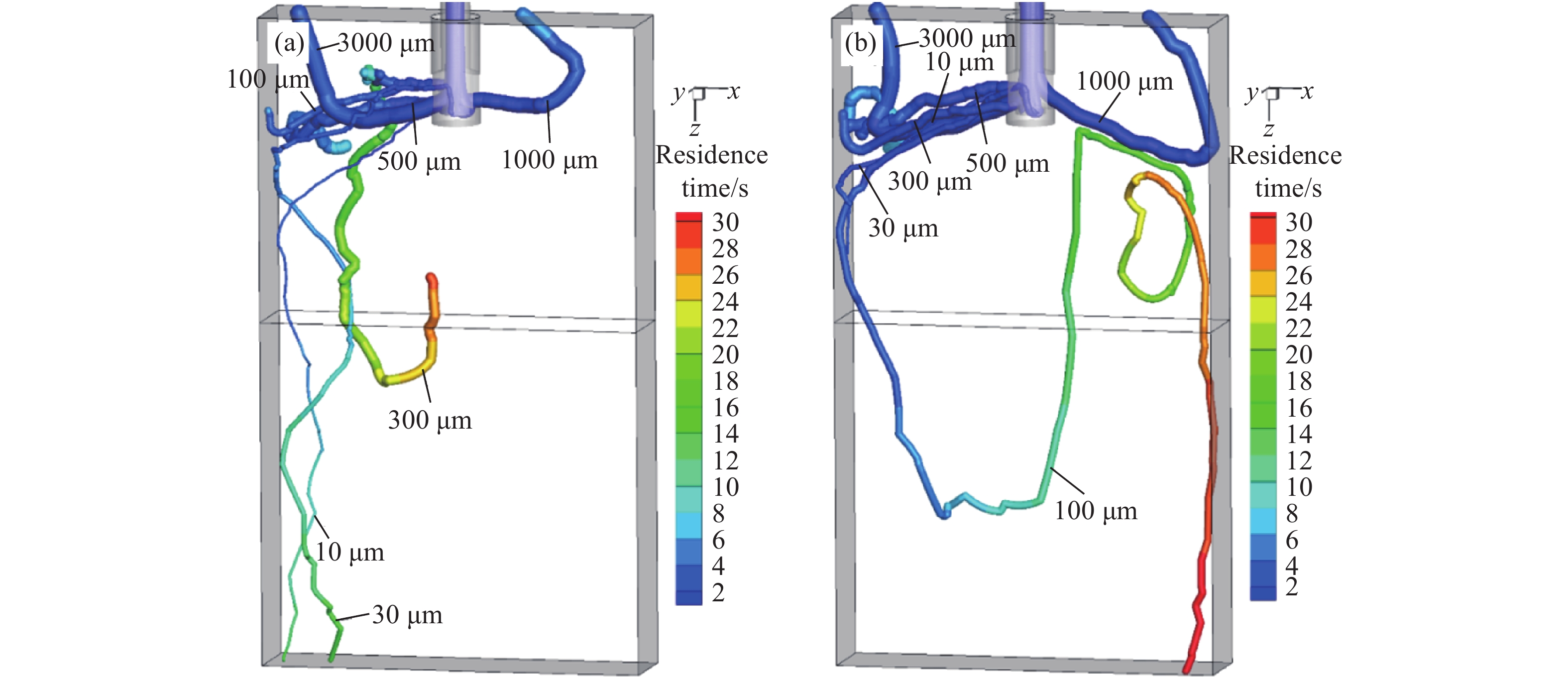

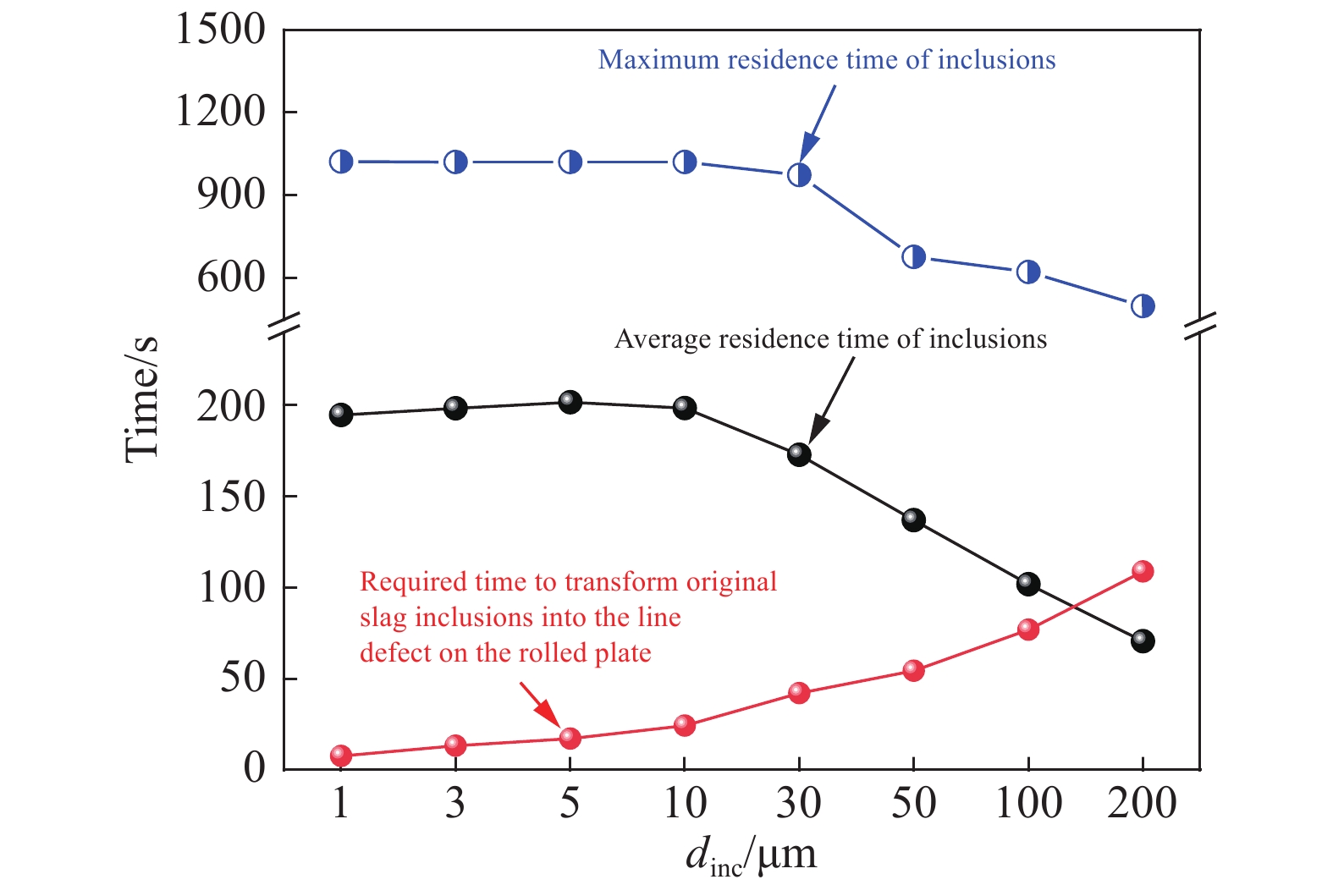

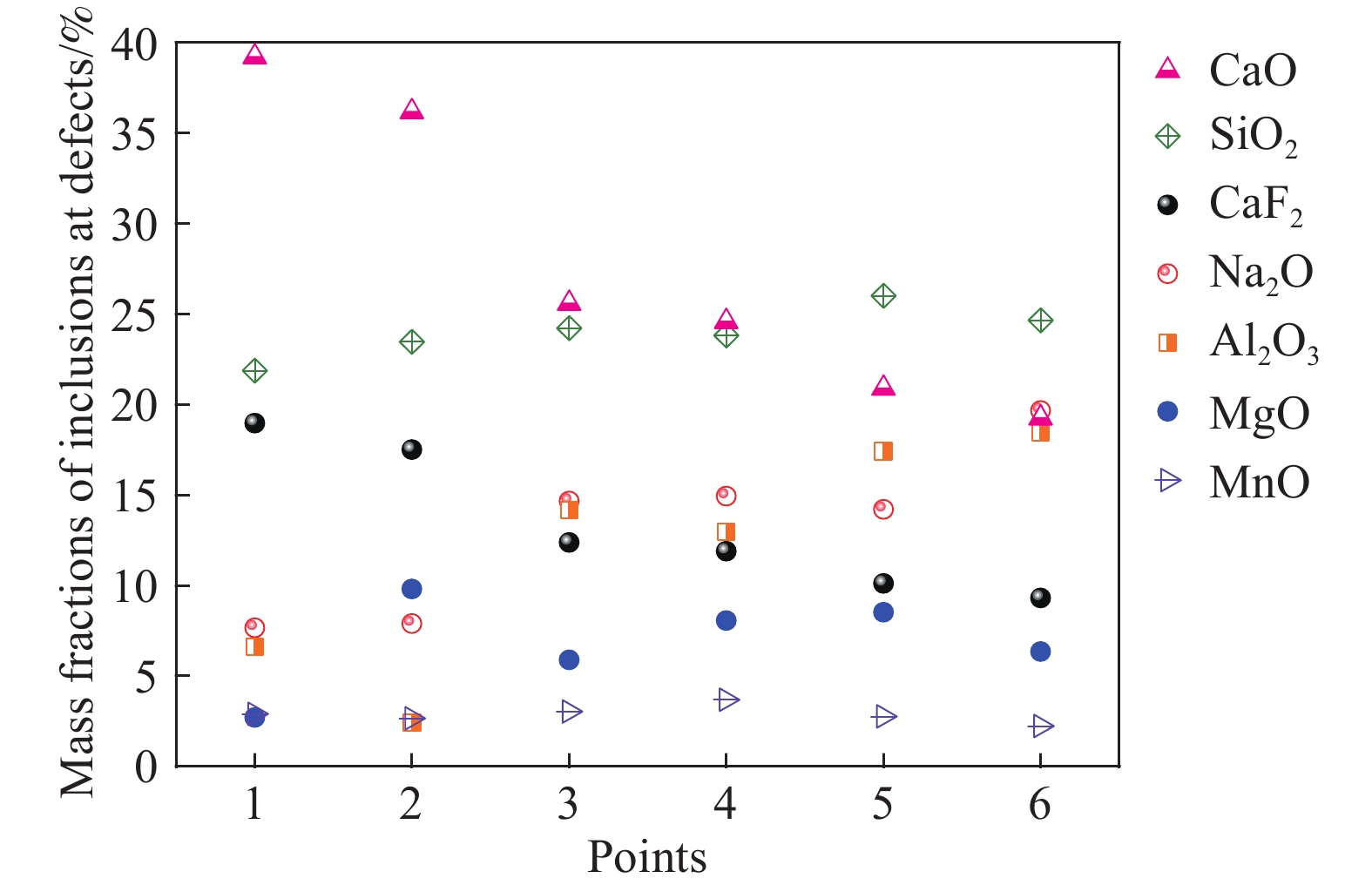

摘要: 國內某廠鍍錫板缺陷處夾雜物主要來自結晶器保護渣的卷入,但其成分與結晶器保護渣有明顯差別。為了進一步研究這種成分差別的原因,建立了耦合熱力學平衡和動力學擴散的結晶器卷渣類夾雜物的成分轉變動力學模型,明確了卷渣類夾雜物的尺寸和密度對其成分轉變的影響規律,并通過對結晶器和液相穴內的鋼液流動和夾雜物運動的數值模擬研究了夾雜物在鋼液中的停留時間。結果表明:結晶器保護渣卷入鋼液后與鋼液不斷發生反應,成分會發生明顯改變。卷渣類夾雜物轉變為缺陷處夾雜物所需要的時間與夾雜物尺寸以及夾雜物密度有關,夾雜物的尺寸和密度越大,轉變為缺陷處夾雜物成分所需的時間越長。卷渣類夾雜物轉變為缺陷處夾雜物所需時間與夾雜物尺寸呈冪函數關系,與夾雜物密度呈二次函數關系。夾雜物在鋼液中的平均停留時間隨夾雜物直徑的增大而減小,并且隨著拉速的增大而減小。小尺寸夾雜物一旦被卷入鋼液中,將有充足的時間轉變為缺陷處的成分。大尺寸夾雜物在鋼液中的平均停留時間小于成分轉變時間,但最大停留時間遠大于成分轉變所需時間,表明部分大尺寸夾雜物依然具有充足的停留時間轉變為缺陷處的成分。Abstract: The inclusions at the defects of tinplate originated from the entrainment of the mold flux, but their composition differed significantly from that of the mold flux. To investigate this difference, a kinetic model was established of the transformation of the composition of the slag inclusions, coupled with the thermodynamic equilibrium and kinetic diffusion. The influences of the size and density of slag inclusions on the variation of their composition were also evaluated. The residence times of the inclusions in the molten steel were studied by simulating the flow of molten steel and the movement of the inclusions in the mold and steel cavity. The results show that after entrainment into the molten steel, the mold flux reacts continuously with the molten steel, which results in a significant change in its composition. The time required for the transformation was related to the diameter and density of inclusions. The larger the diameter and the bigger the density, the longer the time was required for the transformation. The time required for the transformation had a root relationship with the diameter of inclusions, and had a quadratic function with density of the inclusions. The average residence time of the inclusions in the molten steel decreased with increases in the diameter of the inclusions and the pulling speed. There would be enough time for the small inclusions to transform into the compositions of defects once they are entrained into the molten steel. The average residence time of the large inclusions is less than the time required for the transformation, while the maximum residence time is much longer than the time required for the transformation, which indicates that some inclusions with larger size still have enough residence time to transform from the initial composition to the composition of defects.

-

Key words:

- slag inclusions /

- kinetic model /

- mold flux /

- line defect /

- tinplate

-

表 1 鍍錫板缺陷處不同位置元素含量(質量分數)

Table 1. Chemical composition at different defect locations on the tinplate

% Position O F Na Mg Al Si Ca Mn Fe P1 29.71 4.46 7.58 1.99 5.08 11.97 9.63 0.9 28.68 P2 29.81 4.93 6.36 2.79 3.94 12.78 13.59 1.64 24.15 P3 37.2 6.2 3.65 1.05 2.25 13.13 24.24 1.45 10.83 P4 19.21 7.15 3.13 3.16 0.69 11.72 18.61 1.1 35.23 P5 30.08 4.64 6.71 2.19 4.62 13.96 15.19 1.45 21.17 P6 32.38 7.27 6.33 3.09 5.54 14.61 12.09 1.29 17.06 表 2 結晶器保護渣成分

Table 2. Composition of the mold flux

% Composition CaO SiO2 Al2O3 Fe2O3 MgO K2O+Na2O CaF2 Mass fraction 28.49 37.11 3.34 0.97 3.31 10.09 16.69 表 3 鋼液化學成分

Table 3. Chemical composition of the molten steel

% Composition C Si Mn P S T.Al [Al] T.N T.O Mass fraction 0.03 0.01 0.22 0.007 0.006 0.047 0.044 0.0029 0.0016 Note:T.Al is total mass fraction of aluminium; T.N is total mass fraction of nitrogen; T.O is total mass fraction of oxygen. 表 4 夾雜物與鋼液反應動力學模型所考慮的化學反應

Table 4. Chemical reactions considered in the current model

Reaction Δ$ G^{\ominus} $ / (J·mol?1) Reference $\left[ {{\rm{Ca}}} \right]{\rm{ + }}\left[ {\rm{O}} \right]{\rm{ = }}\left( {{\rm{CaO}}} \right)$ $\Delta {G^{\ominus} } = - 138240.86 - 63.0T$ [21] ${\rm{2}}\left[ {{\rm{Al}}} \right]{\rm{ + 3}}\left[ {\rm{O}} \right]{\rm{ = }}\left( {{\rm{A}}{{\rm{l}}_{\rm{2}}}{{\rm{O}}_{\rm{3}}}} \right)$ $\Delta { G^{\ominus}} = - 1206220 + 390.39T$ [21] $\left[ {{\rm{Si}}} \right]{\rm{ + 2}}\left[ {\rm{O}} \right]{\rm{ = }}\left( {{\rm{Si}}{{\rm{O}}_{\rm{2}}}} \right)$ $\Delta { G^{\ominus}} = - 581900 + 221.8T$ [21] $\left[ {{\rm{Mg}}} \right]{\rm{ + }}\left[ {\rm{O}} \right]{\rm{ = }}\left( {{\rm{MgO}}} \right)$ $\Delta { G^{\ominus}} = - 89960 - 82.0T$ [21] $\left[ {{\rm{Mn}}} \right]{\rm{ + }}\left[ {\rm{O}} \right]{\rm{ = }}\left( {{\rm{MnO}}} \right)$ $\Delta { G^{\ominus}} = 288150 - 128.3T$ [21] 表 5 不同元素在鋼液中的擴散系數

Table 5. Diffusivities of elements in the molten steel

10?9 m2?s?1 Element Ca Al Si Mn Mg O DM 3.5 3.5 4.36 4.4 3.5 2.96 表 6 模型初始條件

Table 6. Initial conditions used in the calculations

Initial mass fraction of steel / % C Si Mn P S [Al] T.N T.O [Ca] [Mg] 0.03 0.01 0.22 0.007 0.006 0.044 0.0029 0.0016 0.0001 0.0001 Initial mass fraction of inclusion / % CaO SiO2 Al2O3 Fe2O3 MgO Na2O CaF2 28.49 37.11 3.34 0.97 3.31 10.09 16.69 Parameters Tsteel / ℃ ρsteel / (kg?m?3) μsteel / (Pa·s) ρinc / (kg?m?3) dinc / μm 1500 7000 0.0067 2500 100 www.77susu.com<span id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> <span id="fpn9h"><noframes id="fpn9h"> <th id="fpn9h"></th> <strike id="fpn9h"><noframes id="fpn9h"><strike id="fpn9h"></strike> <th id="fpn9h"><noframes id="fpn9h"> <span id="fpn9h"><video id="fpn9h"></video></span> <ruby id="fpn9h"></ruby> <strike id="fpn9h"><noframes id="fpn9h"><span id="fpn9h"></span> -

參考文獻

[1] Zhang L F. Non-Metallic Inclusions in Steels: Fundamentals. Beijing: Metallurgical Industry Press, 2019張立峰. 鋼中非金屬夾雜物. 北京: 冶金工業出版社, 2019 [2] Zhang L F. Non-Metallic Inclusions in Steels: Industrial Practice. Beijing: Metallurgical Industry Press, 2019張立峰. 鋼中非金屬夾雜物: 工業實踐. 北京: 冶金工業出版社, 2019 [3] Jiang Y F. Analysis of surface defects of medium plate rolled from continuous casting slab. Iron Steel, 1998, 33(8): 29姜亞飛. 連鑄板坯軋制中板的表面缺陷. 鋼鐵, 1998, 33(8):29 [4] Yu H X, Deng X X, Wang X H, et al. Characteristics of subsurface inclusions in deep-drawing steel slabs at high casting speed. Metall Res Technol, 2015, 112(6): 608 doi: 10.1051/metal/2015043 [5] Lan Y, Wang Y F, Yang Z Z, et al. Analyzing and control of surface inclusion defect of hot-rolled coil. Adv Mater Res, 2013, 753-755: 230 doi: 10.4028/www.scientific.net/AMR.753-755.230 [6] Gao X J, Li J S, Yang S F, et al. Application of tracers to investigate source of slag inclusions in surface defects of SPHC steel. Henan Metall, 2014, 22(3): 14 doi: 10.3969/j.issn.1006-3129.2014.03.004高曉杰, 李京社, 楊樹峰, 等. SPHC板卷表面缺陷來源示蹤研究. 河南冶金, 2014, 22(3):14 doi: 10.3969/j.issn.1006-3129.2014.03.004 [7] Jiang C H, Tang D, Zhang C, et al. Morphology and metallurgical factors of line defects on surface of cold rolled 304 austenitic stainless steel sheet. Mater Res Innovations, 2014, 18(Suppl 4): S4-281 [8] Yotsuji J, Koshihara T. Detection system for inclusion defects in hot-rolled steel plates using MFLT with two different magnetizing strengths. AIP Conf Proc, 2014, 1581: 1315 [9] Liu S T, Hu J H, Xu Z Q, et al. Analysis on inclusion defects for titanium containing austenitic steel and related manufacturing way // The 8th Pacific Rim International Congress on Advanced Materials and Processing. Waikoloa, 2013: 2205 [10] Kusano A, Sato N, Okimori M. Formation mechanism of a white spot defect on the tin plate steel produced by continuous cast slab. Tetsu-To-Hagane, 2000, 86(5): 315 doi: 10.2355/tetsutohagane1955.86.5_315 [11] Zhang L F. Nucleation, growth, transport, and entrapment of inclusions during steel casting. JOM, 2013, 65(9): 1138 doi: 10.1007/s11837-013-0688-y [12] Wang S D, Chen W, Zhang X B, et al. Influence of fc-mold on flow pattern and entrapment of inclusions in continuous casting strand. // ICS2018-7th International Congress on Science and Technology of Steelmaking. Venice, 2018 [13] Wang S D, Zhang L F, Wang Q Q, et al. Effect of electromagnetic parameters on the motion and entrapment of inclusions in FC-Mold continuous casting strands. Metall Res Technol, 2016, 113(2): 205 doi: 10.1051/metal/2016003 [14] Chen W, Ren Y, Zhang L F. Large eddy simulation on the fluid flow, solidification and entrapment of inclusions in the steel along the full continuous casting slab strand. JOM, 2018, 70(12): 2968 doi: 10.1007/s11837-018-3118-3 [15] Yamashita S, Iguchi M. Mechanism of mold powder entrapment caused by large argon bubble in continuous casting mold. ISIJ Int, 2001, 41(12): 1529 doi: 10.2355/isijinternational.41.1529 [16] Jiang P G, Lai C B. Numerical simulation of the flow field in a wide slab continuous casting mold. Chin J Eng, 2016, 38(Suppl 1): 50姜平國, 賴朝斌. 寬板坯連鑄結晶器流場的數值模擬. 工程科學學報, 2016, 38(增刊1): 50 [17] Wu H J, Zhang L, Xu Y, et al. Water model study on critical slag entrapment behavior based on PIV technology. Chin J Eng, 2016, 38(5): 637吳華杰, 張漓, 徐陽, 等. 基于PIV技術的鋼包臨界卷渣行為水模型研究. 工程科學學報, 2016, 38(5):637 [18] Ohguchi S, Robertson D G C, Deo B, et al. Simultaneous dephosphorization and desulphurization of molten pig iron. Ironmaking Steelmaking, 1984, 11(4): 202 [19] Harada A, Maruoka N, Shibata H, et al. A kinetic model to predict the compositions of metal, slag and inclusions during ladle refining: Part 1. basic concept and application. ISIJ Int, 2013, 53(12): 2110 doi: 10.2355/isijinternational.53.2110 [20] Harada A, Maruoka N, Shibata H, et al. A kinetic model to predict the compositions of metal, slag and inclusions during ladle refining: Part 2. condition to control the inclusion composition. ISIJ Int, 2013, 53(12): 2118 doi: 10.2355/isijinternational.53.2118 [21] Zhang Y, Ren Y, Zhang L F. Kinetic study on compositional variations of inclusions, steel and slag during refining process. Metall Res Technol, 2018, 115(4): 415 doi: 10.1051/metal/2018059 [22] Zhang Y. Kinetic Study on Composiitoal Variations of Steel, Slag and Incluisons in a Multiphase System of “Steel-Slag -Incluison-Refractory-Alloy-Air”[Dissertation]. Beijing: University of Science and Technology Beijing, 2019張瑩. “鋼–渣–夾雜物–耐火材料–合金–空氣”六相多元體系下的鋼、渣和夾雜物成分變化的動力學研究[學位論文]. 北京: 北京科技大學, 2019 [23] Zhang J. Coexistence theory of slag structure and its application to calculation of oxidizing capability of slag melts. J Iron Steel Res, 2003, 10(1): 1 [24] Li S, Zheng X M, Ma A Y, et al. Construction and application of activity models for CaO?SiO2?Al2O3?TiO2 slag system. Chin J Rare Met, 2020, 44(5): 540李松, 鄭雪梅, 馬愛元, 等. CaO–SiO2–Al2O3–TiO2渣系活度計算模型的建立及應用. 稀有金屬, 2020, 44(5):540 [25] Ren Y, Zhang L F, Pistorius P C. Transformation of oxide inclusions in Type 304 Stainless Steels during heat treatment. Metall Mater Trans B, 2017, 48(5): 2281 doi: 10.1007/s11663-017-1007-8 [26] Yang W, Guo C B, Zhang L F, et al. Evolution of oxide inclusions in Si?Mn killed steels during hot-rolling process. Metall Mater Trans B, 2017, 48(5): 2717 doi: 10.1007/s11663-017-1025-6 [27] Cheng G, Li W F, Zhang X G, et al. Transformation of inclusions in solid GCr15 bearing steels during heat treatment. Metals, 2019, 9(6): 642 doi: 10.3390/met9060642 [28] Chu Y P, Li W F, Ren Y, et al. Transformation of inclusions in linepipe steels during heat treatment. Metall Mater Trans B, 2019, 50(4): 2047 doi: 10.1007/s11663-019-01593-1 [29] Wang J J, Li W F, Ren Y, et al. Thermodynamic and kinetic analysis for transformation of oxide inclusions in solid 304 stainless steels. Steel Res Int, 2019, 90(7): 1800600 doi: 10.1002/srin.201800600 -

下載:

下載: